WARNING! Ensure the air supply does not exceed 125psi (8.5 bar) while operating the unit. Too high an air pressure will shorten the

life of the unit due to excessive wear and may cause damage and/or personal injury.

3.1. Ensure the blaster air valve is in the ‘Off’ position before connecting to the air supply.

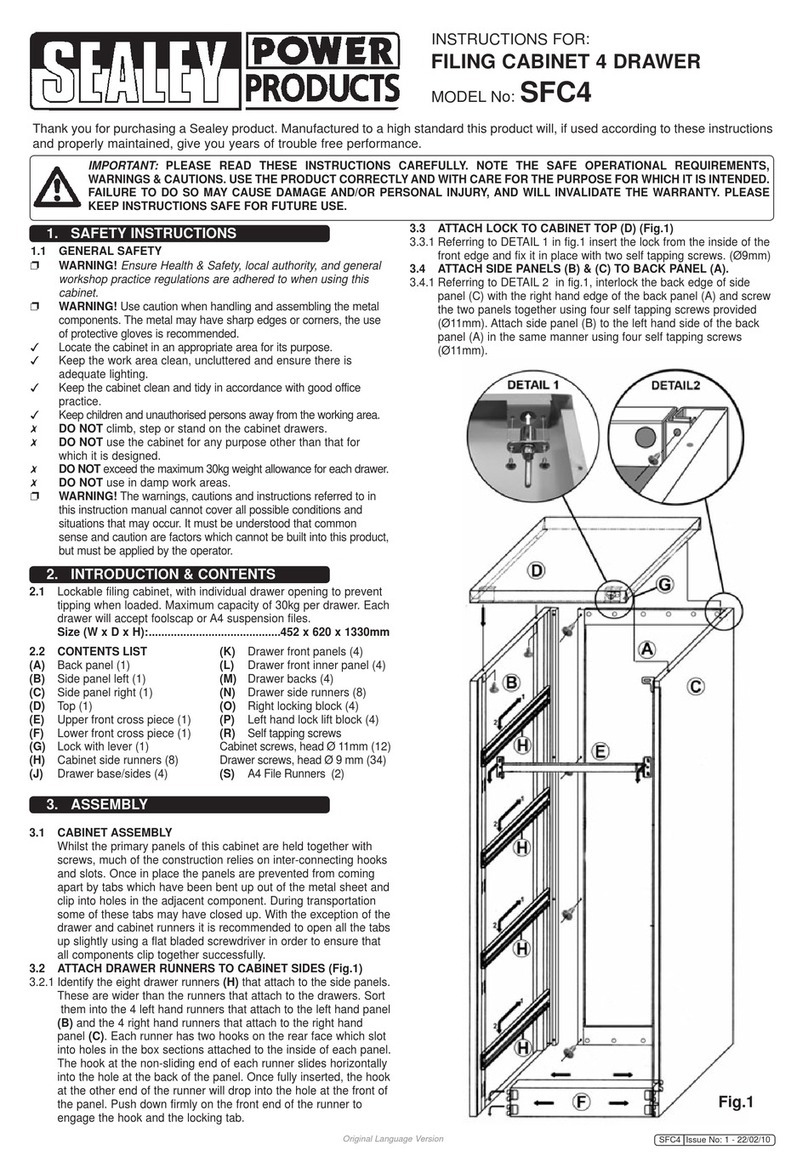

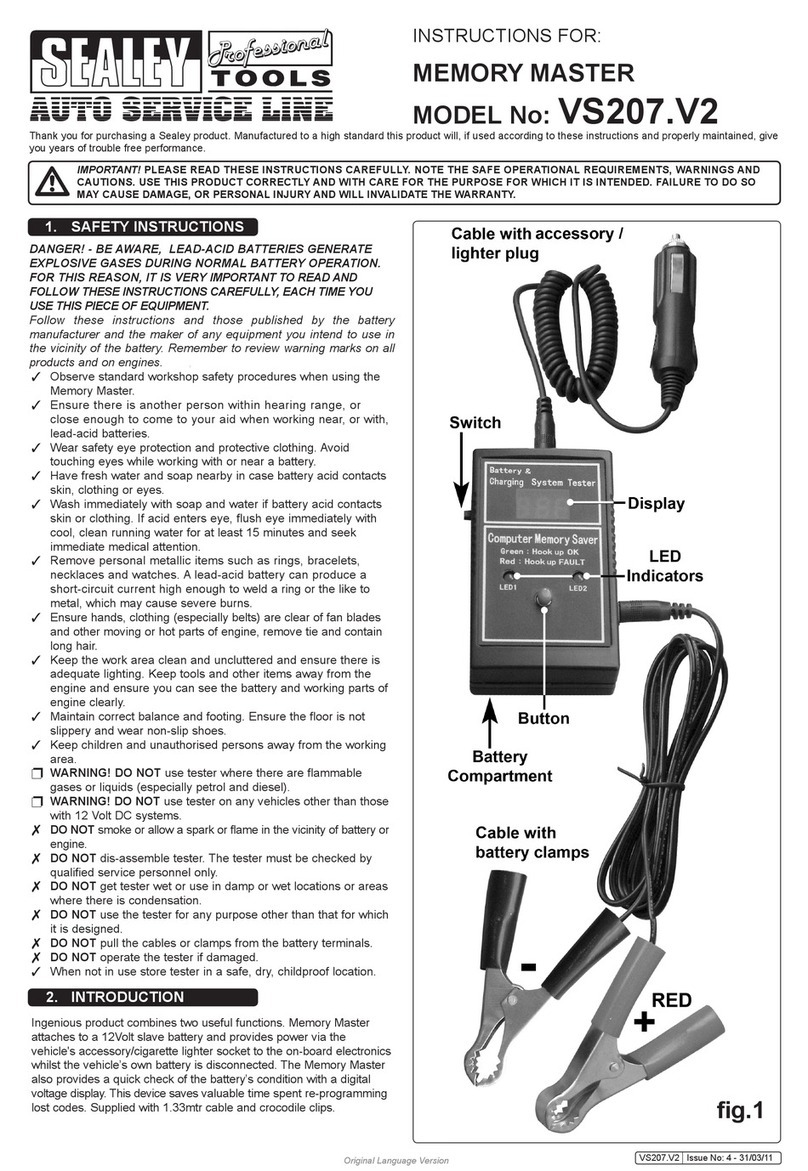

3.2. Keep the air hose between the compressor and the unit a reasonable length and install an air filter and water separator (fig.1).

3.3. Drain the air tank daily. Water in the air line will damage the unit.

3.4. The recommended hook-up procedure is shown in fig.1.

3.5. The minimum hose diameter should be 1/4" I.D. and

fittings must have the same inside dimensions.

3.6. Use correct hoses and fittings. DO NOT use quick

change couplings as they add weight and can cause

failure due to vibration. Add a leader hose and connect

coupling between this and supply hose.

3.7. Keep hoses away from heat, oil and sharp edges. Check

hoses for wear and ensure that all connections are secure.

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained,

give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

2. INTRODUCTION & SPECIFICATIONS

3. AIR SUPPLY

WARNING! Turn off, or disconnect from, air supply before servicing or performing any maintenance and when unit is not in use.

WARNING! The blaster is designed to be used with the lid closed. Never use it with an open lid.

Failure to comply with this instruction may damage the unit and will invalidate your warranty.

WARNING! Wear approved ear, eye, hand and respiratory protection when operating the blaster. A full range of personal safety equipment

is available from your Sealey dealer.

Maintain correct balance and ensure firm footing.

Spillages of abrasive material, which may be slippery, must be cleaned up immediately to avoid injury.

Locate blaster in a suitable, well ventilated, work area. Keep area clean and tidy and free from unrelated materials, and ensure that there

is adequate lighting.

Maintain the blaster in good condition (use an authorised service agent).

Replace or repair damaged parts. Use recommended parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

