NeoDen 7 User manual

Hangzhou NeoDen Technology Co.,Ltd.

7th Generation

High-Speed Pick and Place Machine

User Manual

Manufacturer: Hangzhou NeoDen Technology Co.,Ltd.

Applicable Model: NeoDen7 High-Speed Pick and Place Machine

Version: V1.01

Hangzhou NeoDen Technology Co.,Ltd.

Content

1. Brief Introduction.................................................................................................................. 1

1.1 Product Introduction........................................................................................................1

1.2 Structure of NeoDen7......................................................................................................2

1.3 Operation flow chart........................................................................................................3

1.4 Flow chart of making a programming file...................................................................... 4

2.Edit on the Operation Interface.................................................................................................. 4

2.1 Edit on the Interface........................................................................................................ 4

2.1.1 PCB feed settings................................................................................................. 5

2.1.1.1 Mag Fixture............................................................................................... 5

2.1.1.2 Rail............................................................................................................ 5

2.1.2 Panelized PCB origin (SMD1 coordinate)...........................................................6

2.1.2.1 Single board...............................................................................................6

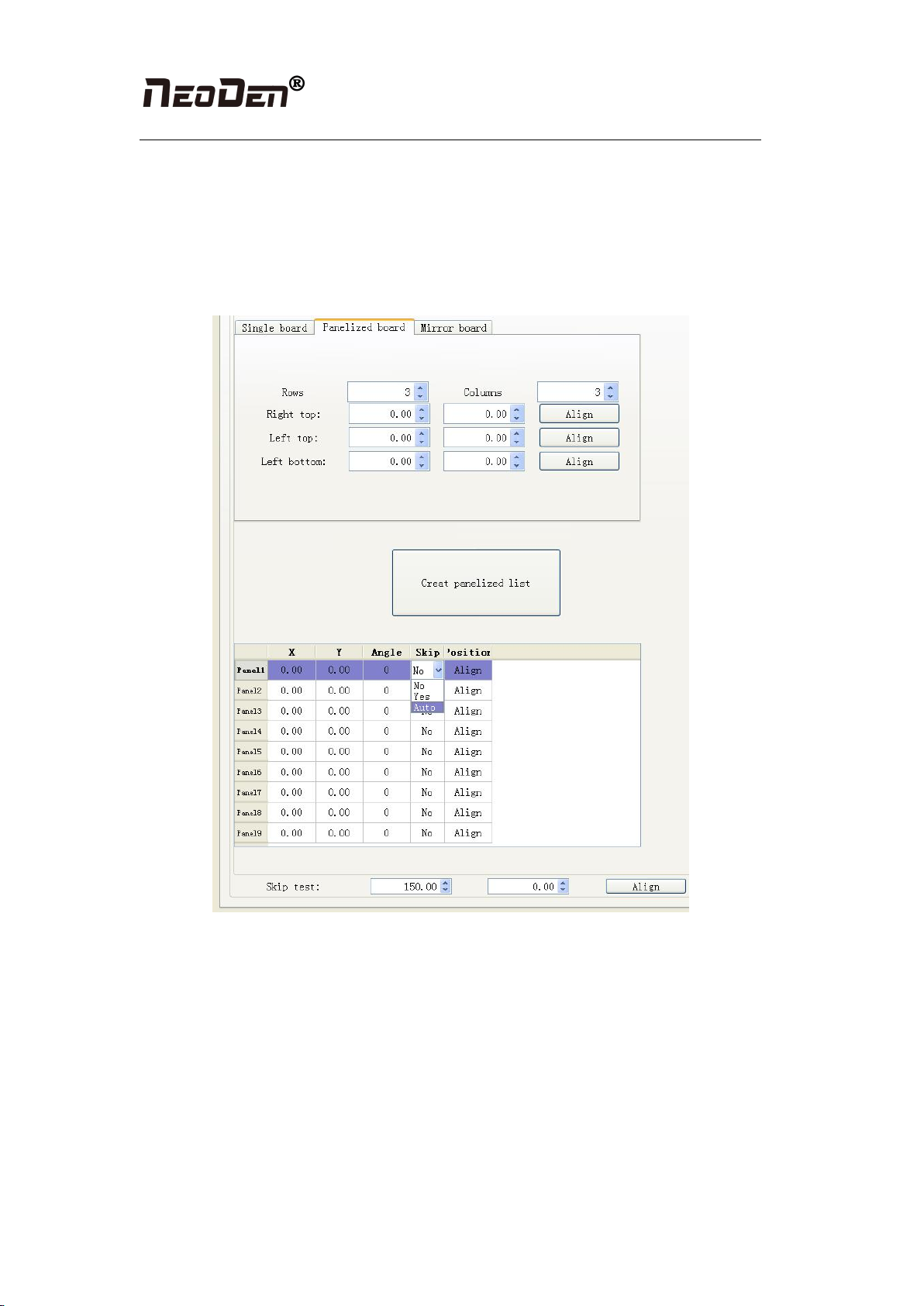

2.1.2.2 Panelized board......................................................................................... 7

2.1.2.3 Mirror board.............................................................................................. 8

2.1.2.4 PCB angle correction................................................................................ 9

2.1.2.5 Skip marked panels................................................................................. 10

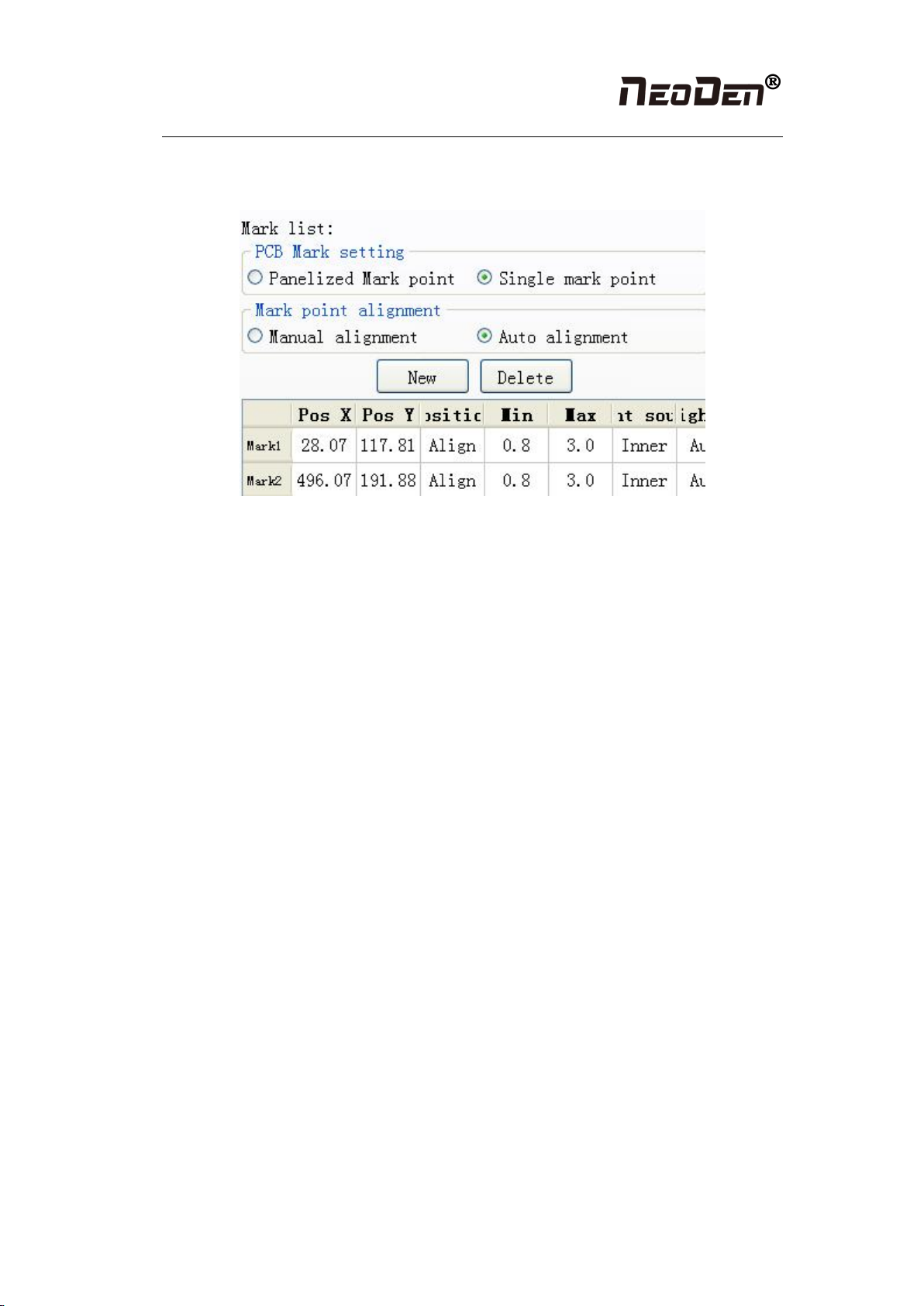

2.1.3 PCB fiducial setting........................................................................................... 11

2.1.3.1 Single fiducial......................................................................................... 11

2.1.3.2 Panelized fiducial....................................................................................11

2.1.3.3 Manual alignment....................................................................................11

2.1.3.4 Add or delete fiducial..............................................................................12

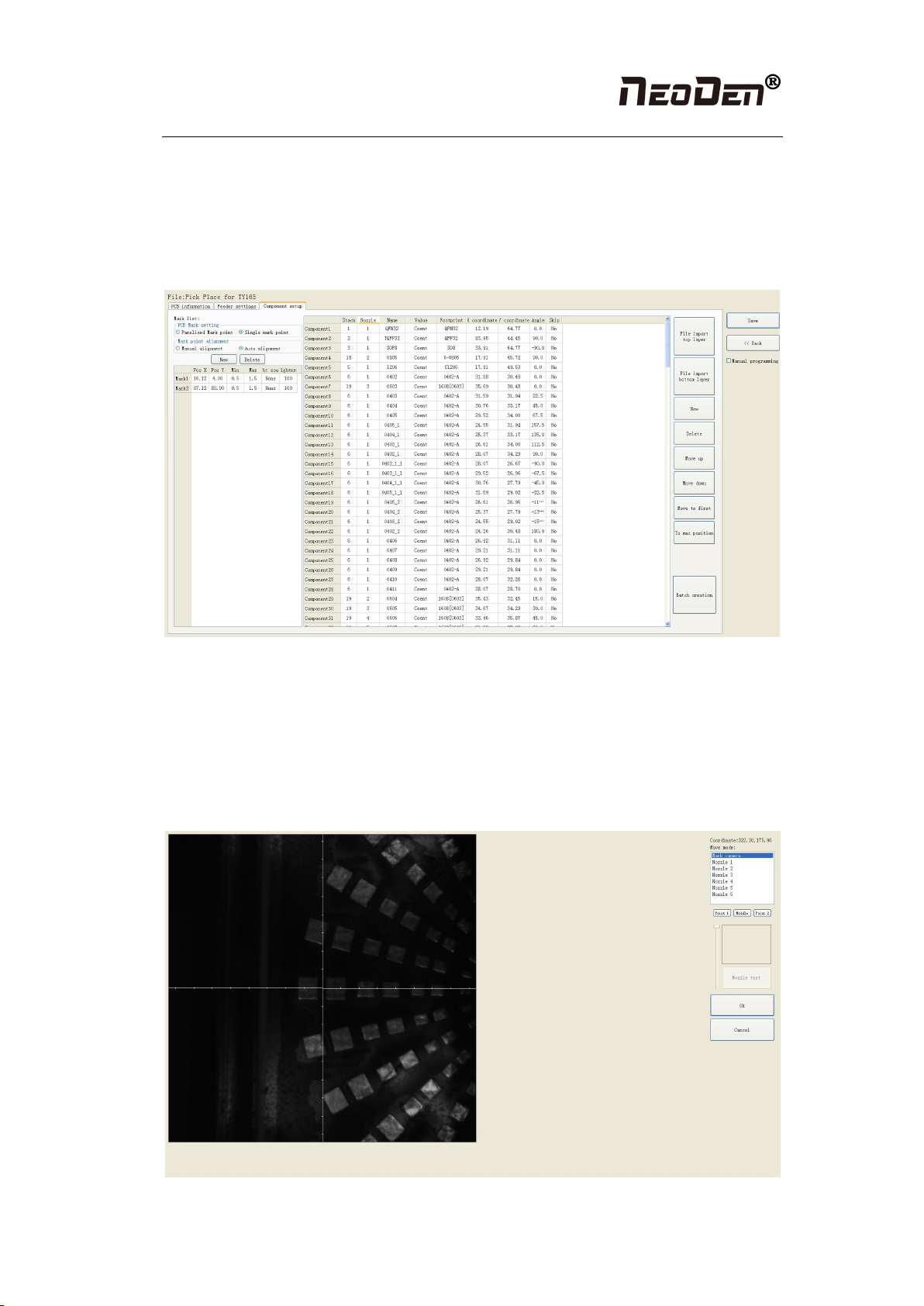

2.1.4 Component list setting........................................................................................13

2.1.4.1 Manual programming..............................................................................13

2.1.4.2 Secondary editing of components...........................................................16

2.1.4.3 Import the mounting file......................................................................... 17

2.1.5 Feeders setting page........................................................................................... 18

2.1.5.1 Feeder arrangement.................................................................................18

2.1.5.2Feeder information configuration............................................................ 18

2.2 File Mounting................................................................................................................ 20

2.3 Factory settings..............................................................................................................22

2.3.1 Feeder configuration.......................................................................................... 23

2.3.2 Nozzles’ Positions Setup.................................................................................... 24

2.3.2.1 Fiducial Camera Position........................................................................24

2.3.2.2 IC Camera Position................................................................................. 25

2.3.2.3 Flying Camera Position...........................................................................26

2.4 First trial and test...........................................................................................................27

2.4.1Program first dry run...........................................................................................27

