1

TABLE OF CONTENT

CHAPTER 1

GENERAL INTRODUCTION - WARRANTY ......................................................................2

1.1

INTRODUCTION___________________________________________________________________________________3

1.2

WARRANTEE _____________________________________________________________________________________3

CHAPTER 2

GUIDE TO THE SIGNS AND SYMBOLS USED IN THIS MANUAL AND THEIR

LOCATION ON THE MACHINE..........................................................................................4

2.1

SIGNS AND SYMBOLS _____________________________________________________________________________5

2.2

WARNING SIGNS__________________________________________________________________________________5

2.3

DANGER SIGNS___________________________________________________________________________________6

2.4

INDICATION SIGNS ________________________________________________________________________________7

2.5

LOCATION OF SIGNS AND SYMBOLS ON THE MACHINE_________________________________________________8

CHAPTER 3

GENERAL SUMMARY OF SAFETY AND ACCIDENT - PREVENTION INSTRUCTIONS

.............................................................................................................................................9

3.1

GENERAL SUMMARY OF SAFETY AND ACCIDENT-PREVENTION INSTRUCTIONS __________________________10

CHAPTER 4

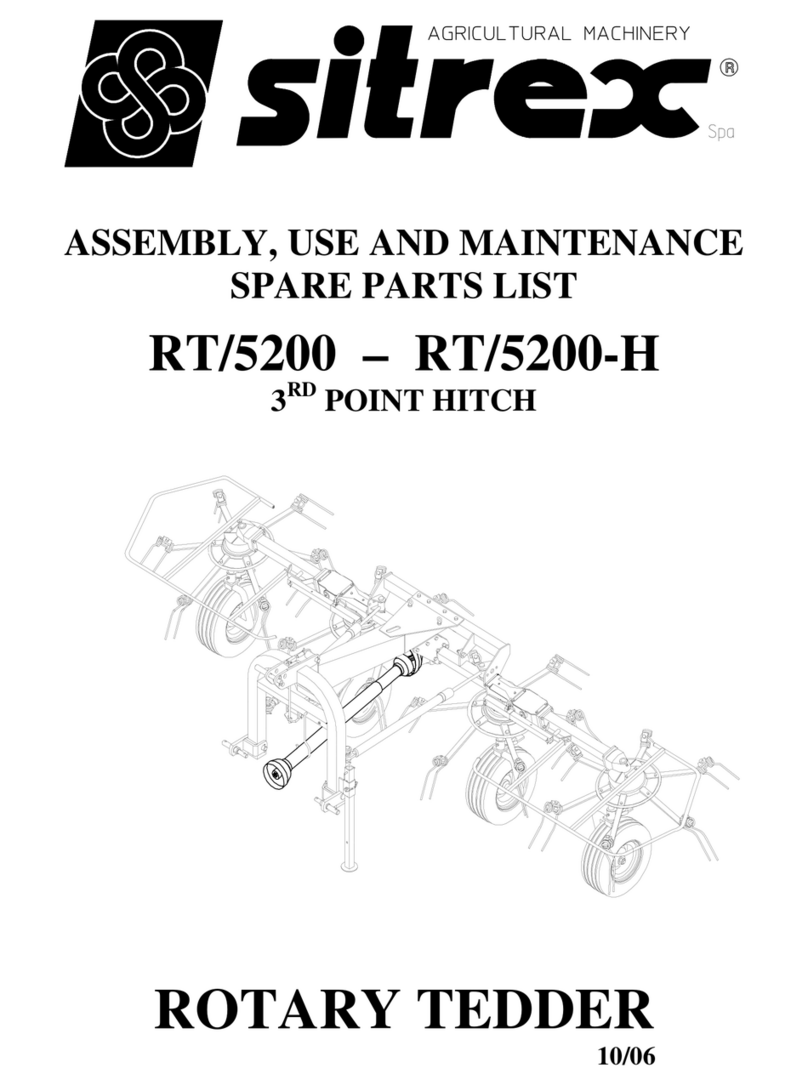

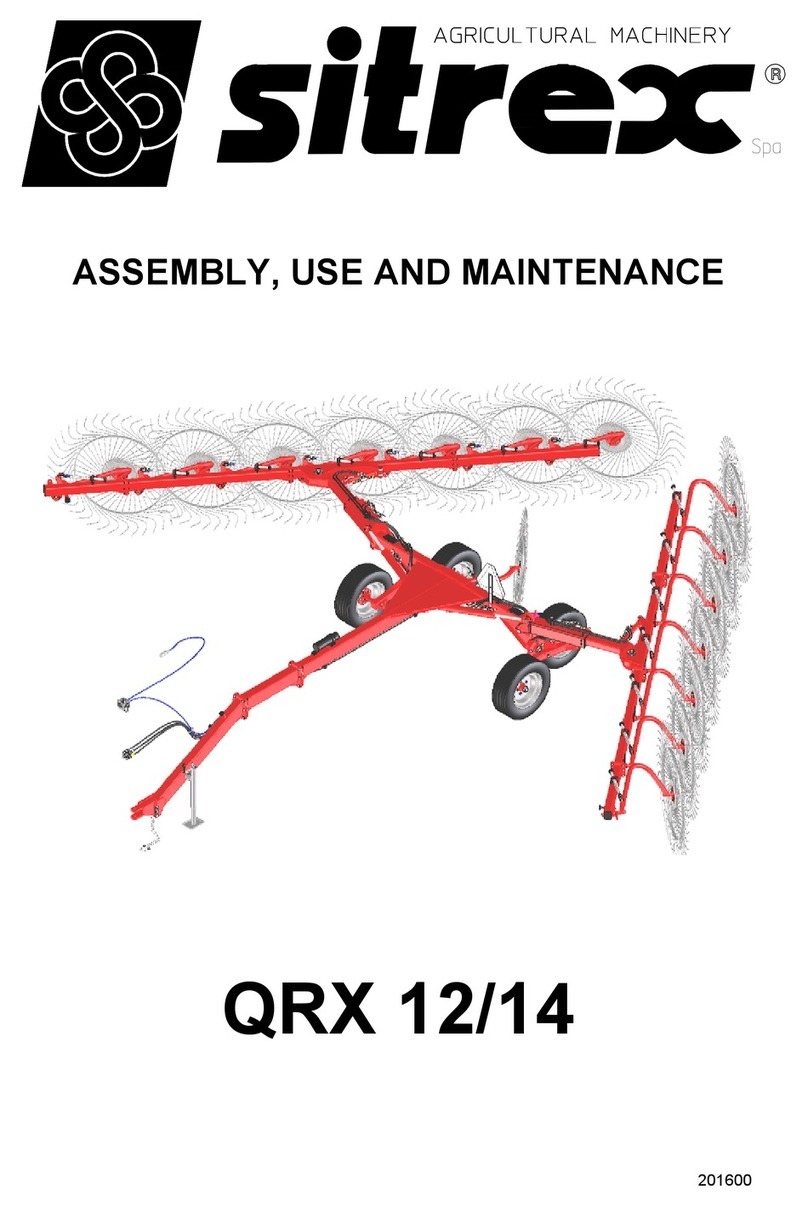

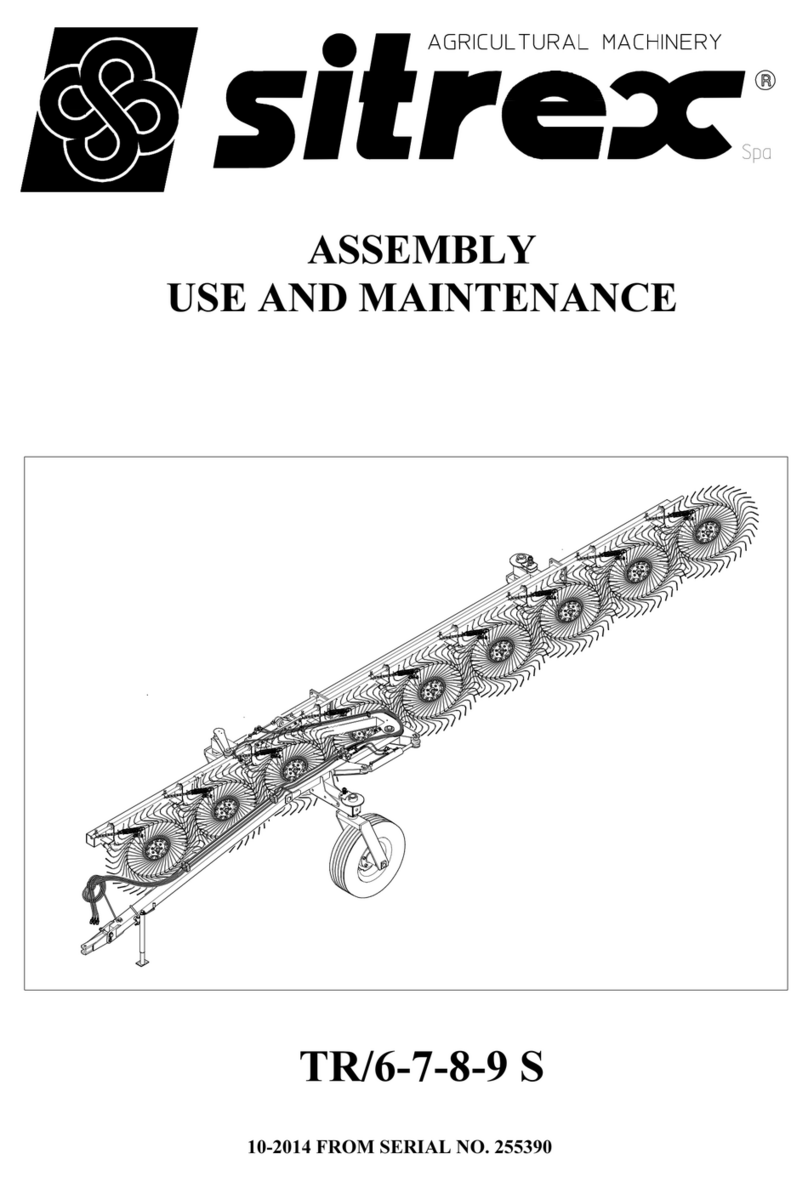

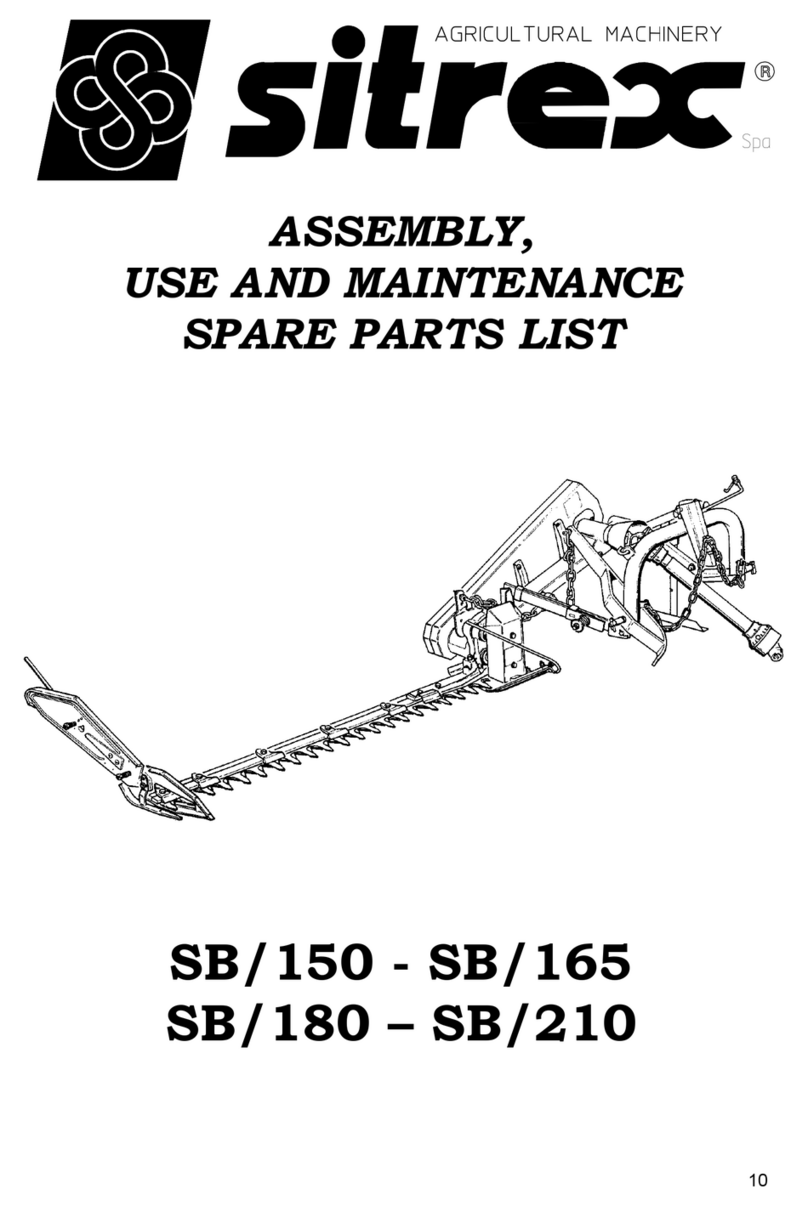

PRODUCT IDENTIFICATION...........................................................................................13

4.1

TECHNICAL DATA ________________________________________________________________________________14

4.2

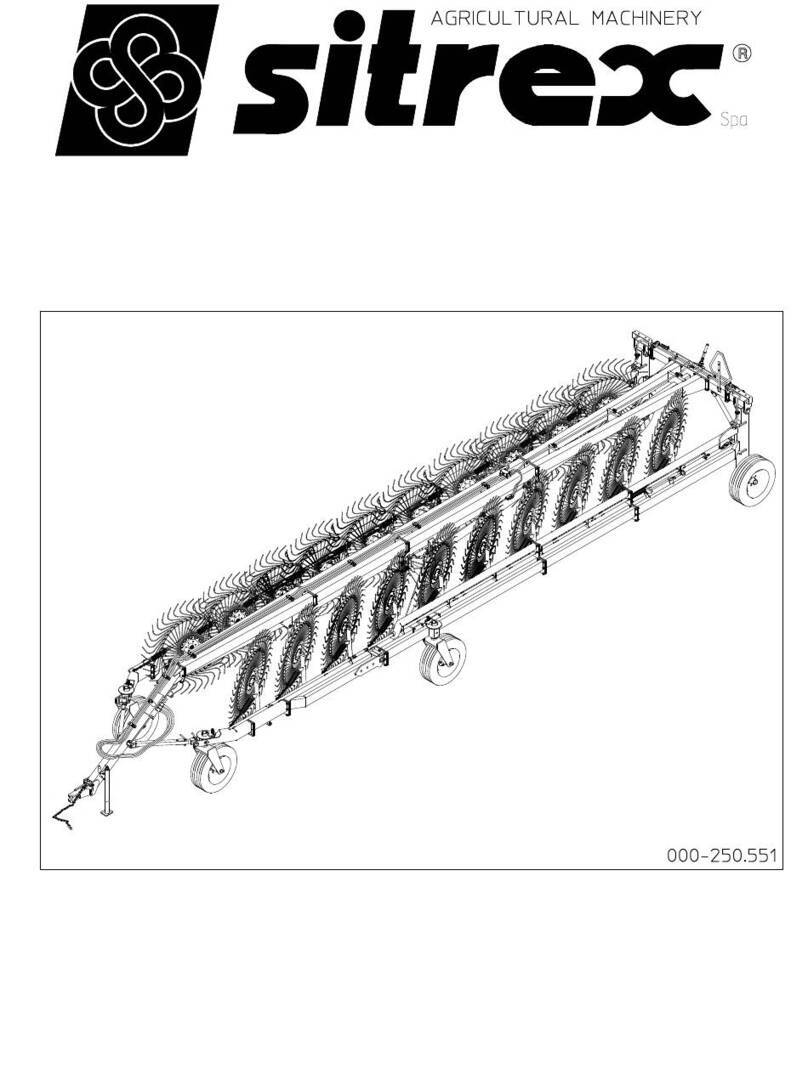

