BLACK NOISE COSMOS Manual

Other manuals for COSMOS

1

Table of contents

Other BLACK NOISE Recording Equipment manuals

BLACK NOISE

BLACK NOISE SAM-C Manual

BLACK NOISE

BLACK NOISE PIPE User manual

BLACK NOISE

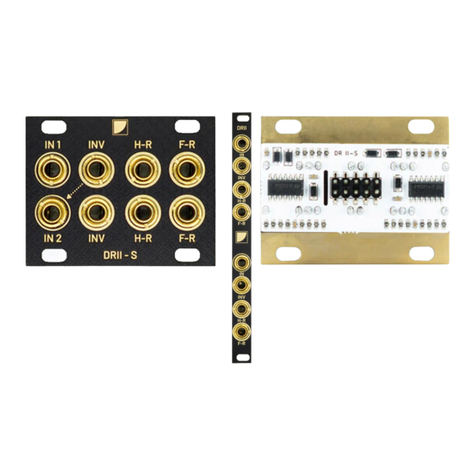

BLACK NOISE DUAL MULTI Manual

BLACK NOISE

BLACK NOISE SAM-C User manual

BLACK NOISE

BLACK NOISE GOMA User manual

BLACK NOISE

BLACK NOISE GOMA Manual

BLACK NOISE

BLACK NOISE QBI User manual

BLACK NOISE

BLACK NOISE MIXER4 User manual

BLACK NOISE

BLACK NOISE SALLEN KEY User manual

BLACK NOISE

BLACK NOISE SALLEN KEY Manual

Popular Recording Equipment manuals by other brands

Auverdion

Auverdion freeDSPx-AnalogIO-x8 Getting started

Car Solutions

Car Solutions QPI LVTX FIAT installation manual

Tascam

Tascam DA-P1 Service manual

Mitsubishi Electric

Mitsubishi Electric M800 Series manual

Fostex

Fostex VF-16 Specifications

Streaming Network

Streaming Network iRecord Pro Reviewer's guide