Brinly PA-40 BH User manual

L-1762 Rev. E

Owner's Manual

LAWN AERATOR

MODELS:

PA-40 BH

PA-48 BH

Assembly•

Installation•

Operation•

RepairParts•

For use with Riders

and Lawn/Garden Tractors

This manual contains information for the safety

of persons and property. Read it carefully before

assembly and operation of the equipment!

Visit us on the web!

www.brinly.com

For the latest product updates and setup tips:

IMPORTANT

L-1762 Rev. E 2

INTRODUCTION

SAFETY

CONGRATULATIONSonthepurchaseofyournewBrinly-HardyLawn

Aerator!Yourlawnaeratorisdesigned,engineeredandmanufacturedto

giveyouthebestpossibledependabilityandperformance.

CUSTOMER RESPONSIBILITIES

Pleasereadandretainthismanual.Theinstructionsenablesyouto

assembleandmaintainyourlawnaeratorproperly.Andplease,always

observethe“Safety”instructions.

TABLE OF CONTENTS

SAFETY......................................................................................... 2-3

PARTSREFERENCE.......................................................................4

PARTSLIST......................................................................................5

ASSEMBLY................................................................................. 6-10

OPERATIONANDMAINTENANCE...............................................11

WARRANTY......................................................................Backpage

PRODUCT COMPATIBILITY

Thislawnaeratorisdesignedforusewithridersandlawn/garden

tractors.

RECORD PURCHASE INFORMATION

Recordyourpurchaseinformationinthespacesprovidedbelow:

DATEOFPURCHASE:

COMPANYNAME:

COMPANYPHONE:

SERIALNUMBER:

SAFETY LABELS

UNDERSTANDING THE MACHINE SAFETY LABELS:

Themachinesafetylabelsshowninthissectionareplacedinimportant

areasonyourmachinetodrawattentiontopotentialsafetyhazards.

Onyourmachinesafetylabels,thewordsDANGER,WARNING,and

CAUTIONareusedwiththissafety-alertsymbol.DANGERidentiesthe

mostserioushazards.

Theoperator'smanualalsoexplainsanypotentialsafetyhazards

whenevernecessaryinspecialsafetymessagesthatareidentiedwith

theword,CAUTION,andthesafety-alertsymbol.

SAFETY ALERT SYMBOL

L-1762 Rev. E

3

SAFETY

TO HELP PREVENT BODILY INJURY DUE TO LOSS

OF STABILITY OR CONTROL:

•Donotexceedmaximumtowingcapacityoftowingvehicle

listedinthevehicleoperator'smanual.

•Donottowthismachinebehindamotorvehiclesuchasa

car,truckorATV.

•TowingthismachinebehindaZTR(ZeroTurningRadius)

mowerisnotrecommendedduetothesharpturningability

oftheZTR.DamagetothismachineortheZTRmayresult.

ZTR’stypicallyoperateathigherspeeds.Operatingabove5

mphmayresultindamagetothismachine.

SAFETY

Readthegeneralsafetyoperatingprecautionsinyourtowing

vehicleoperator'smanualforadditionalsafetyinformation.

PROTECT BYSTANDERS

•Keepbystandersawaywhenyouoperatethismachine.

•Beforeyoubacklookcarefullybehindforbystanders.

•Beforeyouoperateanyfeatureofthismachine,observe

yoursurroundingsandlookforbystanders.

OPERATE SAFELY

•Usethismachineforintendedpurposeonly.

•Thismachineisintendedforuseinlawncareandhome

applications.

•Donottowbehindavehicleonahighwayorinanyhigh

speedapplications.Donottowatspeedshigherthan

maximumrecommendedtowingspeed.

•Towingspeedshouldalwaysbeslowenoughtomaintain

control.Travelslowlyoverroughground.

•Donotletchildrenoranuntrainedpersonoperatemachine.

•Donotletanyone,especiallychildren,rideonthismachine

orthetowingvehicle.

•Checktowingvehiclebrakeactionbeforeyouoperate.

Adjustorservicebrakesasnecessary.

•Keepallpartsingoodconditionandproperlyinstalled.Fix

damagedpartsimmediately.Replacewornorbrokenparts.

Replaceallwornordamagedsafetyandinstructiondecals.

•Donotmodifythemachineorsafetydevices.Unauthorized

modicationstothetowingvehicleormachinemayimpairits

functionandsafety,andvoidthewarranty.

•Keepallnuts,boltsandscrewstight.

TOWING SAFELY

•Stoppingdistanceincreaseswithspeedandweightof

towedload.Travelslowlyandallowextratimeanddistance

tostop.

•Totaltowedweightmustnotexceedlimitsspeciedin

towingvehicleoperator'smanual.

•Excessivetowedloadcancauselossoftractionandloss

ofcontrolonslopes.Reducetowedweightwhenoperating

onslopes.

•Useonlyapprovedhitches.Towonlywithamachinethat

hasahitchdesignedfortowing.Donotattachthismachine

exceptattheapprovedhitchpoint.

•Followthemanufacturer'srecommendationsforweight

limitsfortowedequipmentandtowingonslopes.Use

counterweightsorwheelweightsasdescribedinthetowing

vehicleoperator'smanual.

•Donotturnsharply.Useadditionalcautionwhenturningor

operatingunderadversesurfaceconditions.Usecarewhen

reversing.Toavoidjack-kning,donotallowtowingvehicle

wheelstocontacttowbar.

