BKI Fry Warmer FW-12 User manual

CS-TM-025.01 Revised 3/26/13

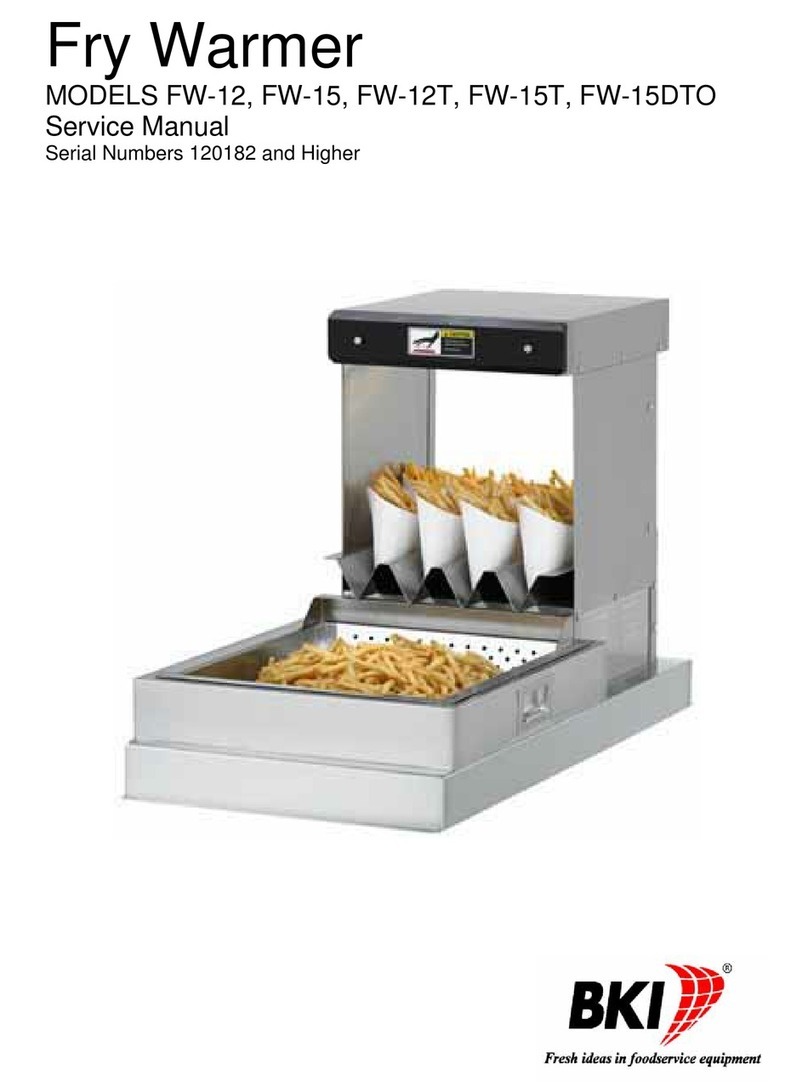

Fry Warmer

MODELS FW-12, FW-15, FW-12T, FW-15T, FW-15DTO

Servi e Manual

Serial Numbers 120182 and Higher

CS-TM-025.01 Revised 3/26/13

BKI LIMITED WARRANTY

2812 Grandview Dr. • Simpsonville, SC 29680 • USA

(864 963-3471 • Toll Free: (800 927-6887 • Fax: (864 963-5316

WHAT IS

COVERED

This warranty overs defe ts in material and workmanship under normal use, and applies

only to the original pur haser providing that:

T

he equipment has not been a identally or intentionally damaged, altered or misused;

The equipment is properly installed, adjusted, operated and maintained in a ordan e

with national and lo al odes, and in a ordan e with the installation and operating

instru tions provided with this produ t.

The serial number rating plate affixed to the equipment has not been defa ed or

removed.

WHO IS

COVERED

This

warranty

is

extended

to the original

pur haser

and applies only

to

equipment pur hased

for use in the U.S.A.

COVERAGE PERIOD

Warranty laims must be re eived in writing by BKI within one (1) year from

date of installation or within one (1) year and three (3) months from data of

shipment from the fa tory, whi hever omes first.

COB Models: One (1) Year limited parts and labor.

COM Models: Two (2) Year limited parts and labor. COM onve tion ovens also have

a two (2) year door warranty.

CO1 Models: Two (2) Year limited parts and labor. Five (5) Year limited door

warranty.

BevLes Produ ts: Two (2) Year limited parts and labor.

Warranty period begins the date of dealer invoi e to ustomer or ninety (90) days

after shipment date from BKI, whi hever omes first.

WARRANTY COVERAGE

This

warranty

overs on-site labor, parts and

reasonable

travel

time

and travel

e

xpenses

of the

authorized

servi e

representative

up

to

(100) miles

round

trip and (2)

hours

travel time and

performed

during

regular,

weekday

business

hours.

EXCEPTIONS

Any ex eptions must be pre-approved in advan e and in writing by BKI. The

extended door warranty on onve tion ovens years 3 through 5 is a parts only warranty and

does not in lude labor, travel, mileage or any other harges.

EXCLUSIONS

Negligen e

or a ts of

God,

Thermostat

alibrations

after (30) days

from

equipment

installation

date,

Air and g

as

adjustments,

Light

bulbs,

Glass doors and

door

adjustments,

Fuses,

Adjustments

to

burner

flames and

leaning

of

pilot

burners,

Tightening

of s rews

or

fasteners,

Failures

aused

by errati

voltages

or gas

suppliers,

Unauthorized

repair by

anyone

other

than

a BKI F

a tory

Authorized

Servi e Center,

Damage

in

shipment,

Alteration,

misuse or

improper

installation,

Thermostats

and safety valves with

broken

apillary tubes,

Freight

–

other

than

normal UPS harges,

Ordinary

wear and

tear,

Failure to follow

installation

and/or

operating

instru tions,

Events

beyond

ontrol

of the

ompany.

INSTALLATION

Leveling, as well as

proper

installation

and he k out of all

new

equipment

-

per

appropriate installation

and use materials – is t

he

responsibility of the

dealer

or

installer, not the

manufa turer.

