2021-11

1 866907 0122 blubathworks.com

11

Attention —Before Installation

If you are installing this product in a new construction or remodel, please make sure you are following all local plumbing and building codes.

please read these instructions carefully before you begin.

- Make sure the system is clear of any impurities.

- In presence of hard water (>12°F) a water softener is advised.

Operation Conditions

- Tapware is manufactured following the EN817 norms.

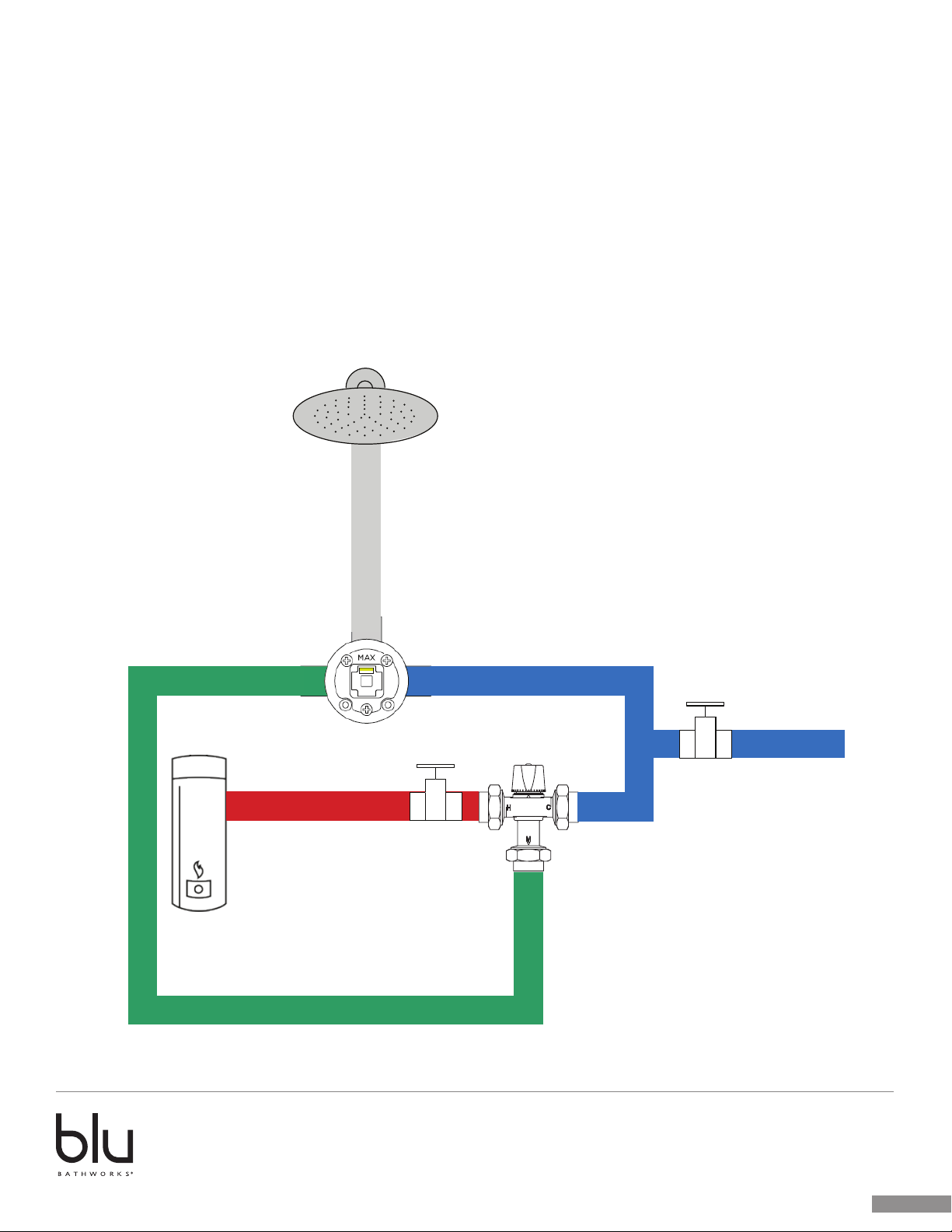

- Heaters allowed upstream: pressure accumulators, instant boilers.

- The installation with low pressure hot water accumulators is not permitted (open circuits).

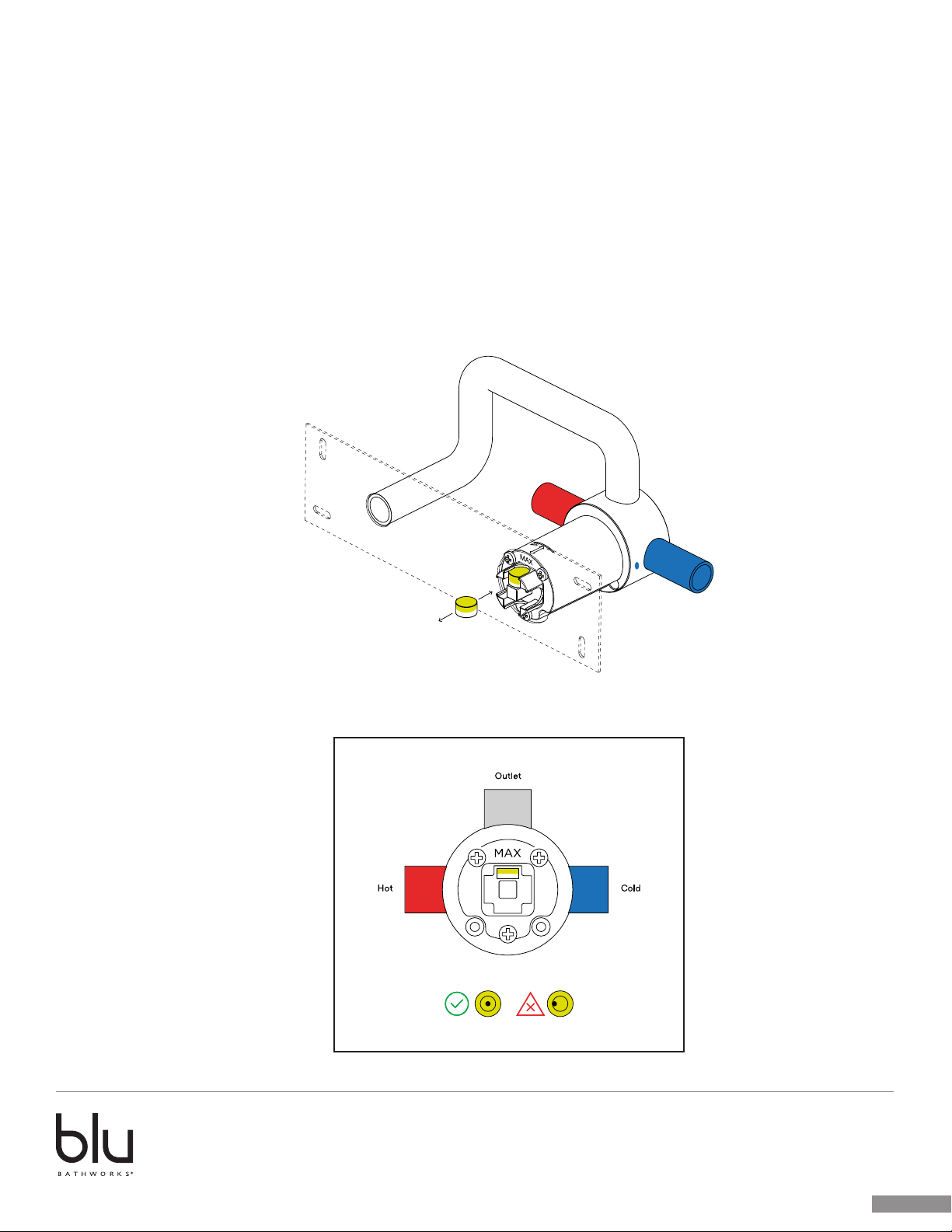

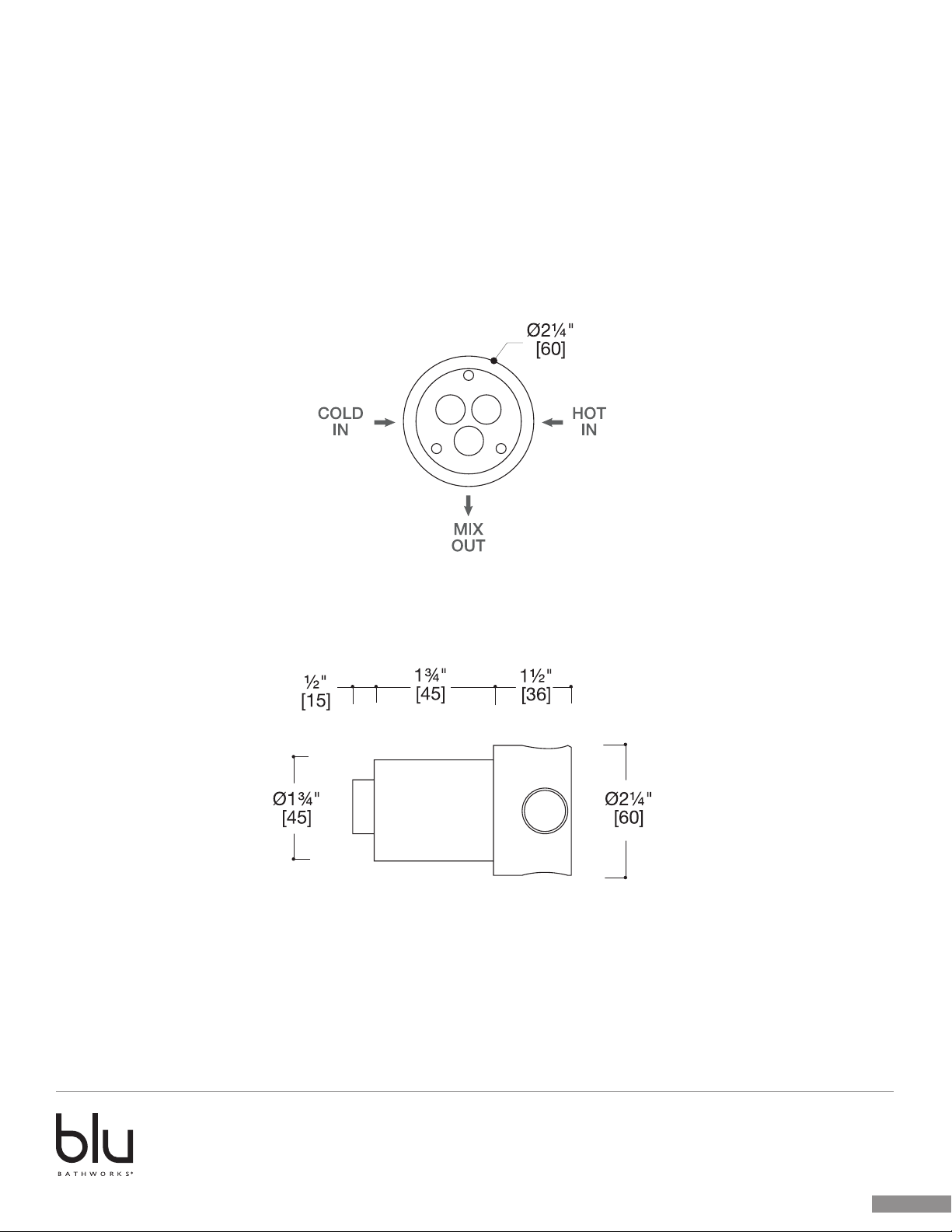

- Left connection. Hot water - Female NPT 3/8. (1/2” and 9”16 for some countries)

- Right connection. Cold water - Male NPT 3/8. (1/2” and 9”16 for some countries)

