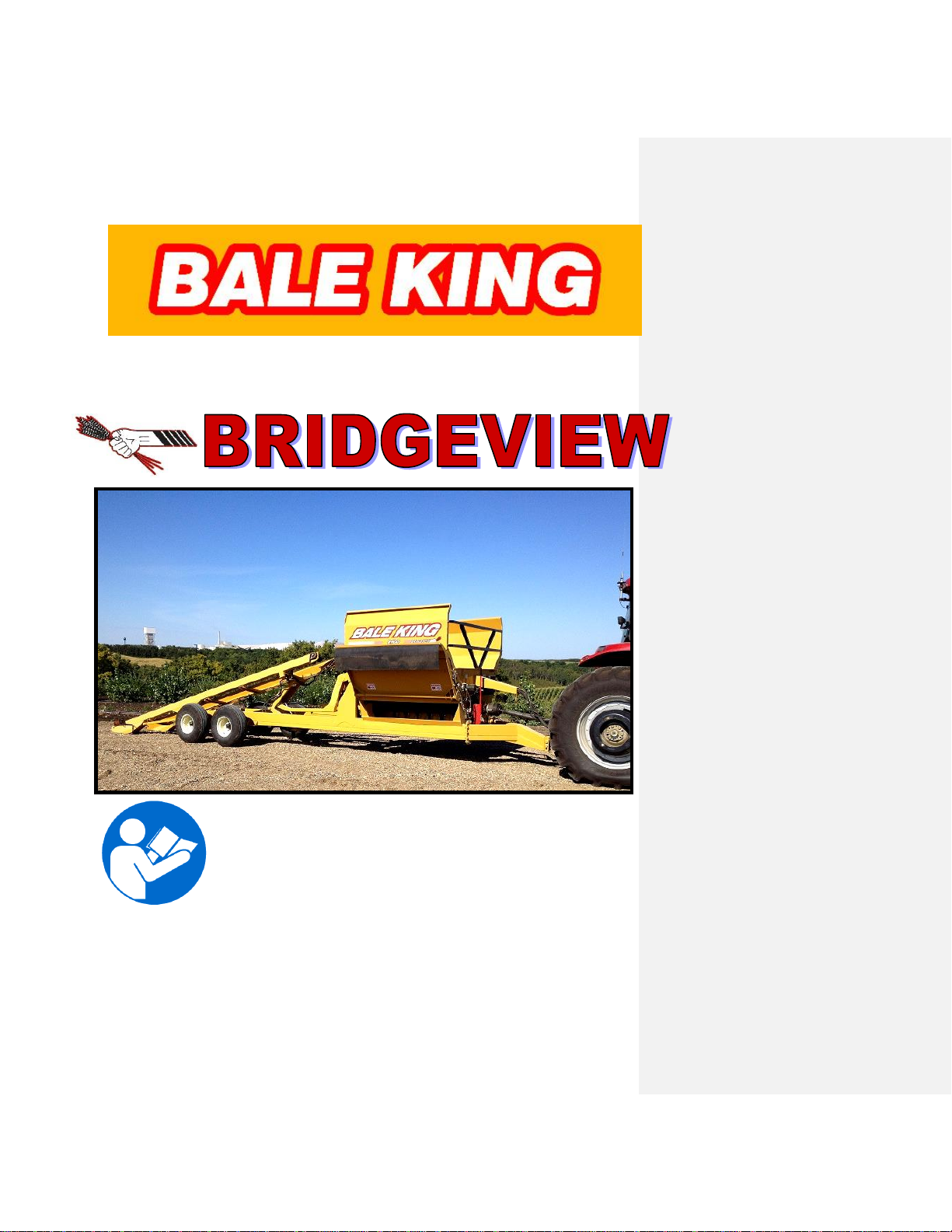

Bridgeview Bale King 6100 Programming manual

Other Bridgeview Farm Equipment manuals

Bridgeview

