CMRR (Common Mode Rejection Ratio)

Common mode voltage is voltage present on both the COM and VOLTAGE input

terminals of a DMM, with respect to ground. CMRR is the DMM's ability to reject

common mode voltage effect that can cause digit rolling or offset in voltage

measurements. This series has a CMRR specifications of > 80dB at DC to 60Hz in

ACV function; and > 120dB at DC, 50 and 60Hz in DCV function. If neither NMRR nor

CMRR specification is specified, a DMM's performance will be uncertain.

Analog bar-graph

The analog bar graph provides a visual indication of measurement like a traditional

analog meter needle. It is excellent in detecting faulty contacts, identifying

potentiometer clicks, and indicating signal spikes during adjustments. Analog bar-graph

is not available in AC+DC True RMS Voltage & Current modes.

4) OPERATION

CAUTION

Before and after hazardous voltage measurements, test the voltage function on a

known source such as line voltage to determine proper meter functioning.

AC Voltage, DC Voltage, DC+AC Voltage, & Hz Line Level Frequency

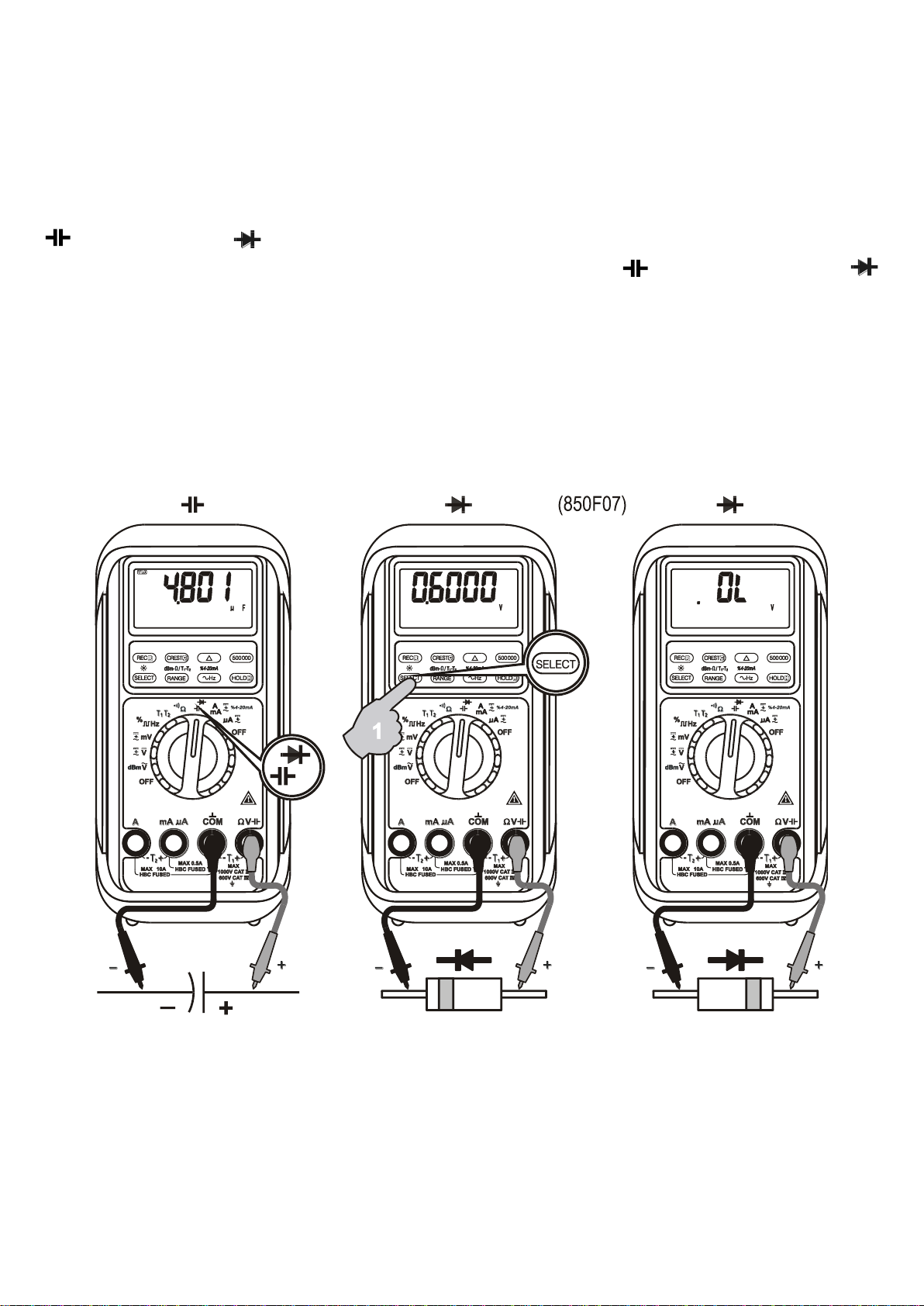

In AC Voltage, press SELECT button momentarily to toggle between AC and dBm. In

DC Voltage, press SELECT button momentarily to toggle between DC, and DC+AC. In

mV Voltage, press SELECT button momentarily to select DC, AC, or DC+AC. The new

settings will be saved automatically to the non-volatile memory as power up default. In

DCV and DCmV, press 500000 button momentarily to toggle between 4-4/5 digits and

5-4/5 digits readings. In voltage or current functions, press the Hz push button

momentarily to activate or to exit Line Level Frequency measuring function. Line Level

Frequency measuring function is designed especially for noisy electrical high voltage

signals.

Note: In dBm function, power up default reference impedance will be displayed for 1

second before displaying the dBm readings. Press dBm-(RANGE) button

momentary to select different reference impedance of 4, 8, 16, 32, 50, 75, 93, 110,

125, 135, 150, 200, 250, 300, 500, 600, 800, 900, 1000, up to 1200. The new

impedance value will be saved automatically to the non-volatile memory as power up

default.