IC-68ND INSTALLATION GUIDE

4

3. General installation guidelines

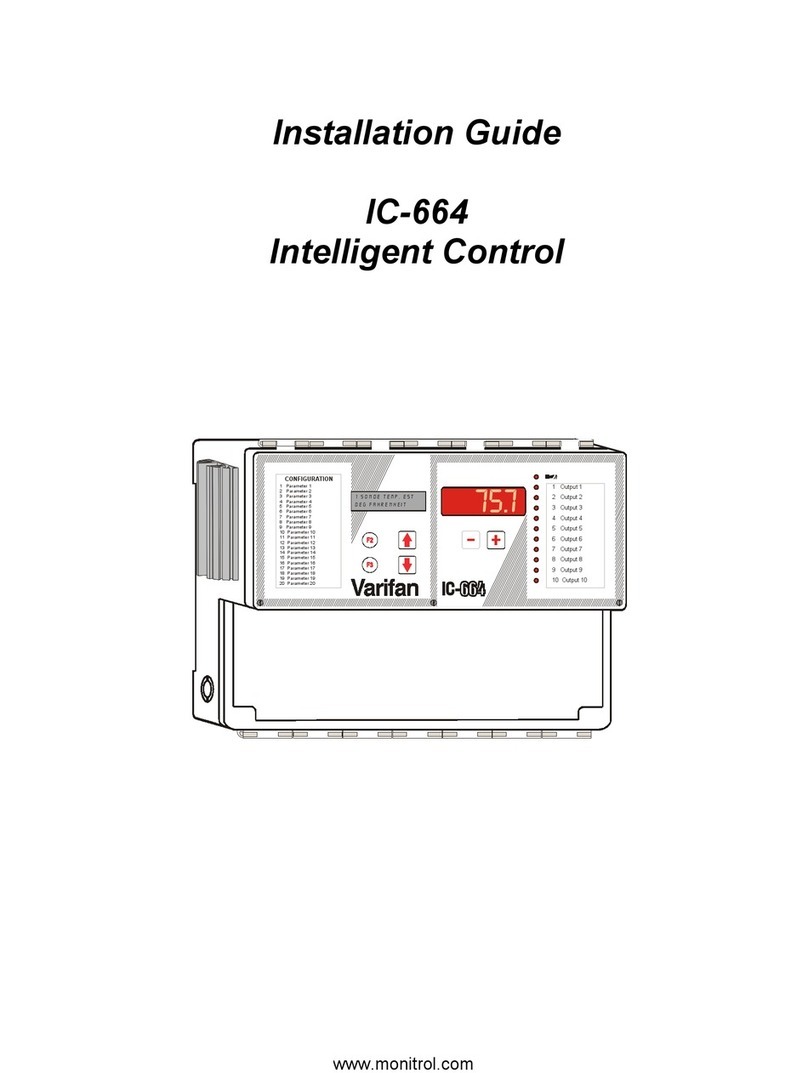

3.1 IC-68ND Control

• It is recommended to install the unit in a hallway to limit the IC-68ND’s exposure to noxious gases.

• In order to avoid condensation problems inside the controller, it is recommended to install the

IC-68ND on an inside wall. If it is not possible, use spacers to have an air gap between the

wall and the IC-68ND.

• It is required to install the IC-68ND side up with the cable entry holes facing down (see figure 1).

• The enclosure is watertight, but not splash proof or immersion proof. DO NOT WATER the

control. Cover it carefully with plastic when cleaning the room.

• The IC-68ND should be installed in easy access location but away from damaging elements

(heat, cold, water, direct sunlight, …).

• It is recommended to punch out knock outs by striking them at the bottom near the back of

the case (see figure 2).

• Do not drill the face, the side, the top or the underside of the control.

• Do not install the IC-68ND control near high voltage equipment, power supply or transformer.

3.2 Electrical Cables

• All electrical cables must be installed according to local wiring codes.

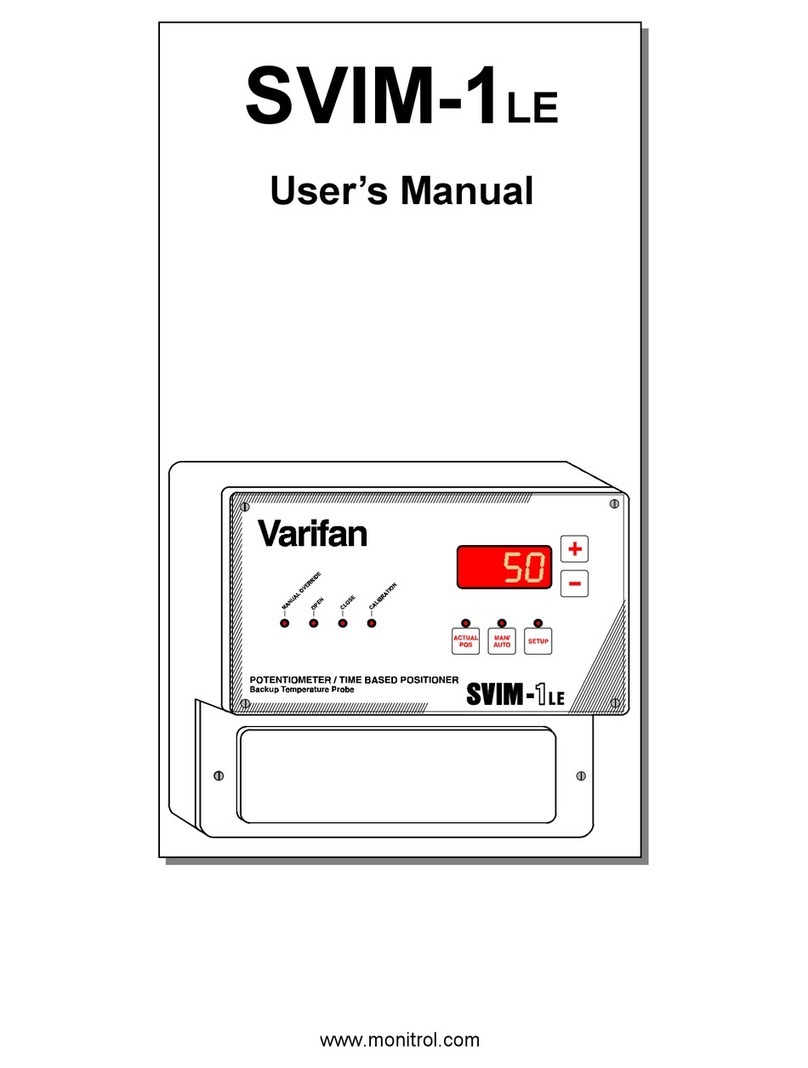

• All cable shields must be connected to the IC-68ND power ground only, except for the cable

connected to the optional PC interface (see SVPC-40 guide). The shield is needed to protect

the IC-68ND and the modules against any electromagnetic interference generated by

lightning or nearby operating machinery.

• Never use the shield as a conductor.

• Connect only one end of the shield to the ground of the IC-68ND.

• Use separate conduit for the low voltage cables (communication and probes) and the high

voltage cables. There must be at least 1 foot (30 cm) between low voltage and high voltage

conduits.

• If a low voltage cable have to cross over a high voltage cable, make this crossing at 90°.

• All cable connections must be soldered or done with approved sealed connectors.

• Probe cables must be 500 ‘ (150m) or less.

• Communication cables must be 750 ‘ (250m) or less.

• It is prohibited to use overhead cables outside the building.

3.3 Electrical Power

• Protection from electrical surge should be included in the planning of each installation.

• Every module should have a separate breaker to avoid serious consequences.

• Certain control modules (VSM-2, VSM-2/2, VPM-2, VPM-1 and CIP-1) require the same

phase and same voltage as the IC-68ND to operate.

• It is strongly recommended to have a backup power source to ensure life-sustaining

conditions in case of power failure (see figure 5).

• It is also strongly recommended to put a backup thermostat to sufficient fan and heating

system parallel to the IC-68ND module output (see figure 6).

• Backup system and alarm must be thoroughly tested and verified as working properly before

using the ventilation system.