BATCH CONTROLLER SE35

8035

E-1- Ref. 419744

TABLE OF CONTENTS

1INTRODUCTION ......................................................................................................................... E-2

1.1 Unpacking and Control ................................................................................................................ E-2

1.2 About this Manual ........................................................................................................................ E-2

1.3 User's Responsibility for Safety .................................................................................................. E-2

1.4 Electromagnetic Compatibility ..................................................................................................... E-2

2SPECIFICATION ......................................................................................................................... E-3

2.1 Type Specification ....................................................................................................................... E-3

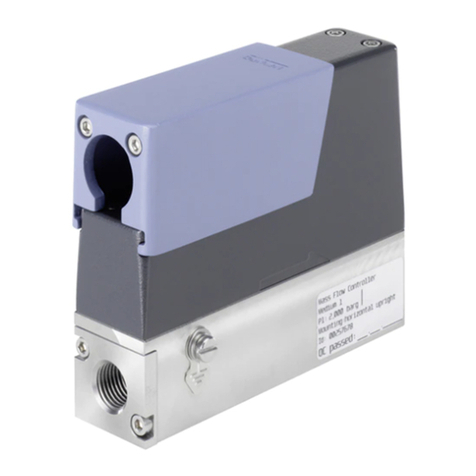

2.2 Design and Measuring Principle ................................................................................................. E-4

2.3 Dimensions Electronic housing SE35 Batch controller .............................................................. E-5

2.4 Technical Data ............................................................................................................................. E-6

3INSTALLATION .......................................................................................................................... E-7

3.1 Installation Guidelines ................................................................................................................. E-7

3.2 Process Mounting ........................................................................................................................ E-8

3.3 General electrical connection ...................................................................................................... E-9

3.4 Electrical Wiring ........................................................................................................................... E-9

3.5 Electrical Wiring with Power Supply 230/115 VAC................................................................... E-10

4. OPERATION AND CONFIGURATION.....................................................................................E-11

4.1 Controller operating and Control elements ............................................................................... E-11

4.2 Description of the Dosing Options ............................................................................................ E-12

4.2.1. «LOC.MANU» Option...................................................................................................... E-12

4.2.2. «LOC.MEM» Option ....................................................................................................... E-12

4.2.3. «MEM+MANU» Option.................................................................................................... E-12

4.2.4. «EXT.MEM» Option ........................................................................................................E-13

4.2.5. «EXT.[T]» Option ............................................................................................................ E-14

4.3 Main menu .................................................................................................................................E-15

4.3.1. Dosage in manual mode .................................................................................................E-15

4.3.2. Dosage in automatic mode ............................................................................................. E-16

4.3.3. Dosage proportional to a pulse duration ........................................................................ E-17

4.3.4. Display of flow rate and the initial preset volume during the dosage ............................ E-17

4.3.5. Pause / reset function ..................................................................................................... E-18

4.4. Calibration Menu ....................................................................................................................... E-19

4.4.1. Language.........................................................................................................................E-19

4.4.2. Measurement units .......................................................................................................... E-20

4.4.3. K-Factor ...........................................................................................................................E-20

4.4.4. Dosing options.................................................................................................................E-21

4.4.5. Overfill correction ............................................................................................................ E-23

4.4.6. Alarm ............................................................................................................................... E-23

4.4.7. Relays ..............................................................................................................................E-24

4.4.8. Totalizer ........................................................................................................................... E-26

4.5. Test Menu ..................................................................................................................................E-26

4.5.1. EXT.ACT. ........................................................................................................................ E-26

4.5.2. Check on operation of relays .......................................................................................... E-27

4.5.3. Transducer frequency readout........................................................................................E-27

5. MAINTENANCE ........................................................................................................................E-28

5.1 Fault prompts ............................................................................................................................. E-28

5.2. Transducer maintenance........................................................................................................... E-30

5.3. Default configuration of 8035 INLINE Batch controller on delivery .......................................... E-31

5.4 Spare Parts List .........................................................................................................................E-31

APPENDIX ................................................................................................................................. A-1

Flow Chart (l/min, DN in mm and m/s)........................................................................................ A-1

Flow Chart (US-gallon/min, DN in inch and Ft/s) ....................................................................... A-2