2.4.2 First production test............................................................................................27

2.4.3 Component Inspection....................................................................................... 27

2.4.3.1 Inspection items...................................................................................... 27

Hangzhou NeoDen Technology Co.,Ltd.

2.4.3.2 Inspection method................................................................................... 27

2.4.3.3 Inspection standard..................................................................................27

2.5 Continuous SMT production.........................................................................................28

3.Structure and maintenance instruction..................................................................................... 29

3.1 Structure chart............................................................................................................... 29

3.2 Feeder Brief Introduction.............................................................................................. 30

3.3 Installing tape and reel components..............................................................................31

3.4 Incorrect installation Samples....................................................................................... 32

3.4.1 Nozzle.................................................................................................................33

3.5 Maintenance.................................................................................................................. 35

3.5.1 Take effective measures to reduce /avoid malfunction......................................35

3.5.1.1 Reinforce daily maintenance...................................................................35

3.5.1.2 Requirements for operator...................................................................... 35

3.5.1.3 Formulate the measures to reduce/avoid big problem............................36

3.5.2 Maintenance....................................................................................................... 36

3.5.2.1 Daily Inspection...................................................................................... 36

3.5.2.2 Monthly Inspection................................................................................. 37

3.5.3 Related issues during solder paste printing process.......................................... 37

3.5.3.1 Stencil Printing Technology.....................................................................37

3.5.3.2 Inspecting of solder paste printing.......................................................... 37

3.5.3.3 The defects of solder paste printing, reasons and solutions.................... 38

Hangzhou NeoDen Technology Co.,Ltd.

1

NeoDen7 User Manual

(High-Speed Fully Automatic Pick and Place machine)

1.Brief Introduction

1.1 Product Introduction

The seventh-generation model NeoDen7(Automatic universal visual pick and place machine)

is NeoDen Tech’s independent product, with completely independent intellectual property.

NeoDen7 has the advantages of fast speed, high accuracy, convenient operation, multiple

feeders, high efficiency, stable performance, convenient and simple operation. NeoDen7

features six independent flying HD cameras, one IC alignment camera and one independent

fiducial camera, perfectly implements standard mounting of components such as

micro-miniature components and fine-pitch IC under the premise of ensuring efficient

mounting; NeoDen7 adopts the most stable pneumatic feeder on the market, the advantages are

stability, easy replacement, easy installation, quick and convenient tape reel installation, it

matching with vision correction system and rail feeding system.

Maximum Board

Dimension

630*300mm(1200mm optional)

Number of Heads

Placement head:1 Nozzle:6

Max Tape Feeder

Capacity

64(8mm or 12mm feeder)

Applicable tape reel

feeder size

8mm,12mm,16mm,24mm,32mm,44mm,56mm

Average Placement

Speed

13,500CPH

Vision Number

8(1 fiducial camera, 6 flying cameras, 1 IC camera)

Component range

Smallest components:0402, TQFP, QFN, BGA and other

conventional components

Feeder Number

Tape feeder:64

Resolution

X/Y axis:0.01mm, Z axis:0.1mm

Rotation

±180°(360°)

Placement Accuracy

0.01mm

Power Supply

AC220V/110V

Power

500W

Machine Size

1420*1220*1665mm

Air Source

Above 0.6MP

Hangzhou NeoDen Technology Co.,Ltd.

2

1.2 Structure of NeoDen7

(7)Pause button

(8)Mouse keyboard

bracket

(9)Conveyor Port

(10)Power Switch

(11)Air source input

(12)Power port

(1)12 inch high-definition

display

(2)Safety cover

(3)USB port

(4)Universal wheel

(5)Heavy load pedestal

(6)Emergency Button

Hangzhou NeoDen Technology Co.,Ltd.

3

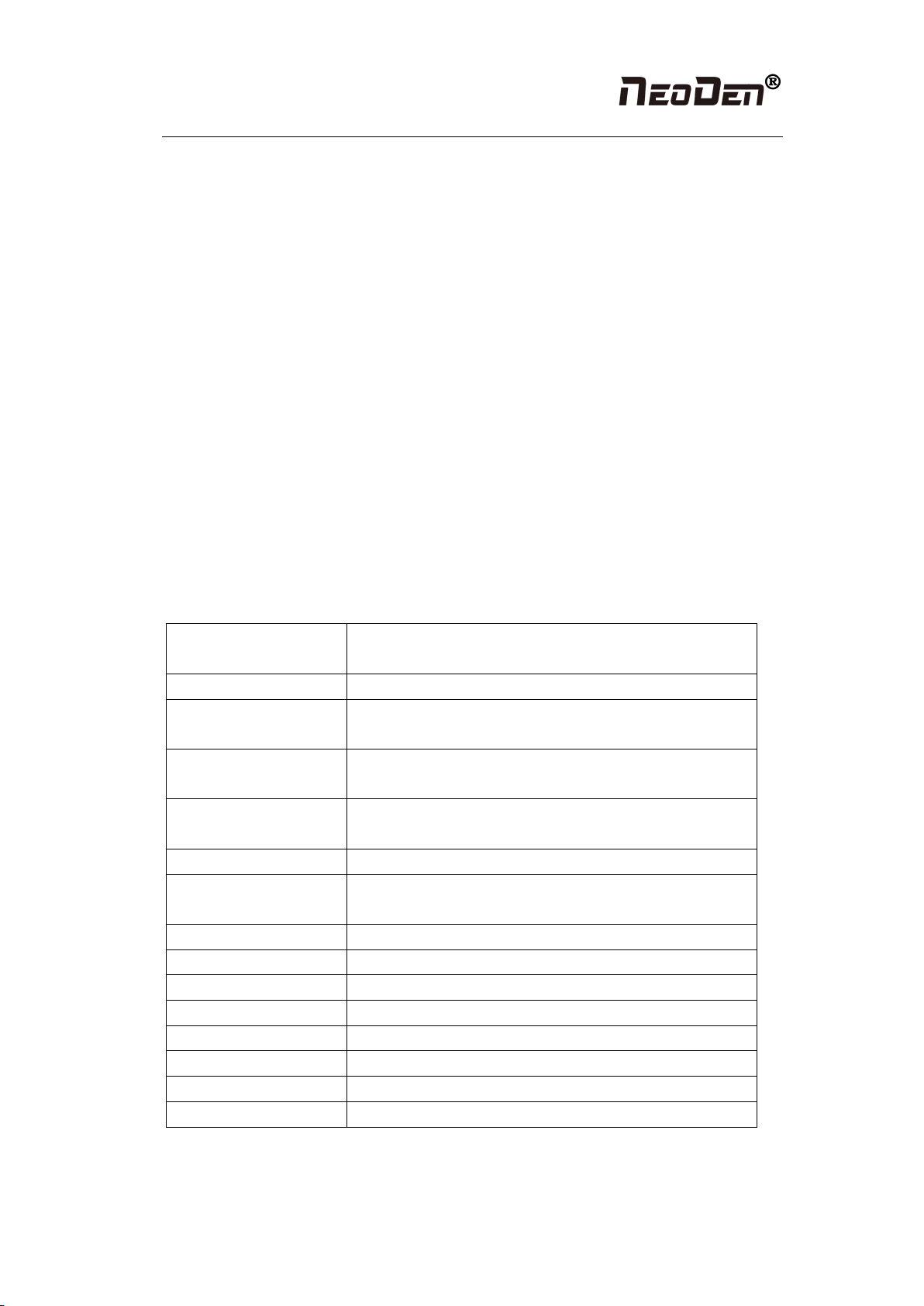

1.3 Operation flow chart

NO.

Flow chart

Note

1

Checking the working area whether it is safe or not,

whether the air source is normally connected and reaches

the calibrated pressure value.

2

3

Click the launcher icons, machine will start self-checking

process, you can see the flash board of the up-looking

camera is flashing, nozzle start initializing, and XY

initializing. After the initialization, machine will go into the

software interface.

4

After power on complete, machine will enter the file list

interface

5

Please refer to the detailed information on page

4—machine operation introduction

6

After making a programming file, it may exist several

programming issues, such as rotation issues of components,

so a production testing is necessary for solving issues.

7

Start to pick and place.

8

Production finish, exit.

9

Shut down the system via computer, then power off the

machine.

10

Disconnect the electricity supply after the system being

powered off.

11

Keep the machine clean, daily maintenance of the nozzles

assures high utility.

System shut down

Power off

Cleaning and

maintenance

Exit

Mounting

Preparation

Turn on

Initialization

Operation page

Edit

Normal

Test

Modify

Abnormal

Hangzhou NeoDen Technology Co.,Ltd.

4

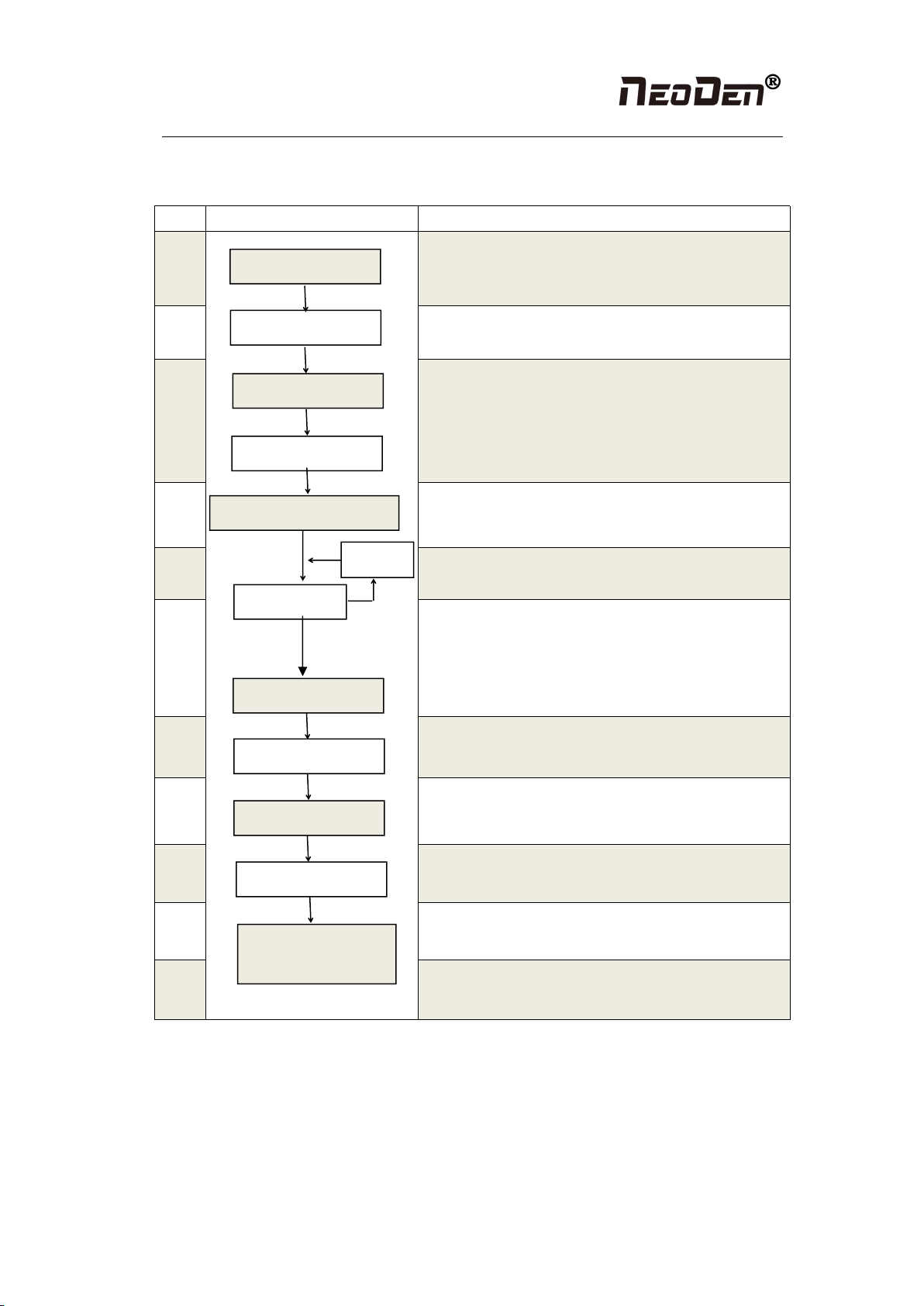

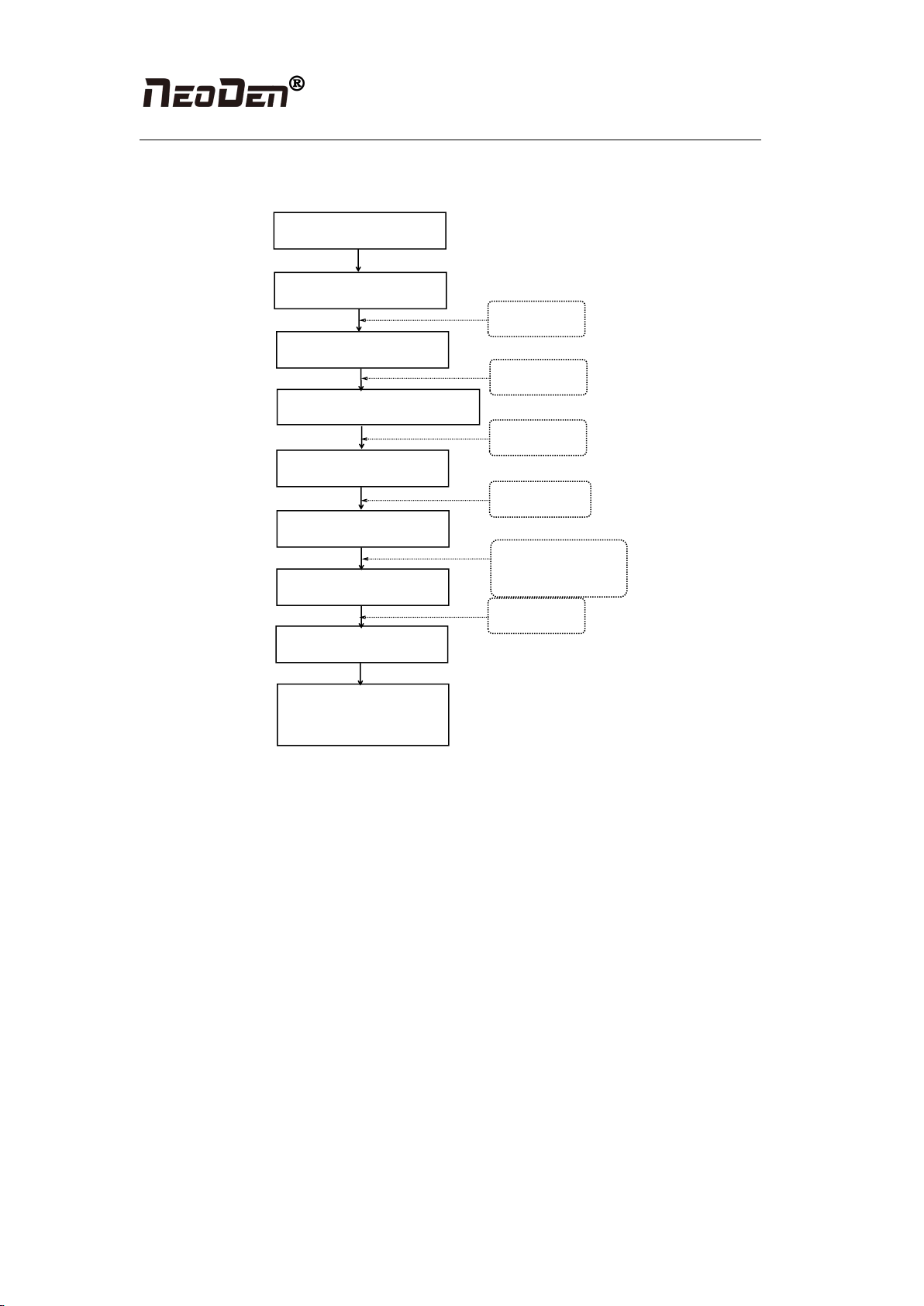

1.4 Flow chart of making a programming file

Component setup

Select file and start

working

Start

Panelized PCB first chip setting

Edit the file

PCB feed setting

Fiducial setting

Feeder settings

Save and cancel

See P6

See P12

Pick up simultaneously

setting

See P18

See P5

See P4

Note: The basic procedure of making a programming file by manual programming or import

coordinate file is similar, but there are two different parts: component list and fiducial setting.

Please find the detailed operation steps of the differences on relative page.

2.Edit on the Operation Interface

2.1 Edit on the Interface

See figure (2.1): On the file list interface, add a file and input the file name, select the file and

edit. Or edit the existed file.

Figure (2.1) is the edit interface

Hangzhou NeoDen Technology Co.,Ltd.

5

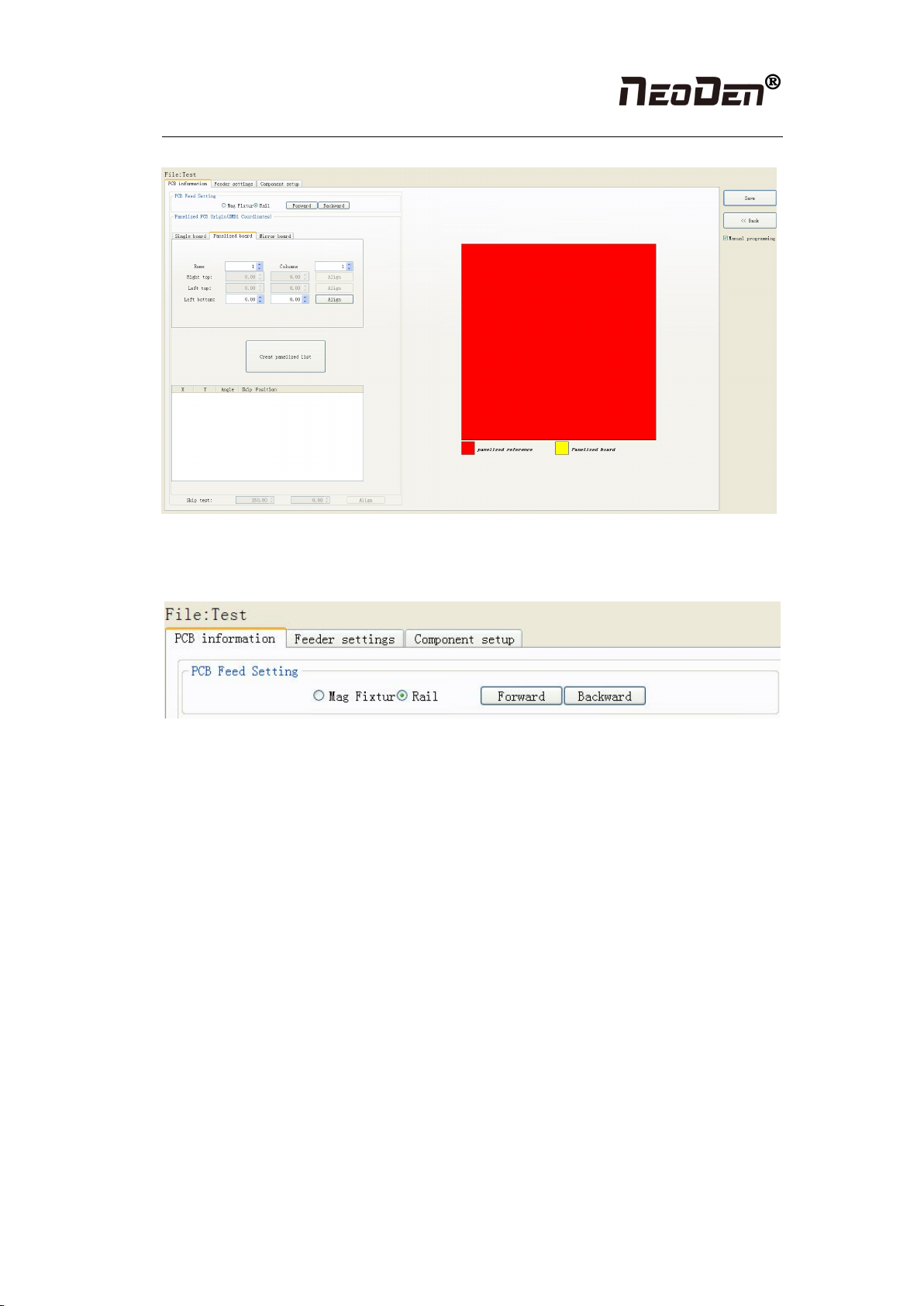

Figure (2.1)

2.1.1 PCB feed settings

Figure (2.1.1)

Function: determine the PCB feed position. On the manual programming mode, it’s the

primary edit item, see figure (2.1.1)

2.1.1.1 Mag Fixture

When you select “Mag Fixture”, the function key of PCB feed setting and setting operation

part will be banned. We only need use positioning pins to fix the PCB.