REPLACEMENT PARTS

BKI

genuine

Fa tory OEM parts re eive a (90) day

materials

warranty

effe tive from the

date of

installation

by a BKI F

a tory

Authorized

Servi e

Center.

Fry Warmer Table of Contents

1

Table of Contents

Table of Contents..................................................................................................................................................... 1

Introduction .............................................................................................................................................................. 2

Safety Pre autions................................................................................................................................................. 2

Safety Signs and Messages.............................................................................................................................. 2

Safe Work Pra ti es.......................................................................................................................................... 2

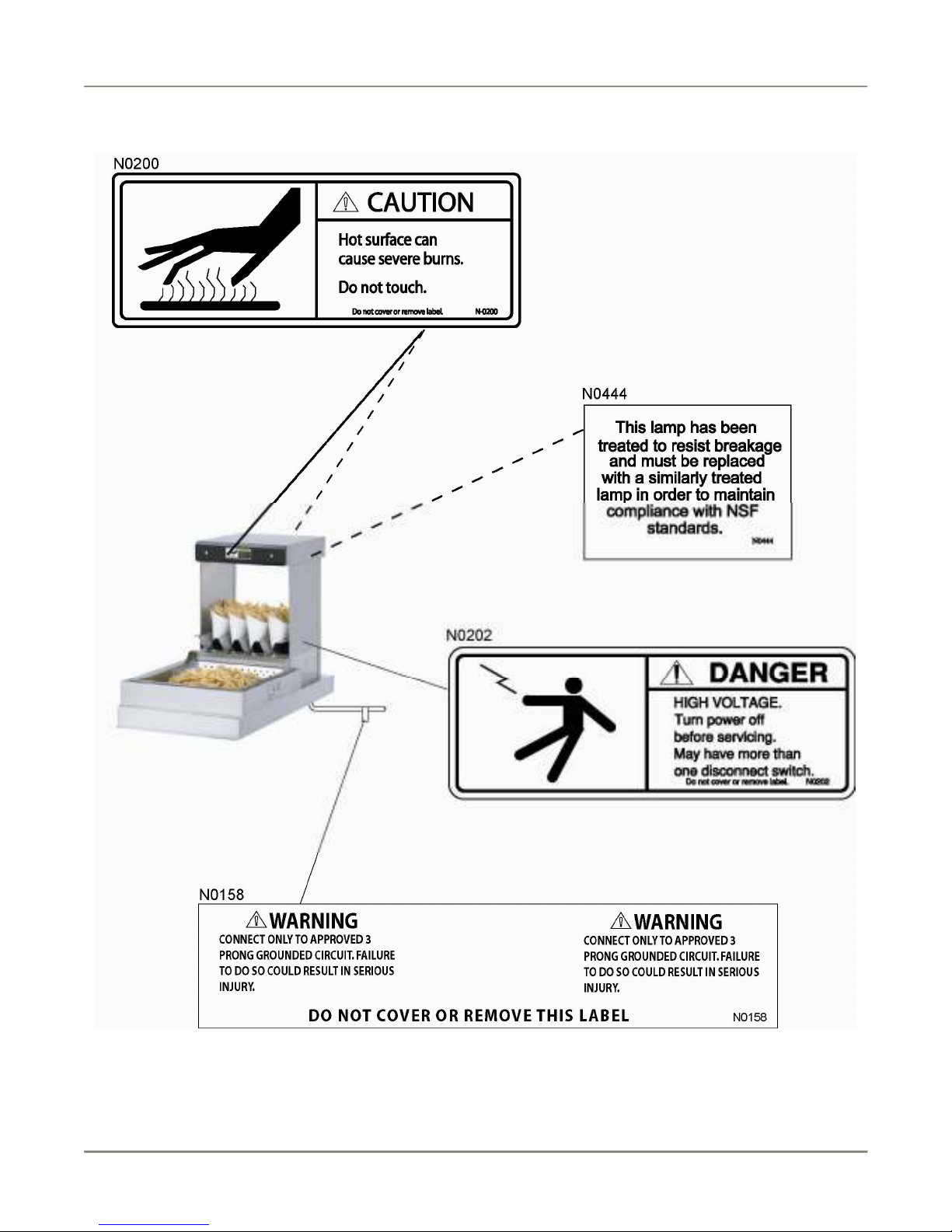

Safety Labels ......................................................................................................................................................... 4

Installation ................................................................................................................................................................ 5

Instru tions For Shipping Damage ........................................................................................................................ 5

Ele tri al Information And Grounding.................................................................................................................... 5

Installation Instru tions .......................................................................................................................................... 5

FW-12 & FW-12T (Side Breather)..................................................................................................................... 5

FW-15 (Side Breather) ...................................................................................................................................... 6

FW-15 (Bottom Breather) .................................................................................................................................. 7

FW-15T/FW-15DTO (Bottom Breather) ............................................................................................................ 9

Maintenance ........................................................................................................................................................... 10

S heduled Maintenan e ...................................................................................................................................... 10

Cleaning .......................................................................................................................................................... 10

Troubleshooting ................................................................................................................................................... 11

Repair .................................................................................................................................................................. 11

Lamp Repla ement ......................................................................................................................................... 11

Replacement Parts................................................................................................................................................. 12

