Index

Unit 1: Installation

Site Requirements..............................................................................................................4

Location of the Serial Number ..........................................................................................4

Water Supply Install ...........................................................................................................4

Electrical Install..................................................................................................................4

Initial Start-Up.....................................................................................................................5

Unit 2: Setup

Setup and Programming....................................................................................................7

Programming Lockout.................................................................................................7

Level 1 Programming.........................................................................................................7

Level 2 Programming.........................................................................................................7

Level 3 Programming.........................................................................................................9

Calibrating Flow Rate.........................................................................................................9

Check and Adjust the Dispense Valve Flow Rate.....................................................9

Check and Adjust the Bypass Valve Flow Rate ........................................................9

Programming the Recipes.................................................................................................10

Default Values.....................................................................................................................11

Unit 3: Machine Composition

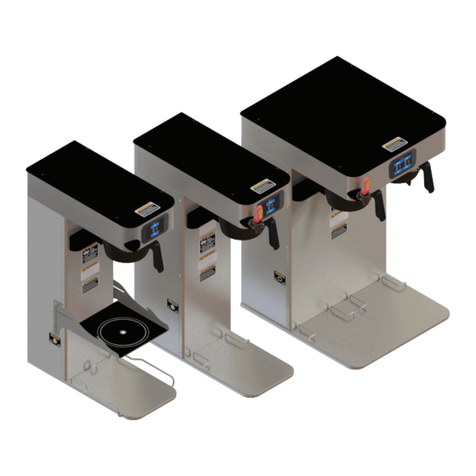

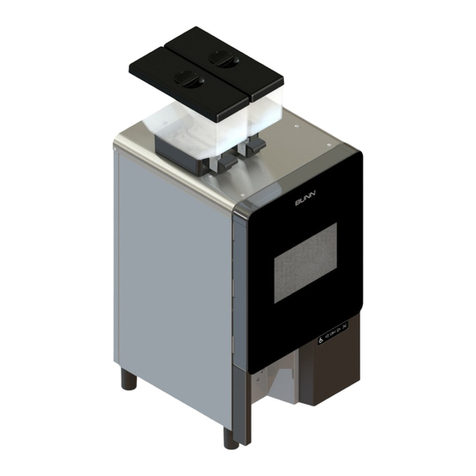

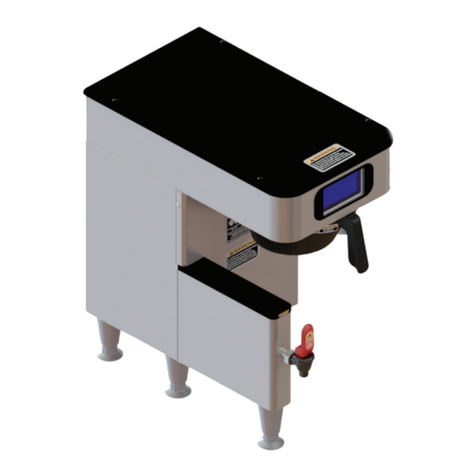

Exterior Overview...............................................................................................................13

Product Outlets and Removable Parts ......................................................................13

User Interface...............................................................................................................13

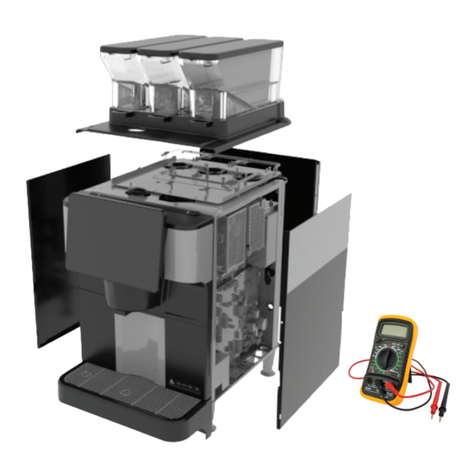

Accessing the Inside of the Brewer..................................................................................13

Machine Function and Operations....................................................................................14

Main Control Board......................................................................................................14

Filling System...............................................................................................................14

Heating System............................................................................................................15

Dispensing System......................................................................................................15

Coffee Holding System................................................................................................16

The Soft Heat®Server...........................................................................................17

Unit 4: Preventive Maintenance

Preventive Maintenance.....................................................................................................19

PM Steps .............................................................................................................................19

Unit 5: Troubleshooting

Service Tools ......................................................................................................................22

Test Outputs.................................................................................................................22

Test Switches ...............................................................................................................23

Test Servers..................................................................................................................23

Test Frequency.............................................................................................................23

Service Fault Messages.....................................................................................................23

Operator Fault Messages...................................................................................................24

Triac Map.............................................................................................................................25

© 2009 Bunn-O-Matic Corporation. All Rights Reserved

Rev. A