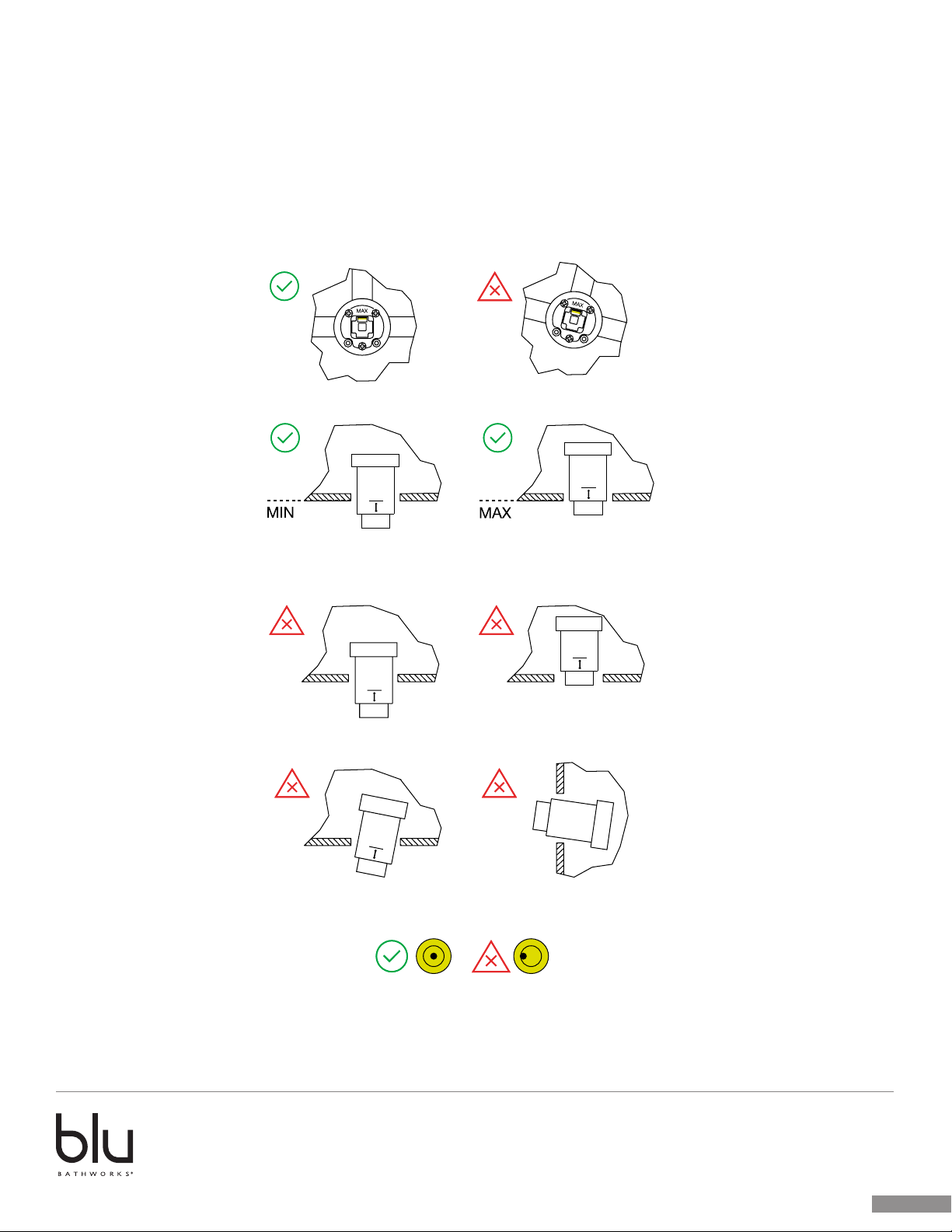

- System pressure: Min./Max. 7 PSI/145 PSI.

- Recommended operating radius: 15 PSI - 72 PSI.

- For higher pressures (>72 PSI) a reducer is advised.

- Avoid pressure unbalance higher than 1:2 between hot and cold water supply.

- Recommended water supply temperature: Cold 10-15° C / 50-59° F. Hot 60-65° C / 140-149° F.