2.1.1.2 Rail

First select the “rail”, the setting operation part will be available.

Operation steps: first adjust the rail width to let the PCB can move smoothly on the rail.

Click “feed”, PCB will move through the sensor to the cylinder thimble position, cylinder will

raise the PCB, then thimble will go down, PCB feeding complete. (If need adjust the PCB

feeding position, need adjust the thimble and rail sensor position)

Hangzhou NeoDen Technology Co.,Ltd.

6

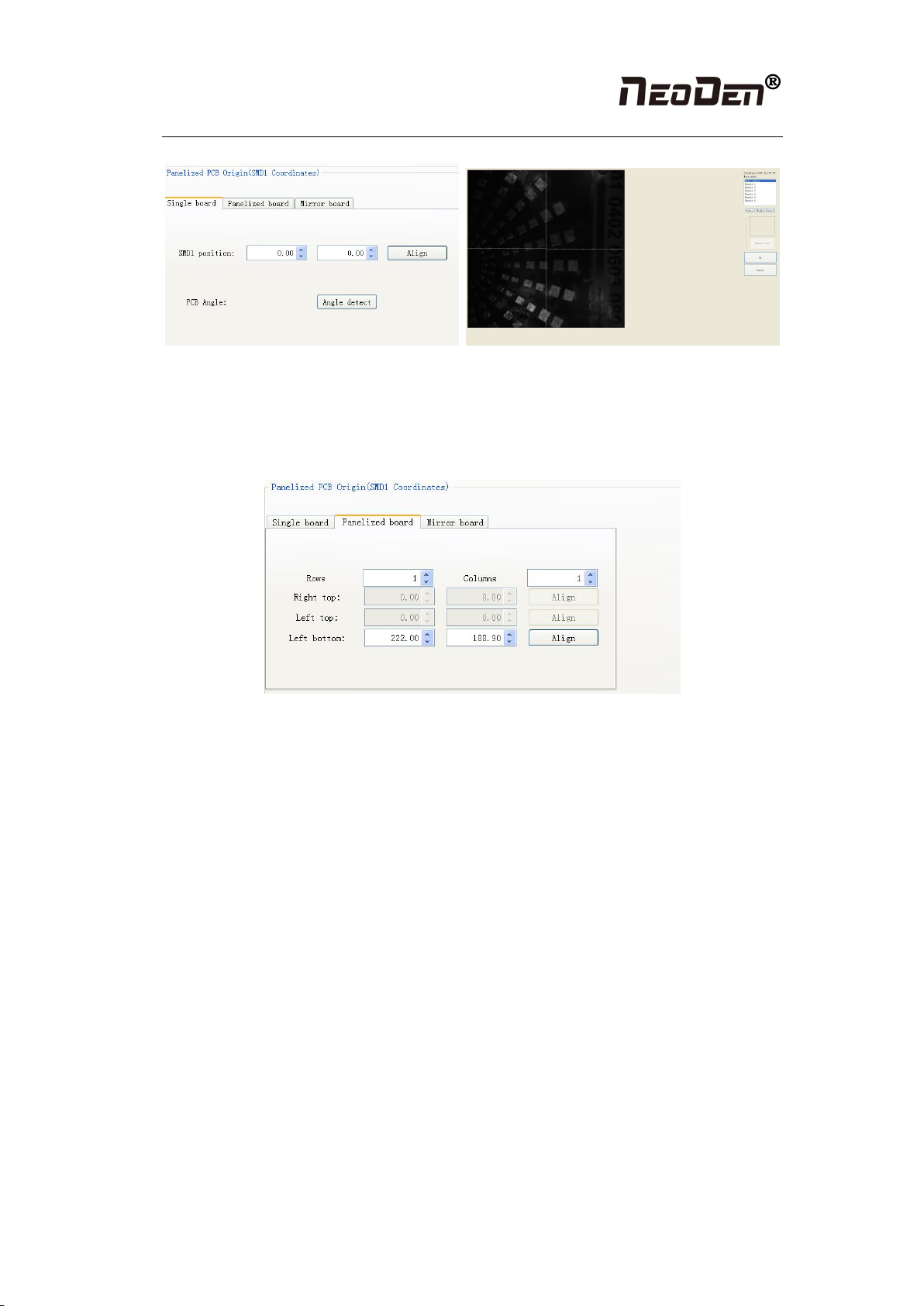

2.1.2 Panelized PCB origin (SMD1 coordinate)

Figure (2.1.2)

Function: This is mainly to determine the first component on single or panelized PCB of

manual program or imported file. The principle is to collect and calculate the data of each

board’s relative spacing, in order to achieve the calculation of the real coordinate.

Note: the panelized PCB origin (SMD1 coordinates) and panelized list setting of the

manual program mode is the same as file import mode.

2.1.2.1 Single board

Click “single board setting”, you will see the “align” button of the SMD1 position that means

the first component on the component setup. Click “align” to enter the vision align interface,

we need find the first component that on the component list, normally we choose the center of

the component, see figure (2.1.2.1)

Hangzhou NeoDen Technology Co.,Ltd.

7

Figure (2.1.2.1)

Click “ok”, it will back to the previous interface, click “create panelized list” button”, the data

which on the panelized list will change.

2.1.2.2 Panelized board

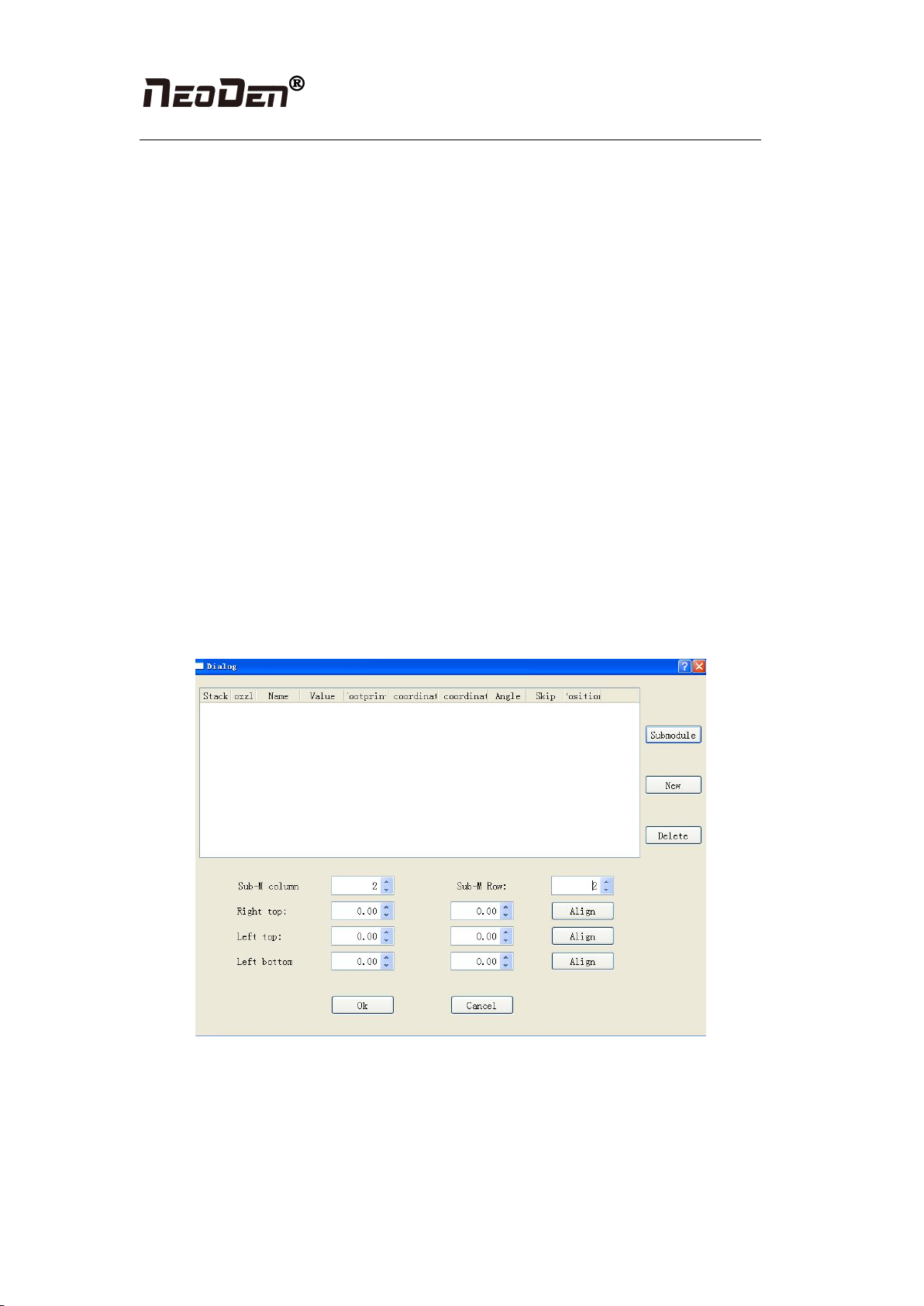

Figure (2.1.2.2)

The steps of the panelized board programming are similar with the single board, but need pay

some attention to several points below

●The row and column are determined by the positioning of PCB on working area. The

direction along the rails is the column, the direction perpendicular to the rail is row, then please

enter data in the row and column.

●About the data collection of “left bottom”, “left top” and “right top”, we should take the

“left bottom” as the basic, and then go to set “left top” and “right top”. Once all the data are

collected, the machine can calculate and process the information of panelized board.

Please refer to the data collecting method of each position information as following:

●The data of “left bottom” is collected according to first component in the component list of

programming file. Press “align” of left bottom, find the left bottom panel that is nearest to the

left side and nearest to the feeding position, then find the first component which on the chip list

of this panel, align the center of this component. After saving the data, it will return to the

“PCB information” automatically.

●The data of “left top”: on the alignment interface, find the left top panel that is nearest to the

left side but farthest to the feeding position, then find the component same as the component

that aligned on the “left bottom”, align the center of this component. Click save and cancel, it

will return to the “PCB information” automatically.

●The data of “right top”: on the alignment interface, find the right top panel that is nearest to

the right side but farthest to the feeding position, then find the same component as the

Hangzhou NeoDen Technology Co.,Ltd.

8

component that aligned on the “left bottom”, align the center of this component, click save and

cancel, it will return to the “PCB information” automatically.

After setup, click “create panelized list”, the panelized list will be generated accordingly in the

blank. You can also double-confirm each position by clicking “Align”.

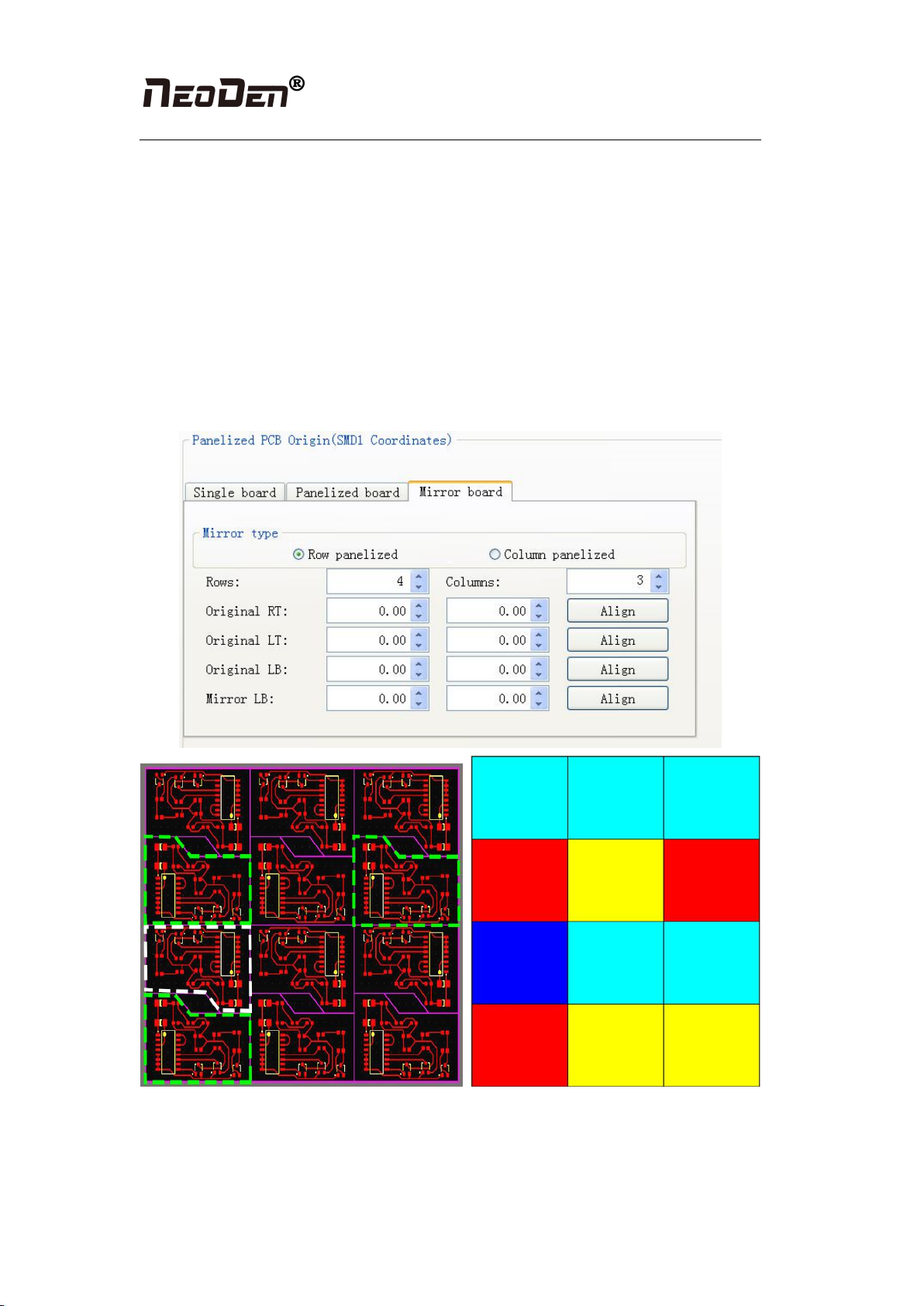

2.1.2.3 Mirror board

Mirror board includes row panelized and column panelized

Row panelized: several same PCBs are arranged in horizontal direction, and the nearby rows

are mirrored

Column panelized: several same PCBs are arranged in vertical direction, and the nearby

columns are mirrored

4

4

4

4

4

1

1

1

2

2

2

3

No.1 red areas are original ref

No.2 yellow areas are original boards

No.3 blue area is mirror ref

No.4 light blue areas are mirror boards

Hangzhou NeoDen Technology Co.,Ltd.

9

Figure (2.1.2.3)

No.1 red areas are original ref

No.2 yellow areas are original boards

No.3 blue area is mirror ref

No.4 light blue areas are mirror boards

Based on actual board to choose an applicable model of panelized mode. Figure (2.1.2.3) left

side is the arrangement way of mirror board and right side is the mirror board showing on

computer.

2.1.2.4 PCB angle correction

PCB angle will influence the accuracy of mounting. The angle closer to 0 degree the better,

and the angel deviation need to be within 1 degree. The angle of PCB is generated according to

panelized PCB coordinates, but we can also adjust the angle by manual. Click “PCB angle”

button, according to the index of machine to choose two points, then a new PCB angle will be

1

3

1

4

2

4

2

4

2

4

1

4

Hangzhou NeoDen Technology Co.,Ltd.

10

generated. (Note, the two points need to be paralleled)

Under panelized PCB model, “PCB angle” is locked. You need to correct from panelized PCB

to single PCB (1*1), after confirm the PCB angle, you can change back to panelized PCB

model.

2.1.2.5 Skip marked panels

Figure (2.1.2.4)

Function: detect marked panels in multiple boards and skip marked panels

Steps:

(1) According to actual panelized PCB to generate panelized list

(2) Choose “Auto” from “Skip” option of panelized list

(3) Click “Align” button of skip test to choose one fixed position and mark it, thus every

time when machine scan this mark, it will skip this bad board.

The conventional practice is to stick a black label to the fixed position (the position that

you aligned on the skip test) on the board. If the label is attached on one panel, this panel

will be automatically skipped. And if the label is not attached on one panel, this panel will

be normally placed.

Hangzhou NeoDen Technology Co.,Ltd.

11

2.1.3 PCB fiducial setting

Figure (2.1.3)

Function: After finishing fiducial setting, when the machine is working, the specific position

and direction of PCB can confirm via setting fiducial. Only in this way the next step of

mounting work can carry out.

2.1.3.1 Single fiducial

It is mainly used for a single PCB board and multiple identical PCB boards consistent of the

whole board (Notice: coordinate programming is done as a single board)

Generally, need to select 2 or 3 fiducials.

2.1.3.2 Panelized fiducial

It is mainly used for multiple identical PCB boards consistent of the whole board, when place

every panel board, the machine will rescan small panel board’s fiducial.

2.1.3.3 Manual alignment

If there is no fiducial on the PCB, which can through some location holes and set up some

special reference point manually to replace and confirm reference position.

Hangzhou NeoDen Technology Co.,Ltd.

12

Figure(2.1.3.3)

●Import the coordinate automatically status: the data collection of fiducial, which through

PCB circuit board to find fiducial coordinate information directly, and input directly. Moreover,

there are some information about min, max, light source and brightness in the fiducial list.

◆Min, max value: means the size of fiducial, it has a floated value, which can prevent

recognizing fiducial wrongly.

◆Light source: Dividing into inner and external, if select the hole as fiducial which need

to choose the inner of light source; If select bright spot as fiducial which need to choose the

external of light source.

◆Brightness: The default automatic is generally used, only in special cases need to

change the value

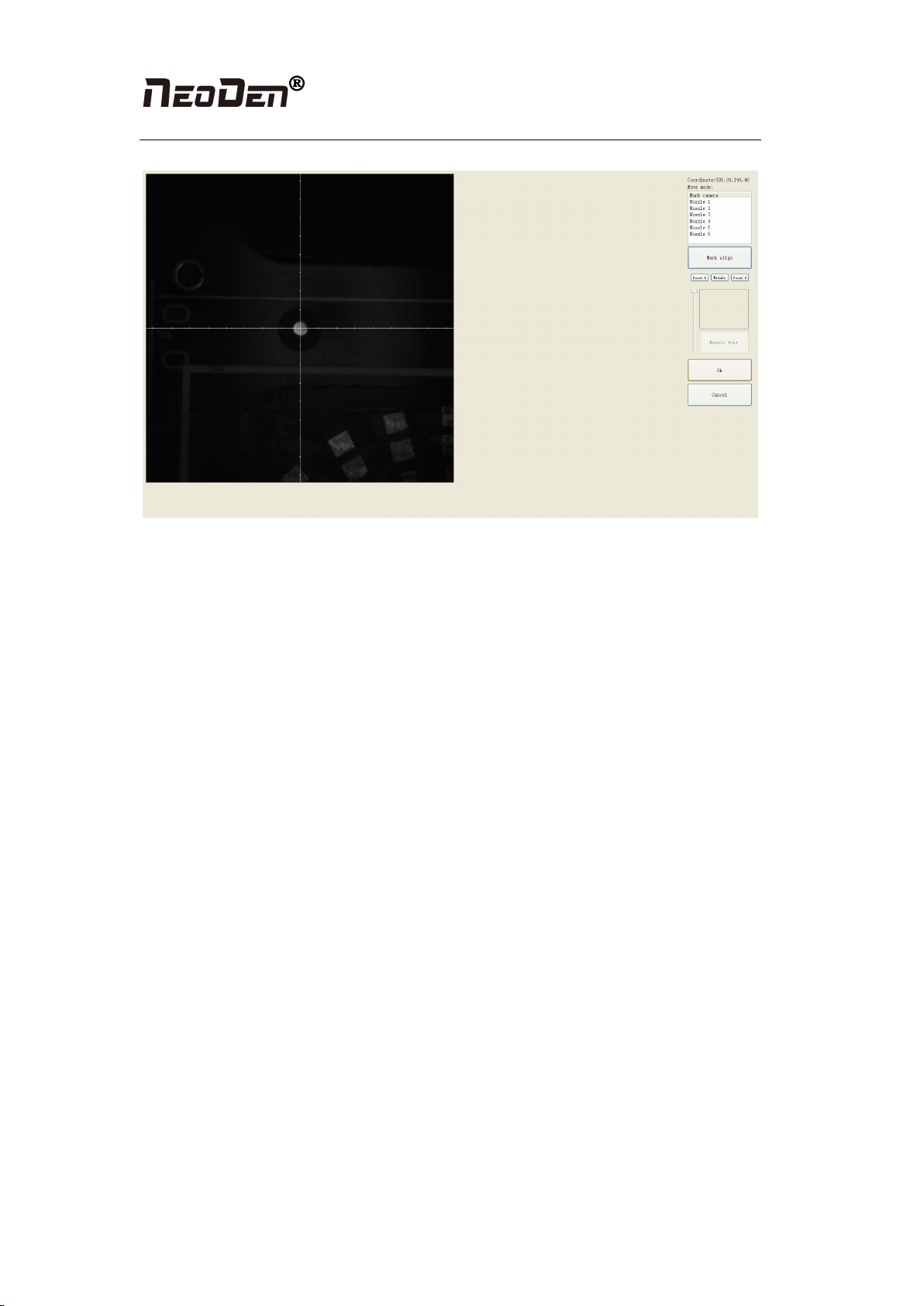

●Manual programming situation: the data collection of fiducial, on the manual programming

status, select the fiducial in the list and click “align”, see figure (2.1.3.3), enter image capture

page, and find the fiducial center via movement, click “fiducial align”, see figure (2.1.3.3),

then click “save”, go back to main page. Another Items (min, mix, light source, brightness)

setting is the same as the above (import automatically) operation. (if need long distance

movement, select visual field to move)

●Manual alignment situation: if there is no available information to set fiducial, we will

choose manual recognition. Notice: Generally, select the first component of mounting

component, select fiducial which is far away with first component and is easy to find, when

setting up like this, the relative mounting result will be better, after reloading process, it needs

to confirm manually.

2.1.3.4 Add or delete fiducial

●Add the quantity of fiducial

●Delete fiducial: when meet fiducial setting wrongly or reset up, tick it and delete directly.

Hangzhou NeoDen Technology Co.,Ltd.

13

2.1.4 Component list setting

Function: display the information of mounting component, the mounting order of component,

which can via manual programming or import process file to add component quantity and

mounting information, see below figure (2.1.4), operation method:

Figure (2.1.4)

2.1.4.1 Manual programming

●Component edit firstly

Firstly, select manual programming, there will be a row of example components in the

component information, modify the sample component and click position “align”, the page

will switch to the vision of up-looking camera automatically, see figure (2.1.4.1)

Figure (2.1.4.1) note: a component diagram has been found

Hangzhou NeoDen Technology Co.,Ltd.

14

We can move down-looking camera or nozzle 1 and nozzle 6, find corresponding component

and confirm the component center coordinate, after clicking “save”, go back to main page,

then input related component information (Notice: name refer to component bit number,

specification refer to component value, footprint refer to common footprint name. Like

0603,0805,1206 etc. The angle is based on the placement direction of component on the circuit

board to confirm, transverse is 0 degree or 180 degree, vertical is 90 degree or negative 90

degree, which is mainly based on the polarity of component, degree must be integer degree;)

after all parameter setting, the first component information has been finished; click the “new”

in next step, the component list will add a row, coordinate information will entirely copy

adjacent up row, then click “align” to find the next component center, ensure to modify, reedit

name, specification, footprint, angle and etc., after finish it, continue to reedit until all edit

finish.

●Component movement

During the process of edit, sometimes, need to do a slightly adjustment for the edited file, we

have three types

(1) move up: The main thing is to move the selected components upward

(2) move down: The main thing is to move the selected components downward

(3) move to head position: The main thing is to move the selected components to the head

position to place.

