Bristan DUL2 SHXARFF C Wiring diagram

Other Bristan Plumbing Product manuals

Bristan

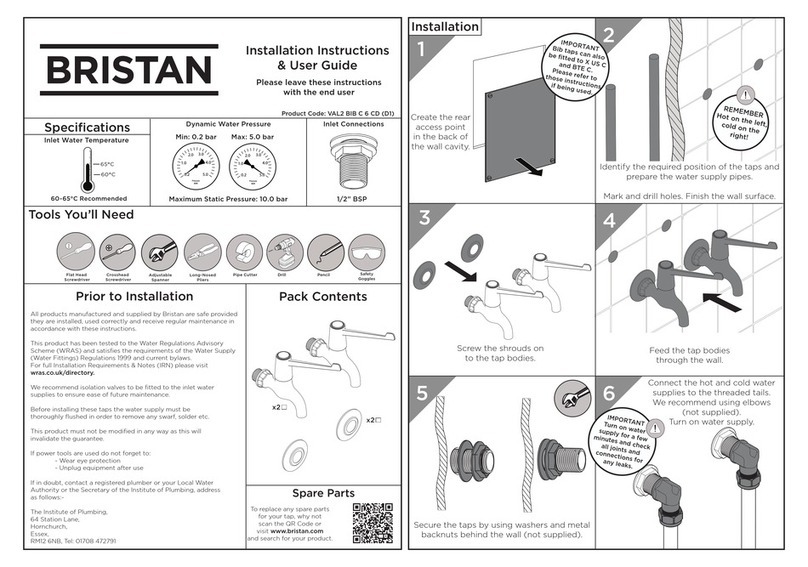

Bristan VAL2 BIB C 6 CD Wiring diagram

Bristan

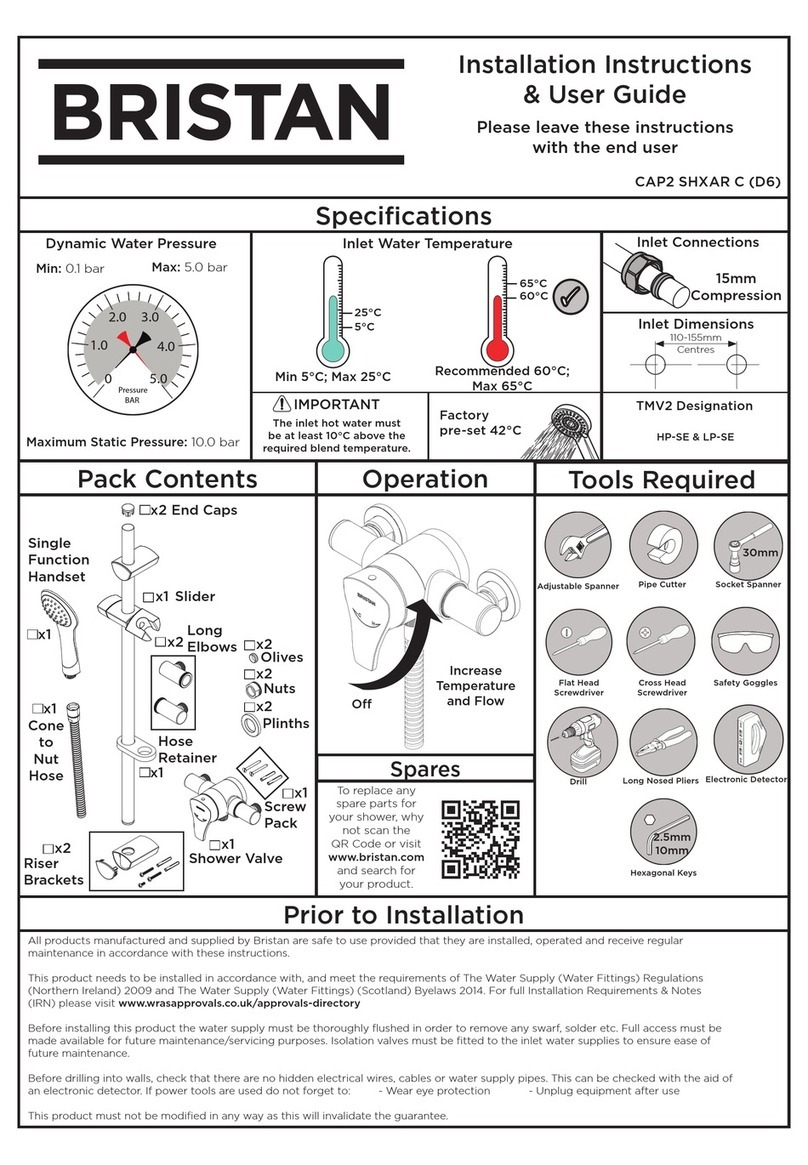

Bristan CAP2 SHXAR C (D6) Wiring diagram

Bristan

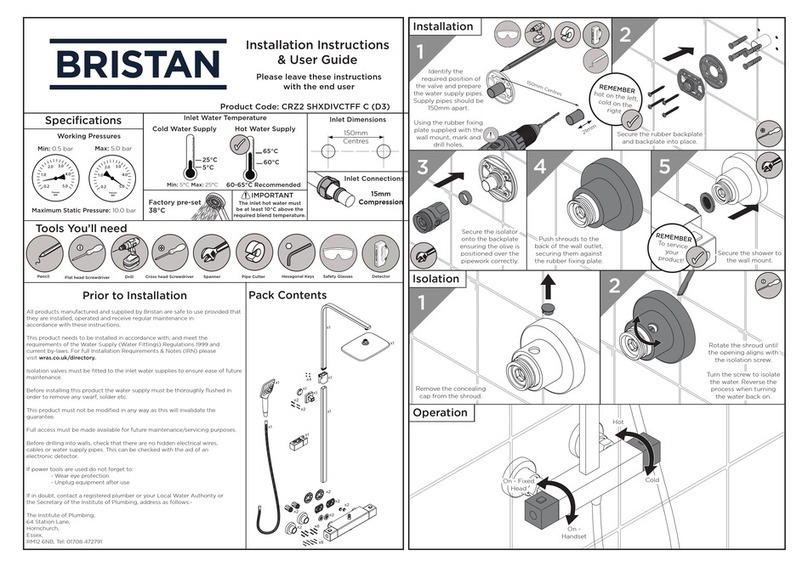

