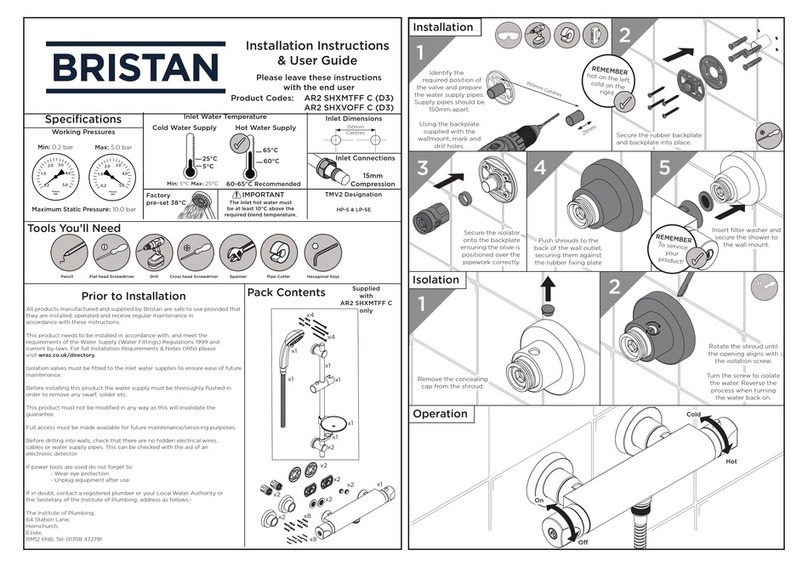

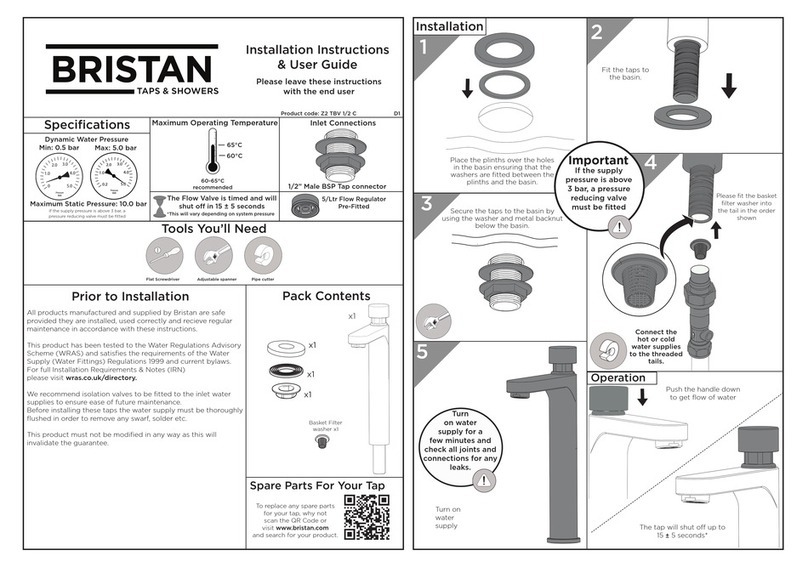

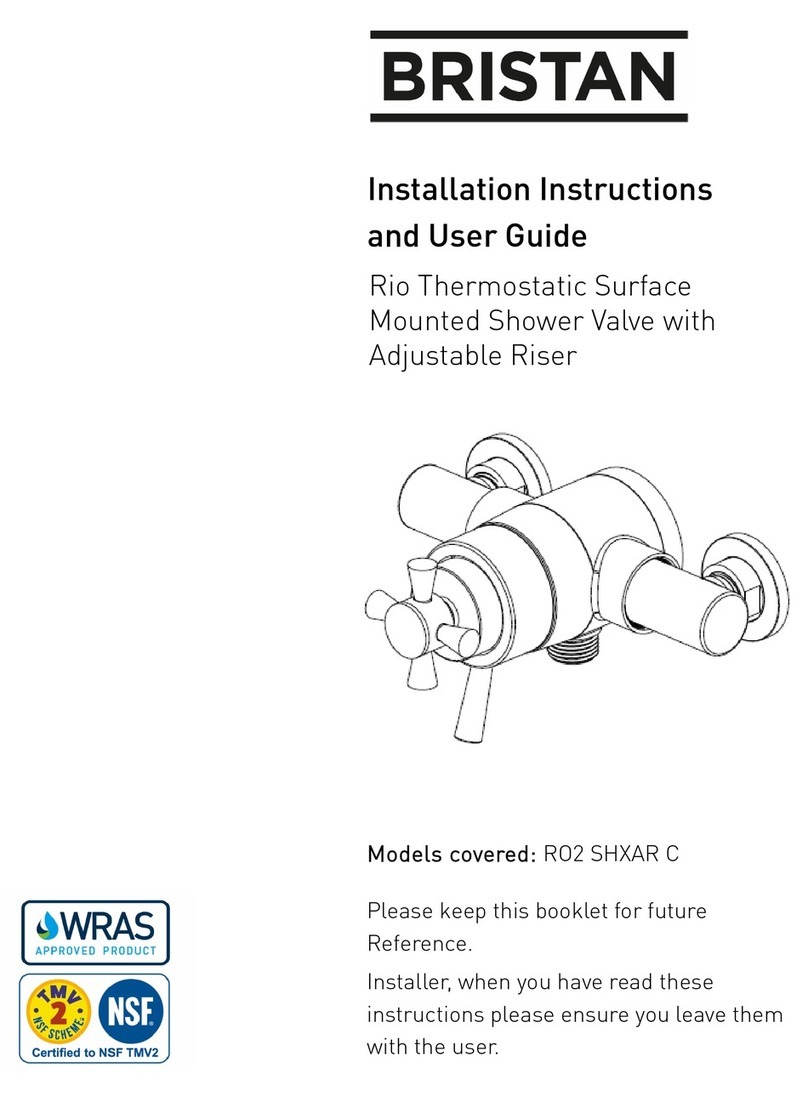

