BOETECH 150 User manual

Buffer Tank | 1

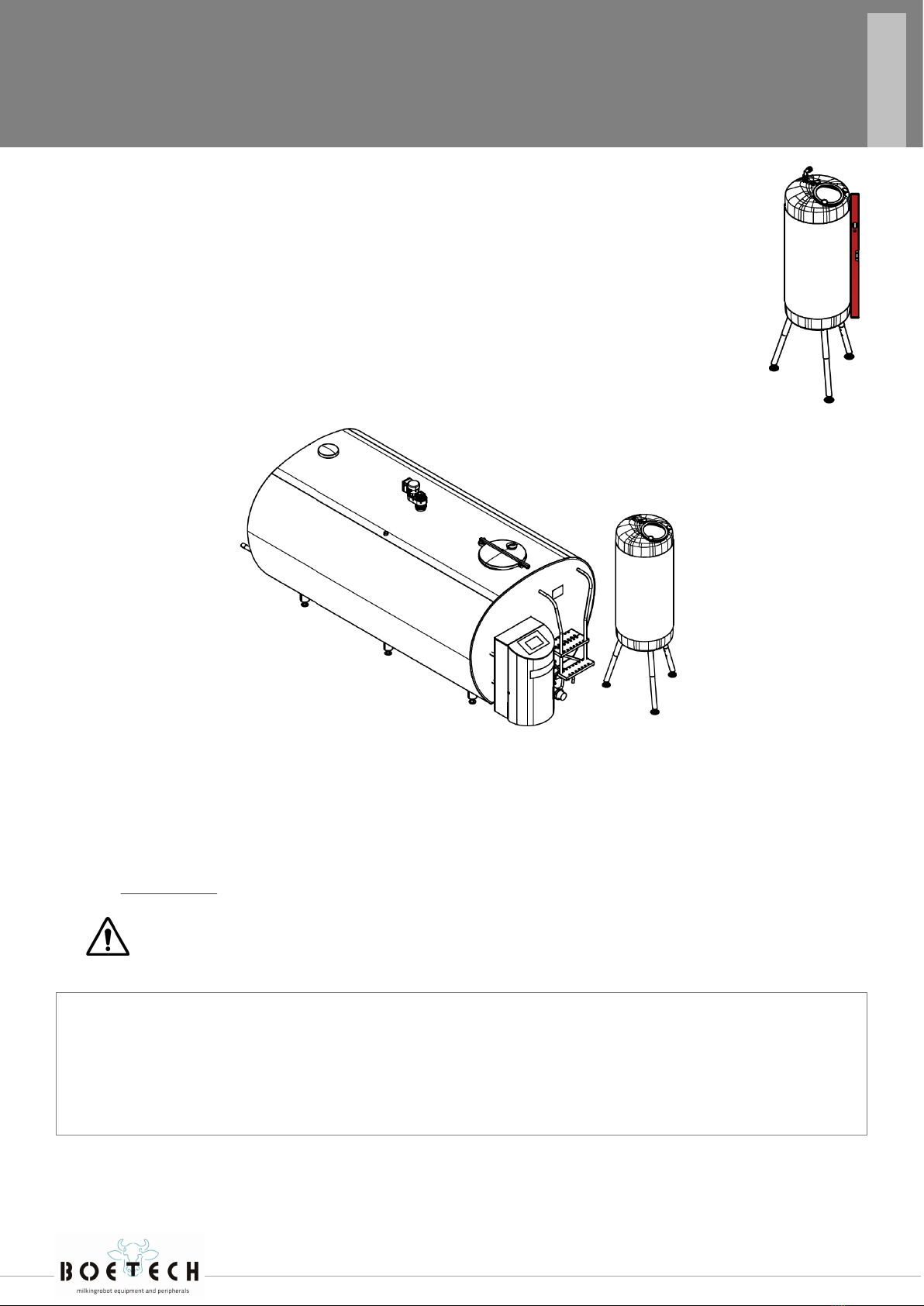

BUFFER TANK

Mounting Instructions

Buffer tank st./w. model 150

Buffer tank st./w. model 250

Buffer tank st./w. model 350

Buffer tank st./w. model 500

Buffer tank st./w. model 650

Buffer tank st. model 800

Buffer tank st. model 1000

Buffer tank st. model 1200

Buffer tank st. model 1600

Buffer Tank | 2

We thank you for choosing our product. These mounting instructions assist you in mounting

(and operating) the product safely. Product images are for illustrative purposes only and may

differ from the actual product.

Before you start the installation, make sure all supplied parts are present and have the right

measurements. This product has been manufactured under rigid inspection and quality ma-

nagement. We ask you to contact your sales department in case of a lack of clarity.

The type and the serial number of the buffer tank system are attached to the buffer valve

system. Always include the type and the serial number of your product, when you contact

your local Lely service provider or when ordering spare parts.

We suggest that you complete the table below with the type and the serial number of your

buffer tank system. Making your find the information easily.

Type number

Serial number

V3

Buffer Tank | 3

1

2

Buffer Tank | 4

PARTS

SPARE PARTS

Amount Article nr. Nr. Description

1x 1Buffer tank + valve system

1x 2144... 2Mounting set

English

Article nr. Description

100051 Actuator standard buffer system without bracket

100012 Spray nozzle for buffer tank

CONTENT

Sealing set Contains

214515

3 x EPDM seal 1” 100121

1 x EPDM seal 1,5” 100122

3 x Tri-Clamp seal DN 20 201079

1 x Tri-Clamp seal 2” 201072

214513

3 x EPDM seal 1” 100121

1 x EPDM seal 1,5” 100122

3 x Tri-Clamp seal DN 20 201079

1 x Tri-Clamp seal 2” 201072

1 x Silicone seal (levelsensor) 203021

214517

5 x EPDM seal 1” 100121

1 x EPDM seal 1,5” 100122

5 x Tri-Clamp seal DN 20 201079

1 x Tri-Clamp seal 2” 201072

1 x Silicon seal (levelsensor) 203021

214514

3 x EPDM seal DN25 100123

1 x EPDM seal 1,5” 100122

3 x Tri-Clamp seal DN25 720201

1 x Tri-Clamp seal 2” 201072

1 x Silicon seal (levelsensor) 203021

214518

5 x EPDM seal DN25 100123

1 x EPDM seal 1,5” 100122

5 x Tri-Clamp seal DN25 720201

1 x Tri-Clamp seal 2” 201072

1 x Silicon seal (levelsensor) 203021

Buffer Tank | 5

TANK PLACEMENT

1. Make sure the buffer tank is on a solid foundation. Use a level measuring instrument.

2. When a milk pipeline is placed at 30cm above the ground, there must be no walking

space between the buffer and the main tank.

3. The buffer tank should be located nearby or above the drain.

4. The best position to install your buffer tank is in front of the main tank. The distance

between the main tank and the buffer tank should be as short as possible. This will re-

duce operating costs and contributes to the deflate process.

AIR SUPPLY

A 6mm airline should be connected from the compressor to the valve block in the CRS+. 4mm airlines

must be connected to the butterfly valves underneath the buffer tank. The air pressure should be be-

tween 6 and 8 bars, to control the butterfly valves.

N.B. The air pressure to the butterfly valves should not be more than 8bar.

CLEANING

Clean the robot a couple of hours before using the buffer tank. When you do not do this, the robot

may proceed with the main cleaning process when the milk tank driver empties to the main tank.

English

MOUNTING INSTRUCTIONS

Buffer Tank | 6

INSTALLATION METHOD

1. Put the buffer tank into position.

2. Loosen all the lock nuts with the wrench.

3. Level your buffer tank by turning the leveling feet in and out as necessary.

4. When your buffer tank is level, tighten the lock nuts

using the wrench. Do not move your buffer tank unless

you tighten the locknuts. This may result in damage to the

leveling feet. Ensure that the buffer tank is stable.

5. Mount the air in/outlet (white elbow) on the top of the

buffer tank. Make sure this part is open and clean at all

times.

To make sure the buffer tank will not fall over, we recom-

mend attaching the cleaning pipe to a wall.

6. Make the tube/pipe connections according to the illustration beside. Connections can be made

with Pex or stainless steel.

English

MOUNTING INSTRUCTIONS

Buffer Tank | 7

Milk goes directly into the

mechanically refrigerated

main tank.

Milk goes into the buffer tank.

The main tank is being clean-

ing and rinsing.

The robot, milk pipeline and

buffer tank are being cleaned.

Milk is stored in the mechani-

cally refrigerated main tank.

Incorrect use of the buffer tank can be dangerous to people, nearby equipment and the environment. Before

reaching into the buffer tank, disconnect the air tubes of the CRS.

TROUBLESHOOTING

Issue Cause Action

Valve does not open or close properly Valve is broken Disassemble and replace part.

No voltage, no air pressure Check power supply, use air pressure to

check the valve

Buffer tank does not discharge water

properly No pressure Disassemble and check the air valve block,

increase the pressure.

High bacteria-count number Insufficient cleaning of the robot,

main tank or buffer tank

First check your robot cleaning, then sprin-

kle ball. Check for congestion in the tank

valve system.

INTEDED USE

English

Description ABC

150 Standing model

150 Wall model

60 cm

50 cm

150 cm

150 cm

180 cm

180 cm

250 Standing model

250 Wall model

60 cm

50 cm

230 cm

230 cm

260 cm

260 cm

350 Standing model

350 Wall model

60 cm

60 cm

220 cm

220 cm

250 cm

250 cm

500 Standing model

500 Wall model

98 cm

60 cm

190 cm

290 cm

220 cm

320 cm

650 Standing model 98 cm 230 cm 260 cm

800 Standing model 98 cm 230 cm 260 cm

1000 Standing model 98 cm 250 cm 280 cm

1200 Standing model 95 cm 280 cm 310 cm

1600 Standing model 140 cm 240 cm 300 cm

A = Diameter tank

B = Minimum height ceiling milk storage room

C = Advised height ceiling milk storage room. Note: Mini-

mum distance between the top of the buffer tank and the

ceiling should be 30 cm, for inspections.

Buffer Tank | 8

Connect the valves of the buffer tank with 4 air tubes (4mm, black PA) into the CRS+. Use the prede-

fined cluster configurations in the Lely CRS+ manual for the right settings and connections.

Menu item Description Min Max Default Unit

Maximum contents

The maximum content of the buffer tank is used

for an internal calculation to make sure the buffer

tank does not overflow.

200 2500 500 Kg

An alarm is generated when the buffer tank is full

(based on yield calculation of the milking robots).

All milking robots in the cluster will be taken out

of operation.

-441 -5511 -1102 (lb)

Maximum buffer time

The maximum time the milk is stored in the buffer

tank. When this time is expired, the milk will get

drained to the sewer. 4360 90 min

An alarm is generated when the set time is ex-

ceeded.

Buffer emptying time

The maximum time to allow the buffer tank to

transport the milk to the milk tank. This is based

on a full buffer tank.

360 60 min

The drain time depends on:

The location of the buffer tank concern-

ing the milk tank.

The amount of milk in the milk tank.

A sensor can be connected to the CRS+ indicating

when the buffer is empty.

If this sensor is installed, an alarm is generated

when the set time is exceeded.

The drainage pauses when a milking robot pumps

milk to the milk tank. The drain timer takes this

pause time into account.

Pre-rinse delay *

During pre-rinse valve V6 or V6b switches to

buffer after the set delay time. This is to prevent

milk residue to enter the buffer tank.

30 600 30 s

* Applicable for USA / Canada only.

English

APPENDIX A: CRS+/ CRS M3 BUFFER TANK SETTINGS

Buffer Tank | 9

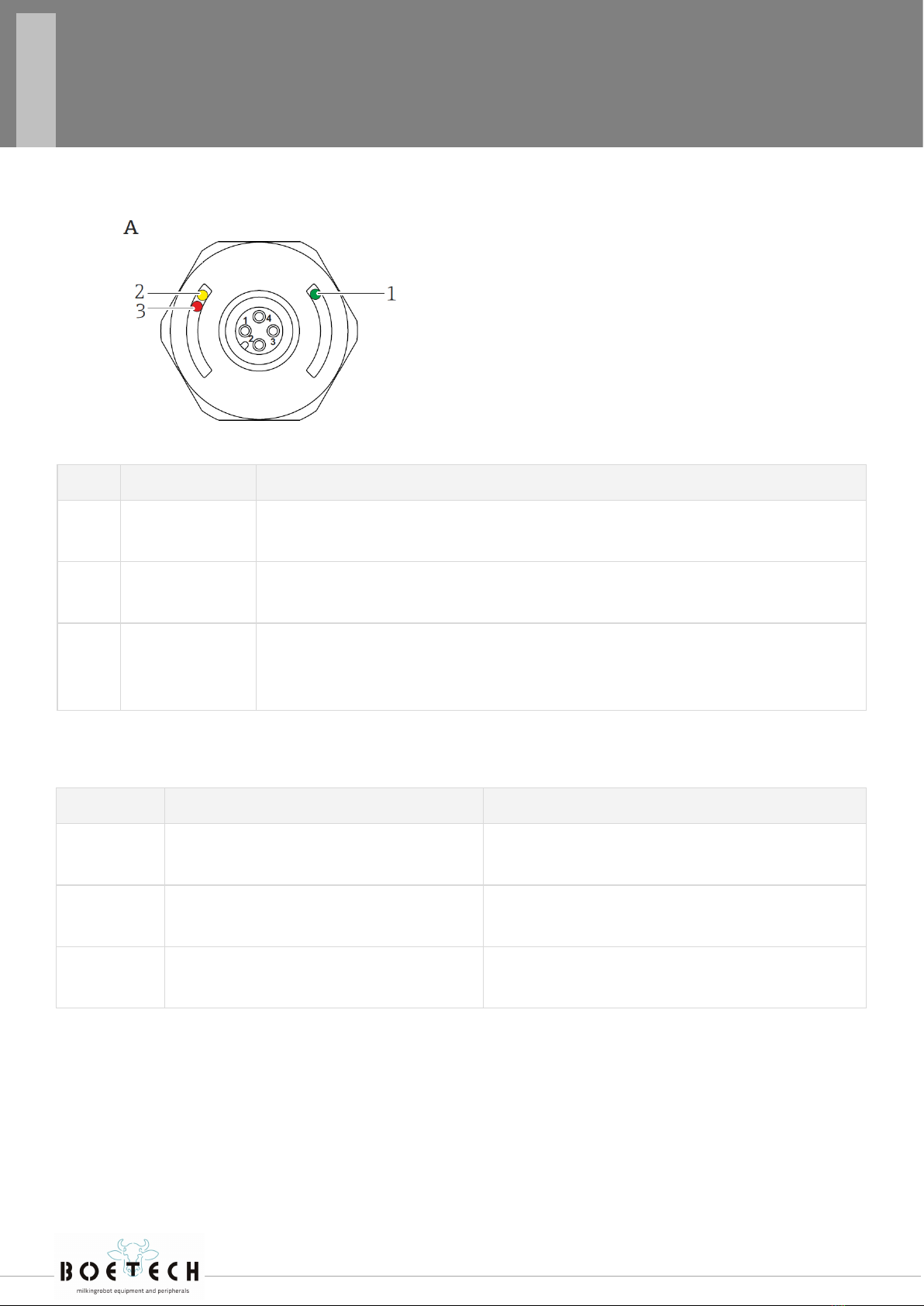

Until May 2019 Valve plug connection

The level sensor is mounted at the lowest possible position in the tank valve

system of the buffer tank. The figure shows the correct wiring between the

level sensor and the CRS+ (3x 0,75mm2).

Note: When the red and green led lights are on, the buffer tank is empty.

From May 2019 M12 connector

A 3 or 4-wire cable is delivered with the system (colors brown, blue, black, [white])

CONNECTION LEVEL SENSOR TO CRS+ OR CRS M3

The sensor can be connected to an input of the CRS+ or CRS M3. Configure the setting: “BV is EMPTY

(BV1)” at ‘configuration inputs’. At ‘test inputs’ the state of the level sensor can be checked.

Check the functioning of the system at the first milk collection! Check the wiring if the “empty tank”

procedure does not work well.