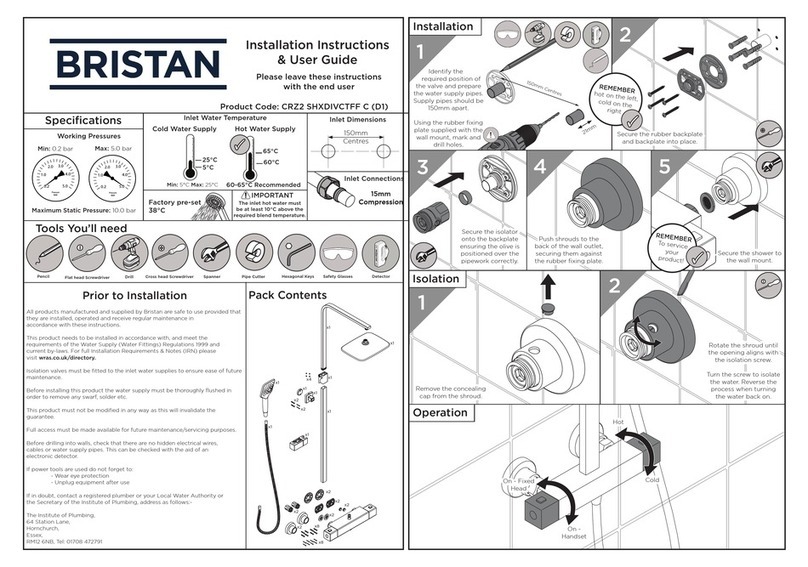

Bristan CRAZE CRZ2 SHXDIVCTFF C Wiring diagram

Bristan

Bristan Z2 DUS 1/2 C Wiring diagram

Bristan

Bristan Jute JU BSM C User manual

Bristan

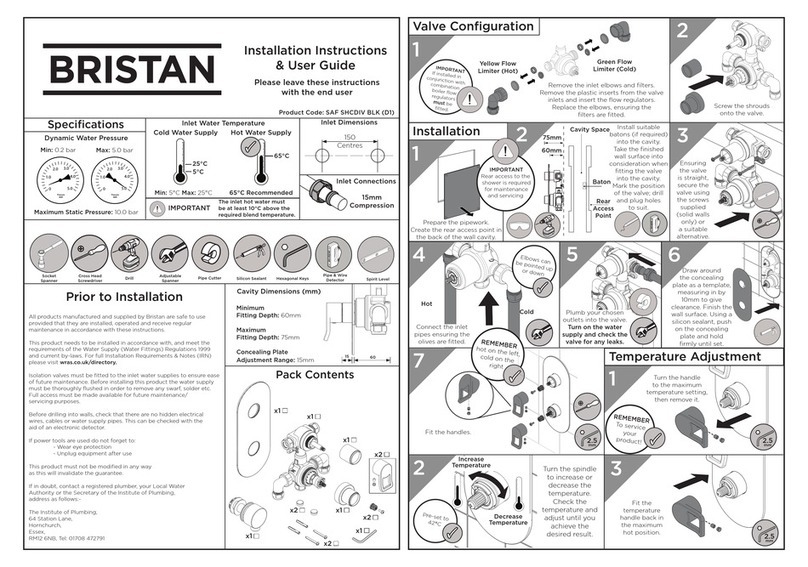

Bristan SAF SHCDIV BLK (D1) Wiring diagram

Bristan

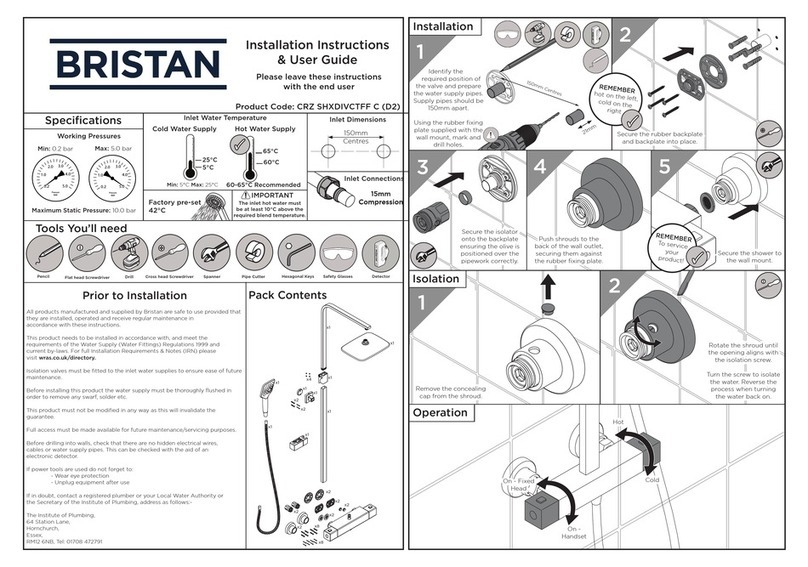