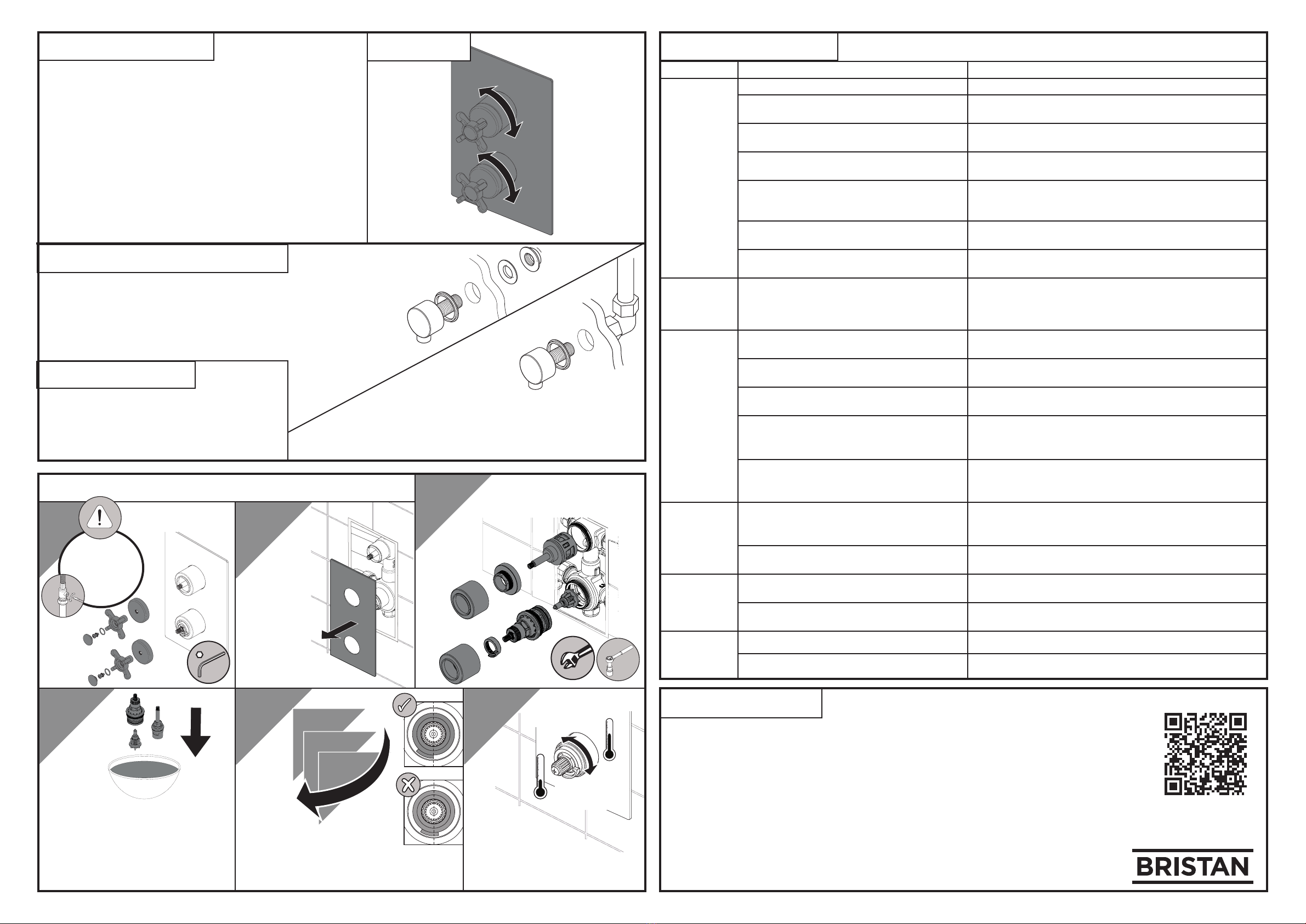

Unscrew the shrouds.

Remove the cartridges

and piston.

24

mm

Increase

Temperature

Decrease

Temperature

Follow the Temperature

Adjustment Steps if required.