•Donotshifttoneutralandcoastdownhill.

KEEP RIDERS OFF TOWED ATTACHMENT

•Keepridersofftowedattachment.

•Ridersonatowedattachmentaresubjecttoinjury,suchas

beingstruckbyobjectsandbeingthrownofftheattachment

duringsuddenstarts,stopsandturns.

•Ridersobstructtheoperator'sview,resultinginthe

attachmentbeingusedinanunsafemanner.

•Keepridersoffoftowbar.

KEEP BODY PARTS FROM UNDER TOW BAR

Beforedisconnectingthismachinefromtowingvehiclehitch

plate:

•Stoponlevelground.

•Stoptowingvehicleengine.

•Locktowingvehicleparkbrake.

•Blockwheelsofthemachine.

•Makesurebodypartsarenotundertowbar.

L-1762 Rev. E 4

PARTS REFERENCE

STOP

Installation Questions?

Missing Parts?

Replacement Parts?

Please call Customer Service

Department Toll Free

877.728.8224 or

customerservice@brinly.com

DON’T GO BACK

TO THE STORE!

3

5

5

4

17

10

11

12

12

15

15

13

13

15

15

15

14

29 32

7

9

86

8

7

32

32

32

32

30

30

30

20

32

32

33

31

32

2

21

24 24

24

24

24

25

25

25

22

22

23

23

20

20

20

20

24

24

18

16

16

27

26

26

26

19

28

28

31

L-1762 Rev. E

5

PARTS LIST

ITEM NO. DESCRIPTION MODEL PA-40 BH MODEL PA-48 BH

PART NO. QTY. PART NO. QTY.

1 Instructions L-1762 1 L-1762 1

2Clevis R-892-10 2R-892-10 2

3 CautionLabel R-1946 1 R-1946 1

4LogoDecal B-5922 1 B-5925 1

5SidePlate B-4851-10 2B-4901-10 2

6TrayWithLabels B-6173-BH 1 B-6257-BH 1

7 TowBar B-6259-10 2B-6259-10 2

8 HexBolt,5/16"x1" 2M1016P 42M1016P 4

9 PluggingSpoon B-4855-10 24 B-4855-10 32

10 AxleAssembly B-5700-10 1 B-5702-10 1

11 LiftHandleAssembly B-5698-10 1 B-5698-10 1

12 EndTubeAssembly B-5309-10 2B-4862-10 2

13 CenterTubeAssembly B-5311-10 1 B-4865-10 2

14 HandleGrip B-4867 1 B-4867 1

15 3/4"NylonBearing B-4866 6B-4866 8

16 TransportWheel B-6174 2B-6174 2

17 HitchPin B-3861 1 B-3861 1

18 HairPinCotter D-146P 1 D-146P 1

19 HexBolt,5/16"x1-1/2" 2M1024P 1 2M1024P 1

20 HexBolt,5/16"x3/4" 2M1012P 37 2M1012P 48

21 HexBolt,5/16"x1-1/4" 2M1020P 1 2M1020P 1

22 HexBolt,5/8"x4" 2M2064P 22M2064P 2

23 LockWasher,5/8" 40M2000P 240M2000P 2

24 FlatWasher,5/16" 45M1111P 12 45M1111P 45

25 FlatWasher,5/8" 45M2121P 445M2121P 4

26 Mach.Bushing,3/4" B-676P 6B-676P 6

27 TransportLockPin B-3307-S 1 B-3307-S 1

28 HexLockNut,5/16" B-1674P 25 B-1674P 33

29 CarriageBolt,5/16"x2-1/4" 11M1036P 211M1036P 2

30 HexNut,5/8" 30M2000P 430M2000P 4

31 MountBracket B-6171-10 2B-6258-10 2

32 NylonLockNut,5/16" B-4786 21 B-4786 24

33 CenterPlate N/A N/A B-4902-10 1

L-1762 Rev. E 6

ASSEMBLY

TOOLS REQUIRED:

1/2"Wrench(2)

SlipJointPliers

TapeMeasure

15/16"Wrench(2)