Technical Details

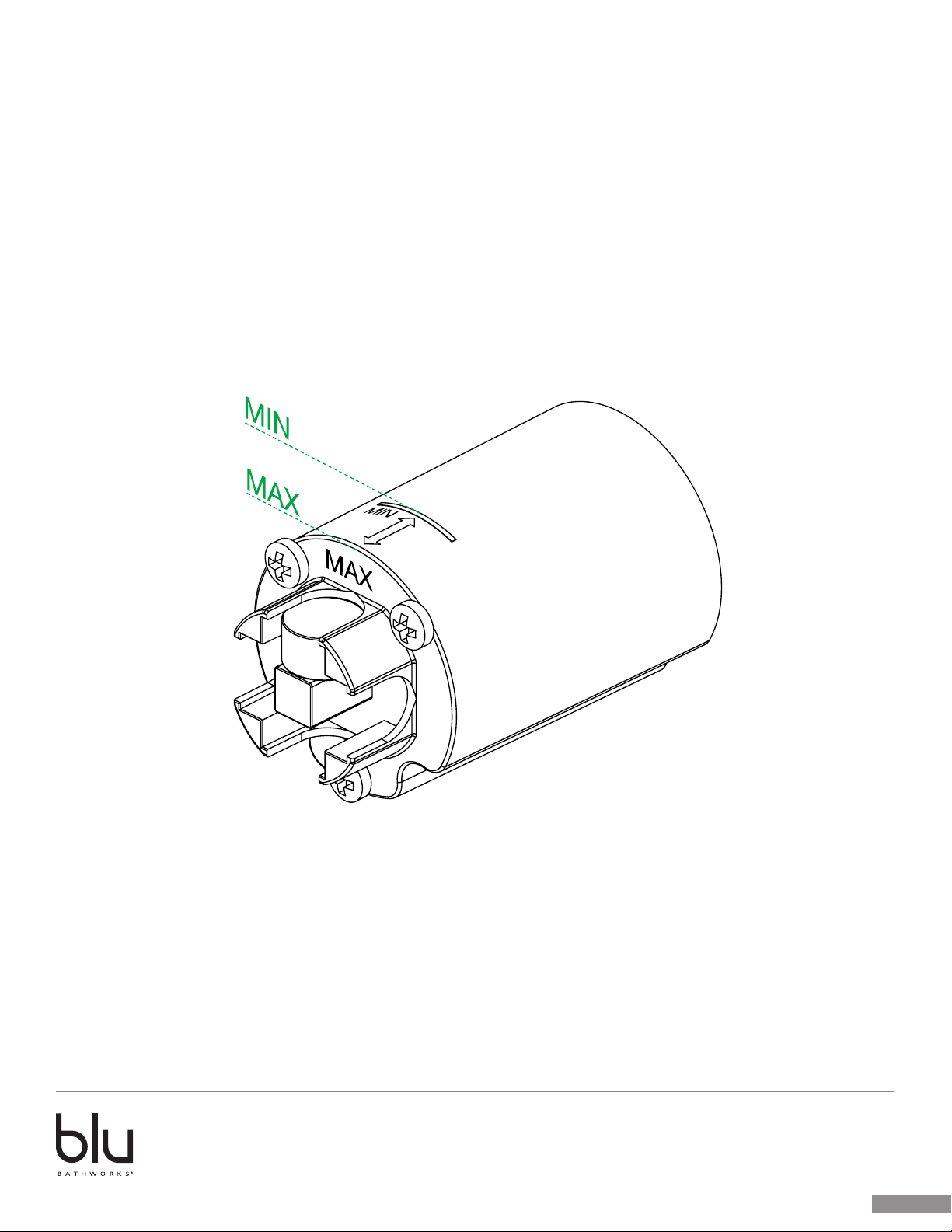

Minimum Pressure: 15 PSI

Maximum Pressure: 145 PSI

Recommended Pressure: 29 - 72 PSI

Maximum Water Temperature: 80° C / 176° F

Maximum Recommended Water Temperature: 65˚ C / 149˚ F

the temperature.

