iii Bridgeview Manufacturing Inc.

TABLE OF CONTENTS

INTRODUCTION .............................................................................................................. 1

Warranty Information ..................................................................................................... 1

Safety Precautions........................................................................................................... 2

Hydraulic System Safety............................................................................................. 2

FEATURES .................................................................................................................... 3

Implement Tongue.......................................................................................................... 3

Axles............................................................................................................................... 3

Lifting Arm..................................................................................................................... 3

Bale Deck........................................................................................................................ 4

Adjustable Roll Over Stop.............................................................................................. 4

OPERATION...................................................................................................................... 5

Hooking up Machine................................................................................................... 5

Loading Bales ............................................................................................................. 5

Unloading Bales.......................................................................................................... 5

Unhooking Machine.................................................................................................... 6

MAINTENANCE............................................................................................................... 7

Lubrication...................................................................................................................... 7

Wheels and Tires............................................................................................................. 8

Tire Inflation and Rating............................................................................................. 8

Hub Removal.............................................................................................................. 8

Bearing and Seal Inspection........................................................................................ 9

Hub Installation........................................................................................................... 9

Sled Chain..................................................................................................................... 10

Cylinder Maintenance................................................................................................... 11

TRANSPORTATION....................................................................................................... 12

TROUBLESHOOTING GUIDE ...................................................................................... 13

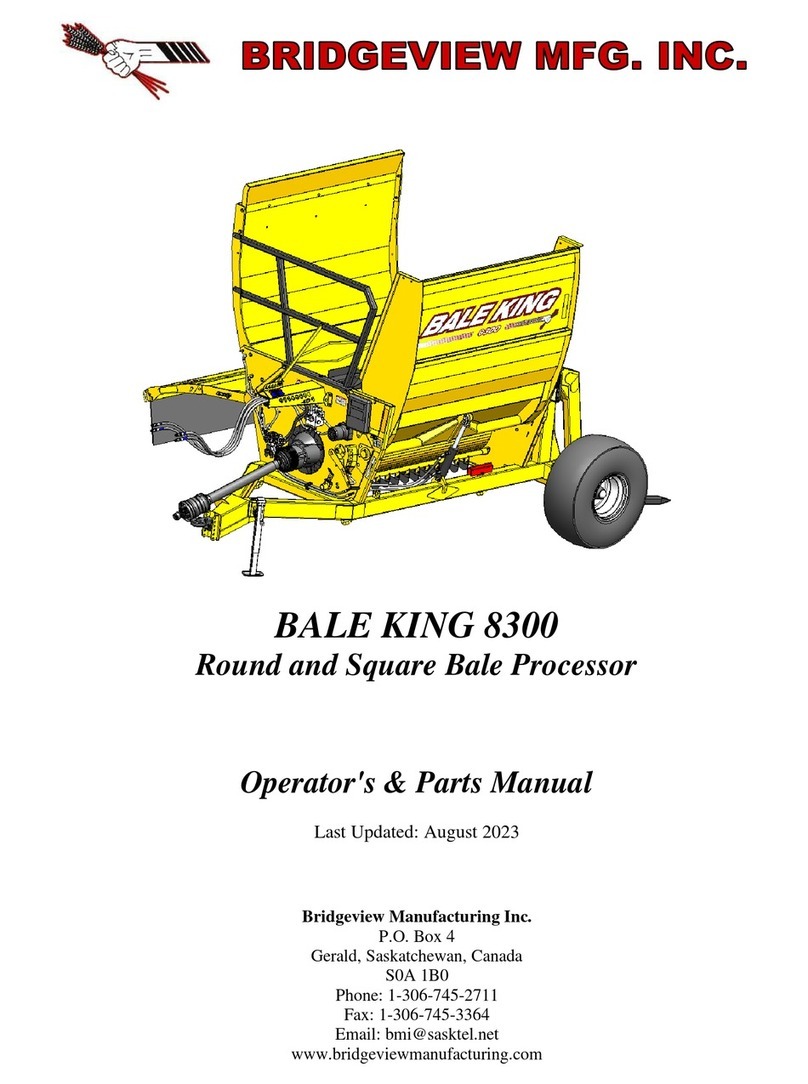

FEATURES AND SPECIFICATIONS............................................................................ 14

PARTS MANUAL............................................................................................................ 15

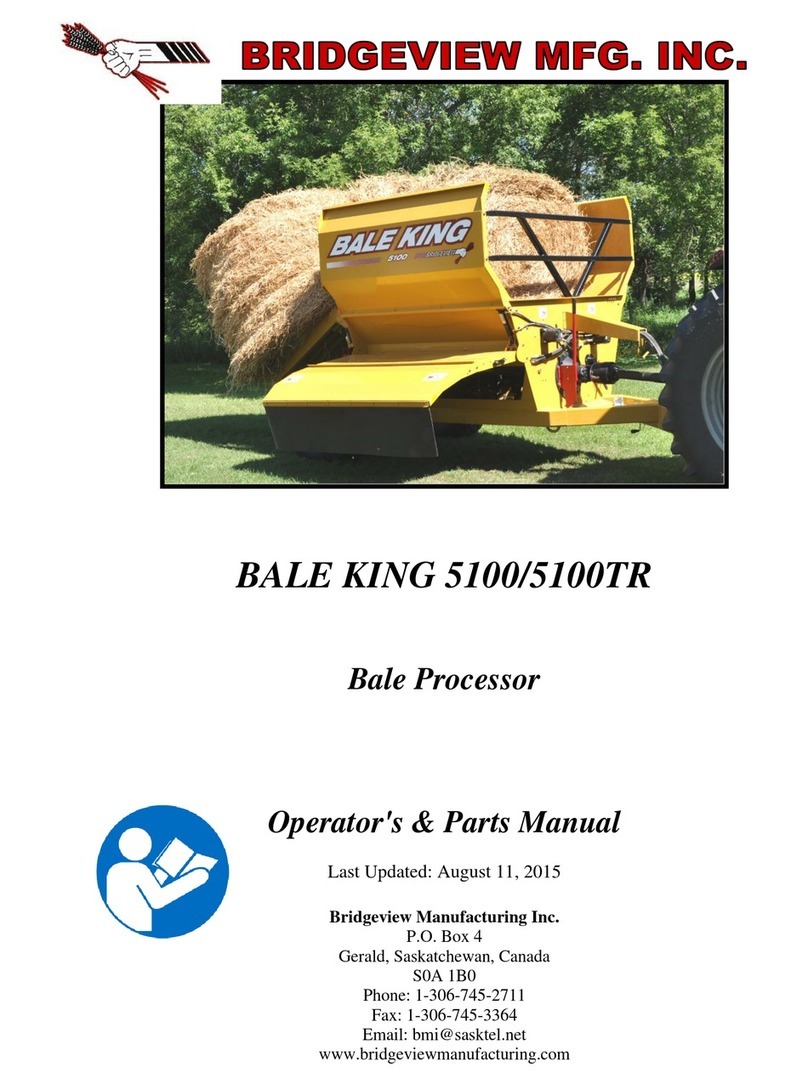

Bale King BRX850....................................................................................................... 15

Front and Rear Deck..................................................................................................... 16

Rocking Axle Weldment Left (and Right).................................................................... 17

NOTE: Quantities are given as per side. For both sides, double the above quantities. 17

Axle Install.................................................................................................................... 18

Spindle and Rim Assembly (Standard Wheels)............................................................ 19