3

Installation S19-690H, S19-690HR

Bradley Corporation • 215-084 Rev. P; ECN 07-527 8/25/08

Installation

Step 1: Assemble Eyewash

1. Assemble the eyewash to the tank outlet with

pipe sealant (by installer) (see page 5).

IMPORTANT: When connecting the

eyewash to the tank outlet, hold the

adapters (items 2 and 3) with a wrench

to prevent stripping. Failure to do

so may damage the seal and cause

leakage. Max. torque 150 in-lbs.

2. Connect the pressure gauge to the adapter

on the pressure side of the tank with pipe

sealant (by installer) (see page 5).

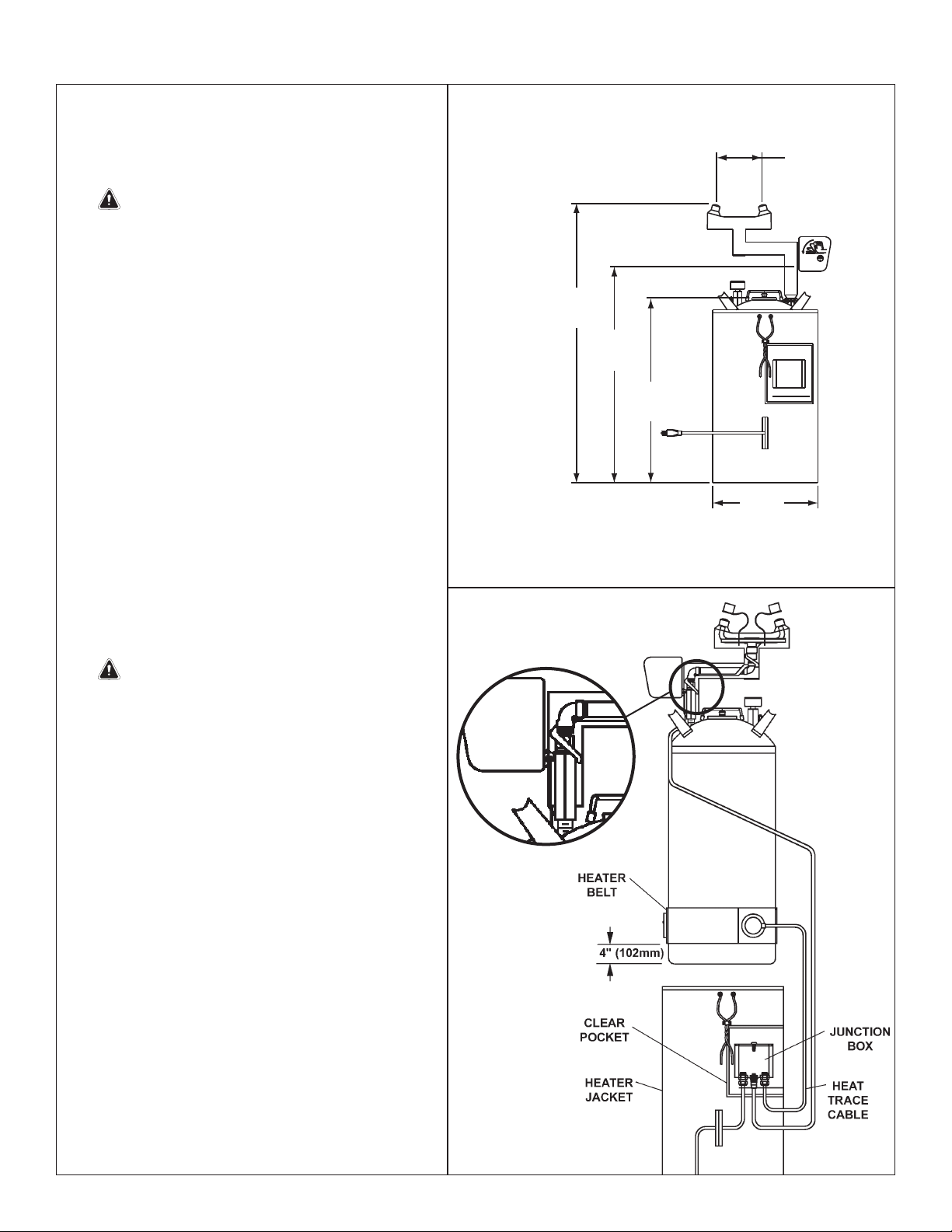

Step 2: Assemble Heater Jacket

1. Secure the pipe insulation and jacket to the

eyewash.

2. Wrap the belt around the tank four inches

from the bottom of the tank; fasten securely.

3. Connect the heat trace cable to the junction

box.

4. Slide the jacket up the side of the tank and

pull the drawstring at the top of the jacket.

5. Place the junction box in the pocket on the

inside of the jacket.

Step 3: Fill tank and pressurize

1. If the tank is pressurized, relieve the tank

pressure by pulling up on the relief tank tab

in the center of the cover until the pressure

gauge reads “0.”

IMPORTANT: DO NOT open the cover

until the pressure gauge reads “0.”

2. Open the tank by pulling up on the wire

handle located on top of the Quicklock

cover. Push down, rotate and remove. Fill

the container with 7 gallons of potable water.

Replace the cover.

3. Pressurize the tank to 95 PSI by applying air

pressure to the tank valve located beneath

the pressure gauge.

NOTE: Relief valve is designed to automatically

vent at 100-130 PSI to prevent the tank from

overpressurizing.

Step 4: Flush tank

1. Discharge the water through the eye wash

and hose spray to flush the system.

2. Refill the tank and pressurize as explained in

Step 3 outlined above.

NOTE: Let unit stand for one hour. If there is a

noticeable pressure drop, repressurize and let

stand for one hour. If problems persist, consult the

Troubleshooting guide found on page 4.

NOTE: This unit will provide at least 15 minutes

of cleansing action. Take the injured person

immediately to a normal emergency station for

additional cleansing and treatment.

3. Plug the heater jacket’s electrical cord into an

electrical outlet.

Back View

14"

(356mm)

24-5/8"

(625mm)

27-3/4"

(705mm)

35-7/8"

(911mm)

6"

(152mm)