Installation Requirements

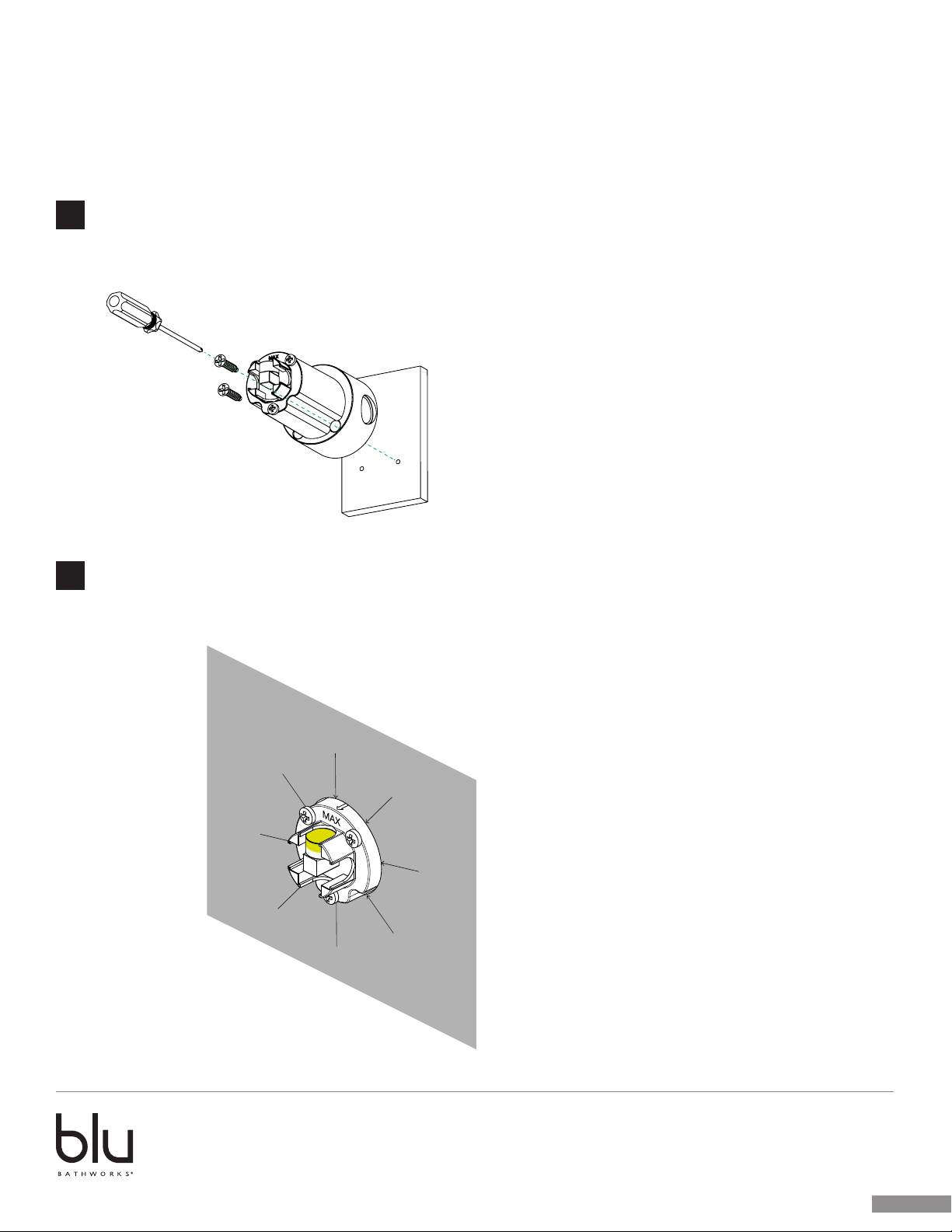

1. To ensure this product is installed properly, you must read and follow these guidelines.

2. The owner/user of the product must keep this information for future reference.

3. Consult local building codes to make sure the installation complies with standards.

4. Remove the unit from its packaging. Before disposing of it, inspect the unit to make sure its in good shape. Should inspection reveal any

installed. Blu Bathworks’ responsibility for shipping damages ceases upon delivery of the product in good order to the carrier.

All complaints regarding damage due to transport must be made directly to the carrier.

5. Place the unit in the bathroom before you start working. Conserve all nuts and bolts.

6. To protect the unit during installation, we recommend that you lay a piece of cardboard on the bottom.

7.

8. Verify that all dimensions on the plan are the same as the ones of the unit.

9. All installations must conform to local and national plumbing, build

10. Inspect this product to assure you have all parts required for proper installation.