4

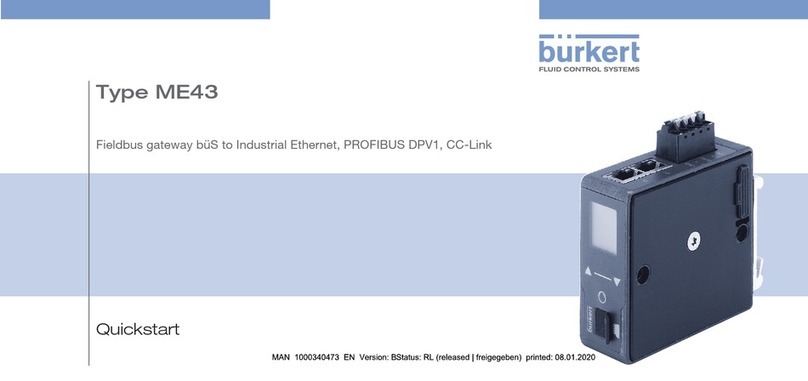

Type ME43

7.4.2 PROFIBUS version .....................................................................................................17

7.4.3 CC-Link version ..........................................................................................................17

8START-UP .............................................................................................................................................18

8.1 Safetyinstructions .....................................................................................................................18

8.2 Basesettings..............................................................................................................................18

8.3 Selectingeldbusprotocol........................................................................................................18

8.4 Congurationoftheeldbusgateway ......................................................................................19

8.4.1 Preparingtoconguretheeldbusgateway ..............................................................19

8.4.2 MethodsforgeneratingaGatewayconguration ......................................................19

8.4.3 Maximum number of data values (objects) ................................................................20

8.4.4 GeneralsettingsfortheGatewayconguration .........................................................20

8.4.5 DeclaringinputsandoutputsfortheGatewayconguration .....................................22

8.4.6 Fieldbus-specicaddressmapping ...........................................................................25

8.4.7 StorageanddownloadoftheGatewayconguration ................................................30

8.4.8 büsnetworkconguration ..........................................................................................31

8.5 ProtocolsettingsforconnectingthedevicetothePLCnetwork..........................................32

8.5.1 Setting the PROFIBUS address..................................................................................32

8.5.2 Setting the CC-Link address ......................................................................................33

8.5.3 Setting the EtherCAT address (Station Alias)..............................................................33

8.5.4 Setting the Ethernet parameters for EtherNet/IP, PROFINET, Modbus TCP ..............34

9OPERATION..........................................................................................................................................35

9.1 Safetyinstructionsforoperation...............................................................................................35

9.2 OperatingelementsofTypeME43 ............................................................................................35

9.3 OperationofTypeME43usingthedisplay ...............................................................................35

9.3.1 Description of the keys...............................................................................................36

9.4 OperationofTypeME43usingthe“BürkertCommunicator”software ..................................37

9.4.1 Bürkert Communicator user interface ........................................................................37

9.4.2 Establishing a connection between the device and Bürkert Communicator..............38

9.5 ImportingandsavingdatausingtheMicroSDcard................................................................39

9.6 DisplayelementsoftheTypeME43..........................................................................................41

9.7 LEDsforindicatingthenetworkconnectiontotheIndustrialEthernet .................................41

9.8 LEDforindicatingdevicestatus ...............................................................................................42

english