Bristan CRZ SHXDIVCTFF C Wiring diagram

Bristan

Bristan Jute JU BF C User manual

Bristan

Bristan CR SHXDIVFF C Wiring diagram

Bristan

Bristan Palermo PA BSM C User manual

Bristan

Bristan Value VAL BSM C CD Wiring diagram

Bristan

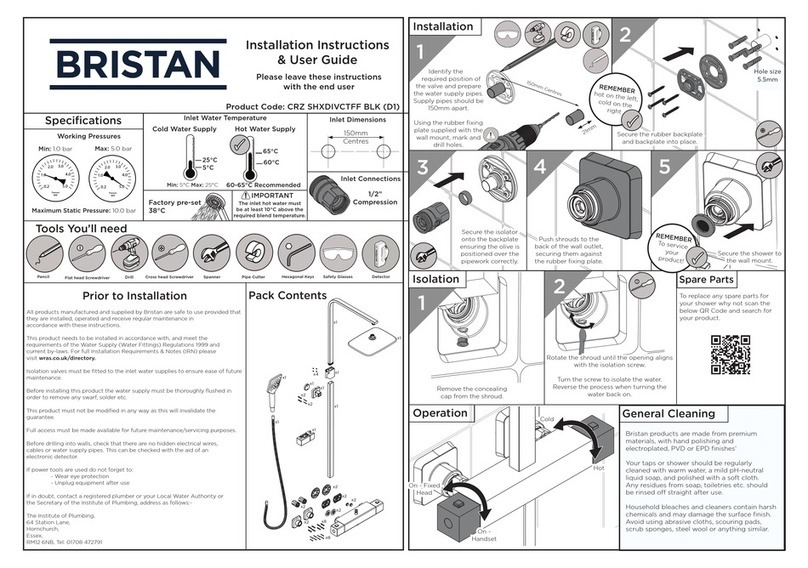