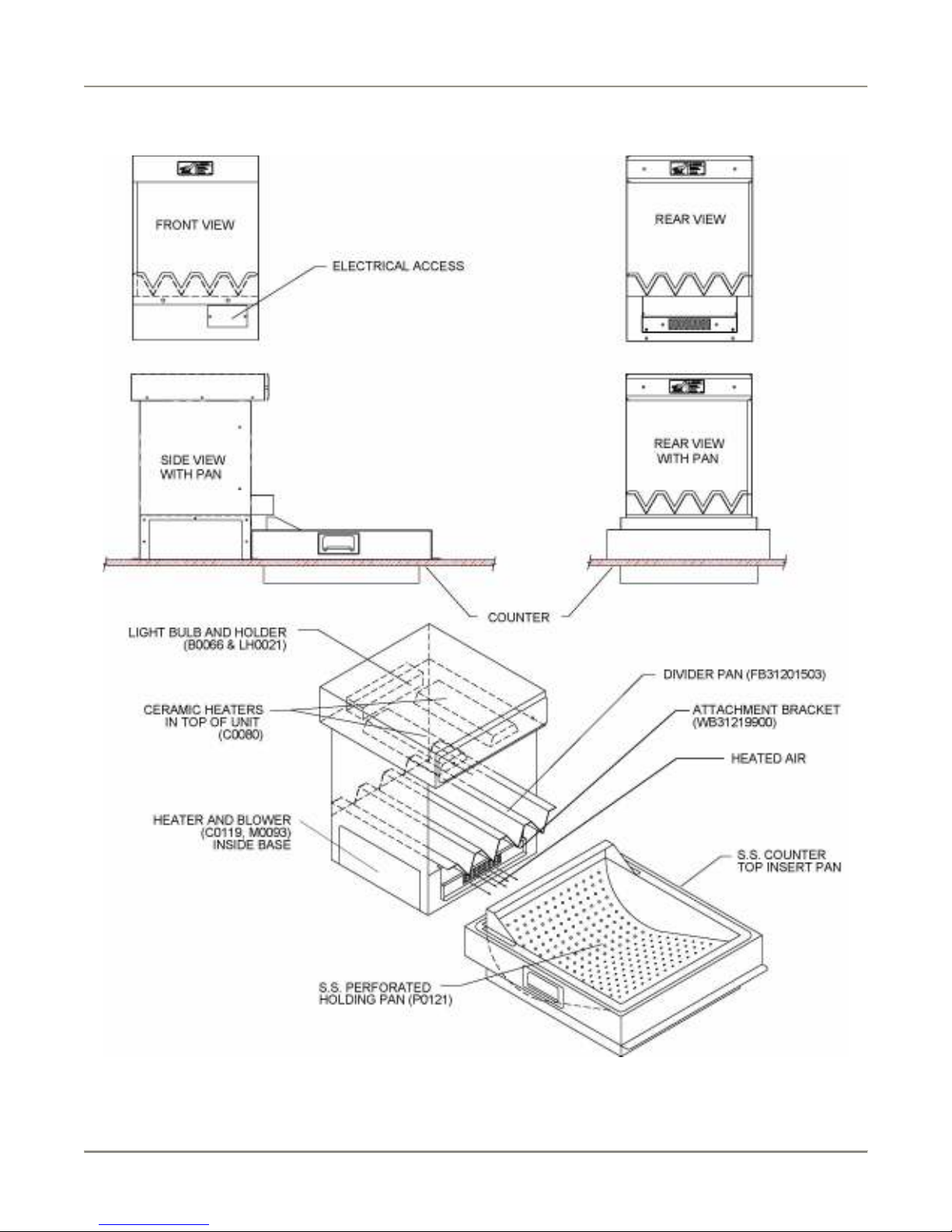

Components ........................................................................................................................................................ 12

FW-12/FW-15 CUF (Side Breather)................................................................................................................ 12

FW-12/FW-15 PASS THRU (Side Breather)................................................................................................... 14

FW-15 CUF (Bottom Breather) ....................................................................................................................... 16

FW-15 PASS THRU (Bottom Breather) .......................................................................................................... 18

FW-12T (Side Breather) .................................................................................................................................. 20

FW-15T (Bottom Breather).............................................................................................................................. 21

FW-15DTO (Bottom Breather) ........................................................................................................................ 22

A essories ......................................................................................................................................................... 24

Wiring Diagrams..................................................................................................................................................... 25

FW-12/FW-15 (Side Breather)............................................................................................................................. 25

FW-12/FW-15 (Bottom Breather) ........................................................................................................................ 26

FW-15 (220V England)........................................................................................................................................ 27

FW-12T/FW-15T.................................................................................................................................................. 28

FW-15DTO (Bottom Breather)............................................................................................................................. 30

Notes ....................................................................................................................................................................... 32

Fry Warmer Introduction

2

Introduction

Congratulations! You have hosen a Fry Warmer that will give you many years of fine servi e from the original

manufa turer, BKI.

The BKI name and trademark on this unit assures you of the finest in design and engineering — that it has been

built with are and dedi ation — using the best materials available. Attention to the operating instru tions

regarding proper installation, operation, and maintenan e will result in long lasting dependability to insure the

highest profitable return on your investment.

PLEASE READ THIS ENTIRE MANUAL BEFORE OPERATING THE UNIT. If you have

any questions, please onta t your BKI Distributor. If they are unable to answer your

questions, onta t the BKI Te hni al Servi e Department, toll free: 1-800-927-6887.

Outside the U.S., all 1-864-963-3471.

This unit must be sealed to the ounter after it is installed to onform to NSF Standard 4,

Item 4.28. (Dow Corning RTV #732 Multi purpose Sealant.)

Safety Precautions

Always follow re ommended safety pre autions listed in this manual. Below is the safety alert symbol. When you

see this symbol on your equipment, be alert to the potential for personal injury or property damage.

Safety Signs and Messages

The following Safety signs and messages are pla ed in this manual to provide instru tions and identify spe ifi

areas where potential hazards exist and spe ial pre autions should be taken. Know and understand the meaning

of these instru tions, signs, and messages. Damage to the equipment, death or serious injury to you or other

persons may result if these messages are not followed.

This message indi ates an imminently hazardous situation that, if not avoided, will result

in death or serious injury.

This message indi ates a potentially hazardous situation, whi h, if not avoided, ould

result in death or serious injury.

This message indi ates a potentially hazardous situation, whi h, if not avoided, may

result in minor or moderate injury. It may also be used to alert against unsafe pra ti es.

This message is used when spe ial information, instru tions or identifi ation are required

relating to pro edures, equipment, tools, apa ities and other spe ial data.

Safe Work Practices

Beware of High Voltage

This equipment uses high voltage. Serious injury an o ur if you or any untrained

or unauthorized person installs, servi es, or repairs this equipment. Always Use an

Authorized Servi e agent to Servi e Your Equipment.

