4

S19-320A, S19-320D Installation

10/26/2012 Bradley • 215-748 Rev. K; ECN 12-05-016F

Installation

Supplies Required:

• Teflontapeorpipesealant

• Black,whiteandgreenAWG18minimumwiretoconnectalarmto

electric power supply

• 1/2"conduitand1/2"x3/4"adapter bushing for electric power supply

wiring

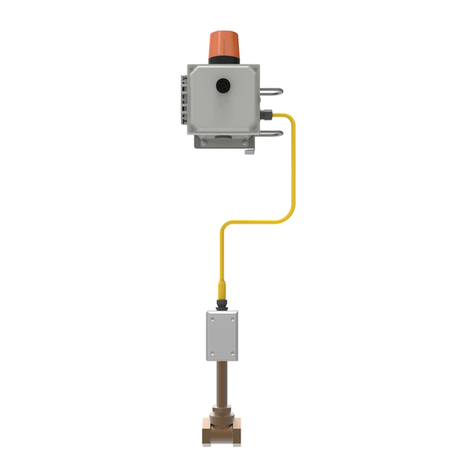

Step 1: Install the flow switch in the water supply

line

NOTE: The flow switch will attach to the mounted alarm via a 6-foot or

12-foot waterproof cable. Keep the location for mounting the alarm in

mind when choosing the flow switch location.

1. Choose a location for mounting the flow switch in a horizontal run of

the water supply line. The inlet and outlet ports of the flow switch must

be a minimum of 6 inches from any tees or elbows in the water supply

line.

2. Mount the flow switch assembly in the water supply line.

• Theswitchbodymustbeintheverticalpositionwiththewaterpipe

horizontal.

• Thewaterflowmustbeinthedirectionmarkedbythearrowonthe

flow switch body.

• Useteflontapeorpipesealant(suppliedbyinstaller)onallwater

pipe connections.

Step 2: Mount alarm assembly to unit

NOTE: Point the alarm speaker in the direction from which help is most

likely to come.

1. Choose a location for mounting the alarm assembly. The alarm should

be mounted at least 7 feet above ground level for best visibility.

• Thealarmmaybemounteddirectlytothedrenchshowerpiping

using the supplied U-bolts and nuts.

• Thealarmcanalsobeboltedtoaflatsurfacesuchasawall

(hardware for this type of installation is NOT supplied).

Step 3: Connect alarm to flow switch

1. Connect the flow switch to the alarm by plugging the prewired cable

into the socket provided in the flow switch junction box. The plug and

socket have an alignment pin and groove which makes for error-free

hook-up.

NOTE: To prevent water condensation from dripping onto the flow switch,

make sure the cable is not taut.

2. Tighten the locking collar on the female cable socket by rotating it

clockwise after plugging in. This makes a good watertight connection.

Step 4: Complete electrical supply connections

1. Loosen,butdonotremove,thetwo5/64"hex screws located on the

sides of the alarm horn casing.

2. Runelectricpowerconduit(and3/4"x1/2"adapter, if necessary) and

AWG 18 minimum power wire into the hole in the bottom of the alarm

horn casing.

NOTE: Compliance and conformity to local codes and ordinances is the

responsibility of the installer.

3. There are three wires inside the alarm horn casing for power supply

connections—two for power and one for ground. Using two wire nuts,

connec black to black and white to white. Ground as required.

4. Replace the front grille onto the alarm horn casing being sure the

prong plugs (that are part of the front grille) line up with the socket

slotsinsidethecasing.Tightenthetwo5/64"hex screws. Test the

alarm system.

16" (406mm)

min.

overhead

clearance

To1/2"

Water

Supply

Flow Switch

Piping supplied

by installer

Applications

S19-240

S19-240FW

Alarm

To

Water

Supply

Flow

Switch

To

Electric

Power