B+B SmartWorx MESR424D User manual

D oc ume nt ati on N umb er : 71 0 -11135 - 0 0 _r 2 _ M ESR 424x _ 2118q sg

1 (888) 948-2248 | Europe: +353 91 792444

707 Dayton Road | PO Box 1040 | Ottawa, IL 61350

Phone: (815) 433-5100 | Fax: (815) 433-5109

www.advantech-bb.com | E-mail: support@advantech-bb.com

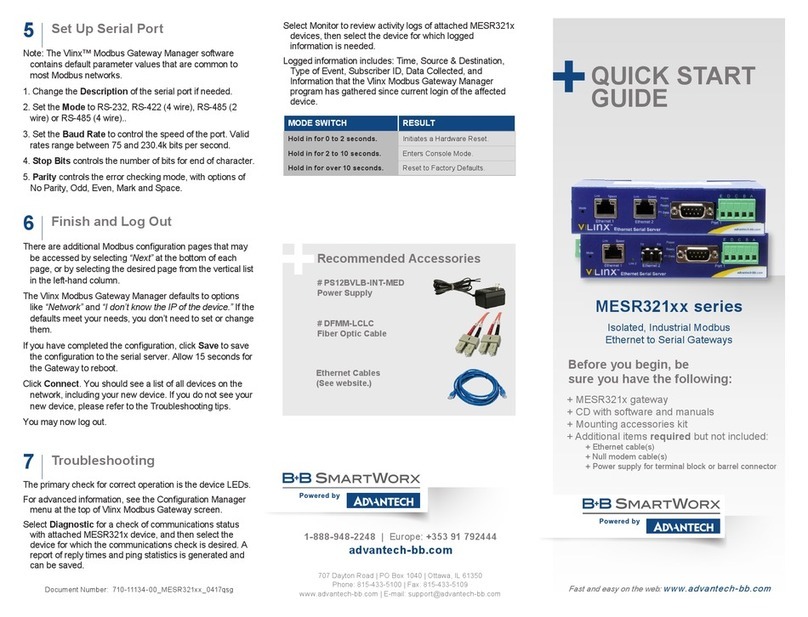

Before you begin, be

sure you have the following:

Model MESR424D or MESR424T

Industrial Modbus

Ethernet to Serial Gateway

Fast and easy on the web:

www.advantech-bb.com

QUICK START

GUIDE

Recommended Accessories

# PS12BVLB-INT-MED

Power Supply

+ MESR424x unit

+ CD with Software and Manual/s

+ Mounting Accessories Kit

+ Additional items required but not included:

- Ethernet cable(s)

- Null modem cable(s)

- Power supply for terminal block or barrel connector

# 232NM9

Null Modem Crossover

Cable for DTE to DTE

Connection

Set Modbus Priority

9

Use this screen if Modbus Priority is to be set.

Enter up to ve different priorities, based on Originating IP Address,

Modbus ID, Modbus Function Code, or a combination of these.

Modbus ID has a valid range from 1 to 247.

Function Code has a valid range from 1 to 99.

If you have completed the conguration, click Save to save the

conguration to the serial server. Allow 15 seconds for the

Gateway to reboot.

Click Connect. You should see a list of all devices on the network,

including your new device. If you do not see your new device,

please refer to the Troubleshooting tips. You may now log out.

Set Modbus Priority

10

Troubleshooting

11

The primary check for correct operation is the device LEDs.

For advanced information, see the Conguration Manager menu, at

the top of Vlinx Modbus Gateway screen.

Select Diagnostic for a check of communications status with

attached MESR424/s device, and then select the device for which

the communications check is desired. A report of reply times and

ping statistics is generated and can be saved.

Select Monitor to review activity logs of attached MESR424 device/s,

then select device for which logged information is needed.

Logged information includes Time, Source & Destination, Type of

Event, Subscriber ID, Data Collected, and Information the Vlinx

Modbus Gateway Manager program has gathered since current

login of the affected device.

MODE SWITCH RESULT

0 to 2 seconds Initiates a Hardware Reset

2 to 10 seconds Enters Console Mode

Over 10 seconds Reset to Factory Defaults

UL Class 1 / Division 2

12

MESR424D

MESR424T

SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS A, B, C AND D

HAZARDOUS LOCATIONS, OR NONHAZARDOUS LOCATIONS ONLY.