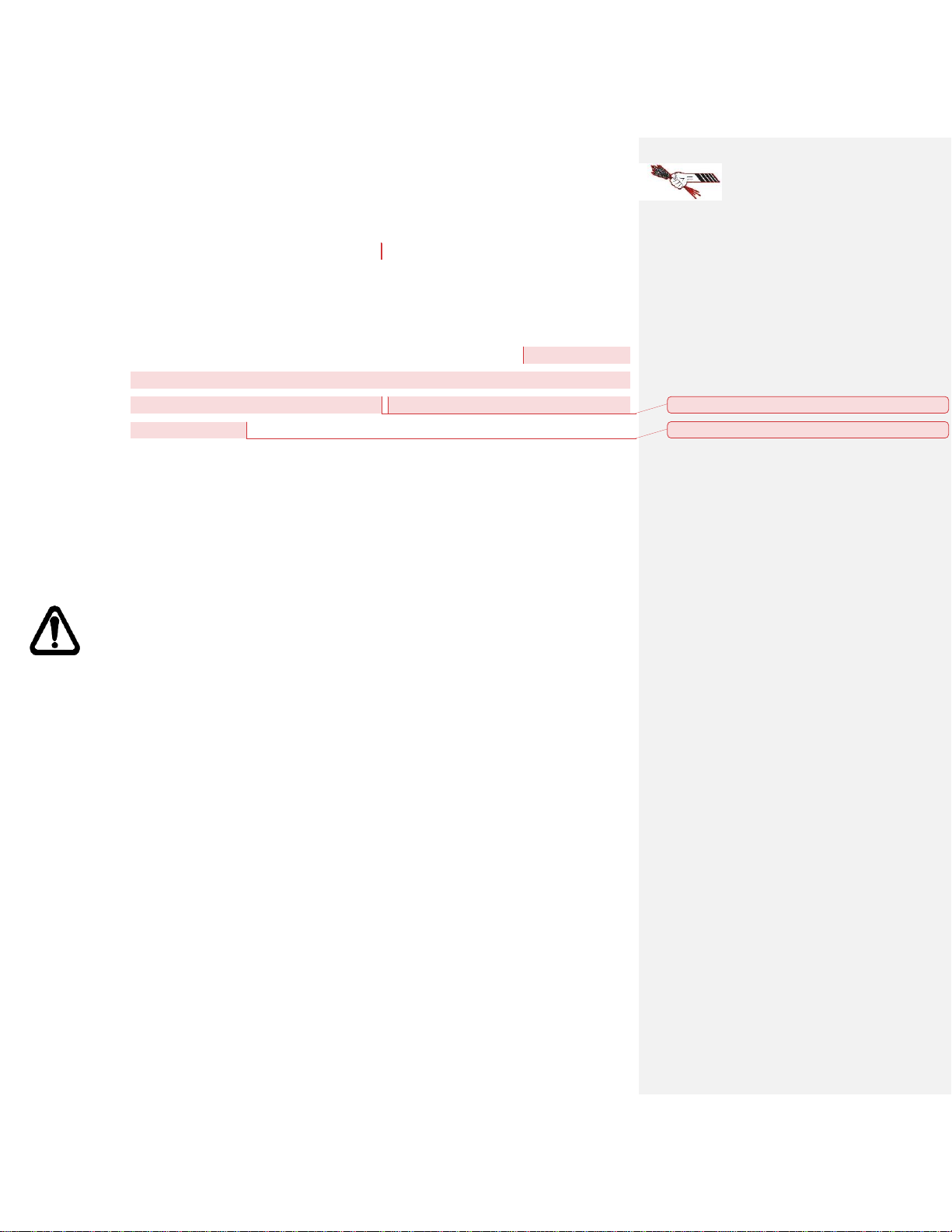

Bridgeview BALE KING 5300 Series Programming manual

Bridgeview

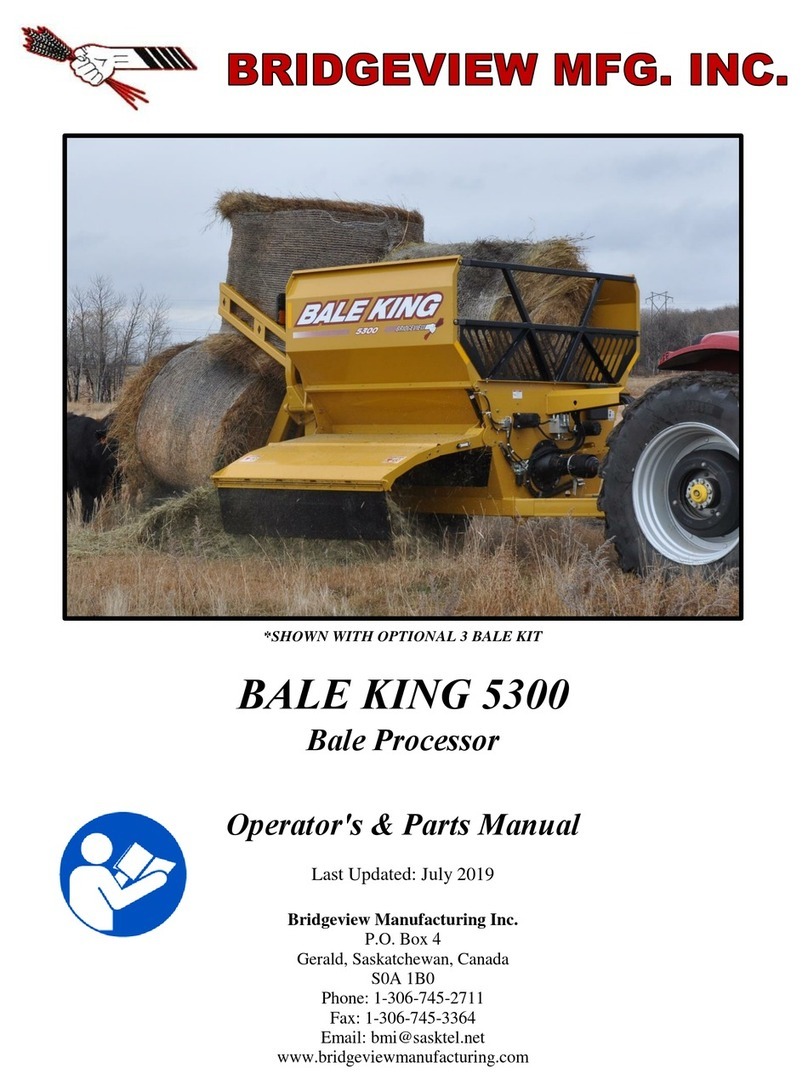

