3

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not consider any contingencies or incidents

which occur during installation, operation and maintenance. The operator

is responsible for observing the location-specic safety regulations, also

with reference to the personnel.

General hazardous situations.

To prevent injury, ensure the following:

▶Operate the device only in perfect condition and in accordance with

the operating instructions.

▶Do not make any changes to the device and do not subject it to

mechanical stress.

▶Secure device or system to prevent unintentional activation.

▶Only trained technicians may perform installation and maintenance

work.

▶Install the device according to the regulations applicable in the

country.

▶After an interruption in the power supply, ensure that the process is

restarted in a controlled manner.

▶Observe the general rules of technology.

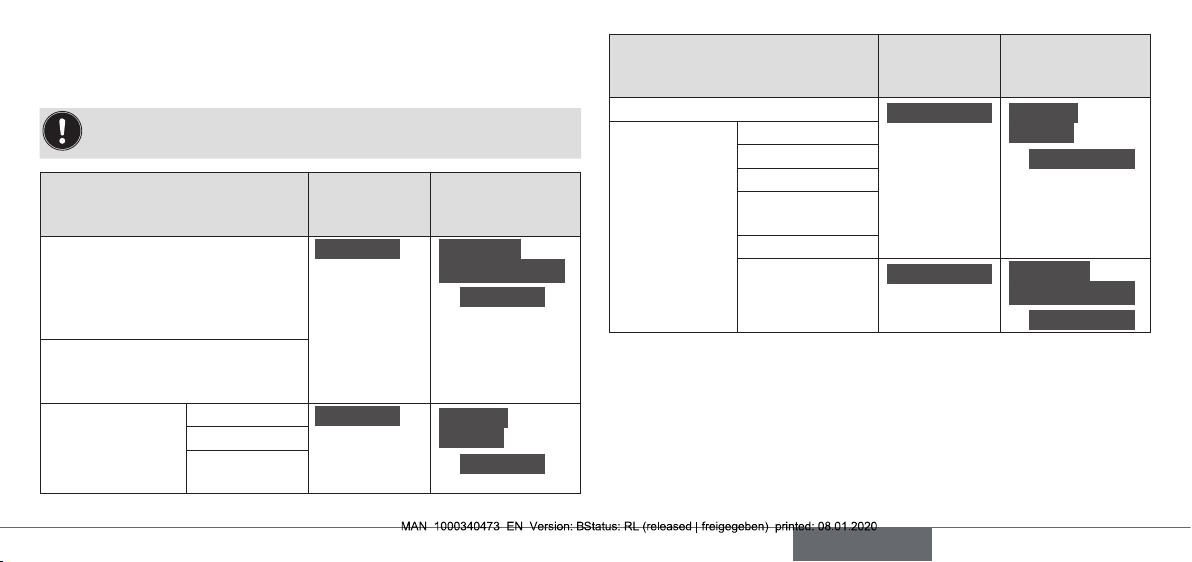

2 INTENDED USE

The eldbus gateway type ME43 is used as a eld bus converter

between büS and Industrial Ethernet, PROFIBUS DPV1, CC-Link.

▶When using the device, observe the permitted data, operating con-

ditions and application conditions. This information can be found in

the contractual documents, the operating instructions and on the

type label.

▶In areas at risk of explosion, only use devices approved for use

in those areas. These devices are labeled with a separate Ex type

label. In use, note the information provided on the separate Ex type

label and the additional explosion-related information or separate

explosion-related operating instructions.

The device

▶Do not use the device outside.

▶Do not open the device.

▶Use the device only in conjunction with third-party devices and

components recommended and authorized by Bürkert.

▶Only operate the device when in perfect condition and always

ensure proper storage, transportation, installation and operation.

▶Use only as intended.

english