Use and Maintenance Manual –VER. 2016-02 Page 13

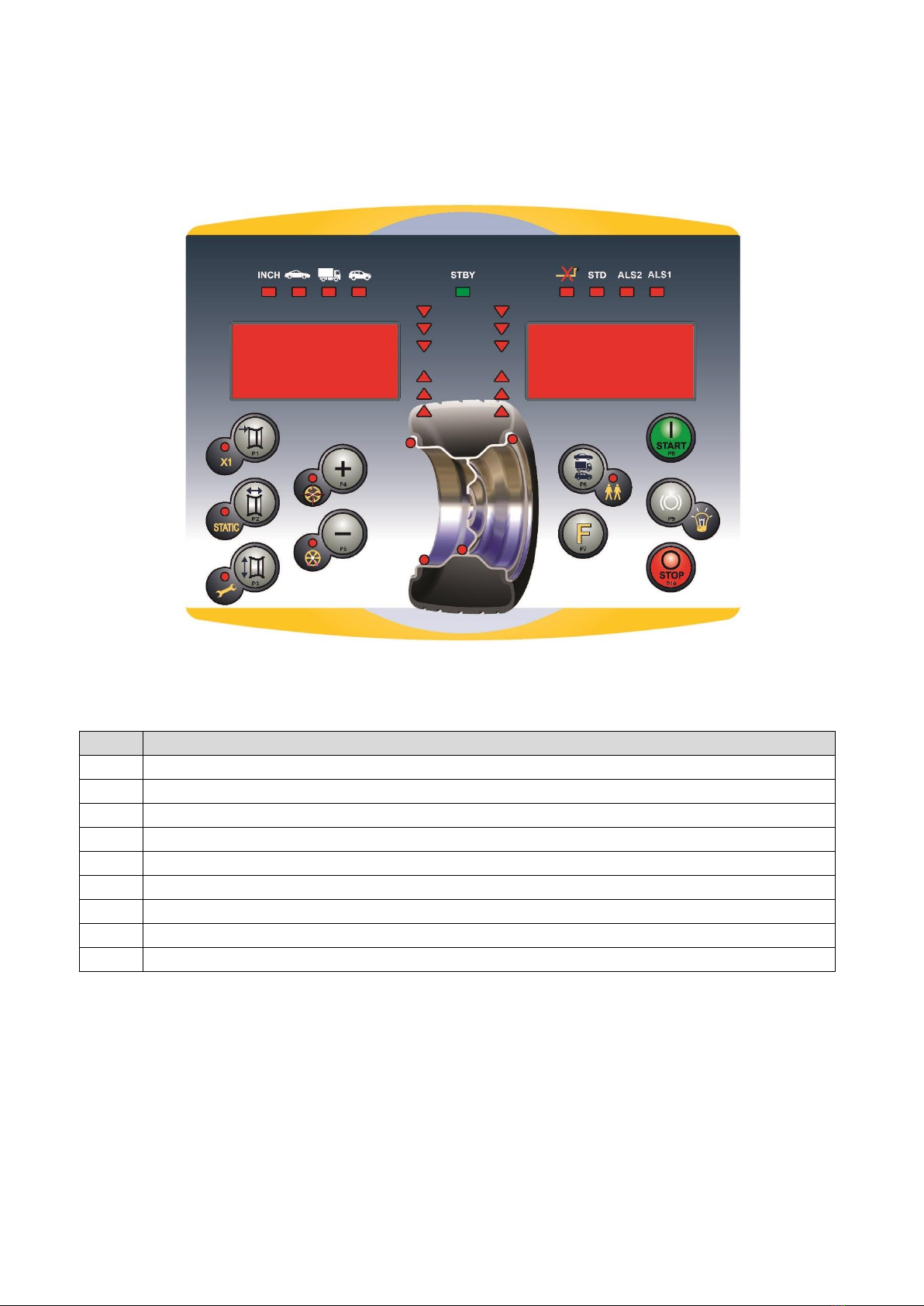

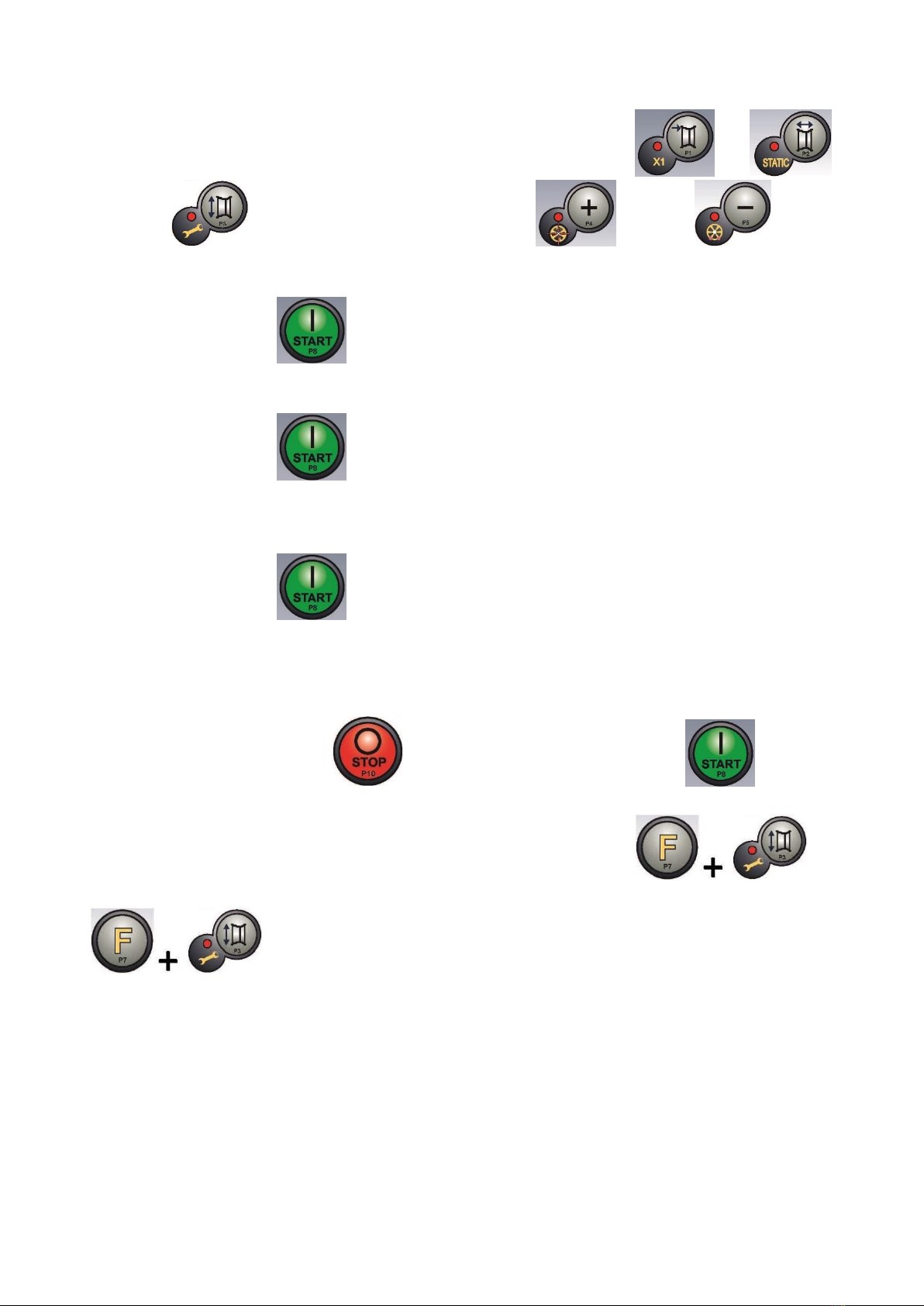

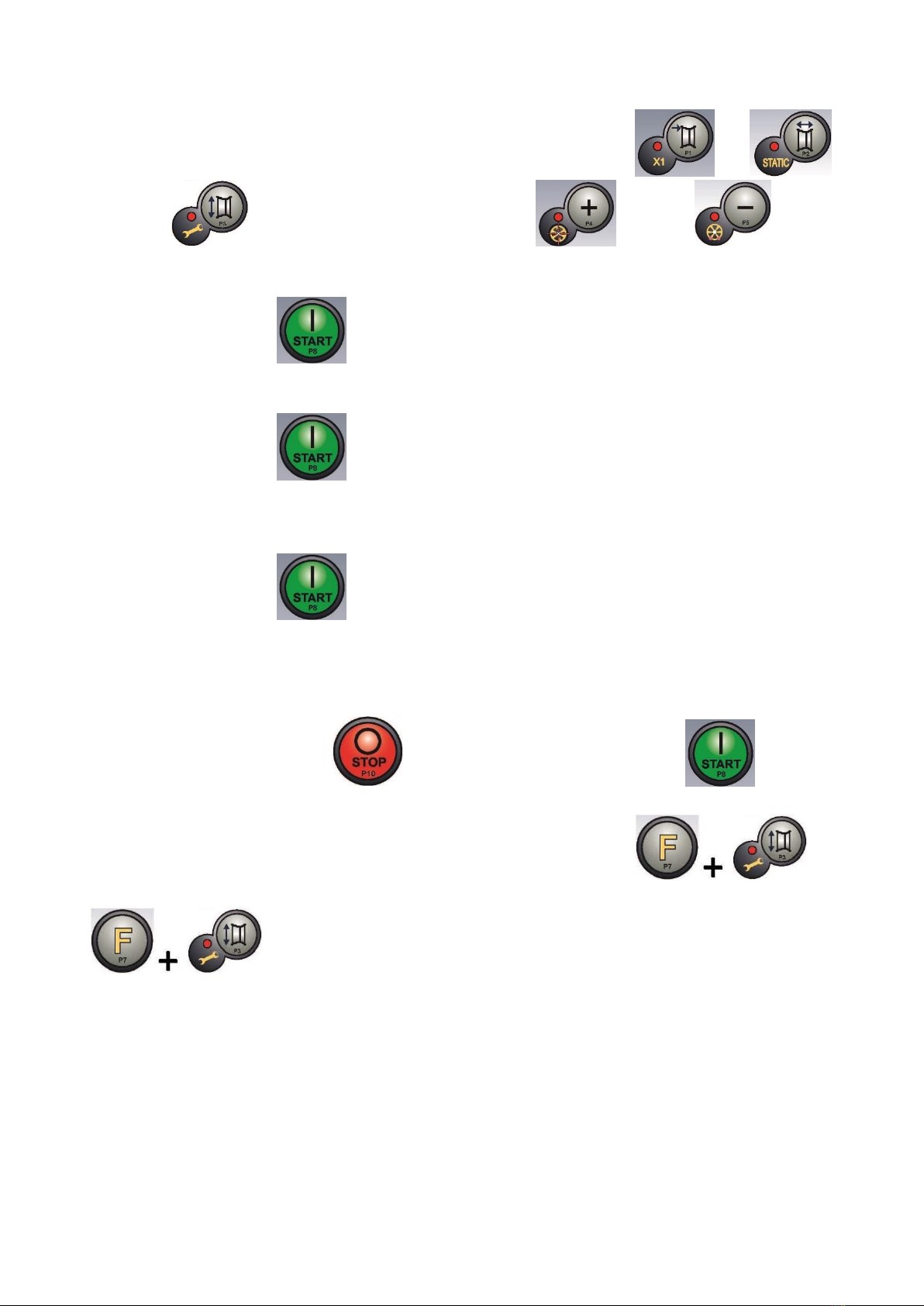

7. Mount the wheel on the shaft and enter the wheel dimensions by pressing the [P1] , [P2] ,

[P3] to select the dimensions for editing, and the [P4] or [P5] keys to edit the

value. If the dimensions of the wheel have been entered before accessing the calibration program, this step can be

skipped. It is not possible to enter the data with the automatic acquisition system;

8. Press Start button [P8] : the machine will run a spin cycle;

9. At the end of the spin, manually rotate the wheel until the left display shows the value 300. On the inner side of the

wheel, at 12 o'clock, apply the 300 g weight.

10. Press Start button [P8] : the machine will run a spin cycle;

11. Remove the 300 gr. weight applied on the internal side;

12. At the end of the spin, manually rotate the wheel until the right display shows the value 300. On the outer side of the

wheel, at 12 o'clock, apply the 300 g weight.

13. Press Start button [P8] : the machine will run a spin cycle;

14. Calibration is finished: the machine automatically exits the calibration program and returns to NORMAL mode, ready to

perform balancing.

If you have anomalies during the calibration procedure, the machine will display the error message (for example ERR 025). See

section “21.1 Error codes” and act accordingly to eliminate the problem and continue/repeat/cancel the calibration in progress.

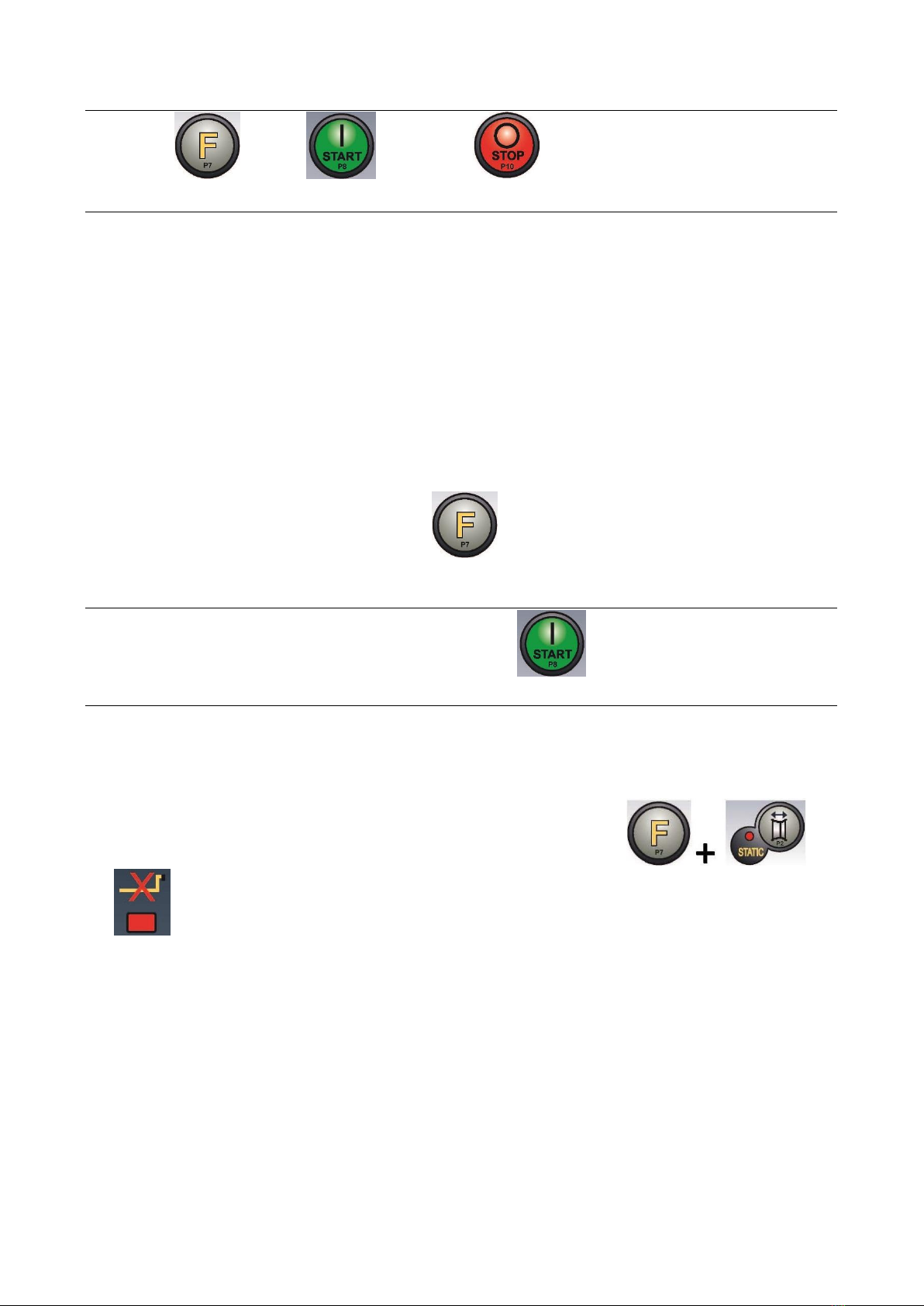

Spins stopped using the [P10] Stop button can be repeated by pressing the [P8] Start button .

How to exit the TRUCK Wheel Type calibration of the machine

At any time it is always possible to exit the calibration procedure in progress by pressing [F+P3] . The

machine will return to SERVICE mode displaying the SER SER writing. To return to NORMAL mode, press [F+P3] again

. The calibration procedure in progress will be cancelled and the machine will use the previous

calibration values.

15.3 Machine calibration for the CAR/SUV Wheel Types

Calibration for the CAR and SUV Wheel Types is the same.

To perform machine calibration, you must first provide for the following material:

A balanced wheel with a steel rim having the following dimensions: Diameter 15” Width 6”. Wheels with dimensions

similar to those specified can also be used provided that the difference is small. It is not possible to use wheels with

aluminium rims.

A 50-gram weight (preferably made of Iron or Zinc).

To perform the machine calibration, proceed as follows: