2

INSTALLATION

Introduction

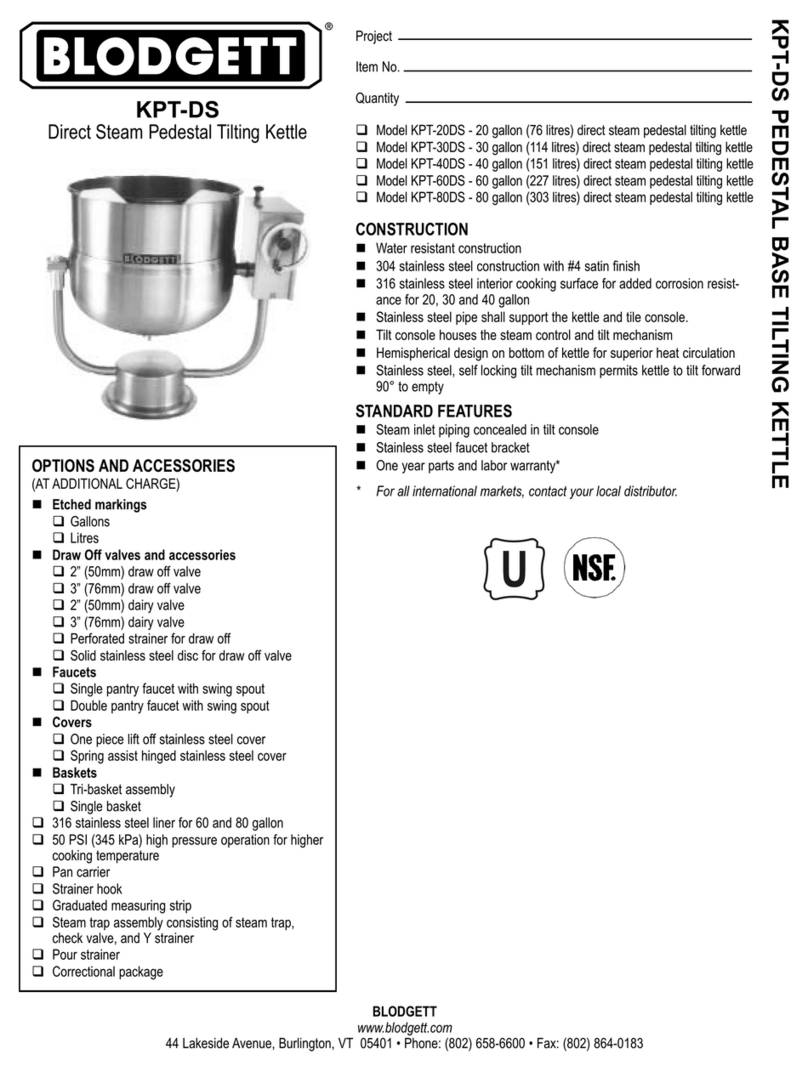

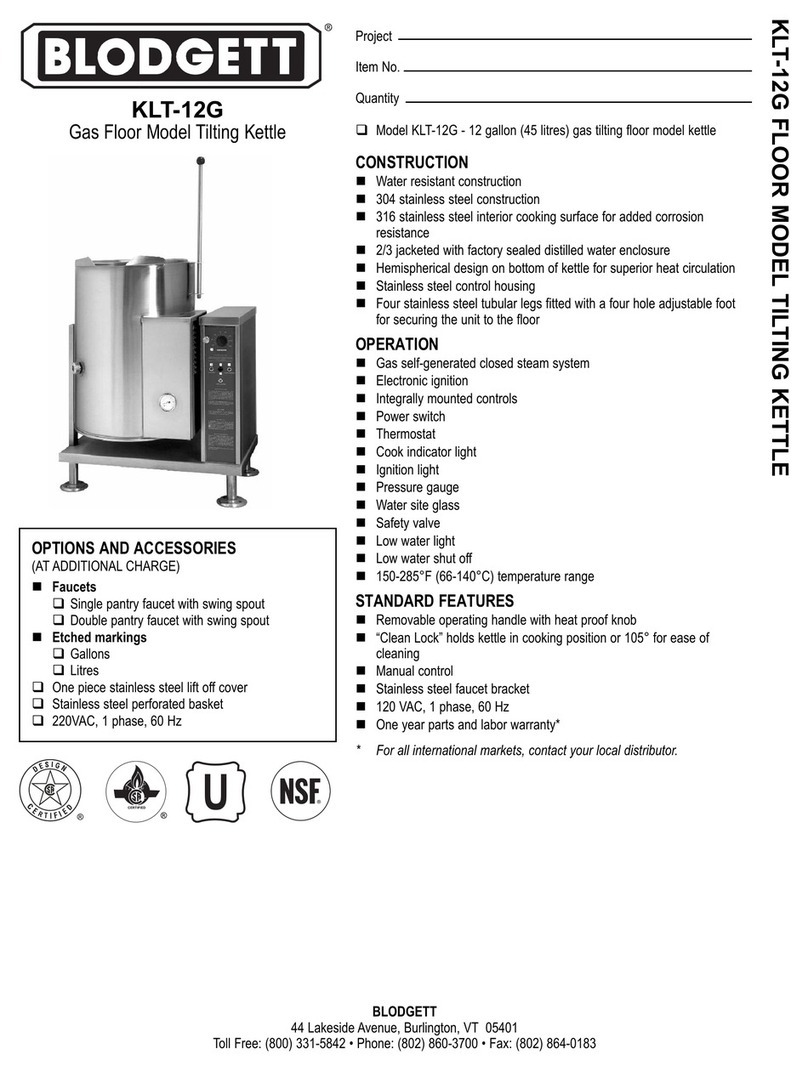

DESCRIPTION

Floor model kettles are self-contained, self-generating

steam jacketed vessels for cooking large volumes of liq-

uid and semi-liquid food products. All models include a

hemispheric shape based on double-wall construction

forming a steam jacket reservoir around the lower two-

thirds of the kettle. The reservoir is charged with distilled

water, rust inhibitor and antifreeze solution and is vacu-

um-sealed. Kettles are equipped with electric heating ele-

ments and controls including a low water cut-o device for

protection of heating elements.

Two model series dier in that KLT-__E units are leg -

mounted tilting kettles while KPS-__E units are pedestal

mounted stationery kettles. Optional leg mounting of the

pedestal models is designated by the model number se-

ries KLS-__E. The missing gures of the model numbers

are the two digits representing the kettle capacity, ie, KLT-

20E for a 20 gallon tilting kettle.

BASIC FUNCTIONING

Self-contained kettles operate by generating steam in the

kettle reservoir; the sequence of functioning, which oc-

curs during operation, is as follows:

1. Operator places the power switch in the ON position

and sets the thermostat knob at the required setting

from ‘’1’’ to”10” – 165°F (74°C) to 285°F (140°C ) -

jacket temperature.

2. Control circuit is normally completed to the thermo-

stat control if two standard conditions exist:

a. Water level in kettle jacket is adequate to’ prevent

circuit interruption by the low water cut-o device.