Bristan CRZ SHXDIVCTFF BLK (D1) Wiring diagram

Bristan

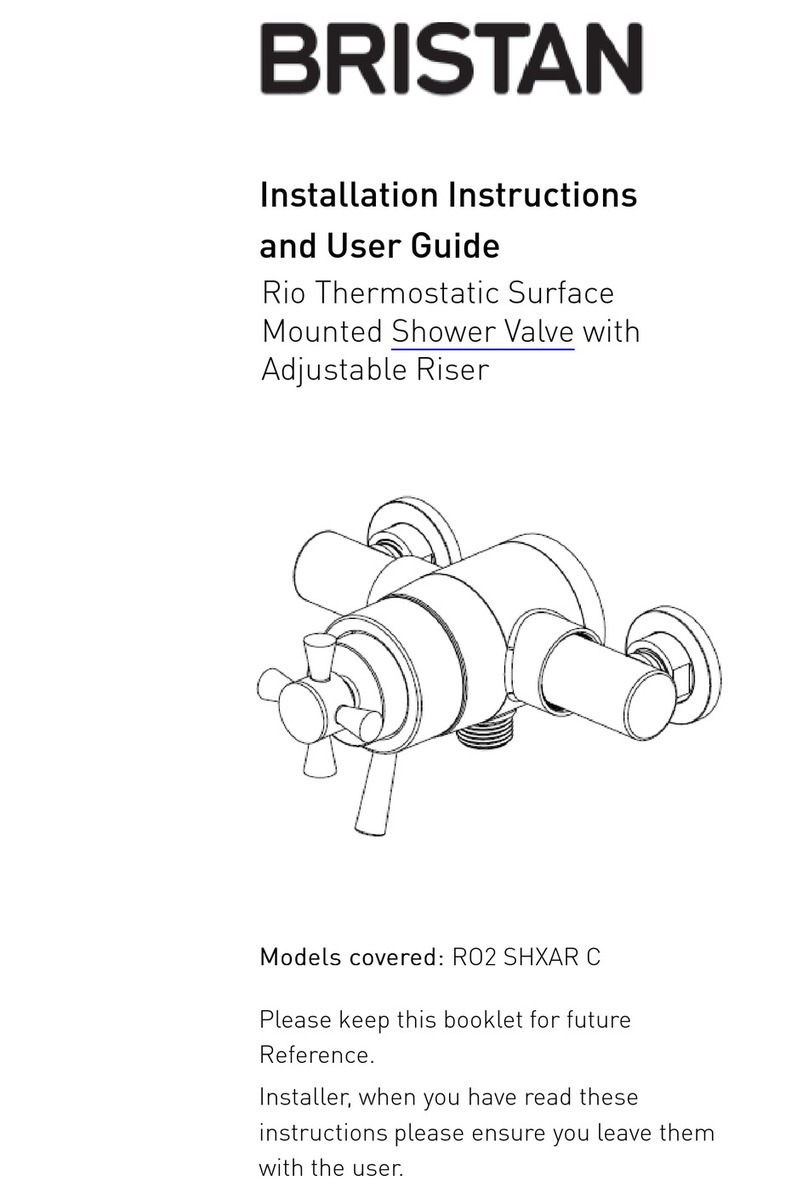

Bristan RO2 SHXAR C Mounting instructions

Bristan

Bristan IRN R001 User manual

Bristan

Bristan CRZ2 SHXDIVCTFF C Wiring diagram

Bristan

Bristan Pisa series Wiring diagram

Bristan

Bristan GLL FLEXSNK C (D1) Wiring diagram

Bristan

Bristan W BASIN07 C Wiring diagram

Bristan

Bristan WASTES W BATH09 C Wiring diagram

Bristan

Bristan WMNT11 C Mounting instructions

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

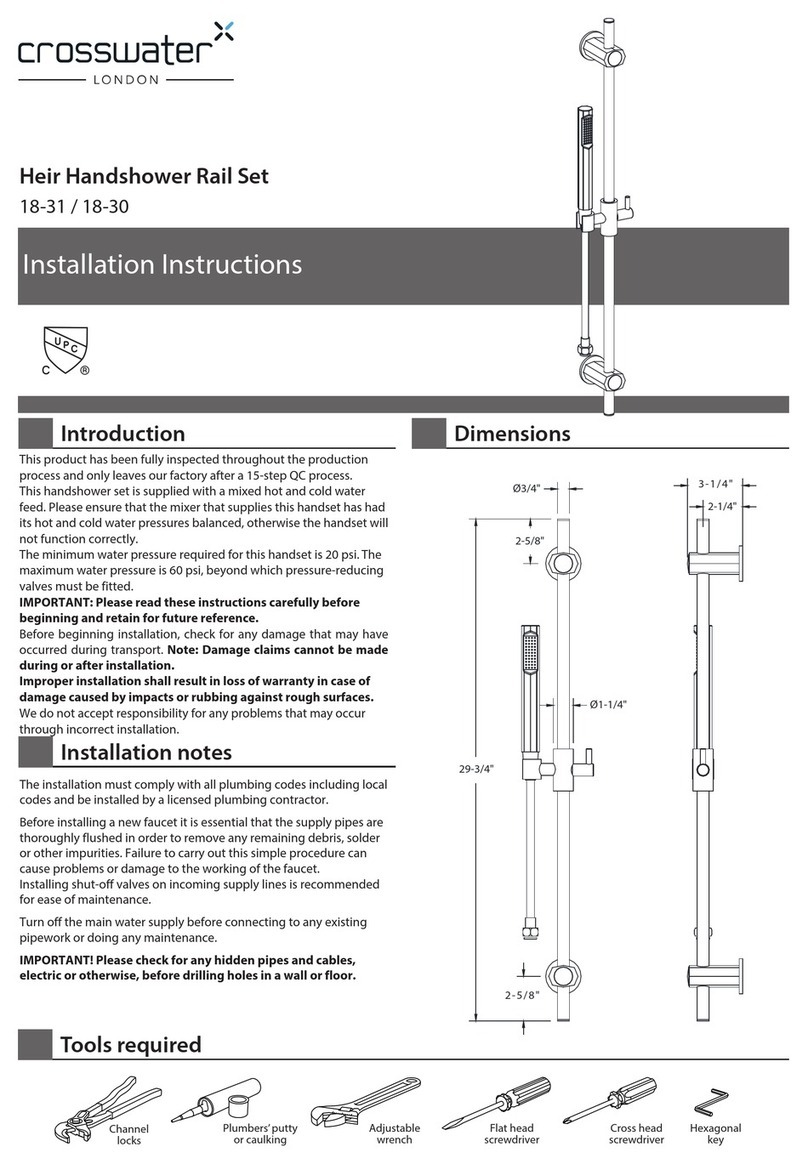

Crosswater

Crosswater Heir 18-31 installation instructions