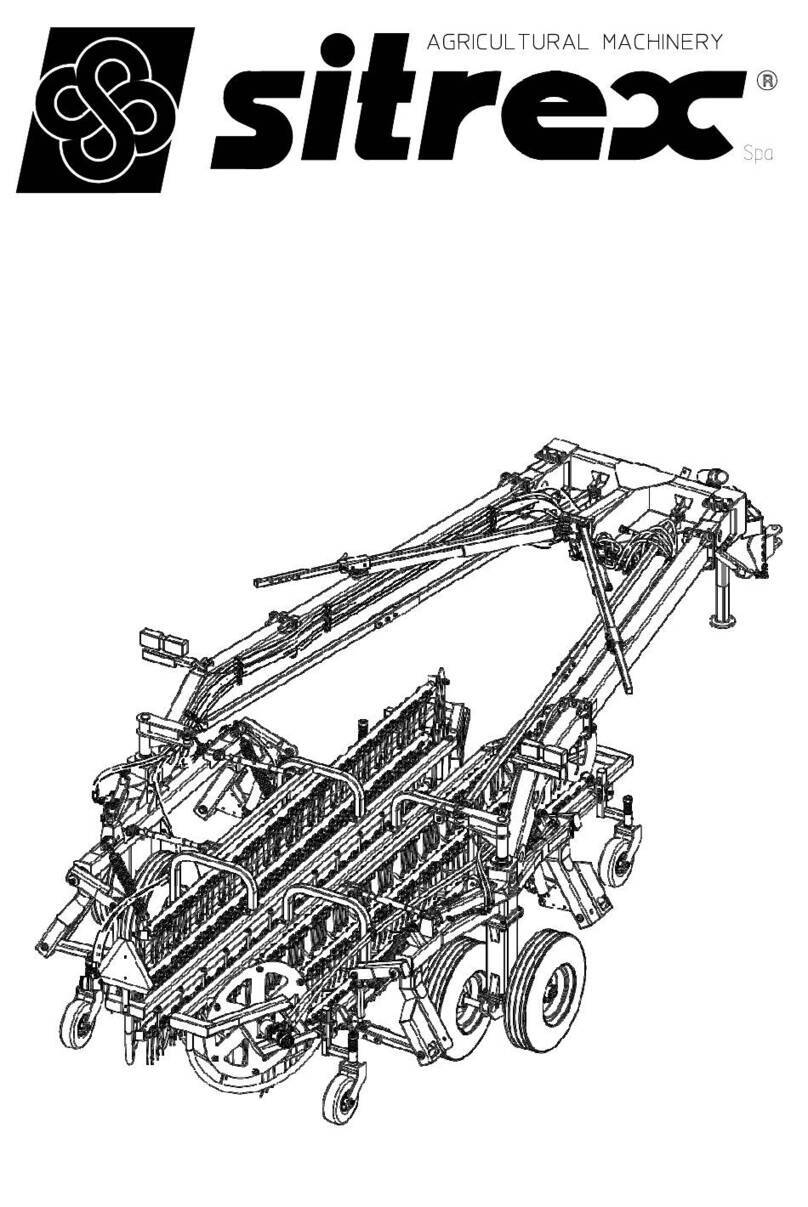

MAIN MACHINE PARTS____________________________________________________________________________14

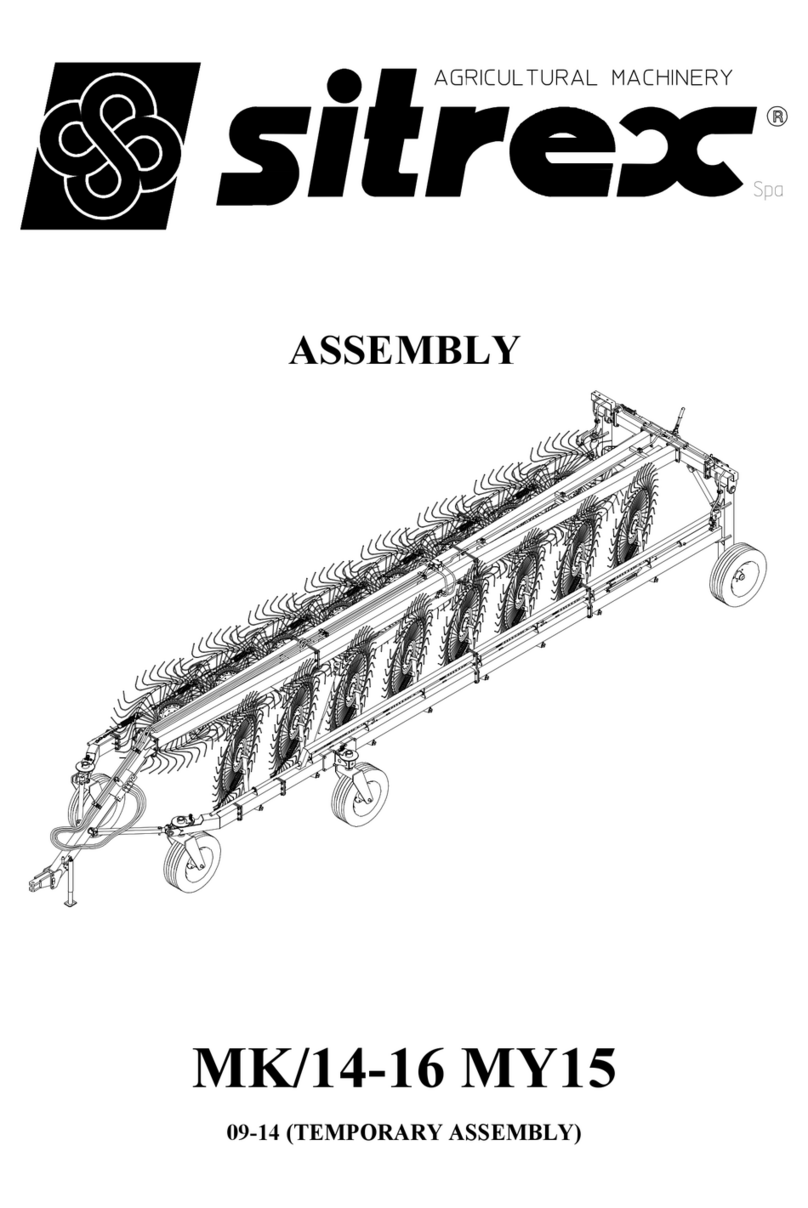

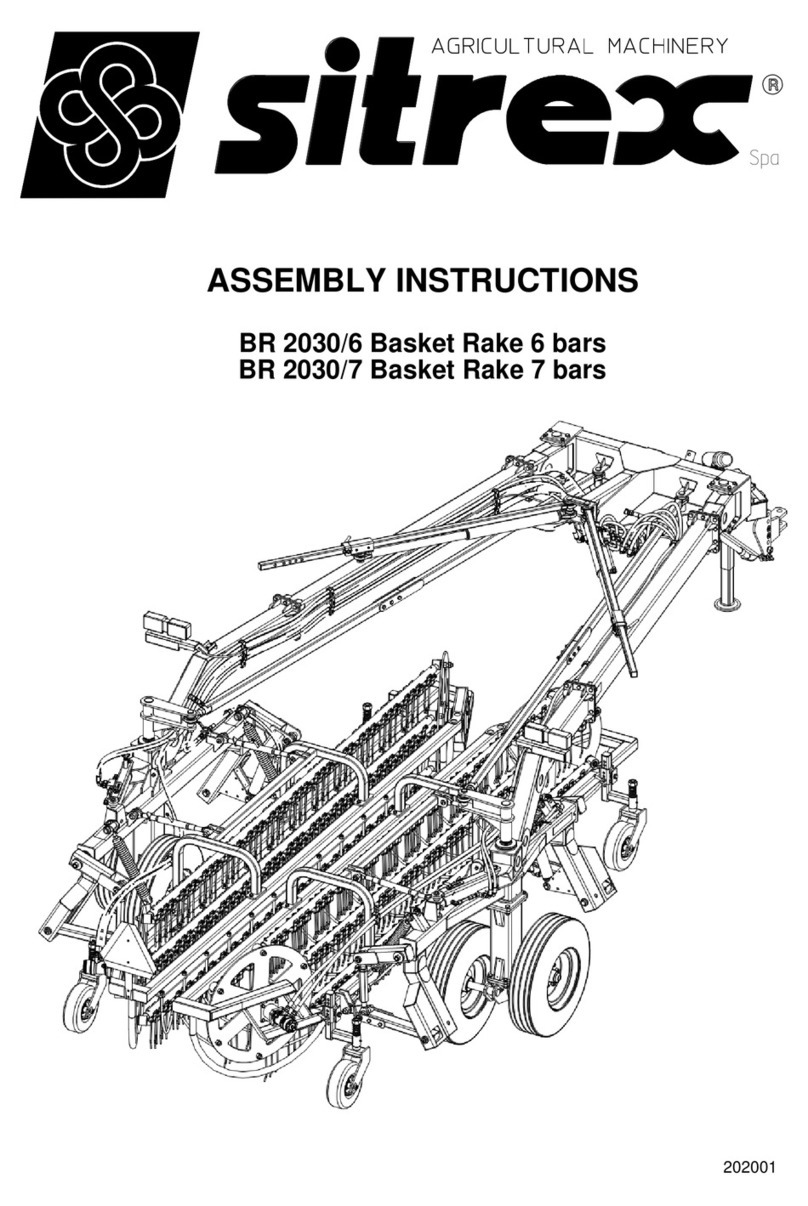

CHAPTER 5

DELIVERY AND ASSEMBLY...........................................................................................15

5.1

CHECKING THE MACHINE ON DELIVERY ____________________________________________________________16

5.2

SEQUENCE D'ASSEMBLAGE _______________________________________________________________________17

CHAPTER 6