CONVENANT À L’EMPLOI DANS LES SITES DANGEREUX DE CLASSE

I, DIVISION 2, GROUPES A, B, C ET D, OU DANS LES SITES NON

HASARDEUX SEULEMENT

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF ANY COMPONENT

MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2.

ATTENTION - DANGER D’EXPLOSION - LA SUBSTITUTION DE

COMPOSANTS PEUT ENTRAÎNER UNE ADÉQUATION À LA CLASSE I,

DIVISION 2.

Maximum Surrounding Air Temperature: 80 °C

Température maximale de l’air ambiant: 80 °C

The unit is to be powered by a Class 2 power source, of a grounded-type, when

power is applied to the barrel connector.

L’unité doit être alimentée par une source d’alimentation de classe 2, de type mise à

la terre, lorsque le connecteur du canon est alimenté.

THE POWER CABLE MUST HAVE A MINIMUM RATING OF 80°C.

LE CÂBLE D’ALIMENTATION DOIT AVOIR UNE INDICATION MINIMALE DE 80

°C.

Power cannot be applied to both the terminal block and barrel connectors

simultaneously.

L’alimentation ne peut pas être appliquée simultanément aux connecteurs du bornier

et du barillet.

The use of coaxial cable for the eld wiring shall be in accordance with Class 2/Class

3 requirements in Article 725 of the NEC.

L’utilisation d’un câble coaxial pour le câblage sur site doit être conforme aux

exigences de classe 2 / classe 3 de l’article 725 du NEC.

One Conductor Per Terminal

Un conducteur par borne

Use Copper Wire Only

Utiliser uniquement du l de cuivre

Wire Size: 28 to 16 AWG

Taille de l: 28 à 16 AWG

Tightening Torque: 5 KG-CM

Couple de serrage: 5 KG-CM

Wire Temperature Rating: 105 °C Minimum (Sized for 60 °C Ampacity)

Indice de température du l: 105 °C Minimum (calibré pour 60 °C)

