7

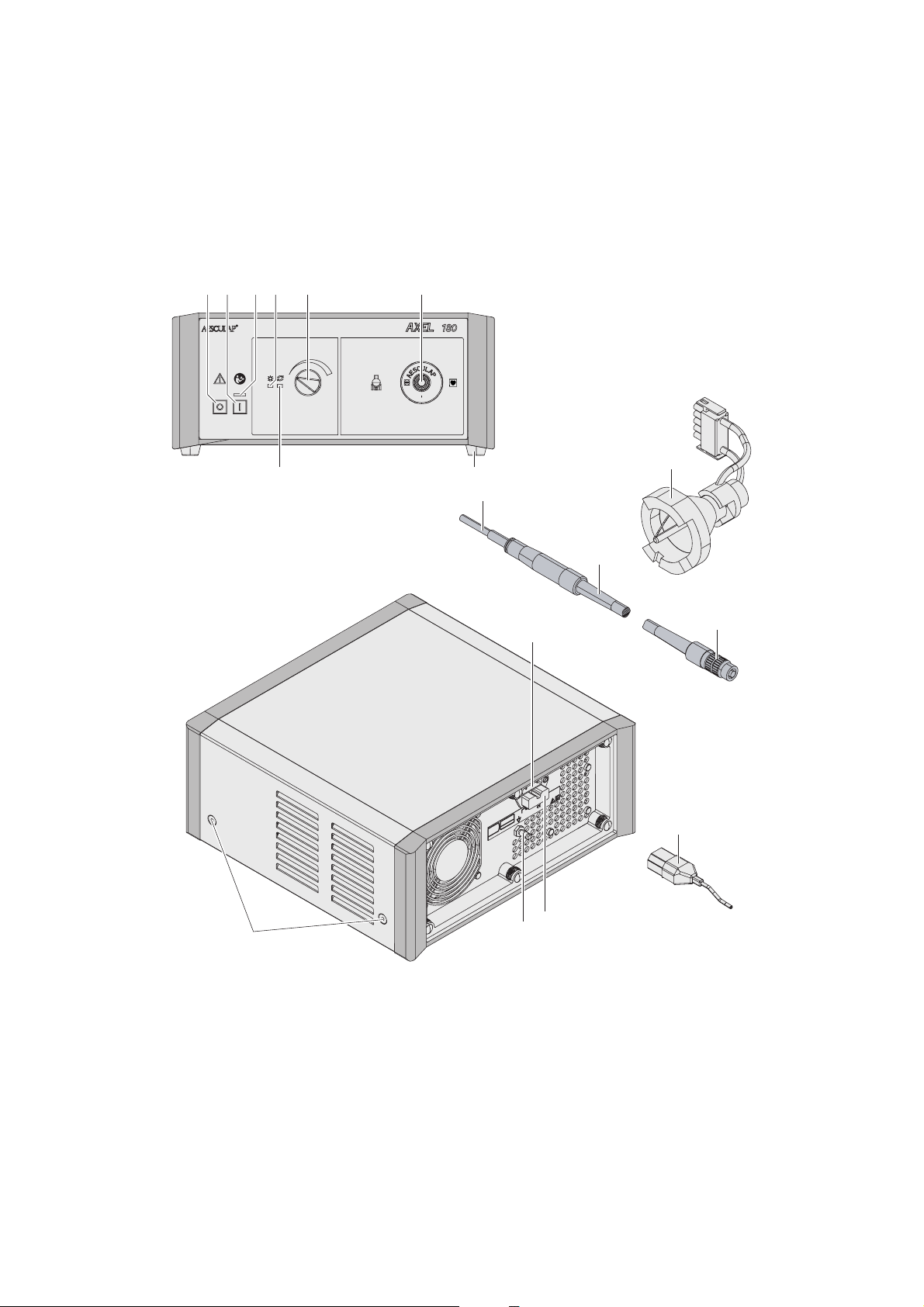

Connecting the power supply

Note

Before operating the device, make certain that the supply voltage marked

on the plug of the device matches that of the supply voltage being used.

►Plug the power 14 cord into the socket 14 at the back of the control

unit.

►Plug in the mains plug at a socket of the building mains.

►Turn on the control unit with the power ON switch 2.

The power ON indicator 3lamp shows that the device is activated.

►When operating multiple devices concomitantly, connect the devices

to the potential equalization terminal.

4.2 Function checks

►Prior to each use, perform a functionality test for the xenon light

source.

►Make certain that the self-test runs in accordance with legal regula-

tions.

If the device is functioning properly, the xenon lamp 9will be ignited after

the device is switched on. After the device is switched on, the power ON

indicator 3on the front of the device is activated. After the self-test has

been successfully performed, the lamp OK indicator 4also comes on.

When the change lamp indicator 8is illuminated:

– The xenon lamp is malfunctioning

– Maximum permissible operating time has been exceeded

►Replace the xenon lamp, see Replacing xenon lamp.

4.3 Safe operation

Automatic self-test

After being switched on, the device automatically carries out a self-test

lasting approximately 3 seconds. During this self-test, all display elements

on the front panel are illuminated. After performance of the test, either

the lamp OK indicator 4or the change lamp indicator 8are activated,

depending upon the length of period during which the lamp has been

operated. If a malfunction is detected during the self-test, the lamp OK

indicator 4and change lamp indicator 8are illuminated simultaneously.

If this happens, the device must be restarted.

Switching the device on and off

►Turn on the control unit with the power ON switch 2.

►Turn off the control unit with the power OFF switch 1.

Brightness control

The desired brightness can be continuously adjusted with the brightness

control 5.

Note

If the cold light source is switched on and off frequently, the xenon lamp

will wear out more quickly. During brief interruptions, instead of switching

the device off, lower the brightness with the brightness control.

5. Validated reprocessing procedure

5.1 General safety instructions

Note

Adhere to national statutory regulations, national and international stan-

dards and directives, and local, clinical hygiene instructions for sterile pro-

cessing.

Note

For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD or possi-

ble variants of CJD, observe the relevant national regulations concerning

the reprocessing of products.

Note

Mechanical reprocessing should be favored over manual cleaning as it

gives better and more reliable results.

Note

Successful processing of this medical device can only be ensured if the pro-

cessing method is first validated. The operator/sterile processing techni-

cian is responsible for this.

The recommended chemistry was used for validation.

Note

If there is no final sterilization, then a virucidal disinfectant must be used.

Note

For the latest information on reprocessing and material compatibility see

also the Aesculap extranet at www.extranet.bbraun.com

The validated steam sterilization procedure was carried out in the Aesculap

sterile container system.

DANGER

Risk of fatal injury from electric shock!

►Connect the product only to a grounded power

supply.

►Set up the device in such a way that a separa-

tion from the network cable is straightforwardly

possible.

WARNING

Risk of injury and/or malfunction!

►Always carry out a function check prior to using

the product.