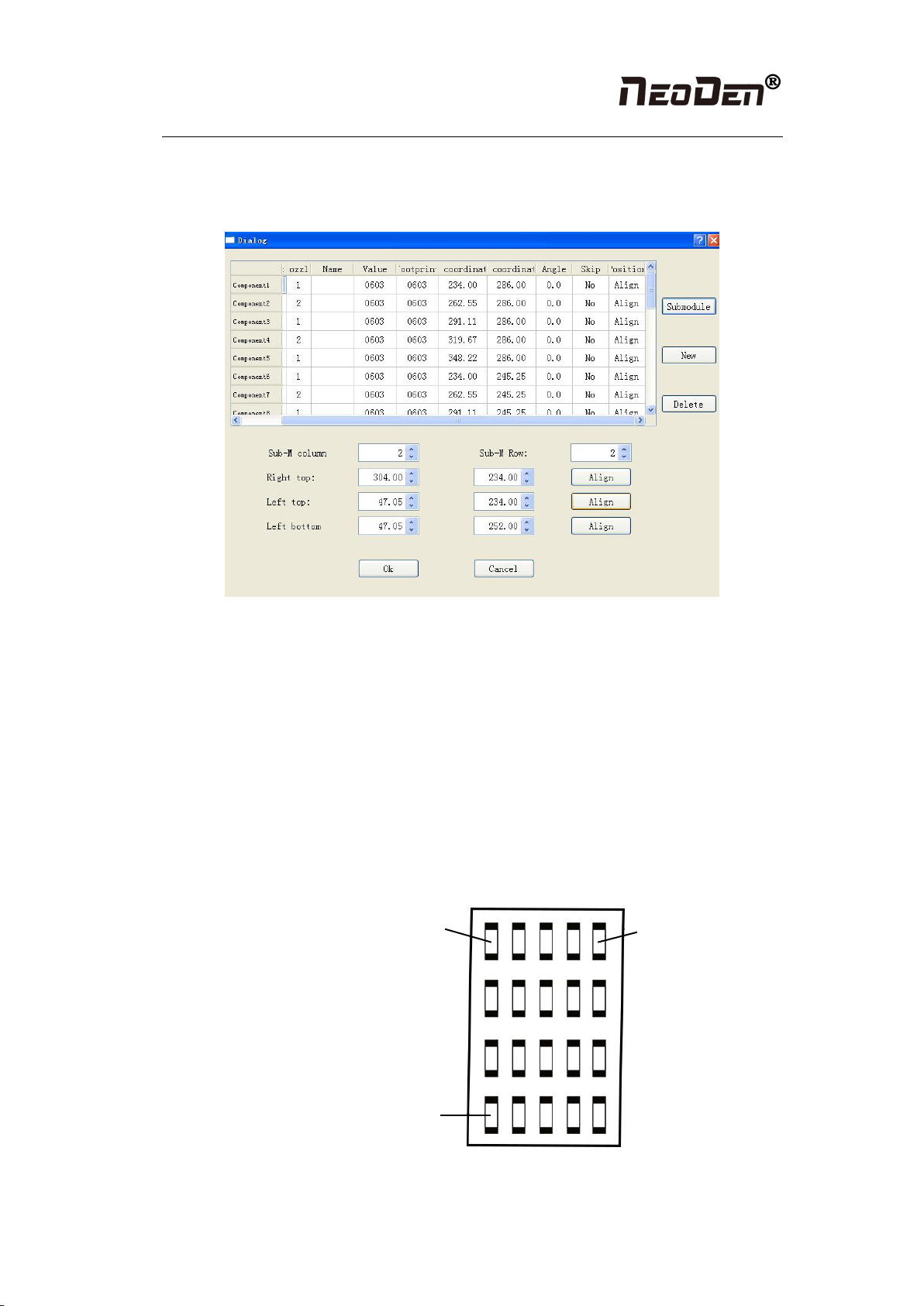

●Batch generate component

Figure (2.1.3.2-3)

Some circuit board is relatively regular and easy in actual edit, as for this type circuit board,

we can through mass production to generate coordinate file, the PCB as shown in figure

(2.1.3.2-3), we can see that it has a rectangular region and a circular region together to form a

small panel. We call this compositive panel as submodule. We can generate this small

imposition through submodule generation. We find it is consisting of 2 rows and 2 column,

Hangzhou NeoDen Technology Co.,Ltd.

15

input 2 rows and 2 columns, find 3 head components, after finishing generating it, the

submodule is shown in the figure: we also can select stack, nozzle, name, specification and etc.

to adjust in this page.

Figure (2.1.3.2-4)

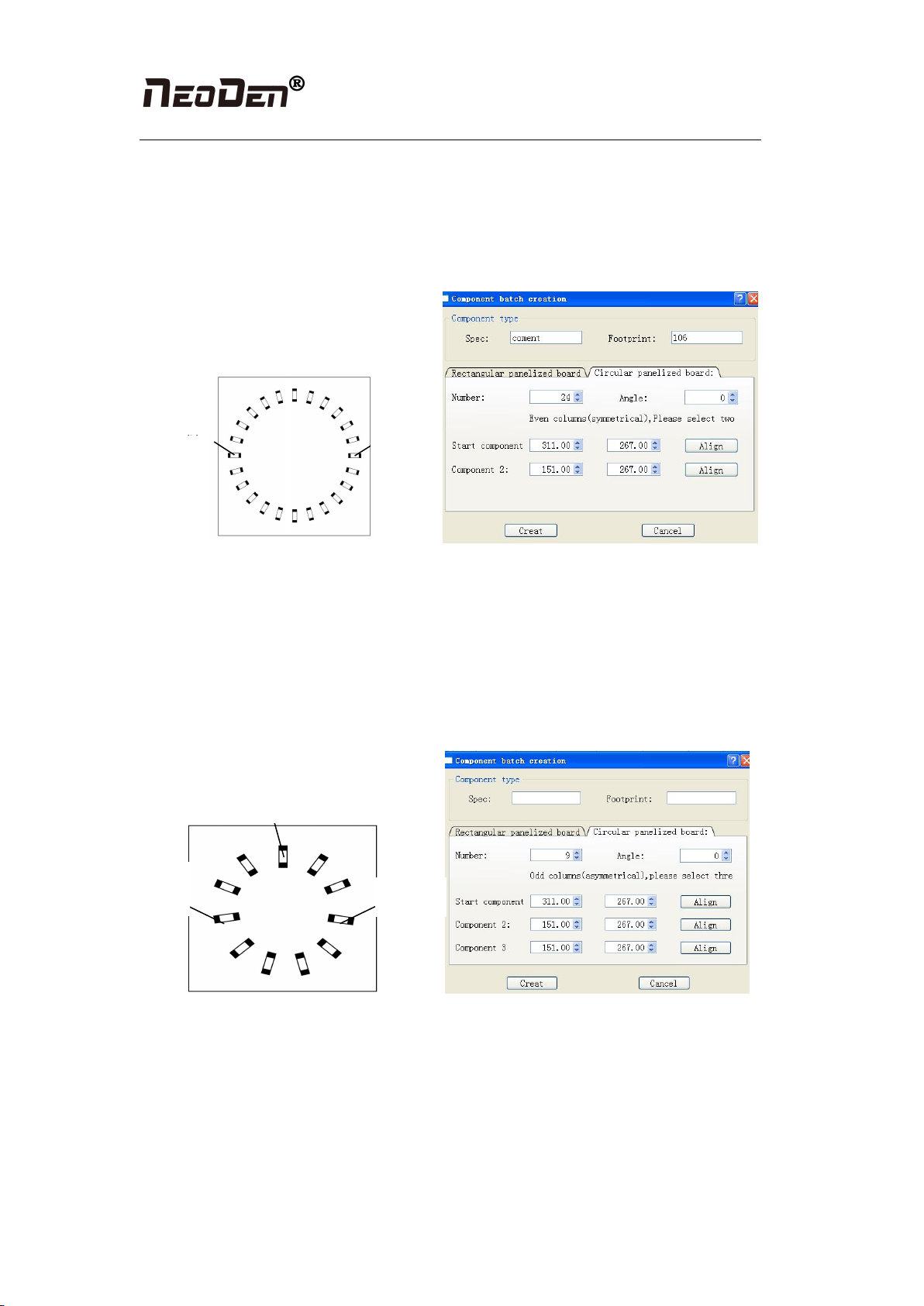

There are two ways to submodules can be produced in batches, one is a rectangle, the other is a

circle

①The way to generate rectangle panel: an example is shown as figure (2.1.3.2-5), click:

“producing component in batches”, which will appear a project is shown as figure (2.1.3.2-5),

component specification and component footprint need to input the specification and footprint

what you need. If you look at this lamp panel figure, we can see that it's uniformly symmetric

in four rows and five columns. We can add 4 rows and 5 columns in the row, column of the

machine, follow the tips to find the 3 points orderly to align. The component degree will be

based on actual situation to choose. (Notice: this angle here is the angle in the stack setting, the

default value is 0, follow the actual situation to modify. Click generate, the machine will

automatically generate all components’ coordinate in the figure (2.1.3.2-5)

右上角

左上角

左下角

Figure (2.1.3.2-5)

Top right corner

Top left corner

Lower left corner

Hangzhou NeoDen Technology Co.,Ltd.

16

②The way about how to generate the circle panel when the component number is double

number: the project and rectangle of the “component type “are the same, we know it has 24

components by observation, the default angle is 0 here, input this value on your own. Because

if the total component is double number, we only need to find two symmetry to align. Click to

generate the 24 components coordinate in the circle panel.

起

元 器

Figure (2.1.3.2-6)

③The way about how to mass generate the circle panel when the component number is

single number: item in the type of components is the same as mentioned above, the circle

panel is shown as figure(2.1.3.2-6), after observing the panel, we know it has 9

components , because the final number of components is single, it is better to find 3

components that are isosceles triangle, and then align the coordinates of those three points

in turn. Click to generate 9 components’ coordinate in circle panel.

起 始

点

元器件

2.1.4.2 Secondary editing of components

Function: add or alter for the information of components based on exist programming

Procedure: firstly, enter into the program edit page, see figure (2.1.4.2):

Put the PCB board into rail which is corresponding with programming, click the “feed” in the

access setting area, confirm the PCB at the designated place, then click “transform into

machine’s current coordinate” and confirm it, at this time, the machine will automatically scan

the fiducial and transform all existing components’ information into current coordinate

Initial

point

Compo

nent

point 2

Initial

point

Component point 2

point 3

Table of contents

Other NeoDen Industrial Equipment manuals