Levelling Guide

4

Introduction

This guide aims to help customers who have assembled a BQ Hephestos 2 get the maximum out

of their 3D printer and troubleshoot any issues with the auto - levelling feature.

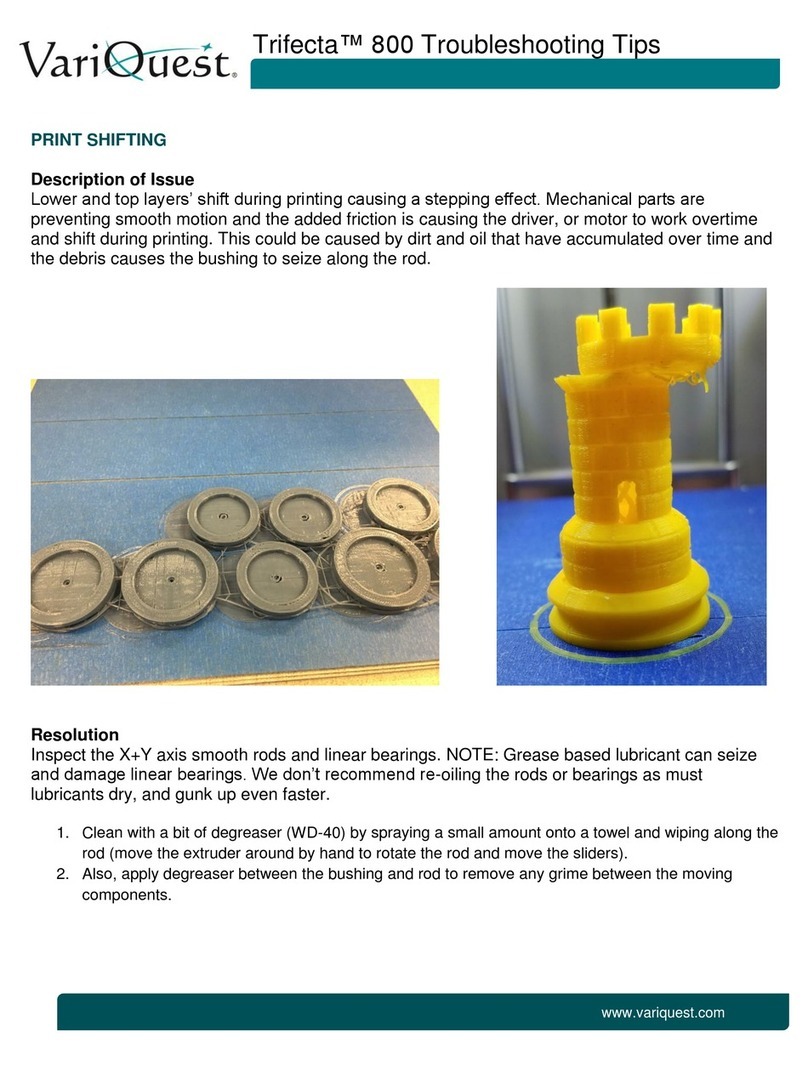

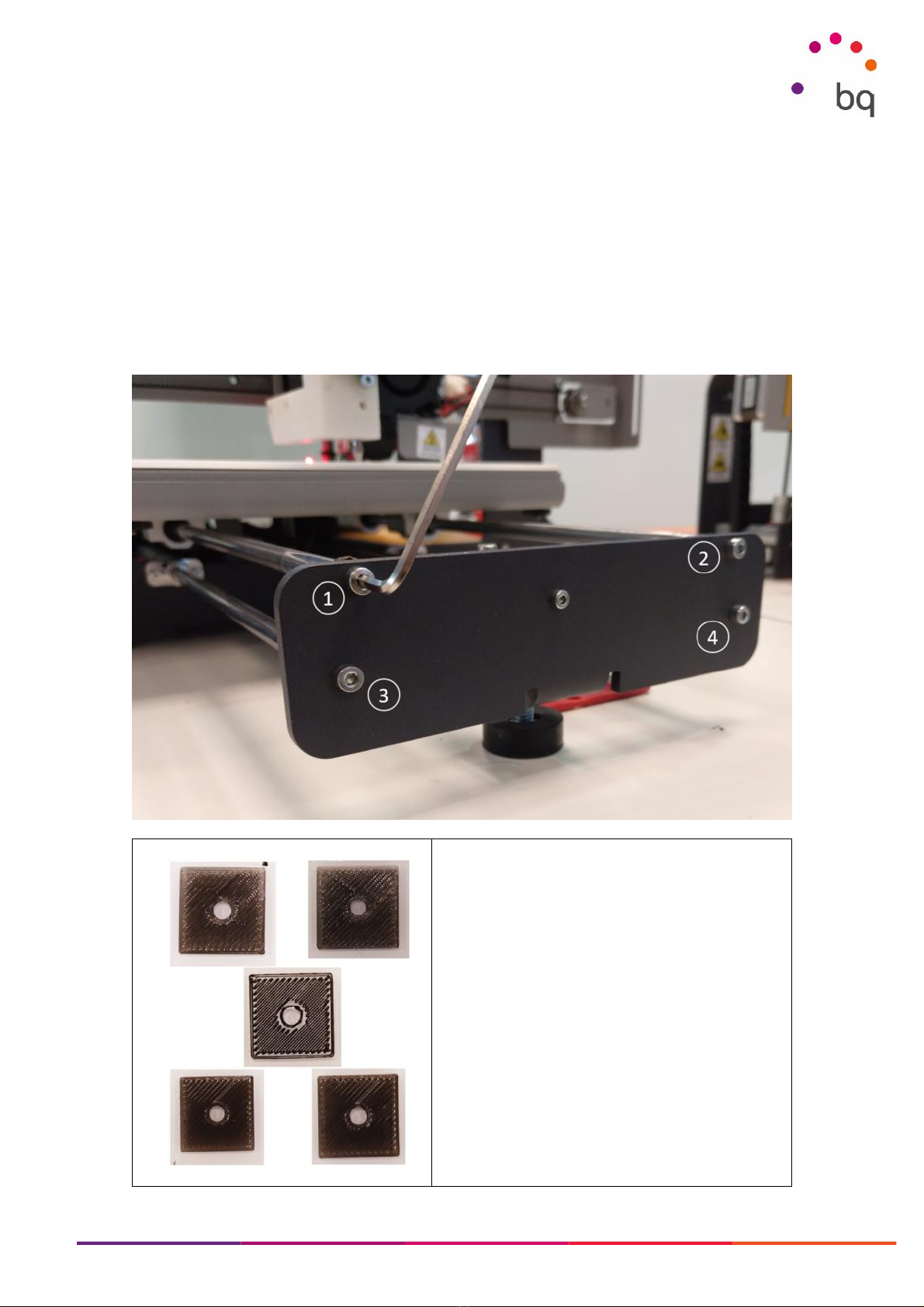

There are some assembly mistakes that can cause the mechanical structure to be deformed,

especially in the Y axis. This means the print bed will not move in a perfect plane over its full area,

causing the levelling algorithm to fail in some places. This can happen even if the print bed and

inductive sensor are in good working order.

There are many factors to consider since each customer assembles the printer in slightly different

ways. The tips and tricks contained in this document are the result of extensive testing and have

proved to fix one or more levelling issues. However, they might not all be appropriate for a particular

printer. Please take this guide as a reference for ideas to try, not as a must-do checklist!