Fry Warmer Introduction

3

Keep this manual with the Equipment

This manual is an important part of your equipment. Always keep it near for easy

a ess. If you need to repla e this manual, onta t:

BKI

Te hni al Servi es Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or all toll free: 1-800-927-6887

Outside the U.S., all 864-963-3471

Protect Children

Keep hildren away from this equipment. Children may not understand that this

equipment is dangerous for them and others.

NEVER allow hildren to play near or operate your equipment.

Keep Safety Labels Clean and in Good Condition

Do not remove or over any safety labels on your equipment. Keep all safety labels

lean and in good ondition. Repla e any damaged or missing safety labels. Refer

to the Safety Labels se tion for illustration and lo ation of safety labels on this unit.

If you need a new safety label, obtain the number of the spe ifi label illustrated on

page 4, then onta t:

BKI

Te hni al Servi es Department

2812 Grandview Drive

Simpsonville, S.C. 29680

Or all toll free: 1-800-927-6887

Outside the U.S., all 864-963-3471

Be Prepared for Emergencies

Be prepared for fires, injuries, or other emergen ies.

Keep a first aid kit and a fire extinguisher near the equipment. You must use a 40-

pound Type BC fire extinguisher and keep it within 25 feet of your equipment.

Keep emergen y numbers for do tors, ambulan e servi es, hospitals, and the fire

department near your telephone.

Know your responsibilities as an Employer

• Make ertain your employees know how to operate the equipment.

• Make ertain your employees are aware of the safety pre autions on the

equipment and in this manual.

• Make ertain that you have thoroughly trained your employees about operating

the equipment safely.

• Make ertain the equipment is in proper working ondition. If you make

unauthorized modifi ations to the equipment, you will redu e the fun tion and

safety of the equipment.

Fry Warmer Introduction

4

Safety Labels

Fry Warmer Installation

5

Installation

Serious injury, equipment damage or death ould result if attempting to install this unit

yourself. Ensure that an authorized BKI servi e agent install the oven.

Instructions For Shipping amage

You are responsible for filing all freight laims with the delivering tru k line. Inspe t all artons and rates for

damage when they arrive. If there is damage noted to shipping rates or artons, or, if a shortage is found, note

this on the bill of lading (all opies) before signing.

If damage is dete ted when the equipment is un rated, immediately all the delivering tru k line and follow up the

all with a written report indi ating on ealed damage to your equipment. Ask for an immediate inspe tion of your

on ealed damage item. Crating material MUST be retained to show the inspe tor from the tru k line.

Electrical Information And Grounding

Ele tro ution, equipment failure or property damage ould result if an unli ensed

ele tri ian performs the ele tri al installation. Ensure that a li ensed ele tri ian perform

the ele tri al installation in a ordan e with lo al odes, or in the absen e of lo al odes,

with the National Ele tri al Code, ANSI NFPA 70-20XX.

The FW-15DTO has 2 power supply ords. Ensure that ea h ord is onne ted to a

separate power supply ir uit. Always unplug both power ords before servi ing, moving

or testing the unit.

BKI Fry Warmers are wired for use in a ordan e with all appli able lo al, state, and federal odes. For spe ifi

ele tri al requirements and onne tions refer to the wiring diagram atta hed to the unit or provided in the Servi e

Manual.

Installation Instructions

If a side or ba k panel is removed on the hute, the other two sides must be sealed with

NSF approved sili one. Seal all inside seams greater than 1/32”.

FW-12 & FW-12T (Side Breather

Countertop Adapter (FW-12 only

1. Obtain a suitable ountertop lo ation for the unit that will provide a learan e of 4” from the side louvers.

2. Position the adapter (WN31206400) on the ountertop.

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure the adapter to the ountertop.

4. Using a 2” hole saw, drill a hole in the ountertop (dire tly under the hole in the adapter) used for the

power ord to pass through.

5. Se ure adapter to ountertop with # 8 sheet metal s rews.

6. Seal adapter to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732 Multi

purpose Sealant.)

7. Feed power ord (supplied), up through holes in ountertop and adapter.

Fry Warmer Installation

6

8. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

9. Position main unit on the adapter and se ure using #8 sheet metal s rews.

10. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the adapter.

Countertop Cutout (FW-12 & FW-12T

1. Obtain a suitable ountertop lo ation for the unit that will provide a learan e of 4” from the side louvers.

2. Cut a 12” x 20” hole in the ountertop to fit the pan insert.

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure the main unit to the ountertop.

4. Using a 2” hole saw, drill a hole in the ountertop (under where the main unit will be se ured) for the

power ord to pass through.

5. Feed power ord (supplied), up through hole in ountertop.

6. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

7. Position main unit on the ountertop and se ure using #8 sheet metal s rews.

8. Seal main unit to the ountertop after it is installed to onform to NSF Standard 4, Item 4.28. (Dow

Corning RTV #732 Multi purpose Sealant.)

9. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the ountertop.

FW-15 (Side Breather

Countertop Adapter (WN31206500

1. Obtain a suitable ountertop lo ation for the unit that will provide a learan e of 4” from the side louvers.

2. Position the adapter (WN31206500) on the ountertop.

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure the adapter to the ountertop.

4. Using a 2” hole saw, drill a hole in the ountertop (dire tly under the hole in the adapter) used for the

power ord to pass through.

5. Se ure adapter to ountertop with # 8 sheet metal s rews.

6. Seal adapter to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732 Multi

purpose Sealant.)

7. Feed power ord (supplied), up through holes in ountertop and adapter.

8. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

9. Position main unit on the adapter and se ure using #8 sheet metal s rews.

10. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the adapter.

Fry Warmer Installation

7

Countertop Cutout

1. Obtain a suitable ountertop lo ation for the unit that will provide a learan e of 4” from the side louvers.

2. Cut a 16” x 18” hole in the ountertop to fit the pan insert.

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure the main unit to the ountertop.

4. Using a 2” hole saw, drill a hole in the ountertop (under where the main unit will be se ured) for the

power ord to pass through.

5. Feed power ord (supplied), up through hole in ountertop.

6. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

7. Position main unit on the ountertop and se ure using #8 sheet metal s rews.

8. Seal main unit to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732 Multi

purpose Sealant.)

9. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the ountertop.