Bridgeview BALE KING V-MAX 1214 Product manual

Bridgeview

Bridgeview BALE KING 5300 Series Programming manual

Bridgeview

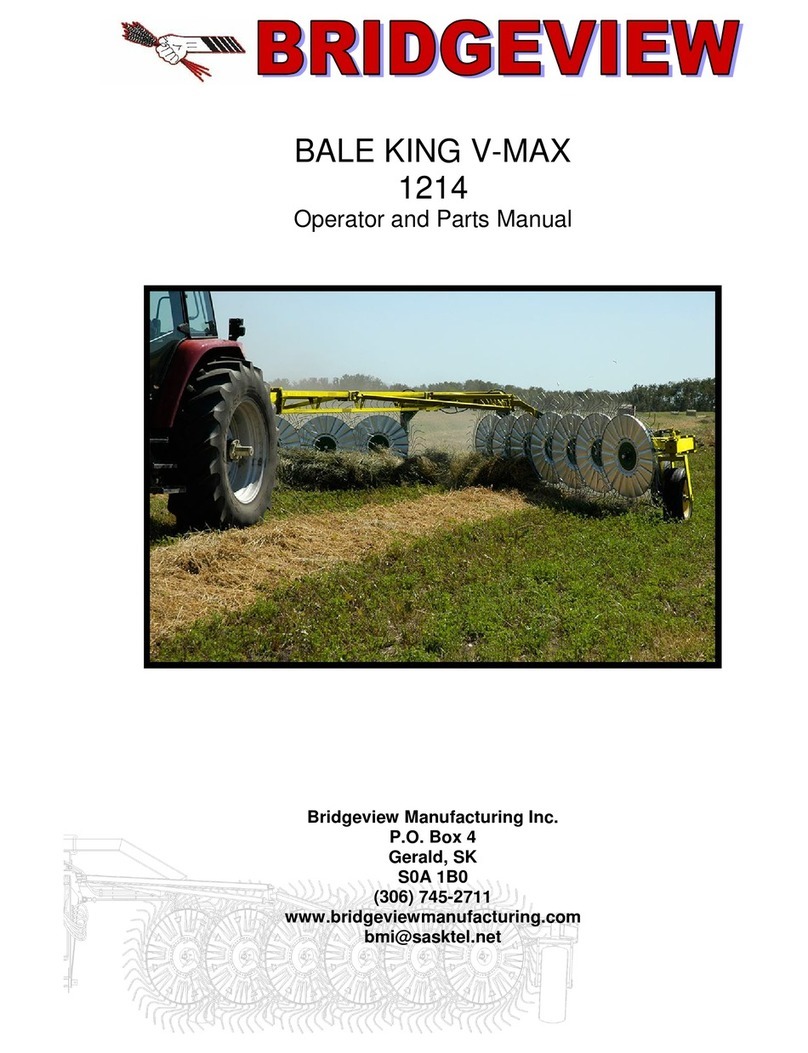

