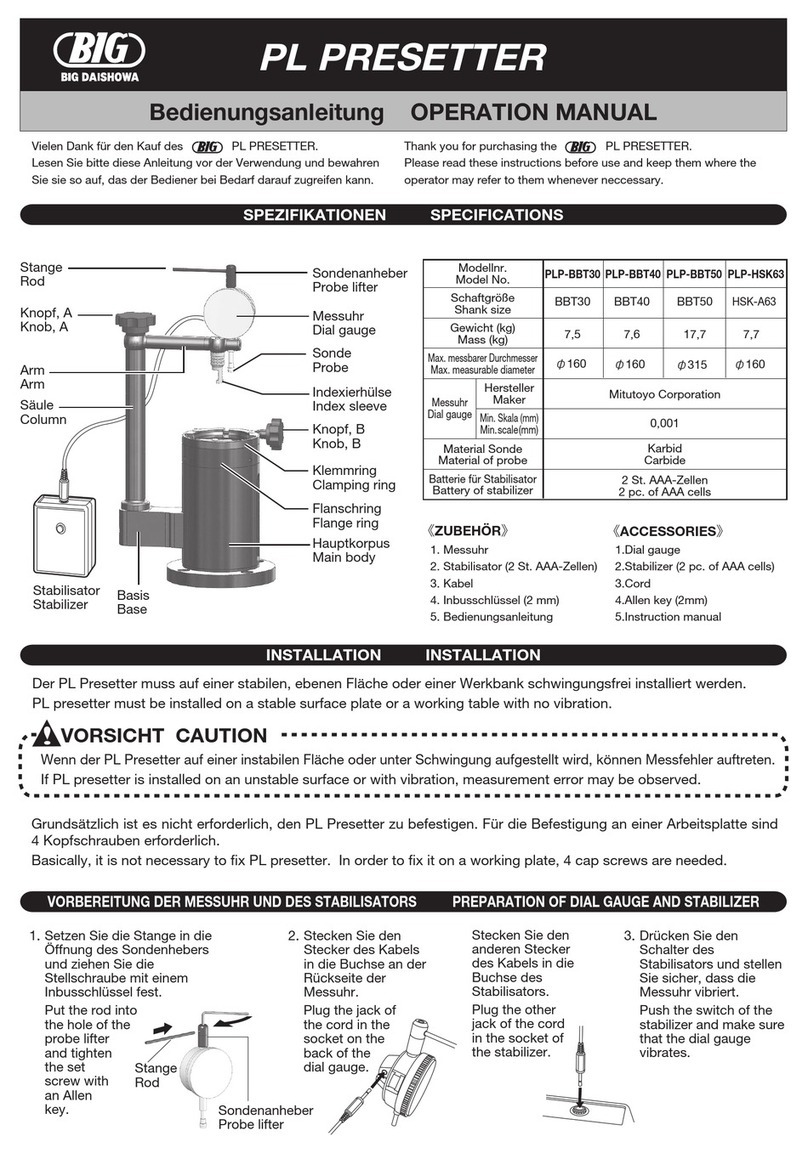

OPERATION MANUAL

DOWNLOAD SITE

http://big-daishowa.com/manual_index.php

OPERATION MANUAL

Before clamping inserts, remove any foreign matter on the insert seat with air blow.

Wipe the side and back faces of inserts with lint-free cloth throughly.

Tighten the screw while applying light pressure on the insert.

Ensure there is no gap between the insert and the insert seat.

Do not substitute other insert clamping screws. Use only genuine BIG FCR screws.

Note: Inserts are very sharp!! Be careful to prevent injury to hands when replacing inserts.

Replace clamp screw periodically.

Do not use torx wrench with damaged tip or clamping screw with damaged torx socket.

Do not apply under inappropriate cutting condition.

Do not use after the body has been in a collision and strongly

shocked.

The tool may cause burns to skin if touched immediately after long

periods of cutting time.

Between FULLCUT MILL FCR and FCM, tools and inserts are not compatible.

Refer to the catalogue of "FULLCUT MILL" to select an insert.

The insert clamping screw set includes 10 screws and 1 exclusive wrench.

HOW TO CLAMP INSERTS

CAUTION

CAUTION

ABOUT CUTTING CONDITION

Refer to the catalogue of "FULLCUT MILL" for cutting datarecommendations.

For oversize models, start operating with lower cutting parameters and increase them gradually.

Use safety sheilds and eye protection during cutting.

Never exceed the maximum allowable rotational speed.

FULLCUT MILL FCR can be used for feeding in Z axis such as ramping,helical interpolation and drilling.

Please observe the following recommendations during operation.

Air blow or coolant supply must be provided when machining pockets.

(Directed through tool center is recommended.)

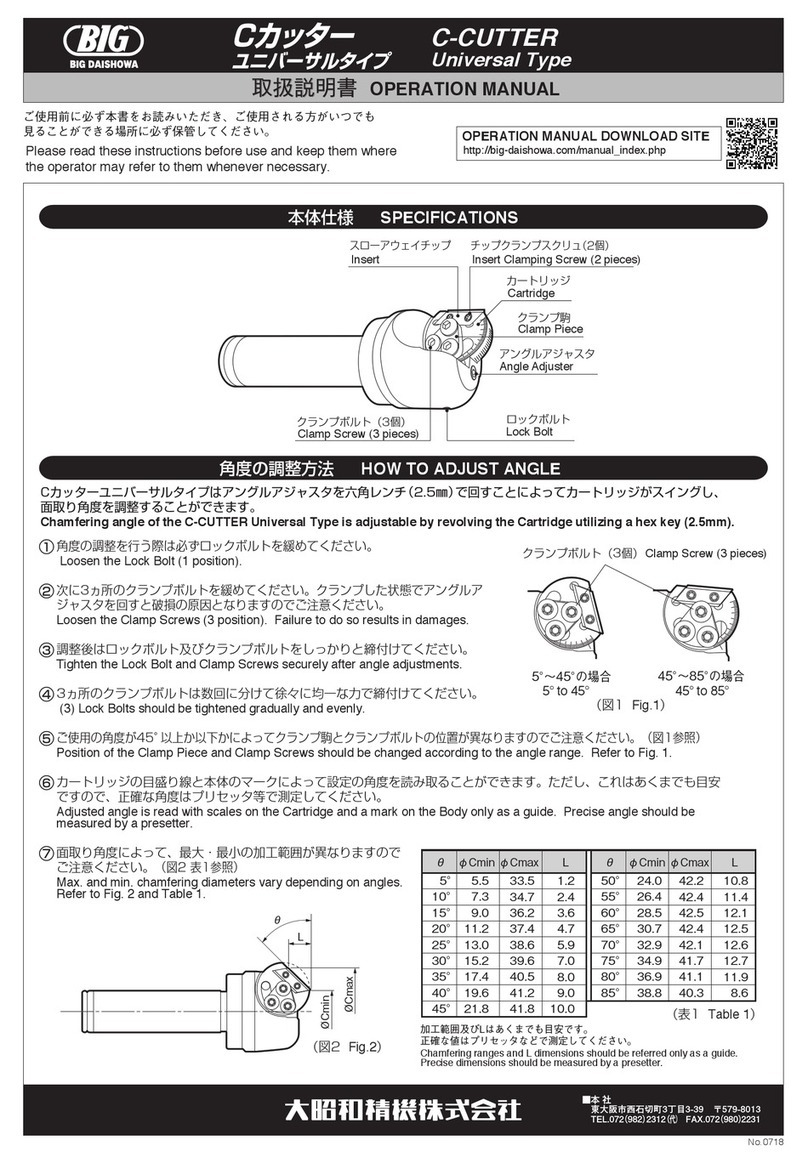

Feed angle should be less than 3 when ramping and helical interpolation.