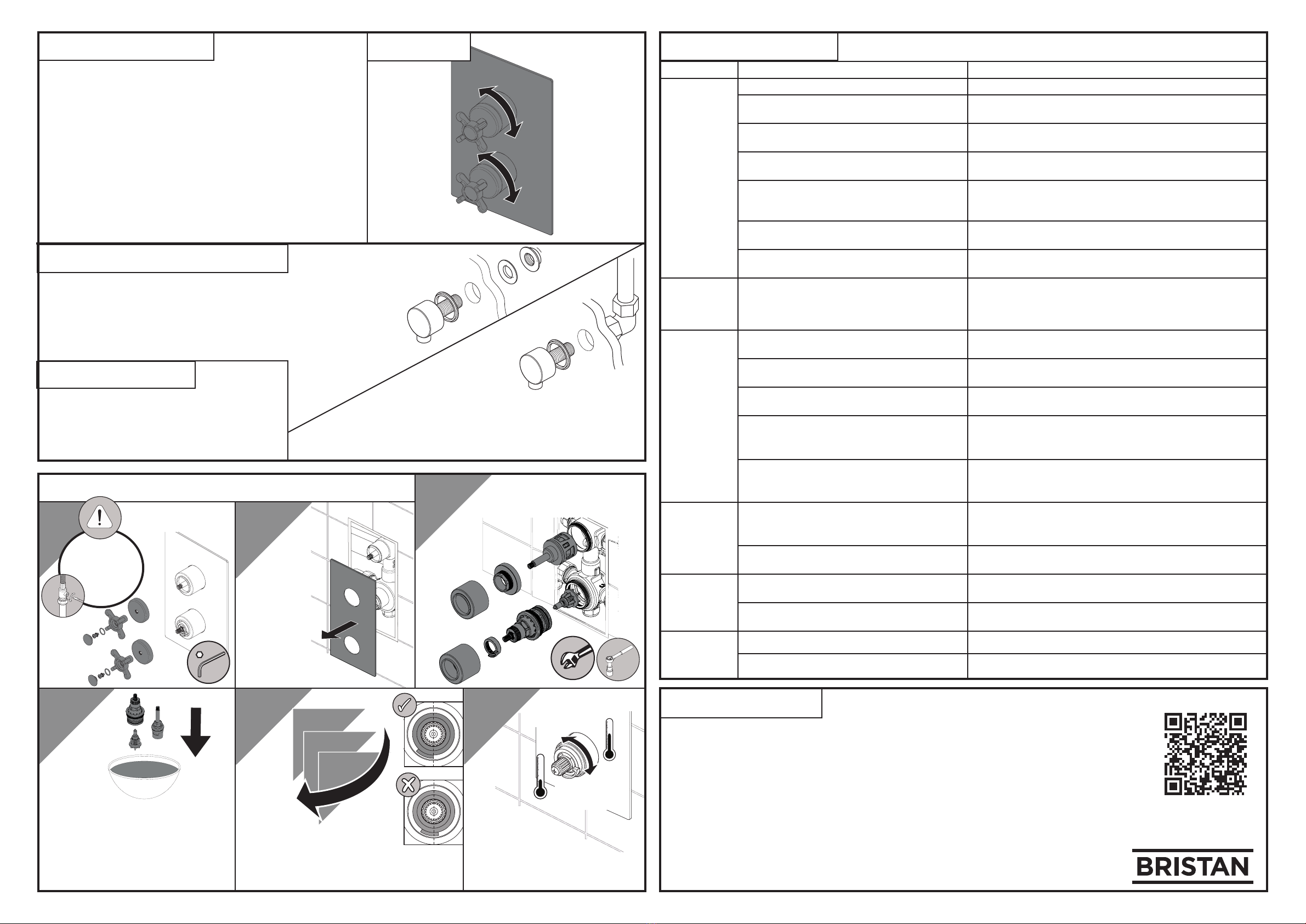

1

46

2

5

3

Maintenance - Cartridge Cleaning

Gently

remove the

concealing

plate from

the wall.

Remove any O-rings and soak all

components in de-scaler and wash o

in clean water. Examine all seals and

replace if needed. Use WRAS

approved silicon based grease

on all seals.

Reverse the installation steps,

ensuring the temperature

stop is aligned correctly.

12

3

IMPORTANT

Isolate the

water supply

before

starting!

2.5

mm

Remove the

handles.