Bridgeview BALE KING 8300 User manual

Bridgeview

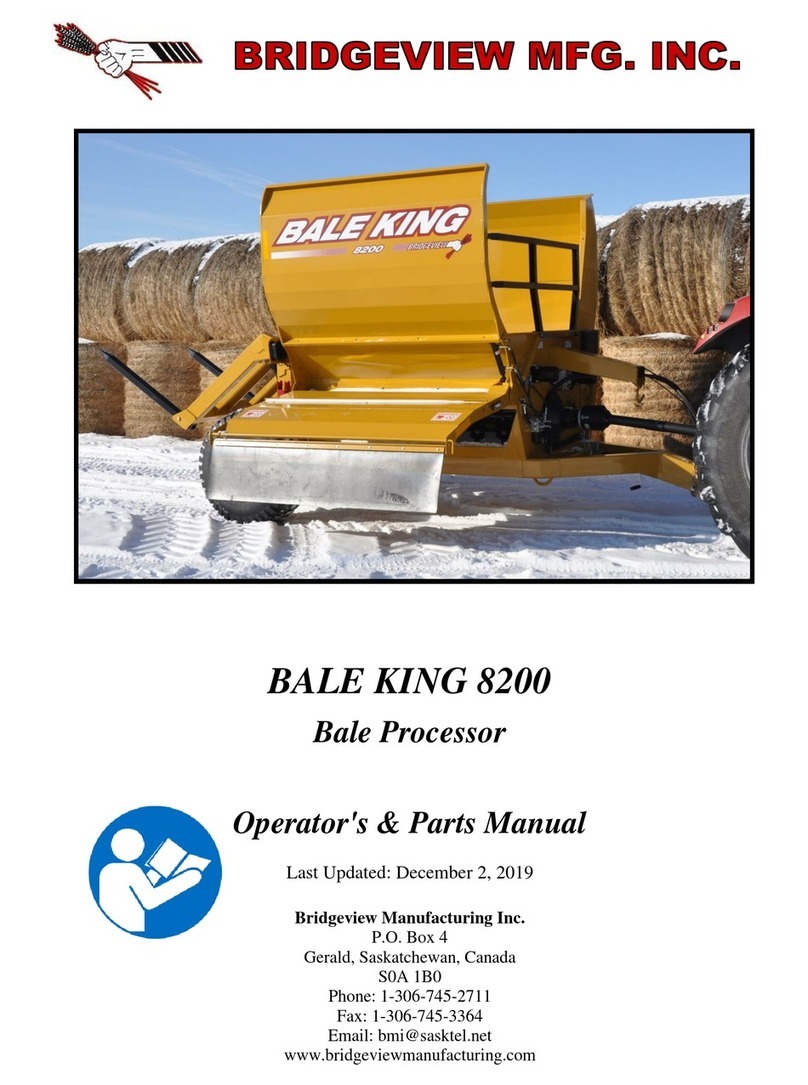

Bridgeview BALE KING 8200 Programming manual

Bridgeview