Keep the unit clean for best and safest performance.

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

Always keep the blast nozzle directed at the workpiece.

If a failure or malfunction occurs immediately disconnect from air supply.

Keep all other persons away from the working area. Contact with high pressure blast or inhaling the dust generated is dangerous.

DO NOT use the blaster for any purpose other than that for which it is designed.

DO NOT operate the blaster if any parts are missing or damaged as this may cause failure and/or personal injury.

DO NOT use any abrasive which contains free silica, as indicated in the Health & Safety Guidance Note EH59 (available from HMSO).

DO NOT attempt to clear a blocked nozzle while the unit is pressurised.

DO NOT allow untrained persons to operate the blaster.

DO NOT get the blaster wet or use in damp or wet locations or areas where there is condensation.

DO NOT leave the blaster operating unattended.

DO NOT operate the blaster when you are tired, under the influence of alcohol, drugs or intoxicating medication.

DO NOT stand on the blaster.

DO NOT direct air from the air hose at yourself or others.

DO NOT operate system with air supply exceeding 125 psi (8.5 bar).

2.2. Specifications

SB990 SB991

Air Pressure ............15-125psi ..........15-125psi

Air Consumption ........8cfm ..............8cfm

Abrasive Ø .............250-800 microns ....30-800 microns

Max. Abrasive Capacity ...12kg/6.8 litres ......12kg/6.8 litres

Abrasive Consumption....30-35kg/h ..........30-35kg/h

INSTRUCTIONS FOR

WORKSHOP SHOT BLASTERS

MODEL No's: SB990 & SB991

fig.1

2.1. Introduction

The SB990 and SB991 are shot blasters suitable for stripping rust and paint from wheels, chassis, panels and other corroded or painted

surfaces. The SB990 is a hand portable unit whilst the SB991 is wheel mounted.

2.3. Abrasives

There are two types of abrasive grit:

1) Expendable - Use once and dispose of, recommended for

large surfaces - Copper Slag and Olivene (silica-free sand).

We recommend Sealey Blasting Grit, part number B/25KG.

2) Re-usable - more expensive and recommended for cabinets -

Glass Beads and Fused Alumina.

Original Language Version SB990, SB991 Issue: 3 - 19/10/09