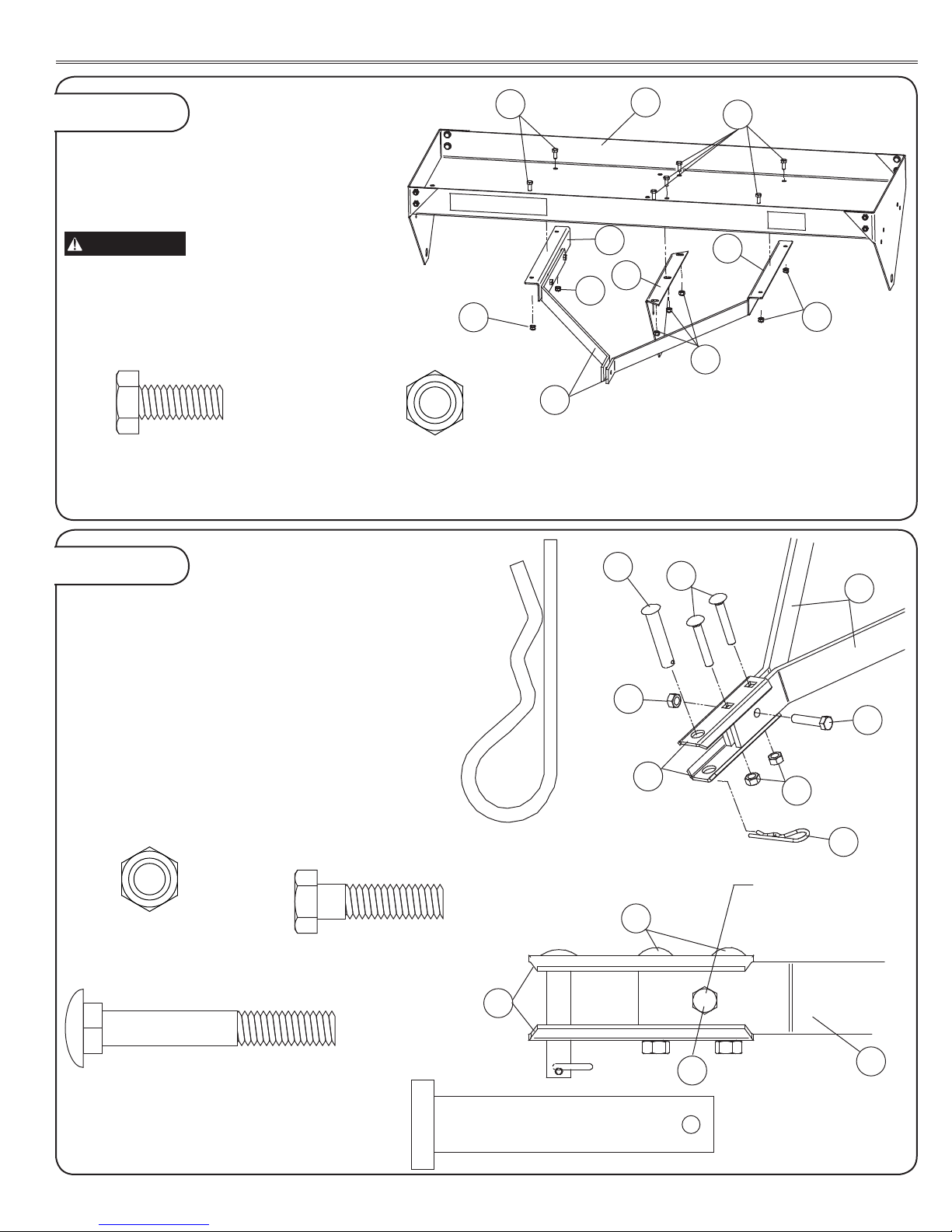

1a.AssembleSidePlates(5)to

Tray(6)asshown.

Pre-assembletheFlatWashers(24)

totheHexBolts(20).Insertthe

BoltandWasherAssemblyfromthe

insideofthetray.SecurewithNylon

LockNuts(32).

Whentighteningthebolts,forthePA-48BHmaintainadistanceof

48"to48-1/8"insidetoinsideofSidePlates(5).ForthePA-40BH

maintainadistanceof41"to41-1/8"insidetoinsideofSidePlates(5).

Figure 1 SIDE PLATE ASSEMBLY

(20)

HexHeadBolt,5/16"x3/4"

Qty.8

(8)

HexHeadBolt,5/16"x1"

Qty.4

(32)

NylonLockNut,5/16"

Qty.8

(32)

NylonLockNut,5/16"

Qty.4

(24)

FlatWasher,5/16"

Qty.8

(24)

FlatWasher,5/16"

Qty.4

2a.AssembleMountBracket(31)totheoutside

ofTowBars(7)asshown.Pre-assemblethe

FlatWashers(24)totheHexBolts(8).Insertthe

BoltandWasherAssemblyfromoutsideofthe

MountBracket.LooselytightenwithNylonLock

Nuts(32).

Figure 2 BRACKET ASSEMBLY

32

32 20

5

6

24

IMPORTANT

32

31

24

24

8

7

8

L-1762 Rev. E

7

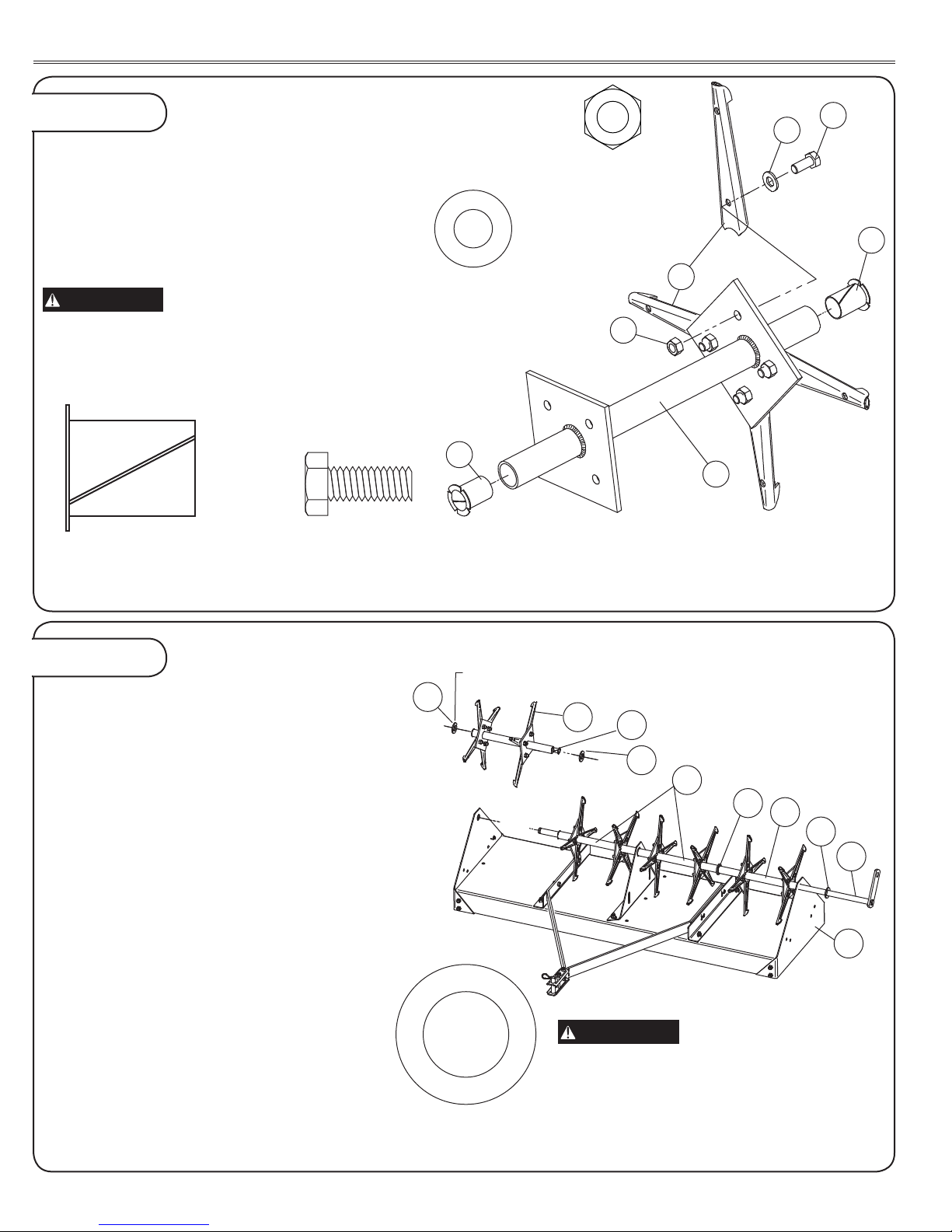

17

2

32

29 7

21

32

18

2

29

21 7

HexBolt(21)Goes

BetweenTheTwo

CarriageBolts(29)

(20)

HexHeadBolt,5/16"x3/4"

Qty.4forPA-40BH

Qty.7forPA-48BH

(21)

HexHeadBolt,5/16"x1-1/4"

Qty.1

(32)

NylonLockNut,5/16"

Qty.4forPA-40BH

Qty.7forPA-48BH

(32)

NylonLockNut,5/16"

Qty.3

(29)

CarriageBolt,5/16"x2-1/4"

Qty.2 (17)

HitchPin

Qty.1

(18)

HairpinCotter,1/8"

Qty.1

3a.AssembleMountBrackets(31)toTray(6)as

shown.InserttheBoltsfromthetopsideofthe

Tray.LooselytightenwithNylonLockNuts(32).

IMPORTANT

Traywithlabelfacesforward.

ForPA-48BHmodelinstallCenterPlate(33)

toTray(6)asshown.InserttheBoltsfromthe

topsideoftheTray.LooselytightenwithNylon

LockNuts(32).

4a.AssembletheClevis(2)toTowbars(7)as

shown.InstallCarriageBolts(29)andNylon

LockNuts(32)ngertight.NextinstallHexBolt

(21)andNylonLockNut(32)ngertight.

4b.InsertHitchPin(17)inClevis(2)andsecure

withHairpinCotter(18).GraspHitchPinandpull

forward.

4c.Tightensecurelyallfastenersinstalledinstep

4a.Thentightensecurelyallhardwareinstalled

inSteps2through3.

Figure 3

Figure 4

TOW BAR ASSEMBLY

CLEVIS ASSEMBLY

ASSEMBLY

6

7

20 20

32

32

32

32

33

31 31

L-1762 Rev. E 8

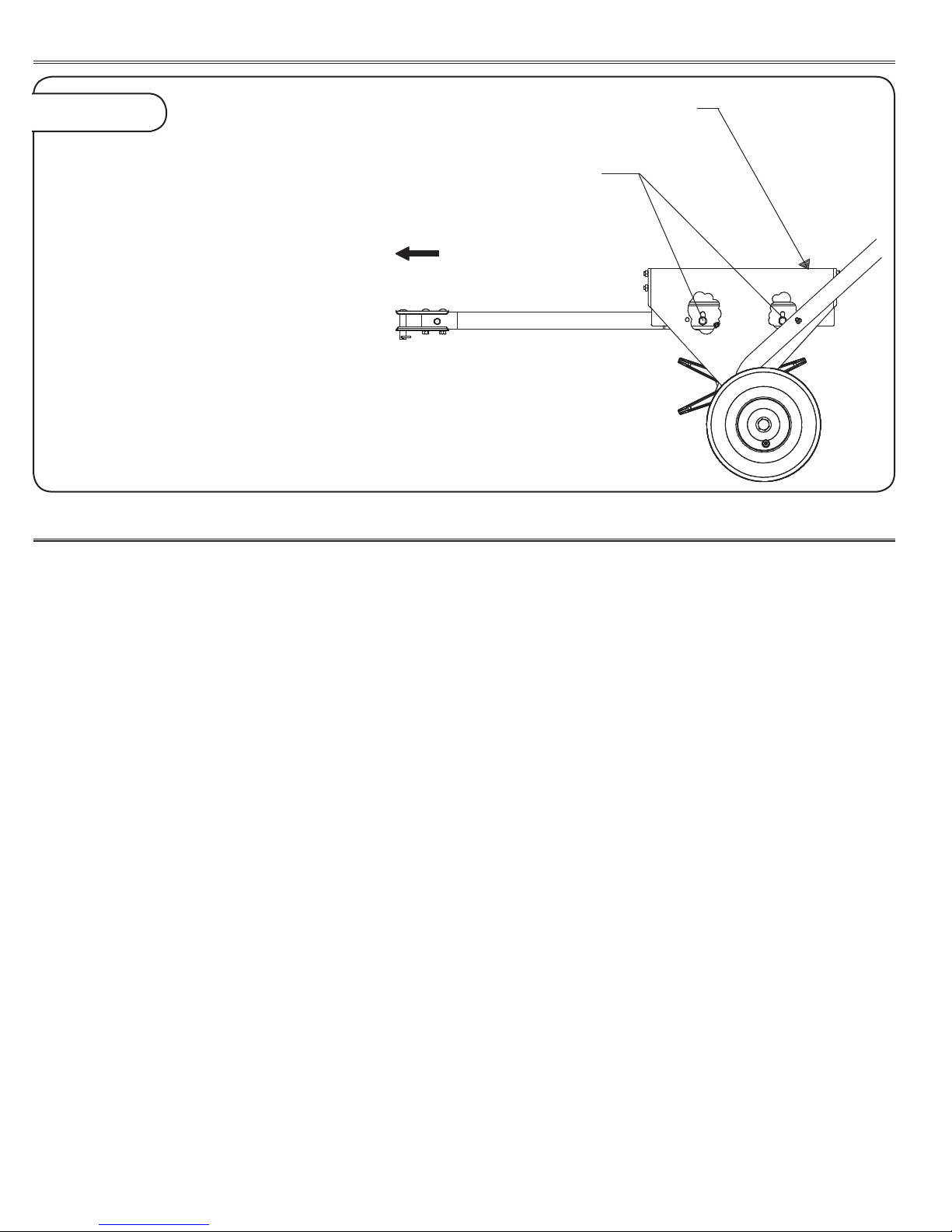

5

10

12 15

13

12

26

26

26

26

9

15

13

28

15

20

24

(20)

HexHeadBolt,5/16"x3/4"

Qty.24forPA-40BH

Qty.32forPA-48BH

(15)

NylonBearing,3/4"I.D.

Qty.6forPA-40BH

Qty.8forPA-48BH

(28)

LockNut,5/16"

Qty.24forPA-40BH

Qty.32forPA-48BH

5a.AssemblePluggingSpoons(9)toeach

weldedplate(sideoppositewelds)ofalltheTube

Assemblies(12and13)asshown.ForPA-48H,

pre-assembleHexBolts(20)andFlatWashers

(24).NOTE:PA-40BHdoesnotuseFlatWashers.

InstalltheBolt(andWasherAssemblies)through

PluggingSpoonsandsecurewithLockNuts(28).

IMPORTANT

Roundedpartofspoonts

againstthetubetolockinplace.

5b.InsertaNylonBearing(15)intoeachendof

thetubeassemblies.

6a.TheEndTubeAssemblies(12)haveone

plateapproximately1-1/8"fromtheendofthe

tube.TheCenterTubeAssemblies(13)have

eachplateapproximately2-3/4"fromtheendof

thetube.

6b.PlaceaMachineryBushing(26)overAxle

Assembly(10).InsertAxleAssemblythrough

RightSidePlateandinstallinthefollowingorder:

EndTubeAssembly(12)withshorthubend•

nexttosideplate.

MachineryBushing(26).•

CenterTubeAssembly(13).•

ForPA-48BHonly:

CenterPlate(33)andthenanotherCenter•

TubeAssembly(13).

Forallmodels:

MachineryBushing(26).•

EndTubeAssembly(12)withshorthubend•

nexttosideplate.

OneormoreMachineryBushings(26)as•

requiredtoeliminateanysideplayinaxle

assembly.

OneormoreMachineryBushingsasrequiredto

eliminateanysideplayinaxleassembly.

Figure 5

Figure 6

TUBE ASSEMBLY

TINE ASSEMBLY

ASSEMBLY

(24)

FlatWasher,5/16"

Qty.32usedon

PA-48BHONLY!

(26)

MachineryBushing,3/4"

Qty.6

MakesureNylonBearings

(15)areinsideTube

Assemblies(InstalledinStep5b)

IMPORTANT

L-1762 Rev. E

9

22

25

25 30

11

23 30

32

27

16

19

14

11 32

10

7a.PushtheAxleAssembly(10)throughtheleft

sideplateasfaraspossibleandrotatesothe

holeintheatplatefacestotherearasshown.

InstalltheLiftHandleAssembly(11)withthe

weldedtubefacingout,totheAxleAssembly

(10).SecurewithHexBolt(19)andNylonLock

Nut(32).

7b.SlipHandleGrip(14)overendofLiftHandle

Assembly(11).NOTE:Soapywaterwillease

theassembly.

7a.Pre-assembleaxlebolt.InstallFlatWasher

(25)overHexBolt(22).Slideassemblythrough

wheel,noteorientation.PlaceFlatWasher(25)

andHexNut(30)onBoltandthreadonasfaras

possible,stillallowingwheeltorotatefreely.

7b.InstallthroughholesinLiftHandle(11)and

AxleAssembly(10).InstallLockWasher(23)

andHexNut(30).TighteninsideHexNutwhile

holdingHexNutnexttowheelstationary.

7c.InsertTransportPin(27)inrearholesame

sideasLiftHandleAssembly(11)asshown.

SecurewithNylonLockNut(32).

NOTE: Make sure the Axle Assembly

Flat Plate and Lift Handle Assembly are

pointing towards the rear as shown.

IMPORTANT: The wheel hub is offset to one

side. Make sure the extended offset is installed

toward plug aerator.

Figure 7

Figure 8

HANDLE ASSEMBLY

WHEEL ASSEMBLY

ASSEMBLY

(19)

HexHeadBolt,5/16"x1-1/2"

Qty.1

(27)

TransportLockPin

Qty.1

(32)

NylonLockNut,5/16"

Qty.1

(32)

NylonLockNut,5/16"

Qty.1

(14)

HandleGrip

Qty.1

(NotToScale)

(25)

FlatWasher,5/8"

Qty.4

(23)

LockWasher,5/8"

Qty.2

(30)

HexNut,5/8"

Qty.4

(22)

HexBolt,5/8"x4"

Qty.2

L-1762 Rev. E 10

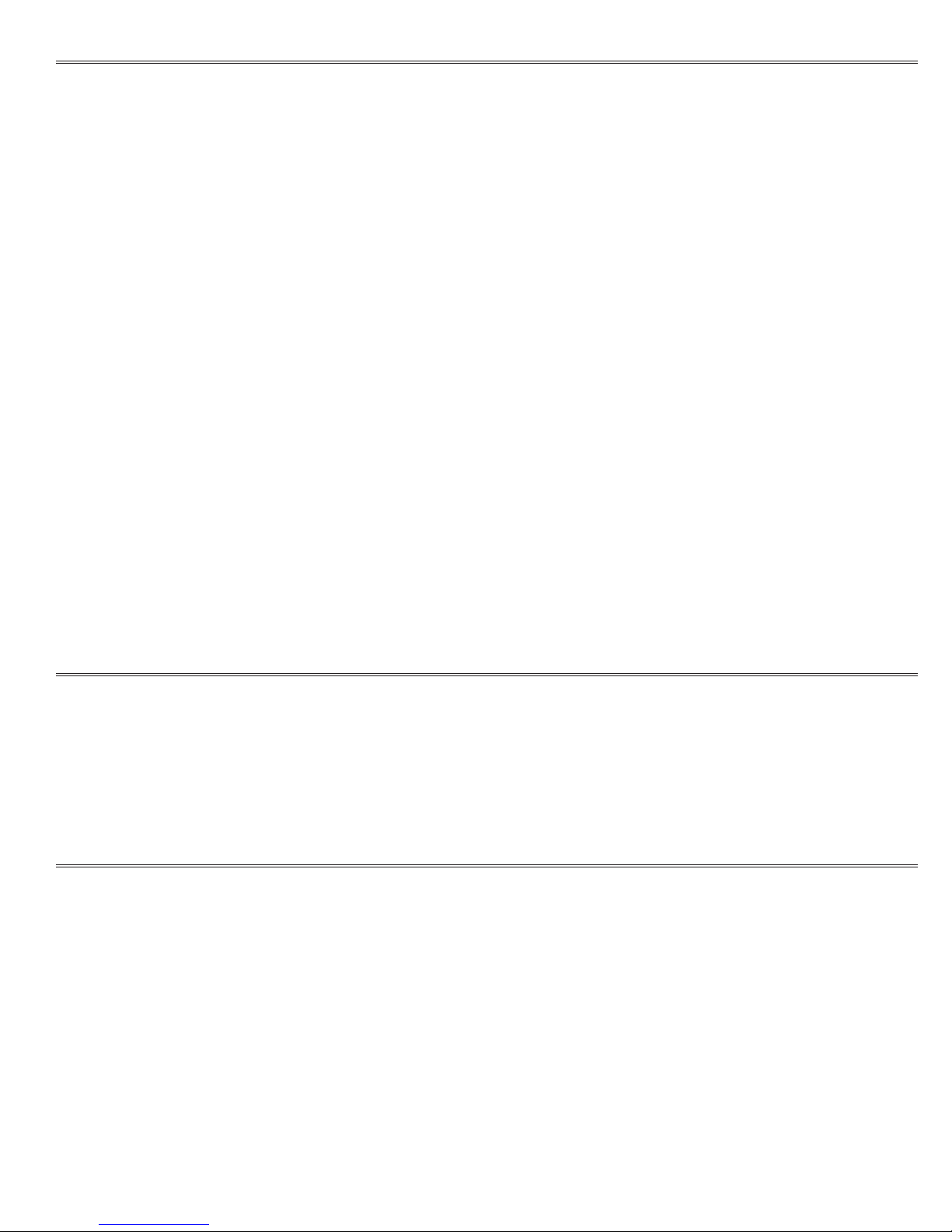

9a.ThenalstepistolevelTray(6)using

adjustmentboltsasshownhereandinstalledin

Step2.Toadjust,loosenBoltsandpositionTow

Barsuntillevel.

NOTE: The adjustment is made with the

aerator attached to the rider or lawn/garden

tractor with the wheels in transport position.

AdjustThisSurfaceToLevel

AdjustmentBolts

ToTractor

Figure 9 LEVELING

ASSEMBLY

OPERATION

CAUTION

Afterrstthirtyminutesofusecheckallfastenersfor

tightness.

Toavoiddamagetospoons,alwaysengagetransportwheels

toraisethespoonswhencrossingconcreteorasphaltwalks,

drives,orroads.

UsetheAeratoronlyonanestablishedlawn,neveronnewly

laidsod.

Toavoidpossiblepersonalinjuryand/orequipmentnever

exceedtherecommendedoperatingspeedrangeof3to5

MPH.

OnlytowAeratorbehindvehiclesforwhichitwasdesigned,

ridersandlawn/gardentractors.

Donotstand/rideonAerator,bodilyinjurycouldresult.

AlwaysdisconnectAeratorfromtractorwhencleaningor

servicingunit.

NeverexceedtheWeightTraycapacity.

DoNotattempttodisconnectAeratorfromtractorwithweight

inTray.

Whenbacking,carefullybackstraighttoavoidJack-kning,

whichcouldresultindamagetoequipment.

WHEN TO AERATE

YourAeratorshouldnotbeusedwhenlawnconditions

aretoowetortoodry.Todeterminecondition,digasmall

amountofyoursoil(aboutthreeinchesdeep):

Ifsoilappearspowderyandbrittle-itistoodry.Waituntila

laterdate,theTineswillnotpenetrateproperly.

Ifsoilappearsdamp,rollasmallamountintoaballinthe

palmofyourhand-ifitformsaball,thenitistoowet.Ideally,

thesoilshouldfallapartwhenrolledinthepalmofyour

hand.Waituntilalaterdateforsoiltodry.Ifsoilistoowet,

theTineswillnotoperateeffectivelyandyourtractorcould

loosetraction,causinglawndamage.

MOUNTING AND TRANSPORTING

Attachaeratortoyourriderorlawn/gardentractorusingPin

andHairpinCotterSupplied.

ToPlaceinTransportPosition:

PushREARWARDonLiftHandle(11)towardsTransport•

LockPininSidePlate.PullHandleOUTandmoverover

LockPin.Aeratornowrestsonwheels.

ToPlaceinOperatingPosition:

PullOUTonLiftHandle(releasingfromTransport•

LockPin)andmoveFORWARD.Aeratornowrestson

PluggingSpoons.

L-1762 Rev. E

11

MAINTENANCE

SPECIFICATIONS

SERVICE

Shouldrustdevelop,sandlightlyandthenpaintareawith

enamel.

Periodicallycheckallfastenersfortightness.

IMPORTANT:

ApplyadropoflubricatingoiltoeachNylonBearingandthe

AeratorAxlebeforeeachuse.

Topreventrustonpluggingspoons,applyalightcoatof

oilontheworkingareasofspoonsaftereachuse.Should

rustappearonanyotherpartofyourAerator,sandlightlyto

removerustandcoatlightlywithenamel.

Pluggingspoonsaremanufacturedwithspecialsteelsand

areheattreatedtoresistwearofabrasivesoil.Striking

sub-surfaceobjectscancausespoonbreakage.Contact

ourCustomerServiceDepartmenttopurchasereplacement

PluggingSpoons(Part#B-4855-10).See“GETTING

QUALITYSERVICE”.

Periodicallycheckthespoonsremoveanydebriswhich

mightbuildupandrestricttheiraction.

Aftereachuse,serviceunitasdescribedandstoreinadry

area,shieldingtinestoavoidinjury.

PA-48

MaximumTowingSpeed............................................. 5MPH

AeratorCapacity.........................................................200lbs.

EmptyWeight...............................................................90lbs.

MaximumTowingWeight............................................290lbs.

RecommendedTirePressure........................Semipneumatic

USE OF ADDITIONAL WEIGHT

Theweightrequiredtogivearecommendedpenetration

ofapproximatelytwotothreeincheswillvaryaccording

tosoiltypeandconditions.Concreteblocks,patioblocks,

sandbags,oranyothertypeofweightcanbeaddedto

AeratorTrayasrequired.Weightcanbesecuredbyusing

tiedownsthroughholesinTrayFlanges.Tiedownsarenot

furnishedwithyourunit.UsuallythreeConcreteBlockswill

besufcient,butmoreorlessweightmayberequired.

DriveyourtractortolocationtobeAerated.•

LowerAeratortoOperatingPosition.•

DrivetheTractorFORWARDapproximatelytenfeetand•

stop.

Observetheoperation-thereshouldbeaPlughole•

approximatelyeverytentotwelveinchesandnotmore

thanthreeinchesdeep.

Addorremoveweighttoobtainthiscondition.•

MAINTENANCE:

Thekeytoyearsoftrouble-freeserviceistokeepyour

Aeratorcleananddry.

NeverallowwetmaterialtoremaininTrayforextended

periodsoftime.

Occasionallycheckallmovingpartsforfreemovementand,

ifnecessary,lubricatewithoil.

PA-40

MaximumTowingSpeed............................................. 5MPH

AeratorCapacity.........................................................150lbs.

EmptyWeight...............................................................66lbs.

MaximumTowingWeight............................................216lbs.

RecommendedTirePressure........................Semipneumatic

Quality Continues With Quality Service

Weprovideaprocesstoremedyyourquestionsorproblems.

Followthestepsbelowtogetanswerstoanyquestionsyoumayhaveaboutyourproduct,ortoorderreplacementparts:

1.Refertoyourattachmentandmachineoperatormanuals.

2.InNorthAmericaandCanada,call1-877-728-8224andprovideproductserialnumberandmodelnumber.

L-1762 Rev. E

ThelimitedwarrantysetforthbelowisgivenbyBrinly-Hardy

Companywithrespecttonewmerchandisepurchasedand

usedintheUnitedStates,itspossessionsandterritories.

Brinly-HardyCompanywarrantstheproductslistedbelow

againstdefectsinmaterialandworkmanship,andwillat

itsoption,repairorreplace,freeofcharge,anypartfound

tobedefectiveinmaterialsorworkmanship.Thislimited

warrantyshallonlyapplyifthisproducthasbeenassembled,

operated,andmaintainedinaccordancewiththeOperator’s

manualfurnishedwiththeproduct,andhasnotbeensubject

tomisuse,abuse,commercialuse,neglect,accident,

impropermaintenance,alteration,vandalism,theft,re,

water,ordamagebecauseofotherperilornaturaldisaster.

NormalWearPartsorcomponentsthereofaresubject

toseparatetermsasfollows:Allnormalwearpartsor

componentfailureswillbecoveredontheproductfora

periodof90days.

Partsfoundtobedefectivewithinthewarrantyperiodwill

bereplacedatourexpense.Ourobligationunderthis

warrantyisexpresslylimitedtothereplacementorrepair,

atouroption,ofpartsfoundtobedefectiveinmaterialand

workmanship.

HOW TO OBTAIN SERVICE:Warrantypartsreplacements

areavailable,ONLYWITHPROOFOFPURCHASE,through

ourPullBehindAccessoriesCustomerServiceDepartment.

Call877-728-8224.

Thislimitedwarrantydoesnotprovidecoverageinthe

followingcases:

Routinemaintenanceitemssuchaslubricantsandlters.•

Normaldeteriorationoftheexteriornishduetouseor•

exposure.

Transportationand/orlaborcharges.•

Thewarrantydoesnotincludecommercialand/orrental•

use.

No implied warranty, including any implied warranty

of merchantability of tness for a particular purpose,

applies after the applicable period of express written

warranty above as to the part as identied below.

No other express warranty whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to

any product, shall bind Brinly-Hardy Co. During the

period of the warranty, the exclusive remedy is repair or

replacement of the product as set forth above.

The provisions as set forth in this warranty provide

the sole and exclusive remedy arising from the sale.

Brinly-Hardy Co. shall not be liable for incidental or

consequential loss or damage including, without

limitation, expenses incurred for substitute or

replacement lawn care services or for rental expenses to

temporarily replace a warranted product.

Somestatesdonotallowtheexclusionorlimitationof

incidentalorconsequentialdamages,orlimitationsonhow

longanimpliedwarrantylasts,sotheaboveexclusionsor

limitationsmaynotapplytoyou.

Duringthewarrantyperiod,theexclusiveremedyis

replacementofthepart.Innoeventshallrecoveryofany

kindbegreaterthattheamountofthepurchasepriceofthe

productsold.Alterationofsafetyfeaturesoftheproductshall

voidthiswarranty.Youassumetheriskandliabilityforloss,

damage,orinjurytoyouandyourpropertyand/ortoothers

andtheirpropertyarisingoutofthemisuseorinabilitytouse

thisproduct.

Thislimitedwarrantyshallnotextendtoanyoneotherthan

theoriginalpurchaserortothepersonforwhomitwas

purchasedasagift.

HOW STATE LAW RELATES TO THIS WARRANTY:This

limitedwarrantygivesyouspeciclegalrights,andyoumay

alsohaveotherrightswhichvaryfromstatetostate.

IMPORTANT:TheWarrantyperiodstatedbelowbeginswith

thePROOFOFPURCHASE.Withouttheproofofpurchase,

theWarrantyperiodbeginsfromthedateofmanufacture

determinedbytheserialnumbermanufacturingdate.

SPREADER WARRANTY PERIOD:

Thewarrantyperiodforthisaeratorisasfollows:Steelframe

parts–2Years.Tires,wheels,andpluggingspoonsare

normalwearitems-90days.

MANUFACTURER'S LIMITED WARRANTY FOR

Pull Behind Accessories

Other manuals for PA-40 BH

2

This manual suits for next models

1

Table of contents

Other Brinly Tiller manuals

Brinly

Brinly VV-100 User manual

Brinly

Brinly SAT2-40BH-S User manual

Brinly

Brinly SAT-40 BH User manual

Brinly

Brinly SAT2-40BH-P User manual

Brinly

Brinly PA-40 BH User manual

Brinly

Brinly SAT-401BH User manual

Brinly

Brinly DD-550 Installation and operating instructions

Brinly

Brinly SA-400BH User manual

Brinly

Brinly SAT-40 BH User manual

Brinly

Brinly CC-1000 User manual