II Contents IPC 40.2

DOK-SUPPL*-IPC*40.2***-PR02-EN-P

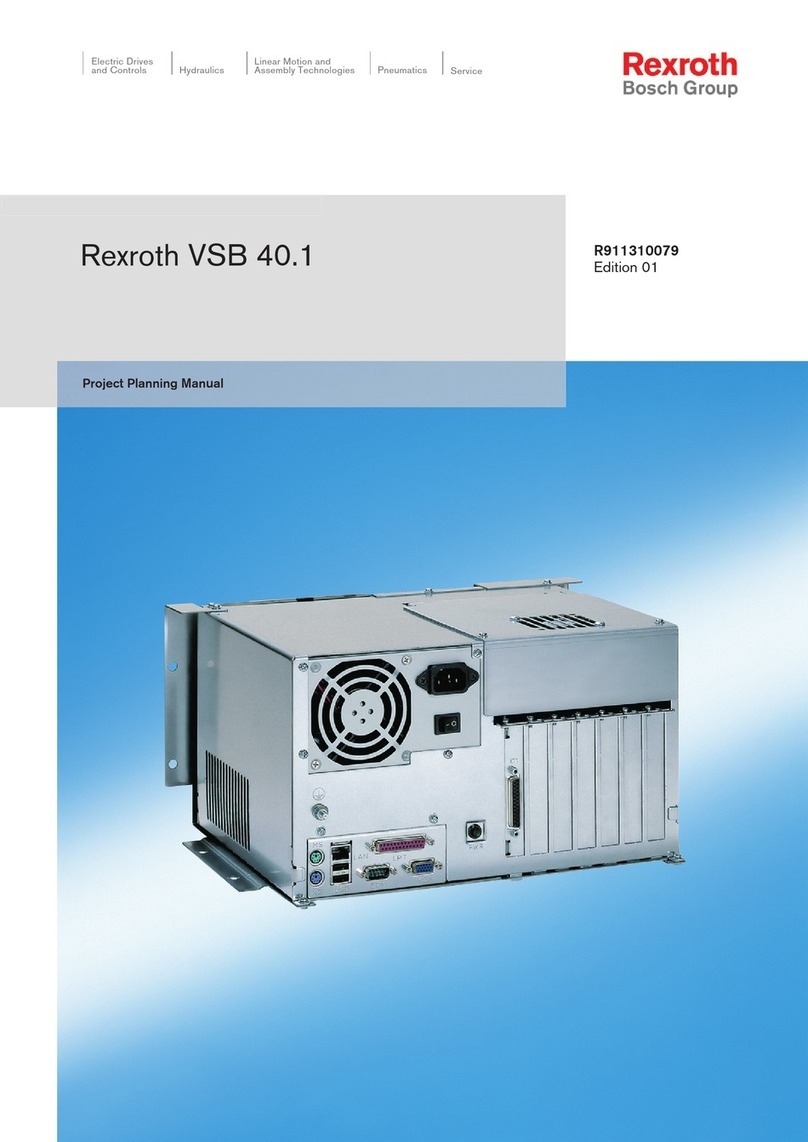

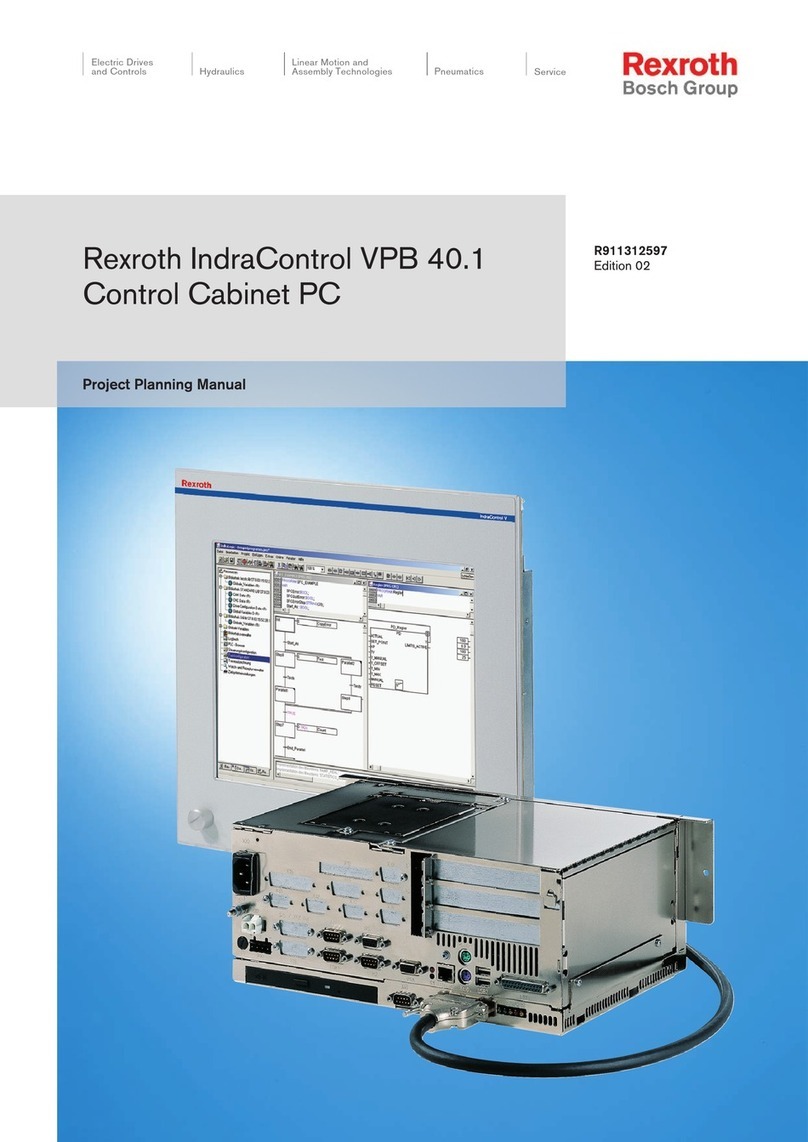

5 Dimensions 5-1

5.1 Housing Dimensions..................................................................................................................... 5-1

5.2 Mounting ....................................................................................................................................... 5-2

6 Display and Operating Components 6-1

6.1 Monitor and Keyboard .................................................................................................................. 6-1

6.2 Operating and Error Indication...................................................................................................... 6-2

7 Connections 7-1

7.1 View on the Connector Panel ....................................................................................................... 7-1

7.2 Interfaces ...................................................................................................................................... 7-1

Overview.................................................................................................................................. 7-2

Serial Interfaces XCOM1 to XCOM3....................................................................................... 7-3

Settings of the Serial Interfaces...............................................................................................7-3

Parallel Interface XLPT1.......................................................................................................... 7-4

USB Interfaces ........................................................................................................................ 7-5

Ethernet Interface XEthernet................................................................................................... 7-6

VGA Interface XVGA ............................................................................................................... 7-6

Combined Keyboard/Mouse Interface..................................................................................... 7-8

Mouse Interface....................................................................................................................... 7-8

PC Power Supply..................................................................................................................... 7-9

Battery Connection ................................................................................................................ 7-13

Optional Interfaces ................................................................................................................ 7-14

8 Maintenance and Installation 8-1

8.1 General Information...................................................................................................................... 8-1

8.2 CMOS Battery............................................................................................................................... 8-1

8.3 Hard Disk ...................................................................................................................................... 8-2

8.4 Rechargeable Battery Pack.......................................................................................................... 8-4

8.5 Extension Cards ........................................................................................................................... 8-6

Installing an Extension Card....................................................................................................8-6

BIOS Settings .......................................................................................................................... 8-9

9Software 9-1

9.1 Application Software of the Monitoring Function .......................................................................... 9-1

Temperature Monitoring ..........................................................................................................9-1

Uninterruptible Power Supply (UPS) ....................................................................................... 9-1

Program UPSNT ....................................................................................................................... 9-2

9.2 Touch Screen Software .............................................................................................................. 9-11