An activated cut-o is evidenced by the

Low Water light turning on and heating element

cut o.

b. Kettle is in vertical position with circuit complet-

ed through the tilt interlock switch (KLT-E series

only).

3. Thermostatic control contacts close to energize heat-

er contactor coils and turn temperature Indicator light

on.

4. Power is applied to heaters through closed contactor

power contacts.

5. As temperature of water rises in kettle reservoir, the

steam pressure increase is indicated by the vacuum

pressure gauge.

NOTE: Gauge normally reads 22-30 IN. Hg (74-100

k/Pa) (below 0 PSI, prior to heaters turning

on. Air is eliminated from the system when

jacket is lled (with the kettle reservoir at a

pressure above 0 PSI) by opening the bleed

vent one full turn for 10 seconds and closing.

6. When temperature of steam in the reservoir reaches

the temperature coinciding with the thermostat set-

ting, the thermostat switch opens to break the circuit

to the contractor coils and shuts o the elements. Any

number of on and o cycles of the control thermo-

stat, contactors and elements will occur as required

to maintain thermostat setting,

SERVICE

Required service, both preventive and corrective. is ex-

plained in the maintenance section. Should repairs be

required, a network of authorized agencies is available

to assist with prompt service. A current Directory of Au-

thorized Service Agencies may be found by visting our

website, www.blodgett.com.

The model and serial numbers must be referenced when

corresponding with Blodgett. The data plate containing

the serial number pertaining to the equipment is located

on rear of kettle.