Left

Outlet On/

Increased

Flow

O

Right

Outlet On/

Increased

Flow

Increased

Temperature Decreased

Temperature

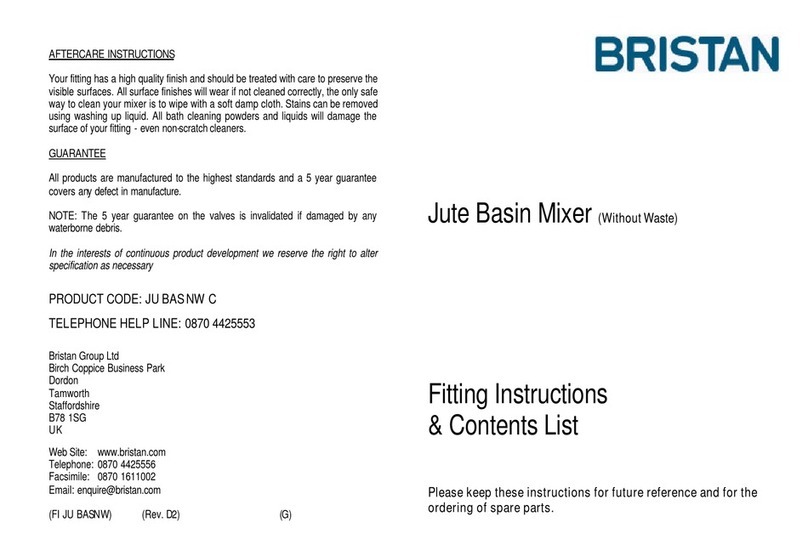

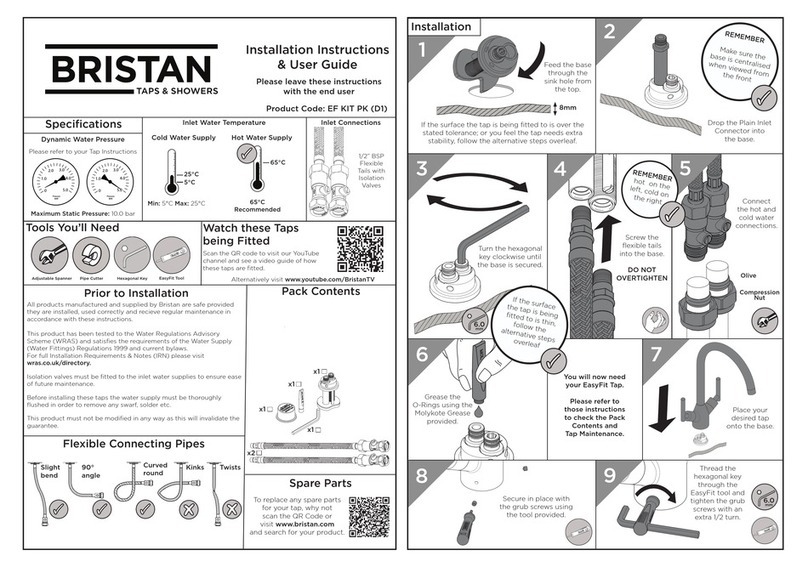

General Cleaning Operation

Bristan products are made from premium materials, with

hand polishing and electroplated finishes.

Your taps or shower should be regularly cleaned with warm

water, a mild pH-neutral liquid soap, and polished with a soft

cloth. Any residues from soap, toiletries etc. should be rinsed

o straight after use.

Household bleaches and cleaners contain harsh chemicals and

may damage the surface finish. Avoid using abrasive cloths,

scouring pads, scrub sponges, steel wool or anything similar.

Some surfaces such as nickel and pewter may be aected by

the dye found in some cloths, so it is also important to avoid

hanging cloths on spouts.

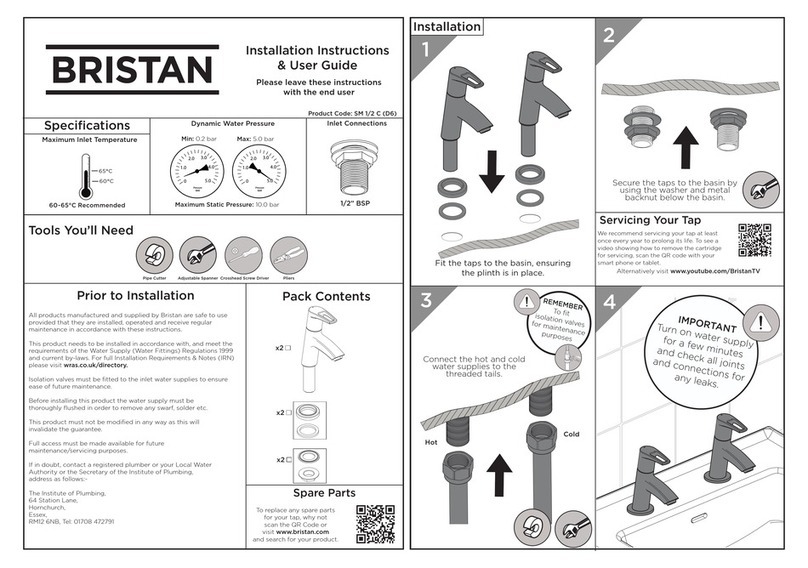

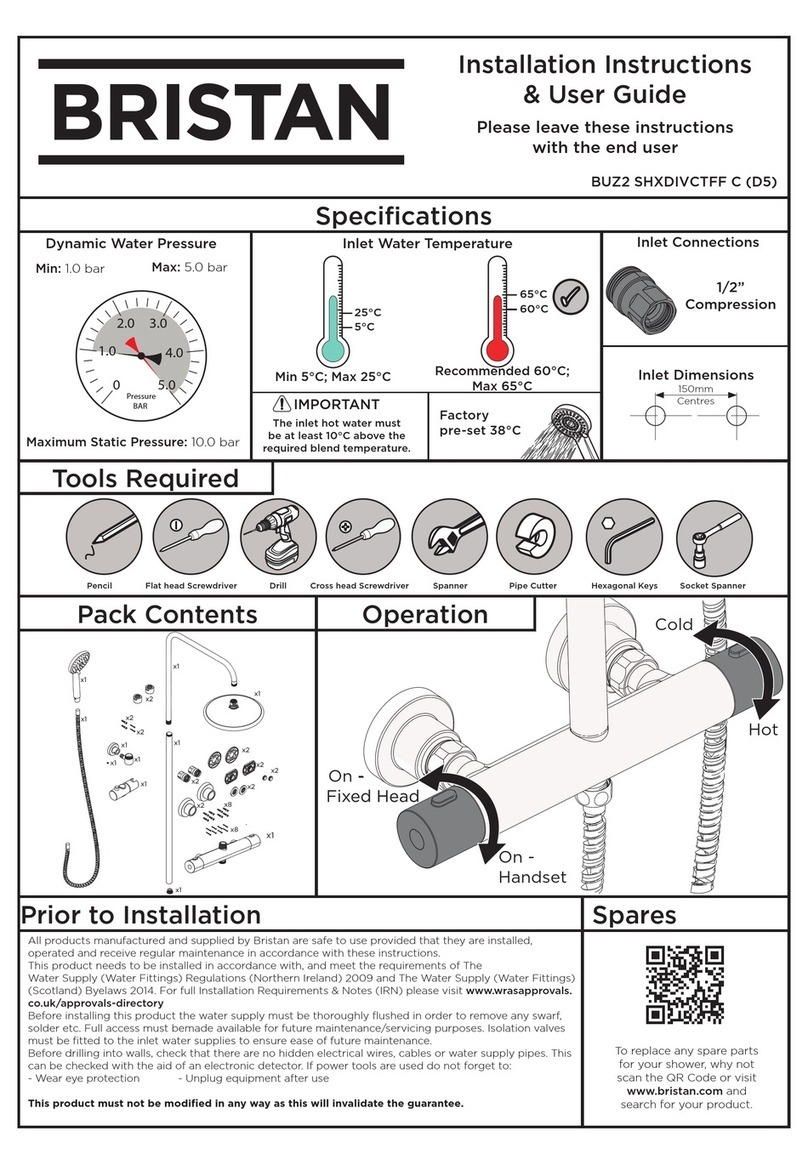

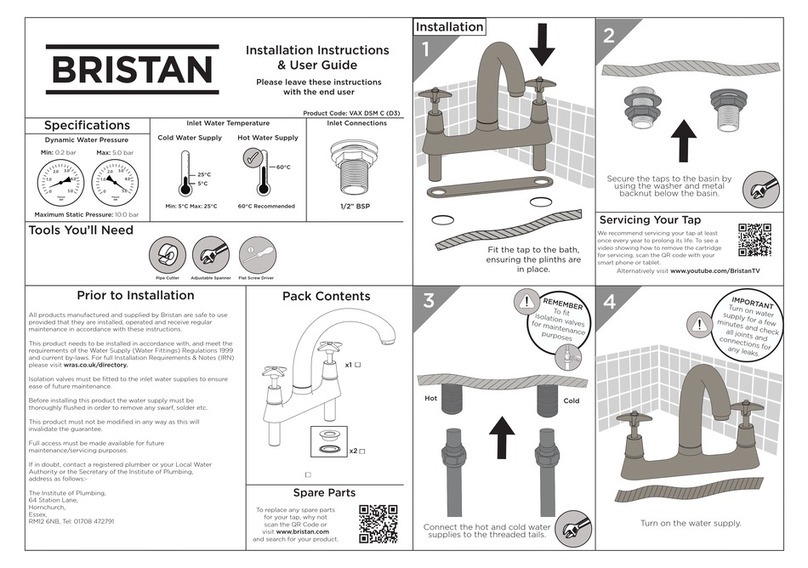

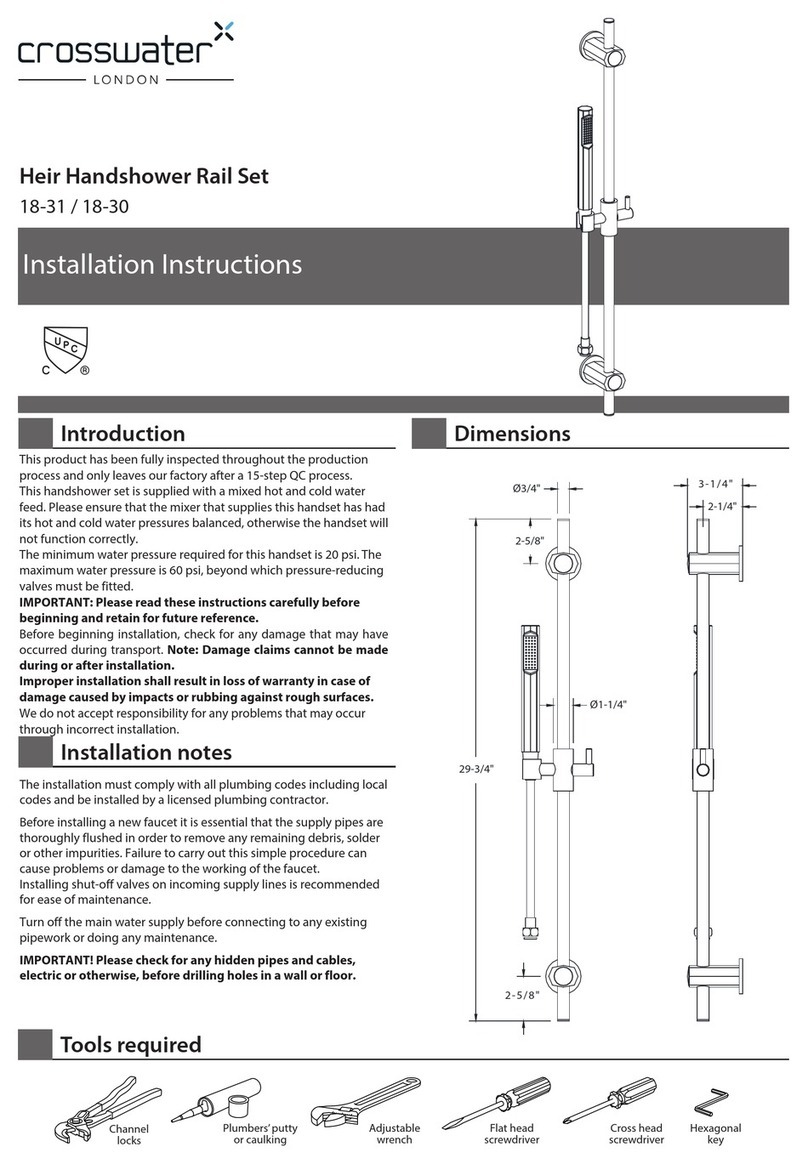

Choose the location for the wall outlet

and create a 25-30mm hole in the wall.

Ensure your shower accessories have

enough reach from that position.

Finish the wall surface.

To reduce the build up of lime scale and to

ensure this shower works to its maximum

performance we recommend this shower

is serviced every 6-12 months depending

on the hardness of your water.

Servicing Intervals

Wall Outlet Installation

Fit the wall outlet,

ensuring the

washers are fitted

either side of

the wall.

Go to Step 6 in the

Installation Steps.

With rear access

Without rear access

Screw the wall outlet into

the 1/2” female connection,

using a suitable thread sealant

ensuring the rubber seal is fitted

to the back of the wall outlet.

Follow Step 6 in the

Installation Steps, fitting a 1/2”

female connection at the hole in

the wall (not supplied).

Troubleshooting

At Bristan, we want to make things as easy as possible for our customers. That’s why we oer

solid guarantees on all our products, eective from the date of purchase, to give you peace of mind.

To start your free guarantee simply scan the QR code and register your product.

Alternatively visit www.bristan.com/register.

For any other queries, please call our Customer Service on 0330 026 6273

where our expert team of advisors will be able to oer you any help and advice.

For full guarantee terms and conditions visit www.bristan.com/service-centre/guarantees.

Our Guarantee

Customer Service: +44330 026 6273

Web: www.bristan.com

A Masco Company

Symptom Cause Remedy

No flow or

low flow rate

Partially closed isolation valve. Open isolation valve.

Instantaneous water heater cycles on and o

as flow rate or pressure is too low.

Increase water flow rate or

pressure through system.

Head of water is below the

minimum distance required.

Refer to the specification for the

minimum distance required.

Are the water supply pressures balanced? If pressures are unbalanced, a pressure reducing valve

should be used for optimum performance.

Hot or cold water being drawn o elsewhere

causing pressure changes or instantaneous

boiler temperature changes.

Do not use other water outlets when using the shower.

Airlock or partial blockage in the supply

pipework.

Flush through pipework and filters to ensure removal

of debris and any airlocks.

Hot/Cold water supply has failed Check the hot and cold feeds. The shower will not

work if either fails.

Maximum

Water

Temperature

too Hot/Cold

Maximum Water Temperature

needs adjusting.

Refer to the Temperature Setting section to set your

desired maximum temperature.

Outlet Water

Temperature

too Hot/Cold

Filter/pipe blockage Flush through pipework and filters to ensure

removal of debris and any airlocks.

Installtion conditions outside

operating parameters.

Refer to the specification for the

minimum distance required.

Hot water temperature is less than 10°C

above the required blend temperature

Adjust hot water temperature or wait for water to

reheat if a stored water system is used.

Instantaneous water not igniting because the

water flow rate is too low.

Increase water flow rate through the system. Refer to the

Maintenance section to clean/check the cartridge and filters

for any damage. Contact your boiler manufacturer.

Instantaneous water not igniting because the

water pressure is too low.

Refer to the specification for system requirements.

Increase water pressure through the system.

Contact your boiler manufacturer.

Only hot/

cold water

from Shower

Valve

Inlet water supplies are reversed.

Check the water inlet connections are the correct way

around: Hot on the left, Cold on the right when viewed from

the front. Rework pipework as necessary.

Filter/pipe blockage Flush through pipework and filters to ensure removal of

debris and any airlocks.

Water

dripping

from shower

This is normal for a short time after using the

shower.

This is caused by residual water tension, the build up of

water in the shower.

If water continues to drip,

possibly due to the cartridge

Remove cartridge and clean, refer to 'Maintenance' section

before starting any maintenance.

Shower does

not turn on

Closed isolation valve. Open isolation valve.

Mains water supply turned o. Turn on mains water supply.

Bristan Group Ltd.

UK: Bristan Group, B78 1SG.

EU: Masco Europe S.à.r.l., 14 Rue Strachen

6933 Mensdorf, Luxembourg.