Updating firmware

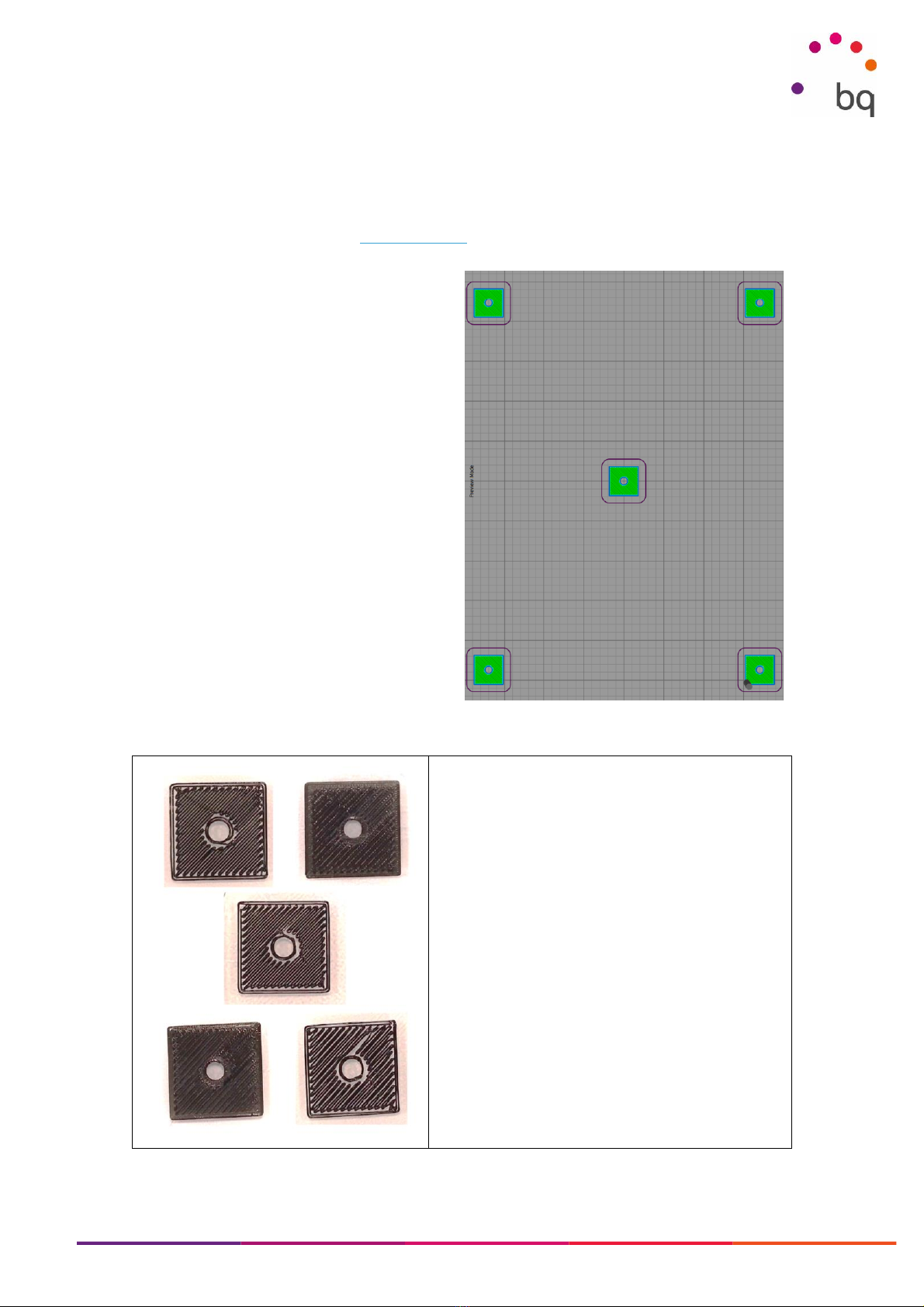

The first and possibly most effective action is to update the firmware on your Hephestos 2. The

latest version fixes some bugs regarding the heated bed and introduces 9-point mesh levelling.

This adds a few more seconds to the levelling routine at the beginning of each print, but allows the

FW to adjust the Z-height much more accurately, since it does not assume that the print surface is

a plane.

Simply updating the FW can fix many levelling issues. To do so, download the BQ firmware updater

or the latest version of the firmware from this link: https://www.bq.com/es/support/hephestos-

2/support-sheet?ssess=5afe90e1e9ef7&sorigin=productList

First layer settings

The success of the first layer depends greatly on the parameters used. The following table lists the

minimum recommended parameters for the first layer: