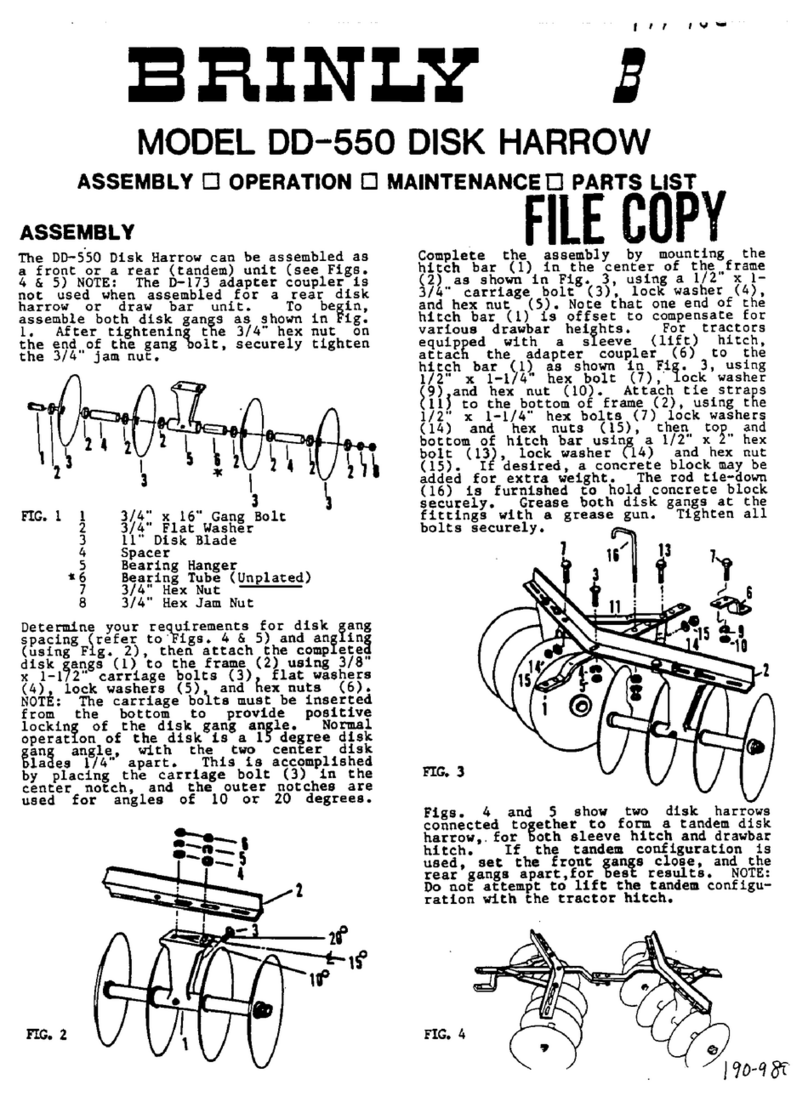

·,ASSEMBLY:

IFIG. I

Assemble lower link pins (4) to

"A"

frame halves (5 & 6),

using

5/8

11 jam nuts

(1'2),

5/8"

lock

washers

(13).,

and

5/8"

hex nuts (11).

Attach

"A"

frame halves together as shown, with spacing

plate (7). Secure with -1/2" x

1-3/4"

hex bolts (9),

lock

washers (14), and hex nuts (10) (in front holes only). FINGER

TIGHTEN.

.Assemble frame angles (1) to HAUframe assembly as shown,

securing .with 1

(2"

x

1-3/4"

Hex Bolts (9)

1/2"

plain washers

(15),

1/2"

lock

washers (14), and 1/2" hex nuts (10). FINGER

TIGHTE-N.

Assemble the two frame

struts.

(2), to rear holes of "AU

,'frame, securing with

1/2"

x

1-3/4"

hex bolts (9),

lock

washers

(14), and hex nuts (10). FINGER TIG-HTEN.

FIG. II

Swing frame struts (2) into

posltlcn

shown, and

assemble·

lawai ends to frame angies

(i)

using two

1/2"

x1-3/4"

hex

bolts (9),

1/2"

plain washers (IS):, 1

/~,

Jock washers (14),

and 1/2" hex nuts (10). (NOTE -Frame is shown' assembled

in the most common 900position.) Frame :an9le

·m·ay

be as

...

sembled or adjusted to

larger

or

smaller angie

as 'desired by

position that frame struts (2) are attached to frame angl'es

(1). (See Fig.

11.)

Ass.amble spring shanks (8) to frame angles (1). Assemble

two shanks at position 1. and 2. using existing frame bolt,

nut and lock washer. DO

NOT

USE

THICK

WASHERS AT

POSITION 1 AND 2.

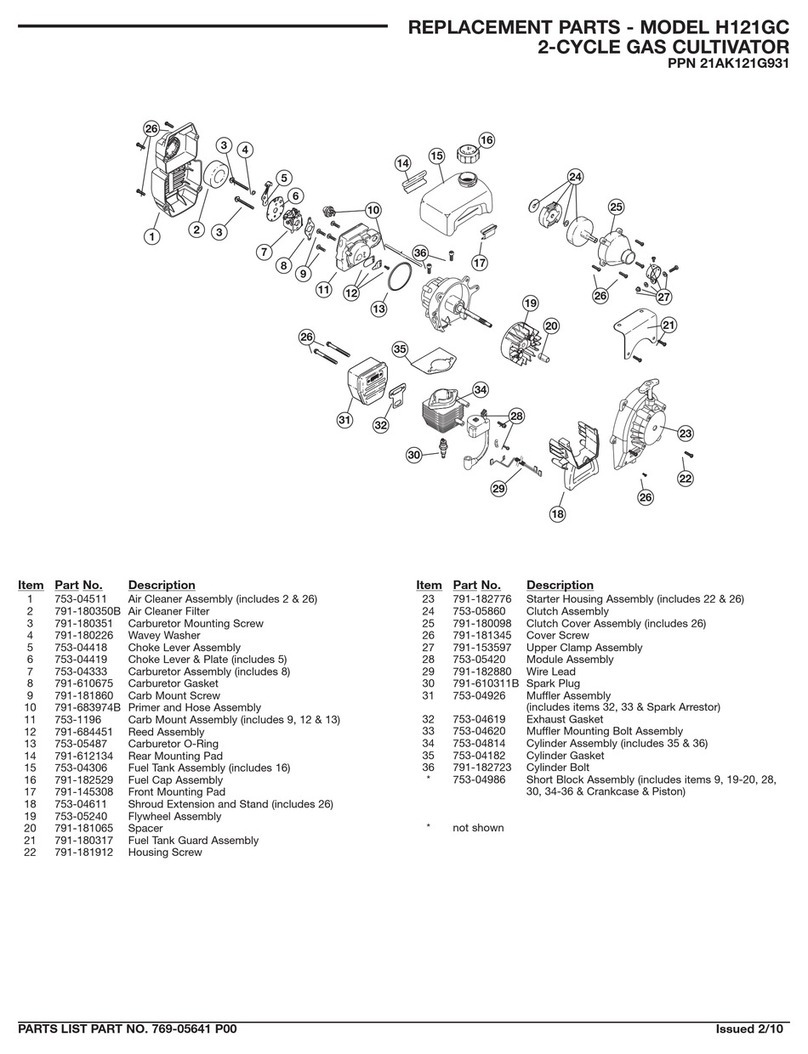

FIG.

I~I

Assemble balance of

~pring

shanks (8) as shown using.112"

x

1-3/4

11 hex bolts (9),

1/2"

plain washers (15),

1/2"

lock

washers (14), and

1/2"

hex outs (10). Use

3/8"

THICK

wash-

ers (3) between frame angle (1) and spring shanks (8). Align

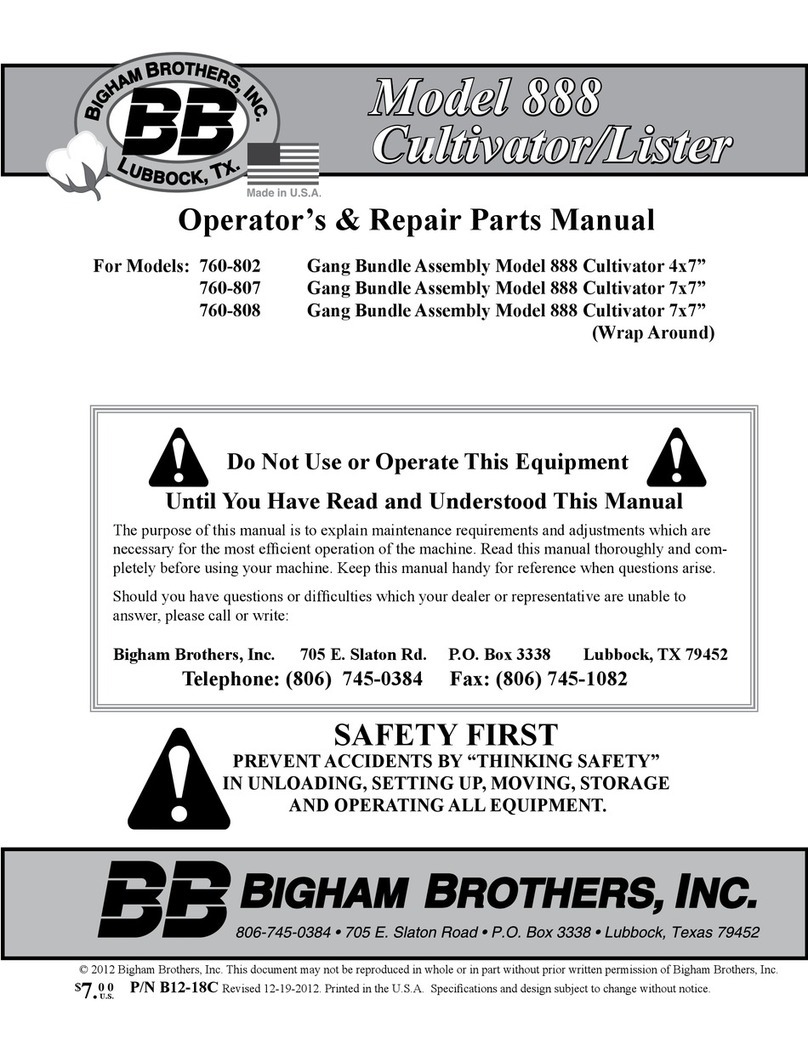

PREPARATION OF TRACTOR &HITCH:.

FIG. IV

Adjust rear wheels in or out to giv'e maximum plant foliage

clearance.

With hitch In lowered position, adjust

lift

rods until

lower

link

ball ends are approximately 8''' from ground.

........

FIG. I

FIG. III

FIG•