ADJUSTMENT, PREPARATION AND USE.....................................................................30

6.1

INTRODUCTION__________________________________________________________________________________31

6.2

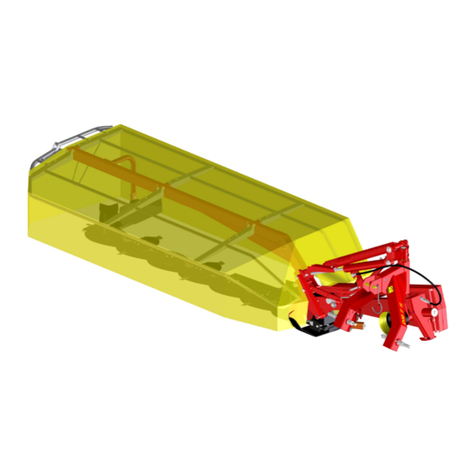

MOUNTING TO THE TRACTOR _____________________________________________________________________31

6.3

CONNECTING THE CARDAN SHAFT_________________________________________________________________32

6.4

TRANSPORT BY ROAD____________________________________________________________________________33

6.5

GENERAL INSTRUCTIONS FOR FIELD USE___________________________________________________________33

6.6

GENERAL INSTRUCTIONS FOR USE ________________________________________________________________34

6.7

WORKING EXAMPLES ____________________________________________________________________________38

CHAPTER 7

MAINTENANCE ................................................................................................................41

7.1

MAINTENANCE DIRECTIONS_______________________________________________________________________42

7.2

REPAIR INSTRUCTIONS___________________________________________________________________________43

7.3

LAYING UP FOR EXTENDED PERIODS_______________________________________________________________43

7.4

MAINTENANCE POINTS ___________________________________________________________________________44

7.5

CARDAN SHAFT MAINTENANCE____________________________________________________________________45

7.6

NOISE AND VIBRATION ___________________________________________________________________________46

7.7

SCRAPPING THE MACHINE ________________________________________________________________________46

CHAPTER 8

SPARE PARTS LIST ........................................................................................................47