Bridgeview BALE KING 7400 User manual

Bridgeview

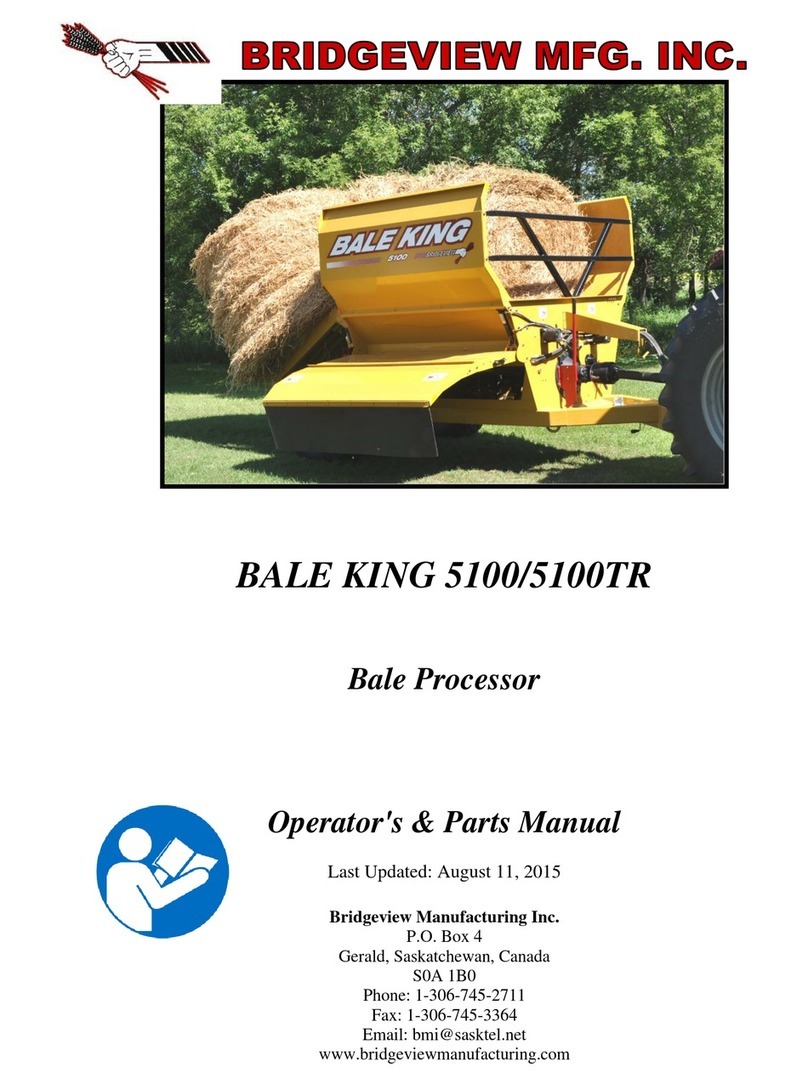

Bridgeview BALE KING 5100 Programming manual

Bridgeview

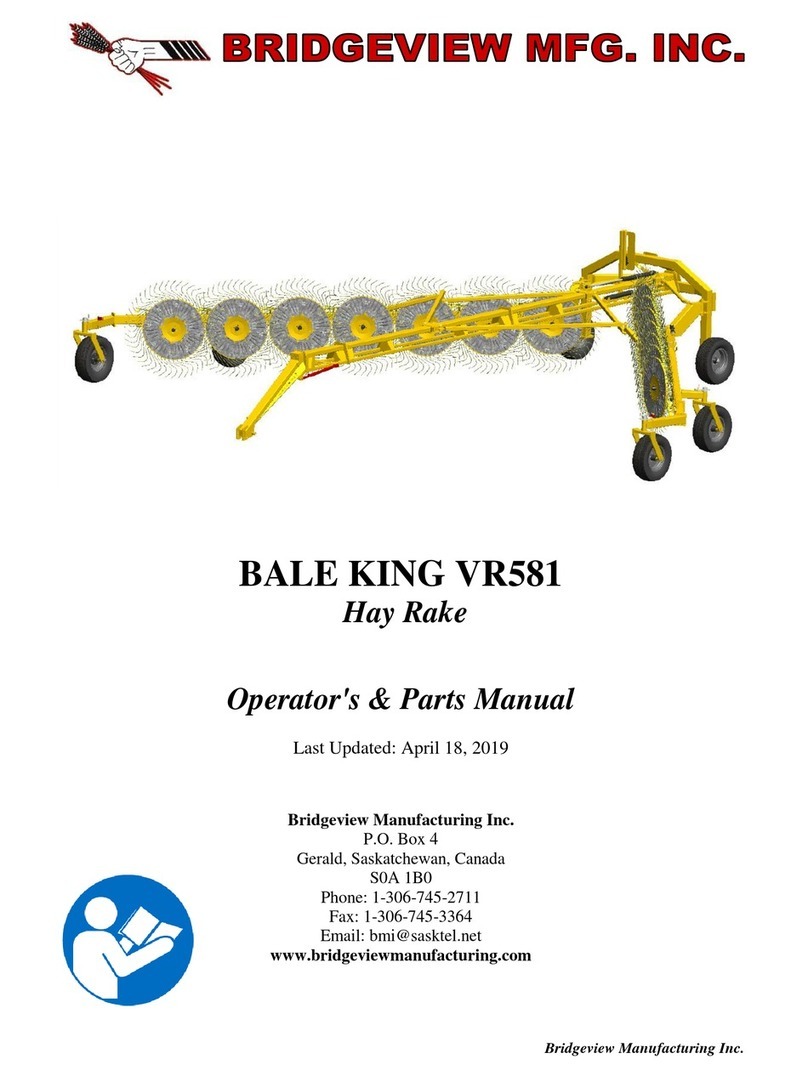