Z-Axis Drilling depth(plunging) in one pass should be less than:

ø

16, 17(

ø

.625") 0.5mm(.020")

ø

20, 21(

ø

.75"),

ø

25, 26(

ø

1") 1mm(.039")

ø

32, 33(

ø

1.25") 2mm(.079")

For deep hole drilling operations, the following procedure is necessary:

1.Plunge in Z-axis to maximum depth defined above

2.Radial feed cutter to required dimensions.

Note: Minimum radial feed must exceed "Cutter diameter minus 2mm

(.079")

"

3.Repeat this procedure until the required depth is completed.

In case 3-flutes oversize model causes chatter, 2-flute model is recommended.

(Caution)

The maximum allowable rotational

speed is the limit for the safety based

on the construction of the tool.

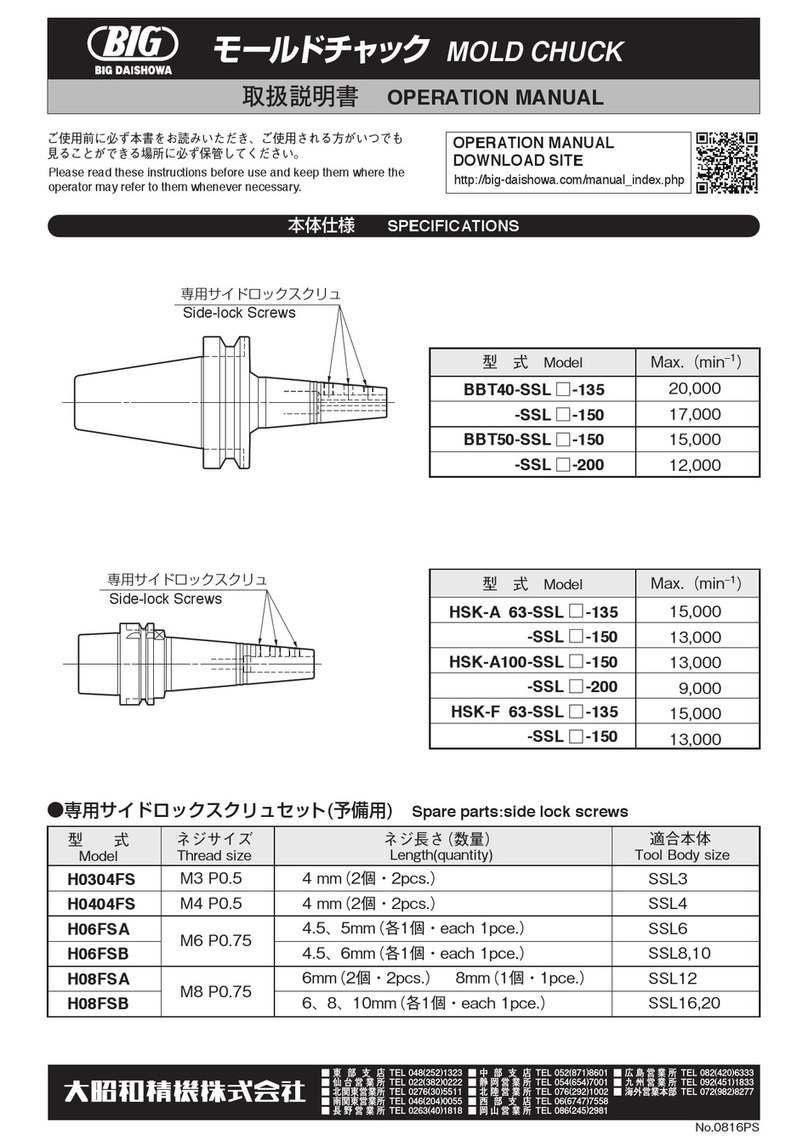

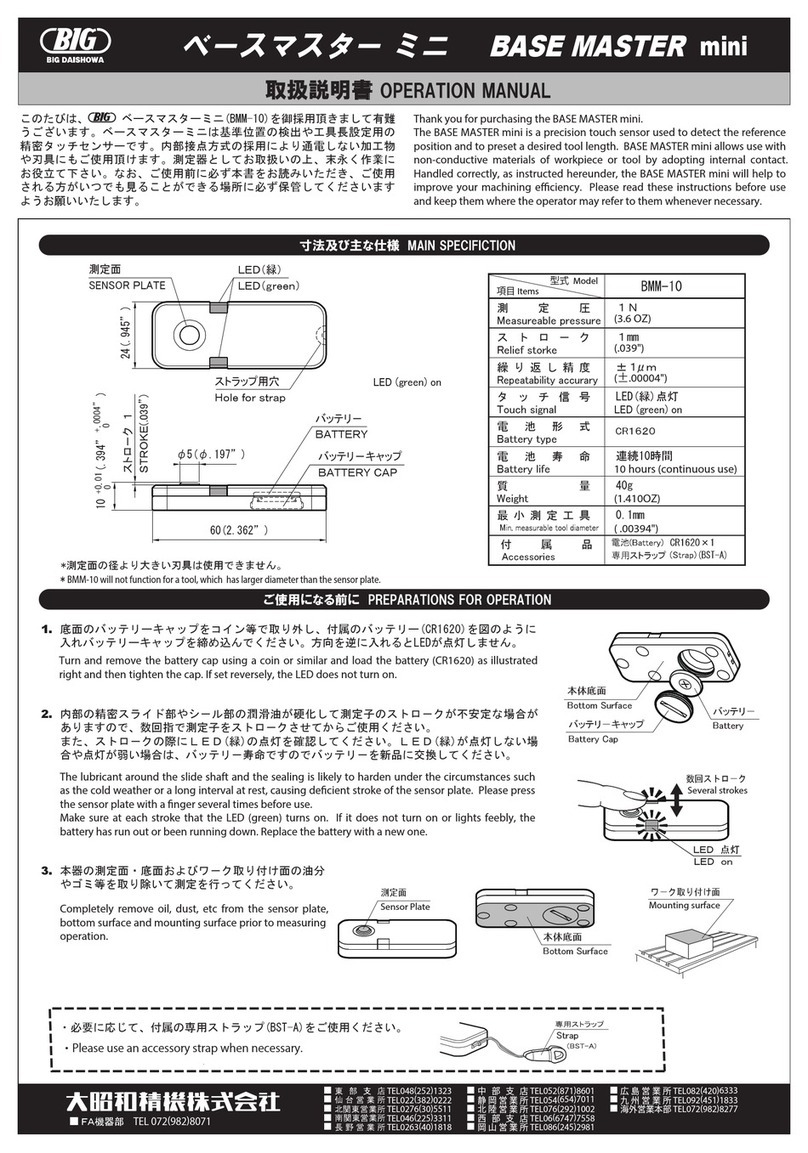

INSERT AND PARTS

FULLCUT MILL has exclusive shape of insert for each cutter diameter.In case an unsuitable insert is used, improper performance will occur.

To prevent confusion, each insert should be returned to its original case.

MAX(r.p.m)

FCR 16,17

FCR .625

FCR 20,21

FCR .750

FCR 25,26

FCR1.000

FCR 32,33

FCR1.250

34,000

34,000

28,000

23,000

Model

FCR16,17 (FCR .625)

FCR20,21 (FCR .750)

FCR25,26 (FCR1.000)

FCR32,33 (FCR1.250)

BRG1608

BRG2008

BRG2508

BRG3210

Model Insert Wrench

Insert Clamping Screw Set

S3508DS

S2506DS DA-T 8

DA-T15

1 (0.7)

3 (2.2)

CAUTION

Use only with machine tool that have sufficient rigidity and horsepower.

Do not use insoluble oil due to the danger of causing fire.

FULLCUT MILL FCR Type

Tightening

torque

N・m(lbf・Ft)

Please read these instructions before use and keep them

where the operator may refer to them whenever necessary.