Valve plug M12 CRS+ / CRS M3

1Blue - /GND

2Brown +

3Black Level high

English

APPENDIX B: LEVEL SENSOR (IF PRESENT)

Level high 24V on input CRS+/CRS M3 (black wire) Test inputs: BV is empty (BV1): full

No level 0V on input CRS+/CRS M3 (black wire) Test inputs: BV is empty (BV1): empty

Buffer Tank | 10

TROUBLESHOOTING

APPENDIX B: LEVEL SENSOR (IF PRESENT)

Item Fuction Description

1Green LED (gn)

Lit Device is operational

2Yellow LED (ye)

Lit

M12 connector

Indicates the sensor state: tuning fork is covered by liquid

3

Red LED (rd)

Flashing

Lit

Warning/maintenance required: error can be rectified, e.g. incorrect wiring

Fault/device failure: error cannot be rectified, e.g. electronic error

Malfunction Possible cause Corrective action

Green LED

Unlit No power supply Check connector, cable and power supply

Red LED

Flashing Overload or short-circuit in load circuit • Rectify short-circuit

• Reduce maximum load current to below 250 mA

Red LED

Lit Internal sensor failure or sensor corroded Replace device

English

AM12 connector, (cable without graphic)

LED DISPLAY LEVEL SENSOR M12 CONNECTOR (FROM MAY 2019)

Buffer Tank | 11

There are two options that you can choose:

• 203001 Electrical acted 3/2 valve

• 203008 Pneumatic acted 3/2 valve

The Pressure Reduce Valve should be adjusted as high as possible. In this situation the system will

work optimal.

MAX PRESSURE 1 - 1,2 bar!

203001 - Electrical acted 3/2 valve

This switchbox can be used for:

• Boetech switchbox

• CRS+

• CRS M3

With a Boetech switchbox the blow valve is con-

nected on terminals 37 + 38.

With CRS+ and CRS M3 a digital output ‘Boetech

air’ has to be configured.

English

APPENDIX C: PRESSURE SYSTEM

Pressure Air outlet Air inlet

Buffer Tank | 12

203008 - Pneumatic acted 3/2 valve

This switchbox can be used for:

• CRS M3

With CRS M3 a pneumatic output ‘Boetech air’ has to be configured

Pressure Air outlet Air inlet

4mm air output CRS ‘Boetech air’

APPENDIX C: PRESSURE SYSTEM

English

Buffer Tank | 13

English

PERSONAL NOTES

Buffer Tank | 14

PERSONAL NOTES

English

Buffer Tank | 15

All rights reserved. The information given in this publication is provided for information purposes only

and does not constitute an offer for sale. Certain products may not be available in individual countries

and products supplied may differ from those illustrated.

No part of this publication may be copied or published by means of printing, photocopying, microfilm or

any other process whatsoever without prior permission in writing by Boetech Meps Int. B.V.

Although the contents of this publication have been compiled with the greatest possible care, Boetech

Meps Int. B.V. cannot accept liability for any damage that might arise from errors or omissions in this

publication. The English language manual is the original manual. Translations into other languages use

the English language manual as the source document. Boetech Meps Int. B.V. accepts no liability for

discrepancies between the original English language manual and versions in other languages. If there is

a conflict over the content and accuracy of any translated manual, the English language manual is the

authority document.

Copyright © 2020 Boetech Meps Int. B.V.

All rights reserved

COPYRIGHT AND DISCLAIMER

Antennestraat 38

1322 AE Almere

The Netherlands

www.boetech.nl www.boetechmeps.com

Buffer Tank | 16

Antennestraat 38

1322 AE Almere

The Netherlands

www.boetech.nl www.boetechmeps.com

This manual suits for next models

8

Popular Tank Equipment manuals by other brands

Astro Pneumatic Tool

Astro Pneumatic Tool PT2-4 quick start guide

Franklin Fueling Systems

Franklin Fueling Systems EVO 600 Operation guide

TransTank

TransTank TopCrop Operator's handbook

WELBA

WELBA TW-32 quick start

Amtrol

Amtrol FILL-TROL FT-109 Installation & operation instructions

Regulus

Regulus RBC 200 Installation and operation manual