RE 95178-01-B/2022-06-22, BoschRexrothAG

Contents | BODAS inertial sensor MM7.10 3/24

Contents

1 About this documentation ........................................................................ 4

1.1 Validity of the documentation ...................................................................... 4

1.2 Required and supplementary documentation............................................... 4

1.3 Representation of information ..................................................................... 4

1.3.1 Safety instructions ....................................................................................... 5

1.3.2 Symbols ....................................................................................................... 5

1.3.3 Designations ................................................................................................ 6

1.3.4 Abbreviations ............................................................................................... 6

2 Safety instructions ................................................................................... 7

2.1 About this chapter........................................................................................ 7

2.2 Intended use ................................................................................................ 7

2.3 Improper use................................................................................................ 7

2.4 Personnel qualifications ............................................................................... 8

2.5 General safety instructions .......................................................................... 8

2.6 Product-specific safety instructions ........................................................... 10

2.7 Personal protective equipment................................................................... 10

3 General instructions on property damage and product damage.............. 11

4 Scope of delivery.................................................................................... 12

5 About this product ................................................................................. 13

5.1 Product description ................................................................................... 13

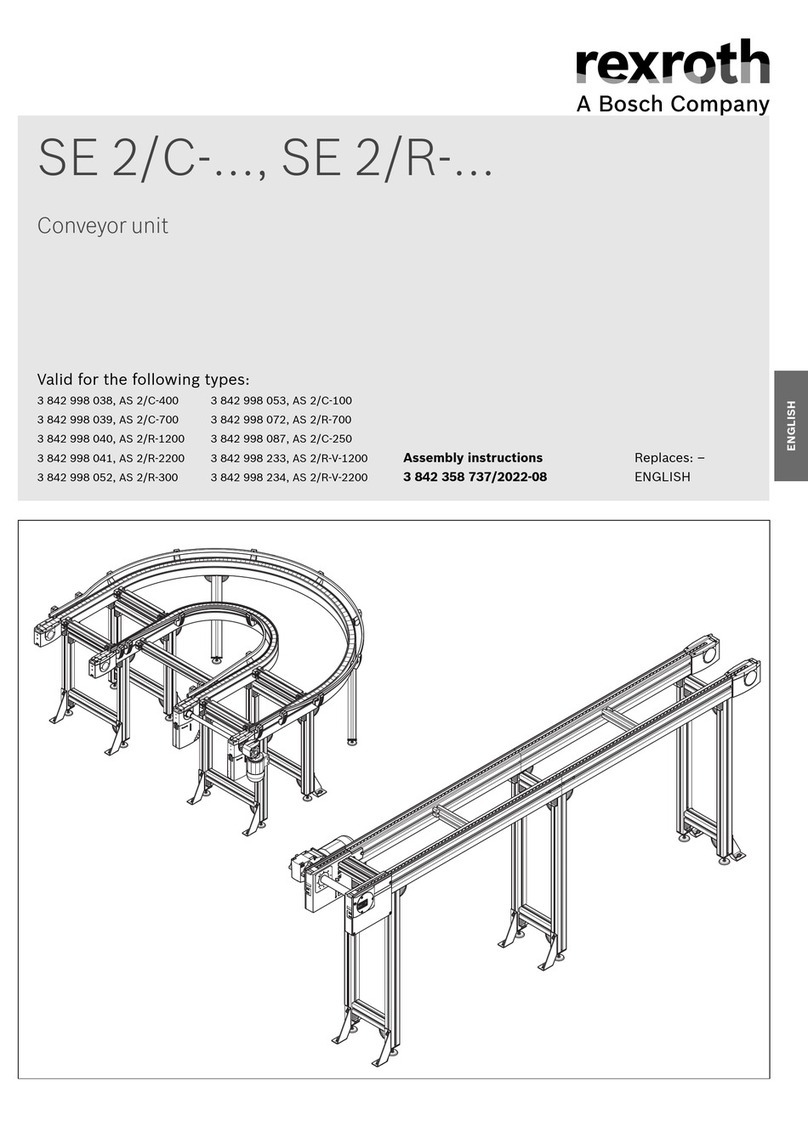

5.1.1 Block diagram ............................................................................................ 13

5.2 Product identification................................................................................. 14

