10

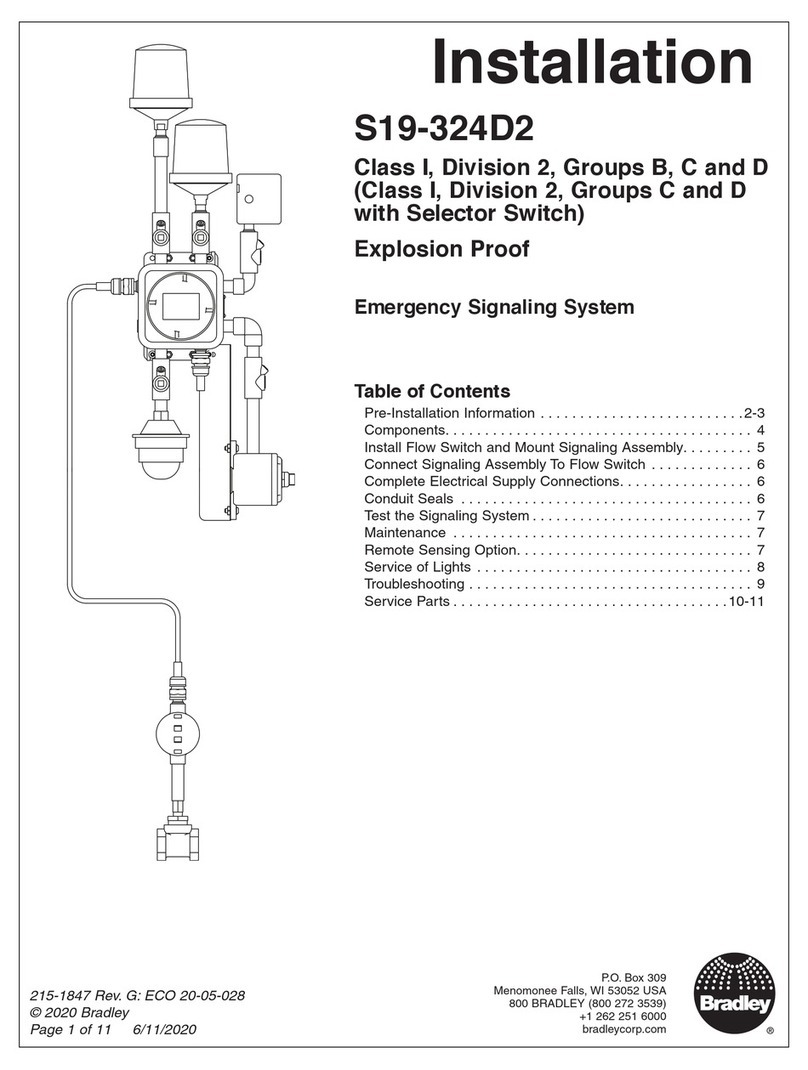

S19-324D1 Installation

6/11/2020 Bradley • 215-1848 Rev. G: ECO 20-05-028

Item Part No. Qty. Description

1 S90-568 1 Sub Assy, Signaling Station

2

269-1593A24

1

Signal Light, Exp. Div1, 24VDC, Amber

2

269-1593R24

1

Signal Light, Exp. Div1, 24VDC, Red

3 269-1306B 1 Horn, Exp. C1D1, 24VDC

20

269-1593C24

1Area Light, C1D1, White**

20

269-1593R24

1Area Light, C1D1, Red**

30

269-1593G24

1Beacon Light, C1D1, Green**

30

269-1593B24

1Beacon Light, C1D1, Blue**

31 269-1780 1 Conduit Coupling

32 269-1316 3 Condiut Nipple, 3/4 x 6

33

269-1596

1-4 Fitting, Seal*

34 269-1582 8 Conduit Nipple, 3/4 x 2

36 269-1294 4 Plug, Conduit, 3/4

37 269-1549 2 Elbow-Street 3/4"

38 269-1308 4 Conduit Connector

39 269-2142 1 Elbow, 90, 3/4, Conduit

41 261-144 1 Selector Switch, Class 1 Div 1 & 2

42 114-310 1 Nameplate

43 255-070 1 Enclosure, Class 1 Div 1 & 2

60 140-1159 1 Plate MN, Surface Mount

60 140-1157 1 Plate PM, Pipe Mount

60 S70-176 1 Mounting Plate, Heat Trace

Item Part No. Qty. Description

61 160-514 5 Screw, 3/8-16 x 1.0 BTNCA

62 161-157 5 Nut, 3/8-16 Hex Jam

63 140-1158 1 Bracket, Alarm, J-Box

64 269-594 2 U-Bolt, SST

65 161-065 4 Nut, 3/8-16 SST

76 269-1588 1 Conduit, Flexible, 3 ft.

77 S90-643 1 Conduit, Flexible, 6 ft.

77 S90-644 1 Conduit, Flexible, 12 ft.

77 S90-645 1 Conduit, Flexible, 50 ft.

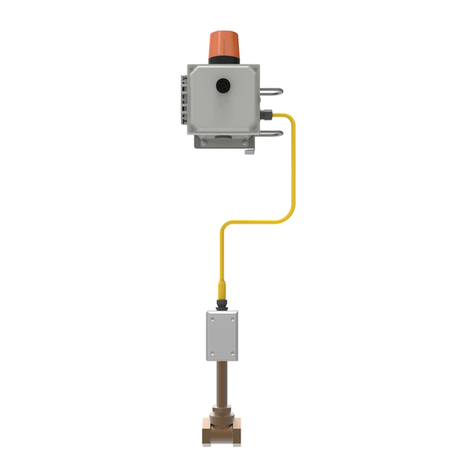

80 269-1421 1 Flowswitch, 1-1/4" T-DPDT, Brass

Tee and Body

80

269-1421SS

1Flowswitch, 1-1/4" T-DPDT, SS

Tee and Body, CSA Listed

80 269-1522 1 Flowswitch, 1/2", T-DPDT

80

269-1522SS

1Flowswitch, 1/2" T-DPDT, SS Tee

and Body, CSA Listed

81 269-1312 1 NEMA 4X Box, Conduit Outlet

81 255-078 1 NEMA 4X Stainless Steel,

Conduit Outlet

84

269-518

3Reducing Bushing

97

269-1935

1Sealing Compound-A 3-3

Item 97 ships lose.

*Requires sealing compound if replaced. One sealing compound will fill two seal fittings.

**Re-program per manufacturer's instructions to be steady state light if ordered for

service.

S19-324D1 Service Parts