80 °C Maximum Surrounding Ambient Air Temperature

80 °C Température ambiante ambiante maximale

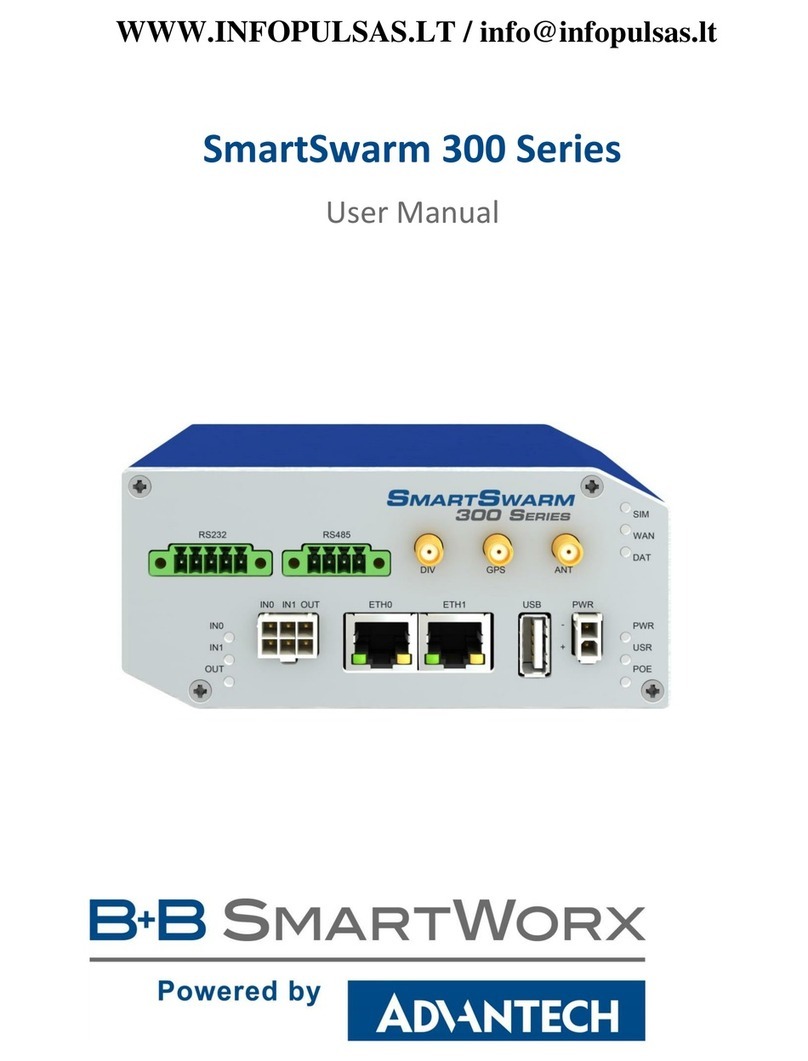

Product Overview Set Up Hardware

1

Power

10 - 48 VDC

Fiber/Ethernet

Ports

Male DB9 Ports or

Terminal Block Ports

LEDs

LEDs

DB9M Pin RS-232 Direction

(RS-232)

RS-422/485

4-Wire

RS-485

2-Wire

1DCD Input RDA(-) -

2RD Input RDB(+) -

3TD Output TDB(+) Data B(+)

4DTR Output TDA(-) Data A(-)

5GND - GND GND

6DSR Input - -

7RTS Output - -

8CTS Input - -

9----

Ready P1

P2

PWR

Speed Link

Ethernet

LEDs

Power Off Power is not connected.

On Power is connected.

Ready On System is in Console Mode.

Blink System is in Normal Mode.

P (1-4) Blink Data present on serial port.

RJ45 Ethernet Port LEDs

Speed Off 10BaseT connection.

On 100BaseT connection.

Link On Ethernet connected.

Blink Data present on Ethernet port.

1. Power the device.

2. Connect the top RJ45 to a network drop using a standard

network cable. (RJ45 ports on the model shown are

interchangeable. One may be used for pass-through Ethernet.)

3. Connect the Serial Device(s). RS-232 with DB9: straight-through

for DCE device. Null modem for DTE device. RS-422/485 with

terminal blocks.

1. Use included CD to install Vlinx™Modbus Gateway Manager. If

Autorun does not start, go to “My Computer” and select the CD

drive. You will see a Vlinx MESR icon. Double-click it to launch

the installation.

2. To open Vlinx Modbus Gateway Manager, click:

Start\Programs\B&B Electronics\Vlinx\Vlinx Modbus Gateway Manager

Note: If the device does not connect, cycle (unplug-replug) power, then try again.

3. To congure via the network, select Network.

4. If you know the IP address, select “The device is at this

address,” and type in the IP address. If not, select “I don’t know

the IP address of the device.” Click Connect.

Alternate Method: Open a web browser and type the IP address of the Gateway

in the Address Bar. When the Gateway is found, the Login window will appear.

5. Click Login. Password is blank from factory. No password is

necessary to operate the MESR unit. The Conguration/General

page appears.

Installation & Setup

2

“I want DHCP” is preselected to set up the network using dynamic

IP addressing. The gateway is set up at the factory to receive an

IP assignment from a DHCP Server.

1. If a DHCP Server is not available on your network, it will default

to 169.254.102.39.

2. If a DHCP server is not available and the default address does

not work on your PC, change your PC network settings to IP

Address: 169.254.102.1, Subnet Mask: 255.255.0.0, Default

Gateway: 169.254.1.1.

If you are not able to use these settings, refer to the user manual

for directions to change the Gateway’s TCP/IP settings.

Set Up Network

3

Note: Vlinx Modbus Gateway Manager software contains default parameter

values that are common to most Modbus networks.

TCP Settings:

“Connect to port” identies TCP port used in TCP client mode. Valid

range is 1 to 65535. Default is 502. Response timeout is the

maximum response time. Valid range is from 1 to 65535. Default

is 100ms.

Setting Up TCP Option

4

Note: Vlinx Modbus Gateway Manager software contains default parameter

values that are common to most Modbus networks.

1. Change the Description of the serial port, if needed.

2. Set the Mode to: RS-232, RS-422 (4-wire), RS-485 (2-wire) or

RS-485 (4-wire).

3. Set the Baud Rate to control the speed of the port. Valid rates

range between 75 and 230.4k bits per second.