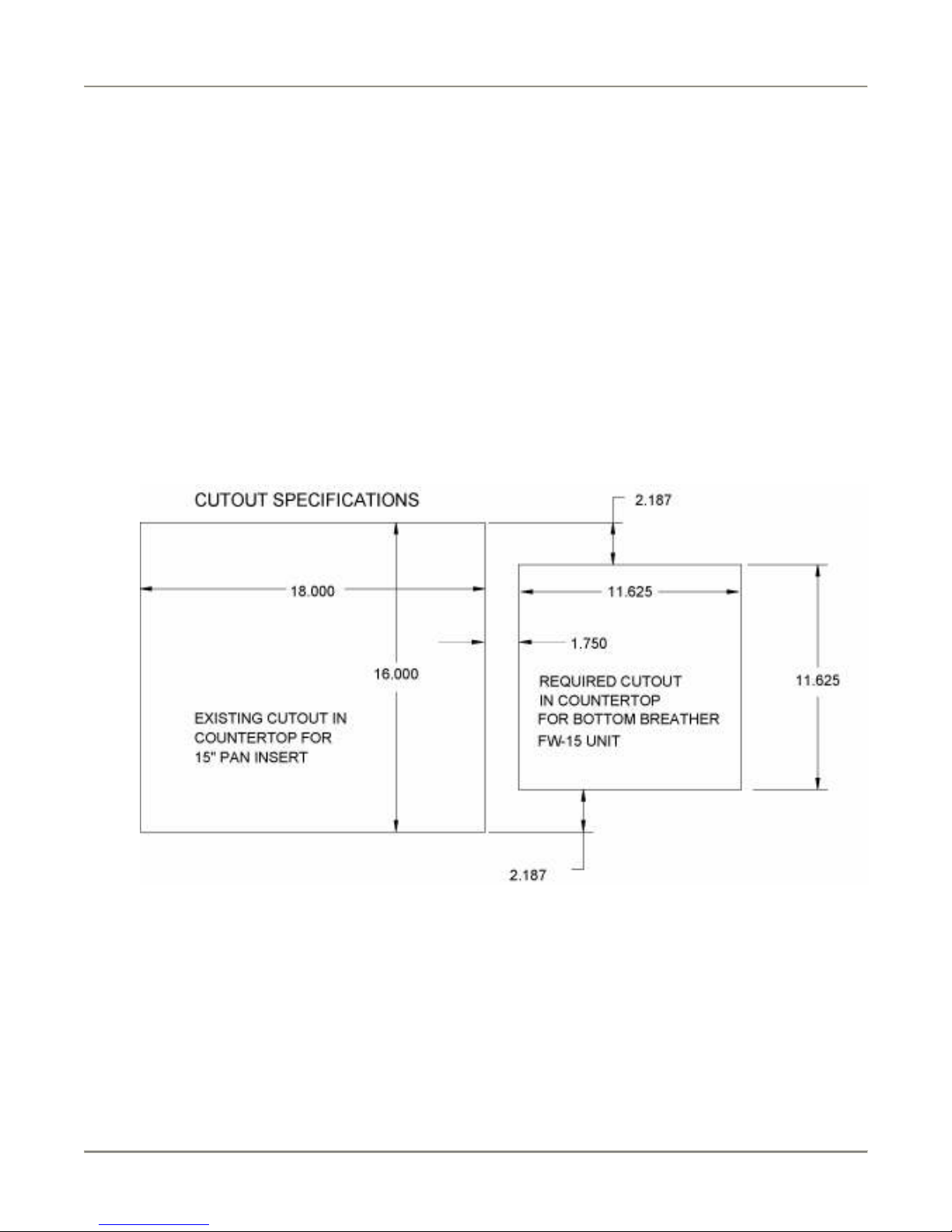

FW-15 (Bottom Breather

Countertop Collar Weldment With Liner Pan (WB31216000

1. Obtain a suitable ountertop lo ation for the unit.

2. Cut holes in the ountertop for the ountertop ollar weldment with liner pan (WB31216000) a ording to

illustration below:

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure WB31216000 to the ountertop.

Fry Warmer Installation

8

4. Se ure WB31216000 to ountertop with # 8 sheet metal s rews.

5. Seal WB31216000 to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732

Multi purpose Sealant.)

6. Feed power ord (supplied), up through holes in WB31216000.

7. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

8. Position main unit on WB31216000.

9. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the WB31216000.

Countertop Collar Weldment Without Liner Pan (WB31211900

1. Obtain a suitable ountertop lo ation for the unit.

2. Cut a hole in the ountertop for the ountertop ollar weldment without liner pan (WB31211900)

a ording to illustration below:

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure WB31211900 to the ountertop.

4. Se ure WB31211900 to ountertop with # 8 sheet metal s rews.

5. Seal WB31211900 to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732

Multi purpose Sealant.)

6. Feed power ord (supplied), up through holes in WB31211900.

7. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

Fry Warmer Installation

9

8. Position main unit on WB31211900.

9. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the ountertop.

FW-15T/FW-15DTO (Bottom Breather

Countertop Collar Weldment With Liner Pan (WB31217700

1. Obtain a suitable ountertop lo ation for the unit.

2. Cut holes in the ountertop for the ountertop ollar weldment with liner pan (WB31217700) a ording to

illustration below:

3. Using a 1/8” drill bit, drill holes in the ountertop used to se ure WB31217700 to the ountertop.

4. Se ure WB31217700 to ountertop with # 8 sheet metal s rews.

5. Seal WB31217700 to the ountertop to onform to NSF Standard 4, Item 4.28. (Dow Corning RTV #732

Multi purpose Sealant.)

6. Feed power ord (supplied), up through holes in WB31217700.

7. Conne t wires of power ord to power entry terminal blo k a ording to the wiring diagram atta hed to

the unit or provided in the Servi e Manual.

8. Position main unit on WB31217700.

9. Fit pan insert to main unit by lifting the open side of pan insert over the two tabs on main unit and lower

the pan insert into the opening in the WB31217700.

Fry Warmer Maintenance

10

Maintenance

Failure to omply with the maintenan e below ould result in a serious a ident.

Ele tro ution, equipment failure or property damage ould result if an unli ensed

ele tri ian performs ele tri al repair. Ensure that a li ensed ele tri ian perform ele tri al

repair.

Scheduled Maintenance

Cleaning

This unit should be leaned at the end of ea h working day. Use the following pro edure:

Failure to remove power from this unit may ause severe ele tri al sho k. This unit may

have more than one dis onne t swit h.

Never use abrasive leaners that may damage the finish.

Never steam lean the interior.

Avoid getting ex ess water in the interior of the unit.

Do not lean the heater/blower assembly by applying ompressed air.

Do not leave this unit on and unattended after business hours.

1. Turn the unit off and allow it to ool down to room temperature.

2. Remove any food.

3. Remove the pan and tray, and lean around the slotted holes at the air dis harge on the hute. Clean the

pan and tray.

4. Clean the air intakes using a mild soap and water solution. When leaning an FW-15 (Bottom Breather),

tilt unit up and lean the dust off the s reen atta hed to the base.

5. Sponge the inside and outside of the unit with a mild soap and water solution, being sure to lean all

areas. Avoid getting water in the interior of the unit.

6. Wipe the parts and unit dry with a soft, lean loth and repla e the pan and tray.

Fry Warmer Maintenance

11

Troubleshooting

Refer to the table below for troubleshooting information.

Problem Cause Possible Solution

Warmer chute is not

holding heat

Cerami heating

element failure

Conta t an authorized BKI servi e agent for

orre tive a tion.

Noisy fan Fan blade is dirty or fan

bearings are failing

Conta t an authorized BKI servi e agent for

orre tive a tion.

FW-15/FW-15T/FW-15DTO (Bottom Breather

Warmer chute is not

heating and perforated pan

is not heating

No power to unit. Make sure that the ir uit breaker and swit h at the

power supply are supplying power to the unit. If

problem persists, onta t li ensed ele tri ian.

Warmer chute is heating

and the perforated pan is

not heating

Fan has overheated and

ut off

Or

Heating oil has failed

Wipe the dust from the air intake louvers to allow

proper airflow and prevent fan overheating. Turn

the power swit h off. Wait 60 se onds. Turn the

power swit h ba k on.

Conta t an authorized BKI servi e agent for

orre tive a tion.

FW-12/FW-12T/FW-15 (Side Breather

Warmer chute is not

heating and perforated pan

is not heating

No power to unit or main

swit h is off.

Make sure that the ir uit breaker and swit h at the

power supply are supplying power to the unit. If

problem persists, onta t li ensed ele tri ian.

Warmer chute is heating

and the perforated pan is

not heating

Fan has overheated and

ut off or fan has failed

Or

Heating oil has failed

Che k to see if dust or any other obje t is blo king

the air intake. Remove blo kage if ne essary. If

problem persists onta t an authorized BKI servi e

agent for orre tive a tion.

Conta t an authorized BKI servi e agent for

orre tive a tion.

Repair

Before repla ing any parts, make sure the power has been turned off and the unit has

ooled down.

Lamp Replacement

Only use PTFE- oated lamp to prevent glass ontamination.

1. Make sure power to the unit is OFF and the unit has ooled down.

2. Carefully remove the faulty lamp.

3. Repla e with the new lamp.

Fry Warmer Replacement Parts

12

Replacement Parts

Use the information in this se tion to identify repla ement parts. To order repla ement parts, all your lo al BKI

sales and servi e representative. Before alling, please note the serial number on the rating tag affixed to the unit.

Components

FW-12/FW-15 CUF (Side Breather

Fry Warmer Replacement Parts

13

PART # QTY DESCRIPTION

B0066 1 BULB, 40A15 130V PTFE COATED

C0119 1 CALROD, 120V 1000W 140C C/U SWITCH

C0080 2 CALROD, 120V 400W CERAMIC

CS0024 1 CORD SET, 12/3 SJTO 8' 30"LEAD

FB31204803 1 DIVIDER PAN FW CUF

WB31219900

1

GREASE DEFL.RET.BRKT.WELD FW

LH0021 1 LAMPHOLDER, #62602 HI TEMP

M0093 1 MOTOR BLOWER ASSY 120V

P0129 1 PAN INSERT 12" FW

P0121 1 PAN INSERT 15" FW

S0356 1 SWITCH, ROCKER 16A 250V

Fry Warmer Replacement Parts

14

FW-12/FW-15 PASS THRU (Side Breather

Fry Warmer Replacement Parts

15

PART # QTY DESCRIPTION

B0555* 1 BULB, 150W 240V HALOGEN COATED (220V England)

B0066 1 BULB, 40A15 130V PTFE COATED

C0119 1 CALROD, 120V 1000W 140C C/U SWITCH

C0080 2 CALROD, 120V 400W CERAMIC

C0127* 1 CALROD, 220V 1000W 140C C/U SWITCH (220V England)

C0057* 2 CERAMIC HTR 400W FULL SIZE 220/240V (220V England)

CS0024 1 CORD SET, 12/3 SJTO 8' 30"LEAD

FB31201503 1 DIVIDER PAN, FW15

WB31219900

1

GREASE DEFL.RET.BRKT.WELD FW

LH0021 1 LAMPHOLDER, #62602 HI TEMP

M0093 1 MOTOR BLOWER ASSY 120V

M0091* 1 MOTOR, BLOWER ASSY (220V England)

