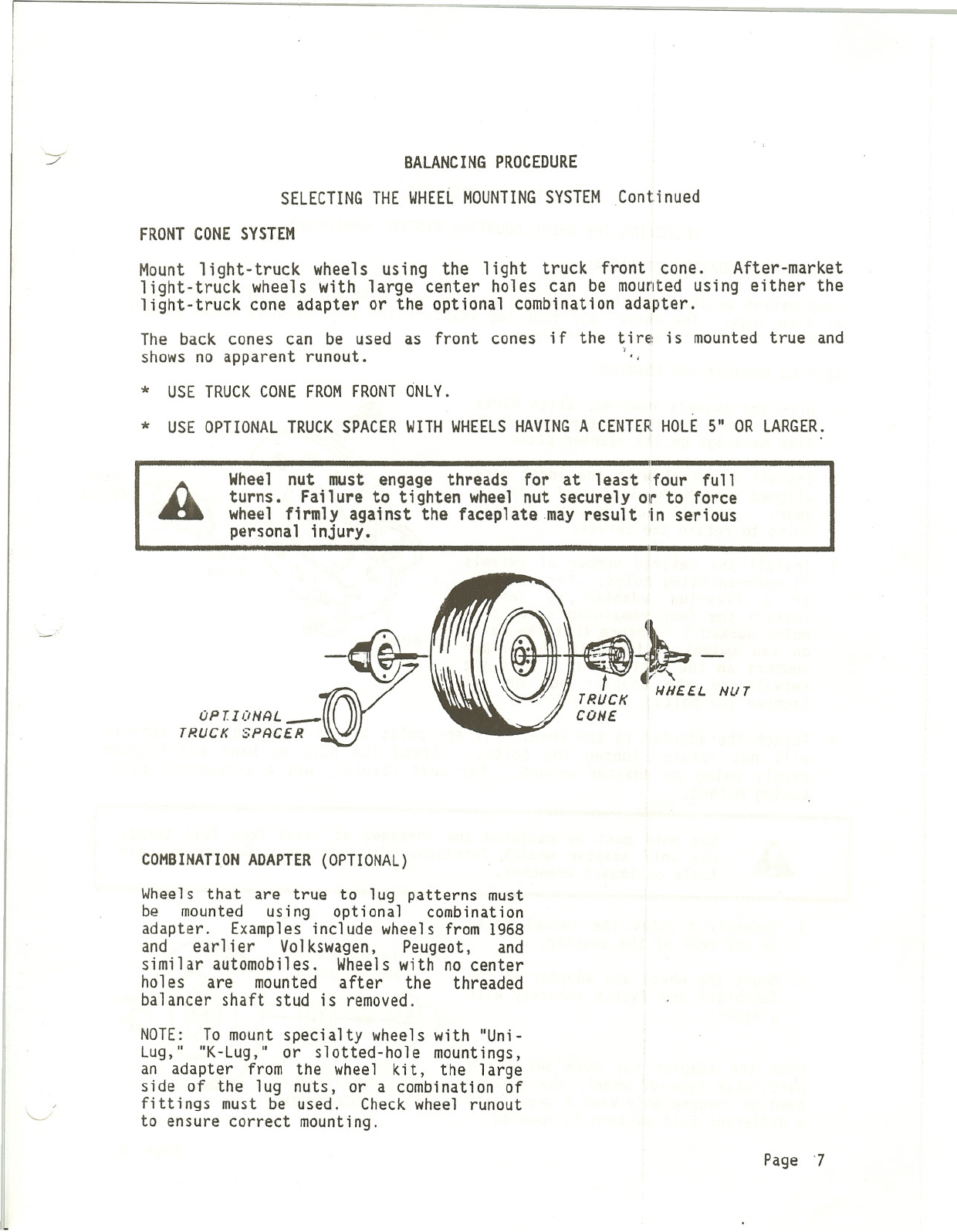

BALANCINGPROCEDURE

SELECTINGTHE WHEELMOUNTINGSYSTEM Contirued

COMBINATIONADAPTER(OPTIONAL)

Combination adapters can be set up to mount wheels with patterns of three, four,

or five lugs. The three- and four-lug adapters are also used to mount wheels

with six and eight lugs, respectively.

SETTING COMBINATIONADAPTERS

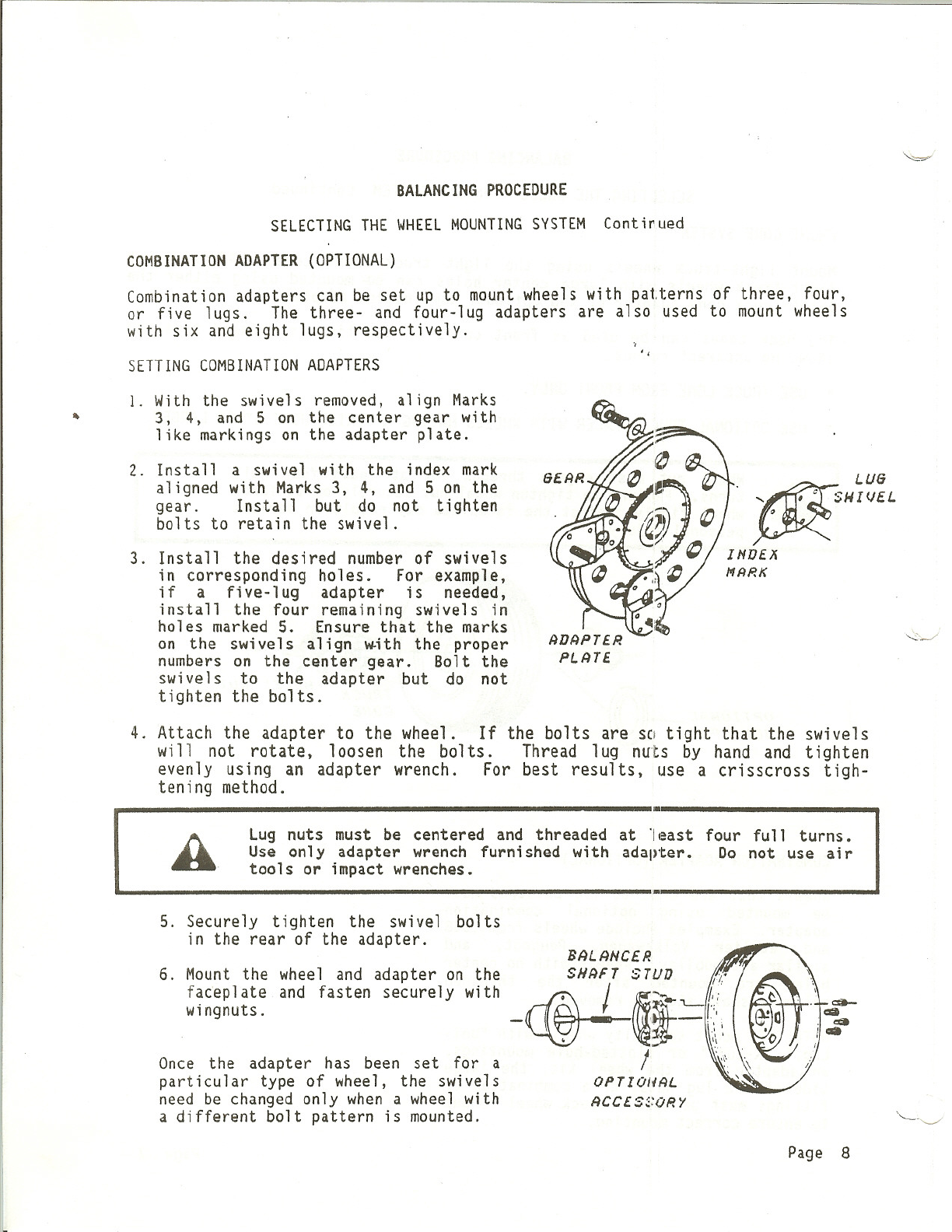

1. With the swivels removed, align Marks

~3, 4, and 5 on the center gear with

like markings on the adapter plate.

2. Install a swivel with the index mark

aligned with Marks 3, 4, and 5 on the

gear. Install but do not tighten

bolts to retain the swivel.

""

~LUG

~SHIVEL

IND£X

MRRK

3. Install the desired number of swivels

in corresponding holes. For example,

if a five-lug adapter is needed,

install the four remaining swivels in

holes marked S. Ensure that the marks

on the swive1s a1ign w.ith the proper

numbers on the center gear. Bolt the

swivels to the adapter but do not

tighten the bolts.

4. Attach the adapter to the wheel. If the bolts are so tight that the swivels

will not rotate, loosen the bolts. Thread lug nuts by hand and tighten

evenly using an adapter wrench. For best results, use a crisscross tigh-

tening method.

81

ALug nuts must be centered and threaded at least four full turns.

Use only adapter wrench furnished with adapter. Do not use air

tools or impact wrenches.

5. Securely tighten the swivel bolts

in the rear of the adapter. B~LRNC£R

6. Mount the wheel and adapter on the SHRFT STUD

~

'l'"

faceplate and fasten securely with c@-L-I

~

~ ~,;

wingnuts. - 'J~r:I.

.

~

' ,

.'

, ,

.~

Once the adapter has been set for a !'

particular type of wheel, the swivels OPTIOH~L

need be changed only when a wheel with ~CC£$~:ORY

a different bolt pattern is mounted.

Page 8