4. Set the Data Bits to control the number of bits in each character.

Only 8 bits is valid when the protocol of the device connected to

the port is RTU.

5. Top Bits controls the number of bits for end of character.

6. Parity controls the error checking mode, with options of No

Parity, Odd, Even, Mark and Space.

Set Up Serial Port

5

Select the Attached as Master or Slave.

1. Select the Modbus protocol to be used, either RTU or ASCII.

2. As needed, check option boxes for “Enable Modbus broadcast,

“Enable 0Bh Exception” and “Enable serial message buffering.”

3. Select from 0 to 5 Modbus Serial Retries.

4. Enter Milliseconds Modbus Message Timeout, from 1 to 65535.

5. Enter Milliseconds TX Delay, from 1 to 65535.

6. Set up additional Modbus ports the same way.

Set Up Modbus Port

6

TCP Server Settings:

Listen on Port identies TCP port in TCP server mode. Valid

range is from 1 to 65535. Default is 502.

Limit the Number of Connections controls the number of

simultaneous TCP clients that can be connected.

Set Up Port ID Remap

7

Use this screen if Modbus Slave IDs are to be remapped. On each

line, select a range of Modbus IDs to remap.

1st box - enter the rst Modbus ID of the range to remap FROM.

Valid port IDs range from 1 to 247.

2nd box - enter the last ID of the range to remap.

3rd box - enter starting ID of the range to remap TO.

4th box - auto lls based on ranges entered in rst three columns.

Set up additional ID ranges the same way.

Use this screen if Modbus Slave IDs are to be rerouted.

On each line, select the range of IDs to re-route.

1st box - enter the starting ID. Valid IDs range from 1 to 247.

2nd box – enter the last ID of the range to re-route.

3rd box - enter the IP Address or Port that has slave devices

attached.

4th box - shows the IP address of the slave device, if an IP

address is chosen in the third box.

Set Modbus ID Routing

8

Connection Filter Mode options like “allow everyone,” “allow

specic IP address” and “allow a range of IP addresses” control

which TCP clients can connect.