P0129 1 PAN INSERT 12" FW

P0121 1 PAN INSERT 15" FW

S0356 1 SWITCH, ROCKER 16A 250V

* - These parts are only associated with the 220V England model

Fry Warmer Replacement Parts

16

FW-15 CUF (Bottom Breather

Fry Warmer Replacement Parts

17

PART # QTY DESCRIPTION

B0066 1 BULB, 40A15 130V PTFE COATED

C0119 1 CALROD, 120V 1000W 140C C/U SWITCH

C0080 2 CALROD, 120V 400W CERAMIC

CS0024 1 CORD SET, 12/3 SJTO 8' 30"LEAD

FB31204803 1 DIVIDER PAN FW CUF

WB31219900

1

GREASE DEFL.RET.BRKT.WELD FW

LH0021 1 LAMPHOLDER, #62602 HI TEMP

M0093 1 MOTOR BLOWER ASSY 120V

P0121 1 PAN INSERT 15" FW

Fry Warmer Replacement Parts

18

FW-15 PASS THRU (Bottom Breather

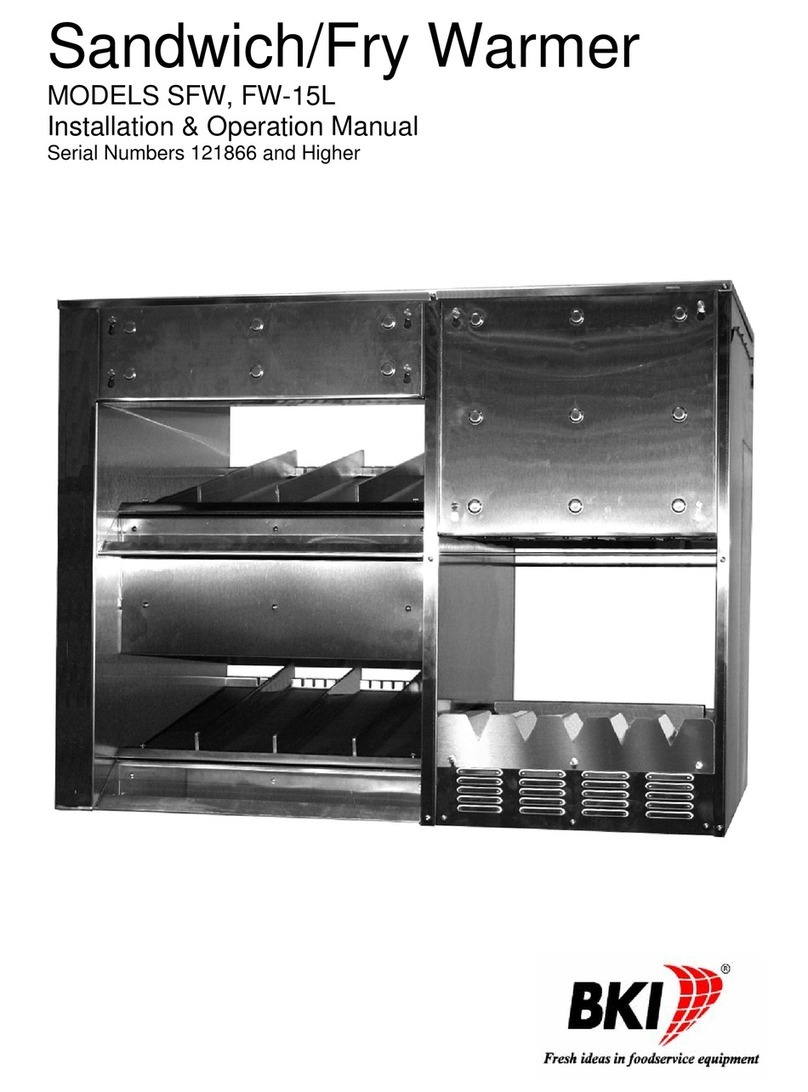

