1

0) BRIEF INTRODUCTION

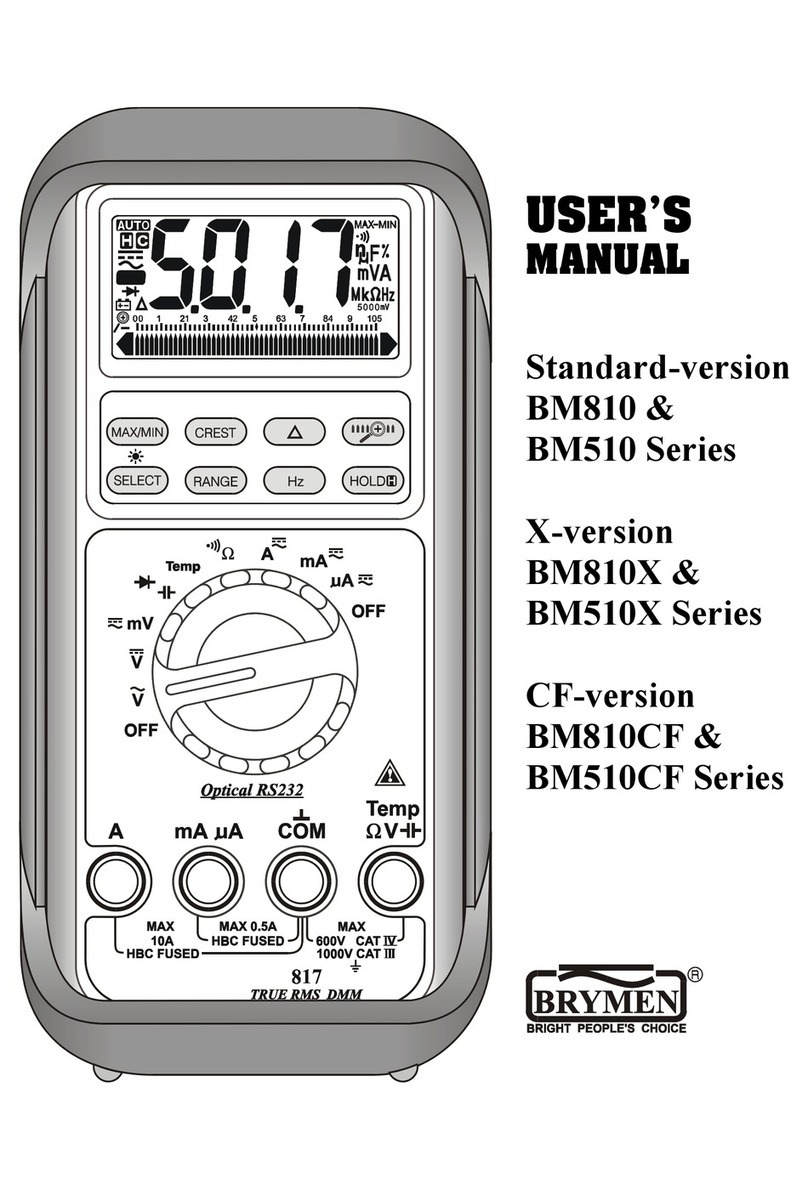

This 2800 CSE meter series is a safety Category and EMI Shielding Enhanced (CSE)

version of our popular 800 practical meter series. Apart from the added up-to-date

features and improvements in safety ratings, it is also equipped with EMI shielding on

both sides of the circuitry module to improve measurement stability under harsh

electromagnetic interferences, especially in the electrical and automotive industries.

1) SAFETY

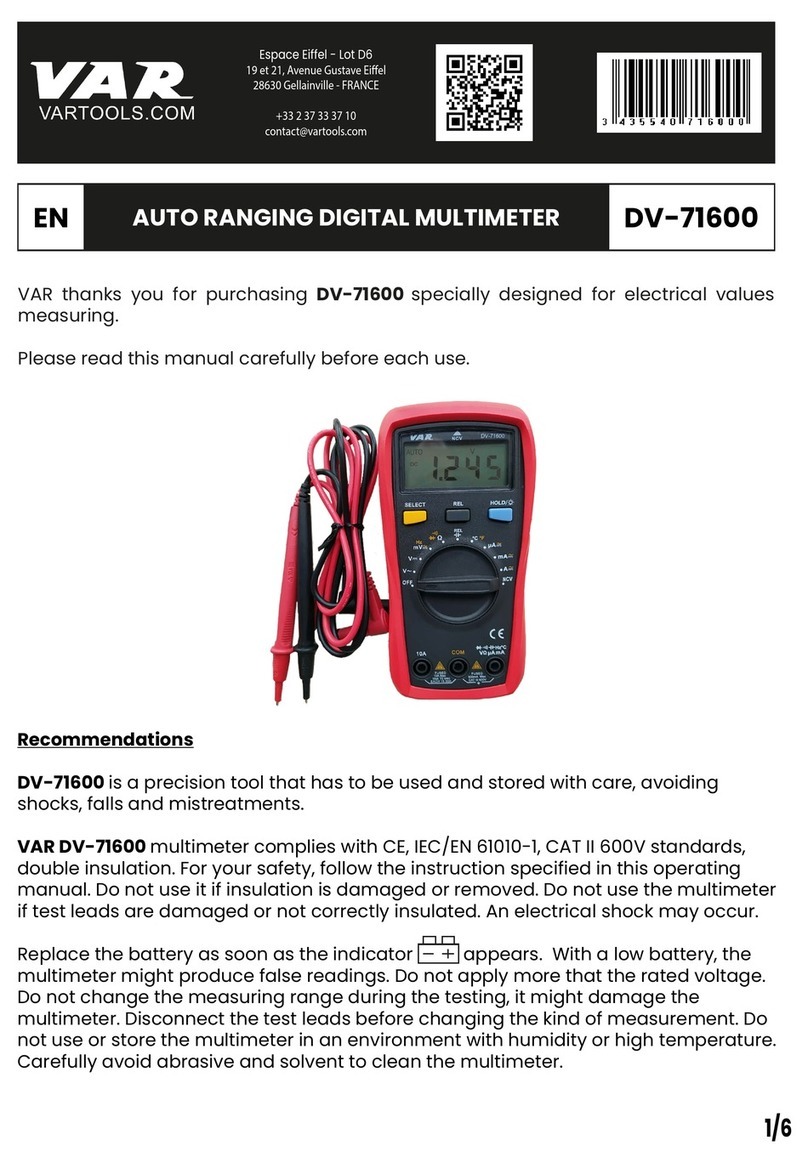

This manual contains information and warnings that must be followed for operating the

meter safely and maintaining the meter in a safe operating condition. If the meter is

used in a manner not specified by the manufacturer, the protection provided by the

meter may be impaired.

Observe proper safety precautions when working with voltages above 30 Vrms, 42.4

Vpeak, or 60 VDC. These voltage levels pose a potential shock hazard to the user.

Disconnect the test leads from the test points before changing functions. Do not

expose this product to rain or moisture. The meter is intended only for indoor use.

Keep your hands/fingers behind the hand/finger barriers (of the meter and the test

probe assembly, where applicable) that indicate the limits of safe access of the hand-

held parts during measurements. Inspect lead wires, connectors, and probes for

damaged insulation or exposed metal periodically. If any defects are found, replace

them immediately. Only use the test probe assembly provided with the meter or a UL

Listed test probe assembly to the same meter ratings or better. Optional offer premium

test probe assembly using silicone lead wire insulation, at agent’s discretion, is

equipped with white inner insulation layers as wear indicators. Replace them

immediately if any of the white layers has become visible.

The meter meets IEC/EN/BSEN/CSA_C22.2_No./UL standards of 61010-1 Ed. 3.1 and

61010-2-033 Ed. 2.0 to Measurement Categories CAT III 1000V and CAT IV 600V. The

accompanied test probe assembly meets IEC/EN/BSEN/CSA_C22.2_No./UL

standards of 61010-031 Ed. 2.0 to the same meter ratings or better. The 61010-031

requires exposed conductive test probe tips to be ≤ 4mm for CAT III & CAT IV (≤

19mm for CAT II) ratings. The accompanied add-on caps (or permanent insulated tips

option) have to be used for applications under CAT III & CAT IV. Refer to the category

markings on your probe assemblies as well as on the add-on accessories (like

detachable Caps or Alligator Clips), if any, for applicable rating changes.