6 Transport and storage ............................................................................ 15

6.1 Storing the inertial sensor.......................................................................... 15

7 Installation............................................................................................. 16

7.1 Unpacking .................................................................................................. 16

7.2 Installation conditions................................................................................ 16

7.3 Mounting the inertial sensor ...................................................................... 16

7.3.1 Preparation ................................................................................................ 16

7.3.2 Installation ................................................................................................. 17

7.3.3 Information on wiring and circuitry ............................................................ 18

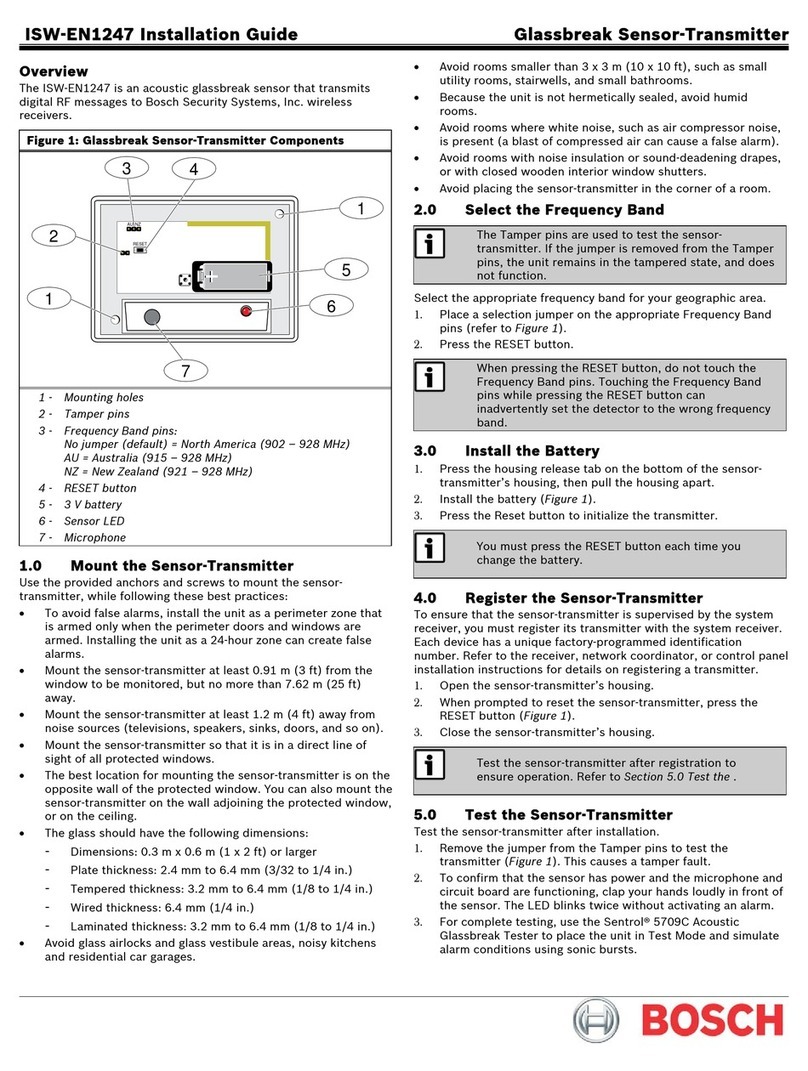

7.3.4 Connecting the inertial sensor ................................................................... 18

8 Commissioning....................................................................................... 19

9 Operation ............................................................................................... 19

10 Maintenance and repair.......................................................................... 19

10.1 Cleaning and care ...................................................................................... 19

10.2 Inspection and maintenance ...................................................................... 20

10.3 Repair ........................................................................................................ 20

11 Removal and replacement ...................................................................... 20

12 Disposal ................................................................................................. 20

13 Extension and conversion....................................................................... 20

14 Troubleshooting ..................................................................................... 21

14.1 Malfunction table for MM7.10.................................................................... 21

15 Technical data ........................................................................................ 22

16 Alphabetical index ................................................................................. 23