Bridgeview BALE KING VR581 Programming manual

Bridgeview

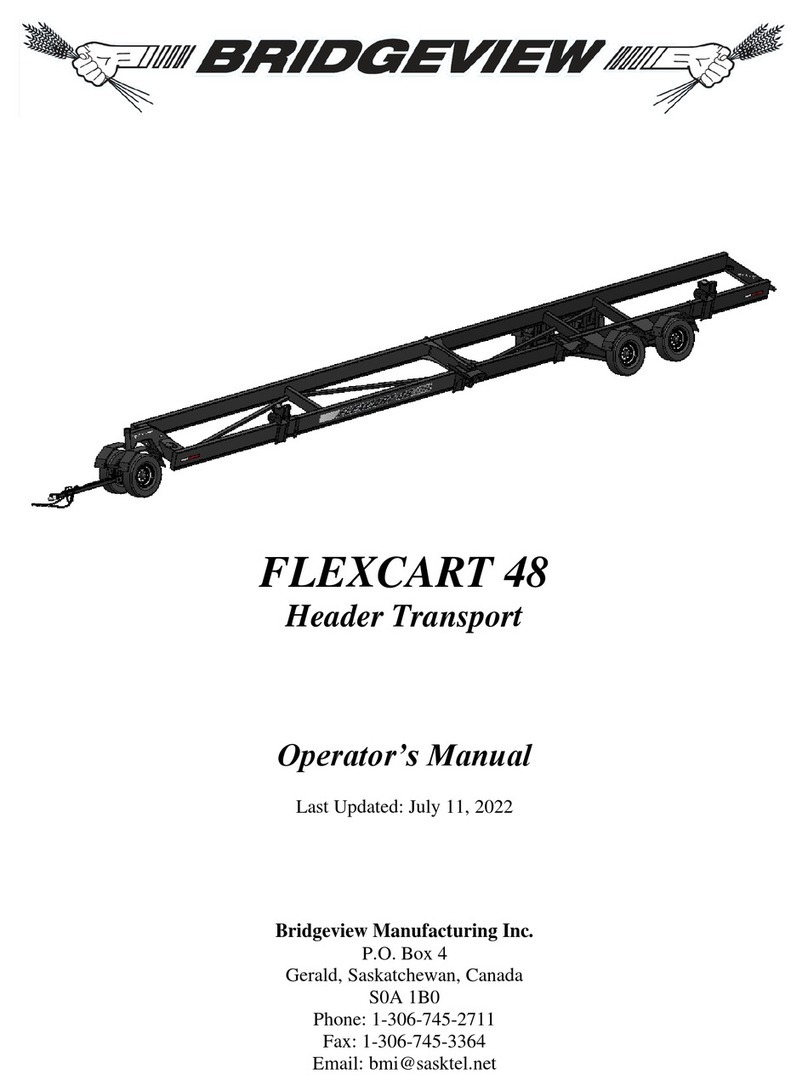

Bridgeview FLEXCART 48 User manual