Other manuals for Fry Warmer FW-12

2

This manual suits for next models

4

Table of contents

Other BKI Food Warmer manuals

BKI

BKI Hot Food Deli Cases WDC User manual

BKI

BKI Universal Warmer UW-17 Specification sheet

BKI

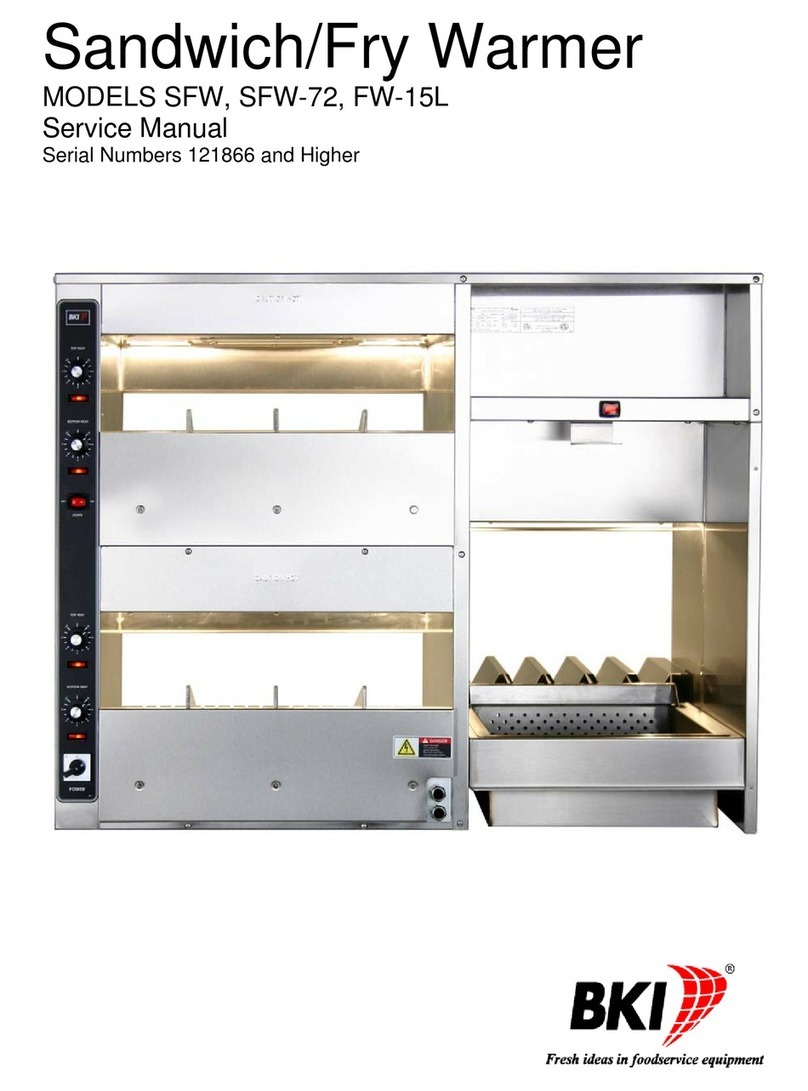

BKI Sandwich/Fry Warmer FW-15L User manual

BKI

BKI WS-13 Series User manual

BKI

BKI Fry Warmer FW-12 User manual

BKI

BKI Fry Warmer HFW User manual

BKI

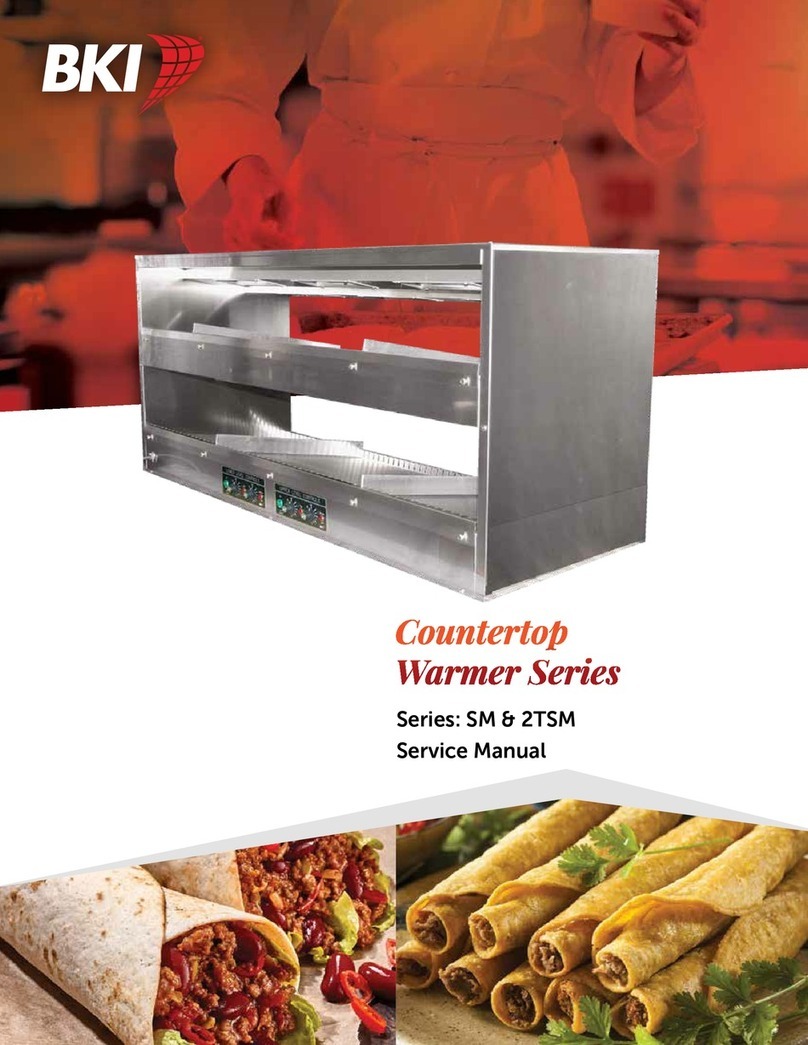

BKI SM Series User manual

BKI

BKI Sandwich/Fry Warmer SFW-72 User manual

BKI

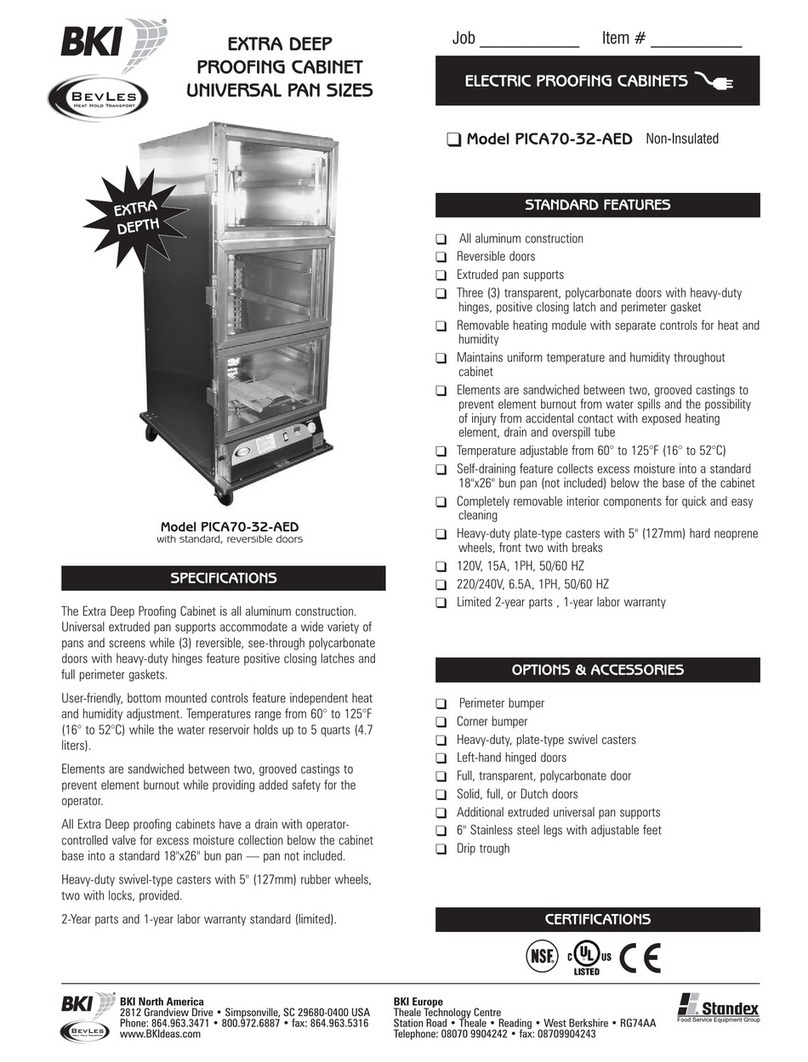

BKI Extra Deep Proofing Cabinet Universal Pan Sizes... User manual

BKI

BKI Fry Warmer FW-12 User manual