This manual suits for next models

1

Table of contents

Other B+B SmartWorx Gateway manuals

Popular Gateway manuals by other brands

Adeunis RF

Adeunis RF AMR Gateway user guide

hilscher

hilscher NIOT-E-TIJCX-GB-RE user manual

Hypercom

Hypercom IN-tact 1202 installation guide

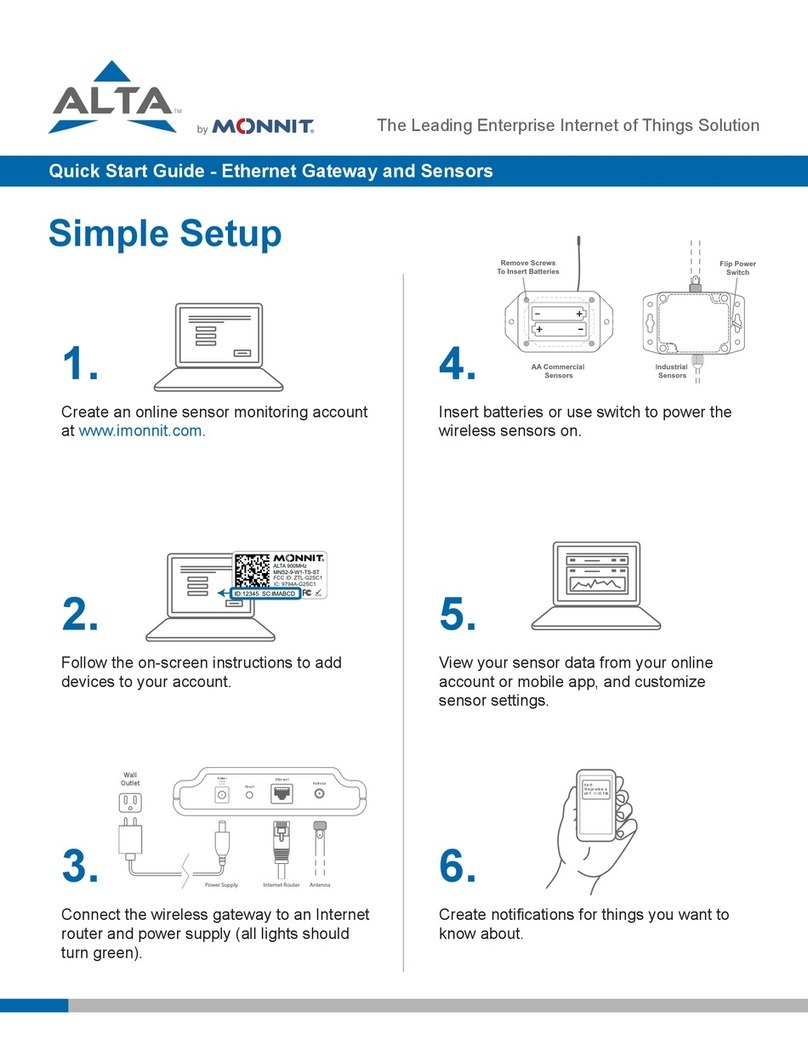

Monnit

Monnit Ethernet Gateway Series quick start guide

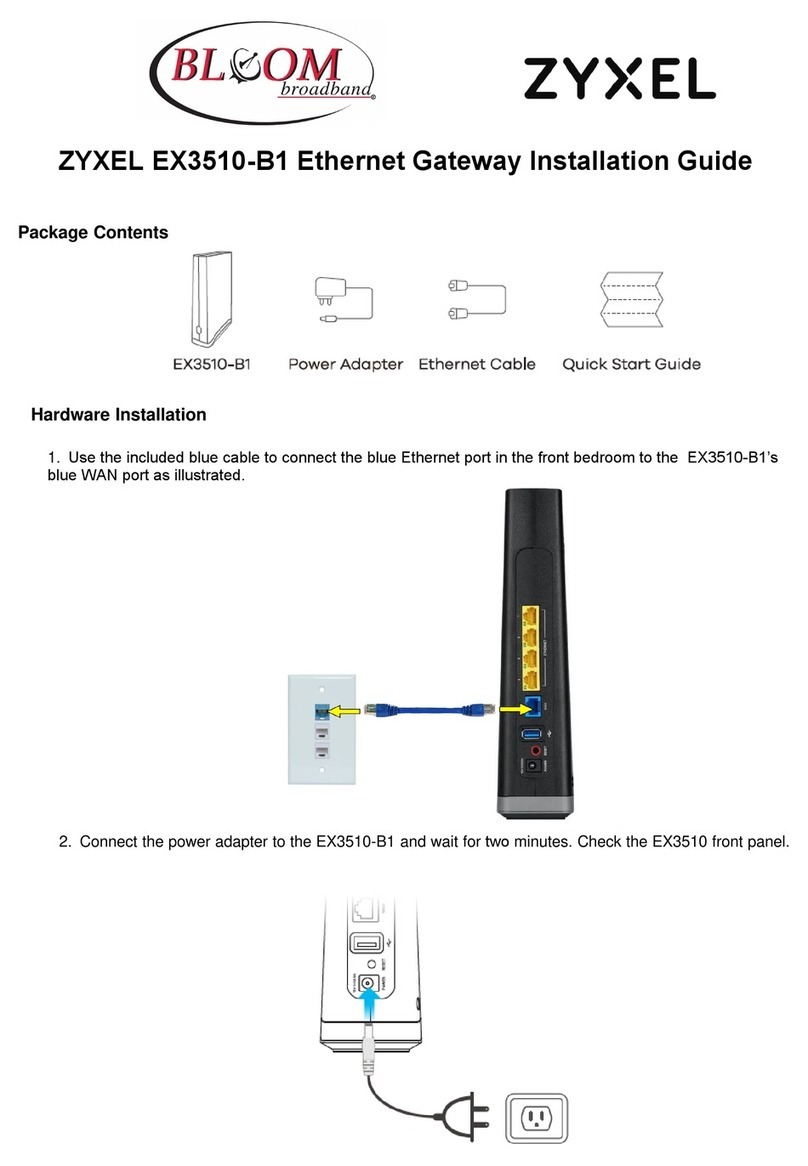

ZyXEL Communications

ZyXEL Communications EX3510-B1 installation guide

Define Instruments

Define Instruments Nimbus IoT manual