Operating Instructions Type 0330/0331

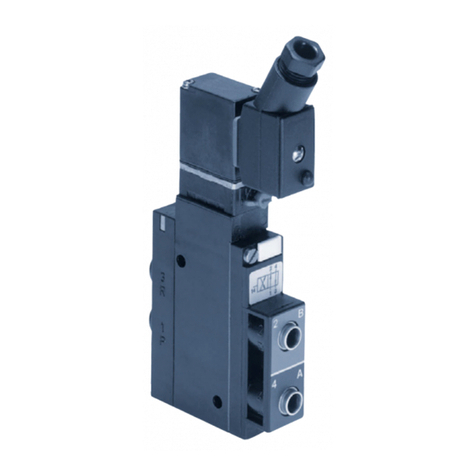

Design:

The pivoted armature valves are direct acting 2/2 or 3/2-way

solenoid valves in a wide variety of circuit functions. Solenoid

system and media chamber are separated from one another by a

separating diaphragm system

Function:

A

(NC)

2/2-way valve,

closed in rest position

B

(NO)

2/2-way valve,

open in rest position

C

(NC)

3/2-way valve; closed in rest

position, output A unloaded

D

(NO)

3/2-way valve, in rest position, output

B pressurized

E3/2-way mixing valve; in rest position,

pressure connection P2 connected to

output A, P1 closed

F 3/2-way distribution valve, in rest

position, pressure connection P con-

nected to output B

Seal Materials and Fluids handled:

See Table1.

Fluid and Ambient Temperature:

For Hazardous Locations Div. 1 (T4 rated)

Max. Ambient Temperature 104 °F (40 °C)

Max. Fluid Temperature 194 °F (90 °C)

For Hazardous Locations Div. 2 and Ordinary Locations:

See Table1 and 2.

Pressure Range:

Maximum inlet pressure see label on valve.

Manual override:

The manual override can be retained in position if, after depressing

the button, it is turned in a clockwise direction.

Installation:

Type 0330: PTFE tape is recommended for sealing ports.

Mounting is accomplished by means of four M4 x 8 mm tapped

holes located on the valve underside.

Type 0331: Ports A (B) are coded on side of body. For common

pressure, align "A(B)" markings on valve and manifold. Valve ope-

ration C an D valves can be mounted on the same manifold but the

manual override buttons will point in opposite directions.

To remove valve from manifold loosen only the two unsealed

screws. Manifolds can be connected together with nipples.

Blanking plugs, Order No. 0315-1016, should be screwed into

the unused ports. Manifolds can be fixed in position using M5

screws.

Operating Instructions 1511/15_EU-EN_00893144

Assembly instructions: (Fig. 1 : Torque)

The conduit connector on the coil (4) must be supported against

torque during the assembly using appropriate tools (1) (i.e. pliers,

gripper...) (for example a gripper).

While tightening for example a fitting (3) into the conduit connec-

tor attention must be paid to the fact that a max. torque of 20Nm

(177lbf in) is not exceeded.

Fig. 1: Torque

Marking (example):

Body Material

BR = Brass

SS = Stainless steel

PP = Polypropylen

PD = Polyvinyl fluoride

Seal Material

EPDM = EPDM

NBR = NBR

FKM = FKM

Circuit Function

Seal materials with metal valve bodies Seal material with plastic valve bodies

Fluid Temperatures [°F] NBR EPDM FKM NBR EPDM FKM

Air Fluid

Ambient

+ 32 to + 176

+ 32 to + 131

- 22 to + 194

+ 14 to + 131

+ 32 to + 194

+ 32 to + 131

+ 32 to + 122

+ 32 to + 122

- 22 to + 122

+ 14 to + 122

+ 32 to + 122

+ 32 to + 122

Water Fluid

Ambient

+ 41 to + 176

+ 32 to + 131

+ 41 to + 194

+ 14 to + 131

+ 41 to + 194

+ 32 to + 131

+ 41 to + 122

+ 32 to + 122

+ 41 to + 122

+ 14 to + 122

+ 41 to + 122

+ 32 to + 122

Inert

gas

Fluid

Ambient

+ 32 to + 176

+ 32 to + 131

- 22 to + 194

+ 14 to + 131

+ 32 to + 194

+ 32 to + 131

+ 32 to + 122

+ 32 to + 122

- 22 to + 122

+ 14 to + 122

+ 32 to + 122

+ 32 to + 122

Oil Fluid

Ambient - - + 32 to + 194

+ 32 to + 131 - - -

LP-gas Fluid

Ambient - - + 32 to + 194

+ 32 to + 131 - - -

Oxygen Fluid

Ambient - - + 32 to + 194

+ 32 to + 131 - - -

Identity Number

Voltage / Frequency / Power consumption

Maximum Pressure

Approvals

The valve is FM/CSA approved as Explosion Proof valve

for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 4

FM approved as Nonincendive for Hazardous Locations

Class I, Division 2, Group A, B, C, D

Class II, Division 2, Group F, G

Class III, Division 1 and 2

Operating Temperature T 4A

CSA approved for Ordinary Locations

UL Recognized and UL Listed for General

Purpose and Fire Protection Services.

See label on the valve.

0330 C 1/8 FKM BR

NPT1/4 PMAX 145PSI

24V DC 8W

00450750 W34ME

Made in Germany