Bridgeview

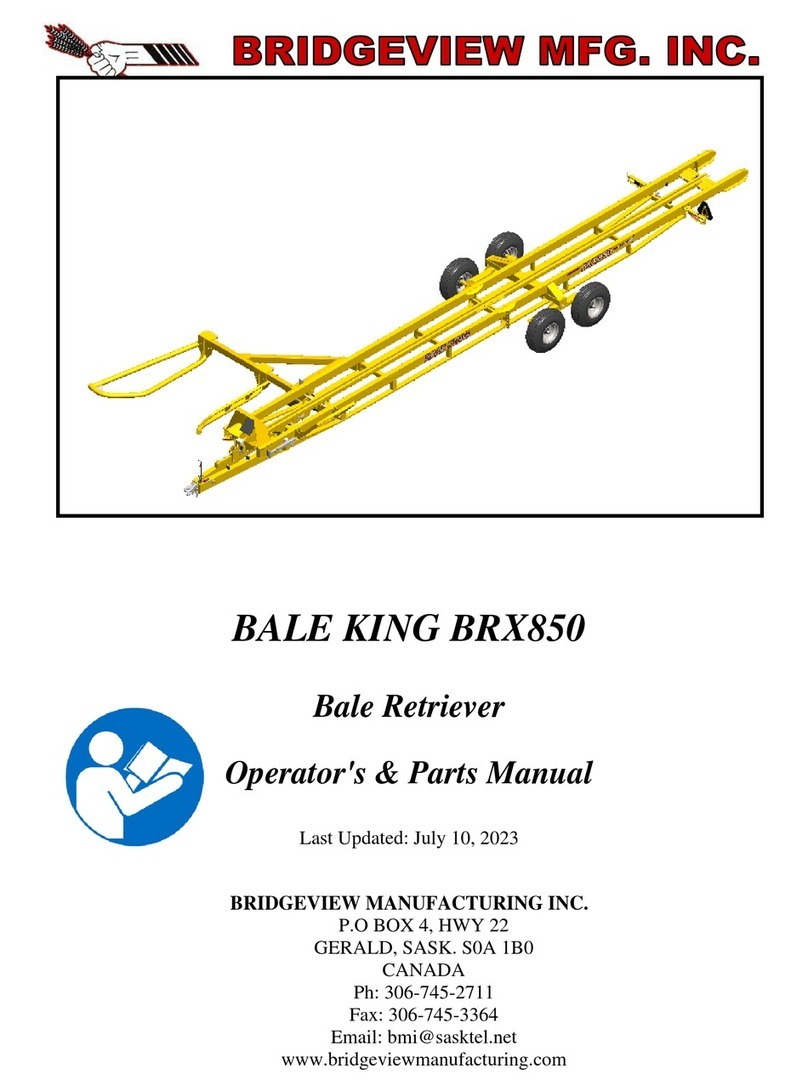

Bridgeview BALE KING BRX850 Programming manual

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions