3

3.1 Predictable misuse

ವDo not put any loads on the housing (e.g. by placing objects on it

or standing on it).

ವ'RQRWPDNHDQ\H[WHUQDOPRGLıFDWLRQVWRWKHGHYLFHKRXVLQJV'R

not paint the housing parts or screws.

ವ7KHVDIHW\VKXWRijGHYLFHLVGHVLJQHGIRUKHDWLQJRLOV',1

3DUWZLWKYLVFRVLW\F677KHXVHRIRWKHUPHGLDLVQRW

SHUPLWWHGZLWKRXWDSULRUDJUHHPHQWZLWKWKH%ĞUNHUWVDOHVRĴFH

3 AUTHORIZED USE

1RQLQWHQGHGXVHRIWKHVDIHW\VKXWRijGHYLFH7\SHPD\

EHDKD]DUGWRSHRSOHQHDUE\HTXLSPHQWDQGWKHHQYLURQPHQW

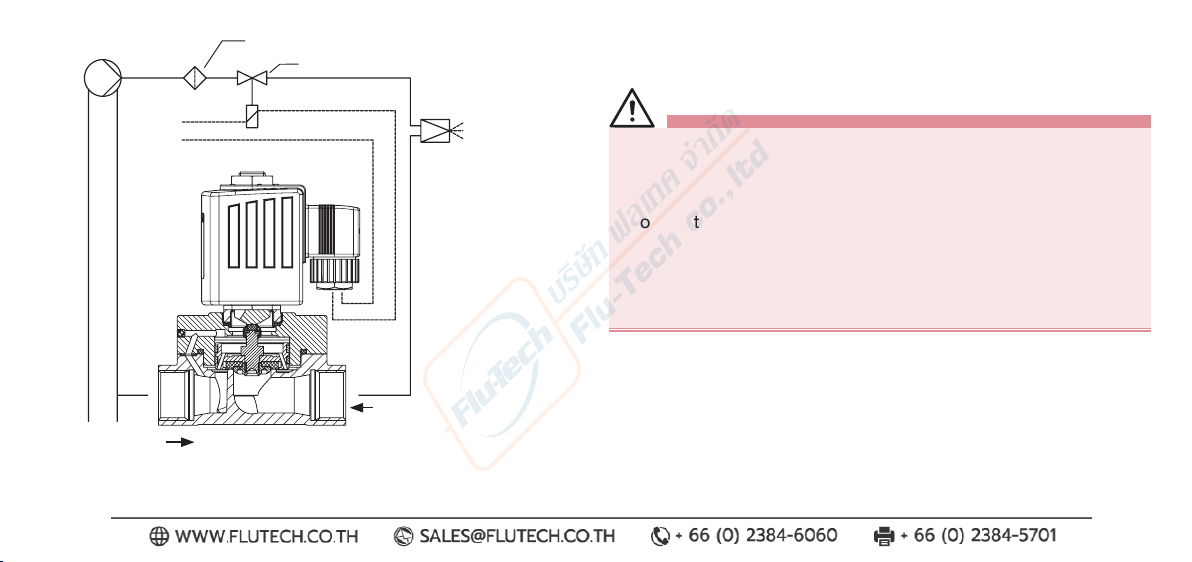

ႧThe device, which controls the supply of heating oil to a burner,

ZDVVSHFLıFDOO\GHVLJQHGIRUIXUQDFHVDQGLVDSSURYHGLQ

accordance with DIN EN ISO 23553-1.

ႧUse according to the authorized data, operating and service

FRQGLWLRQVVSHFLıHGLQWKHFRQWUDFWGRFXPHQWVDQGRSHUDWLQJ

instructions. These are described in the chapter on „Technical

Data“.

ႧBürkert valves must not be used in combination with valves

from other manufacturers.

ႧCorrect transportation, storage and installation, and careful

use and maintenance are essential for reliable and faultless

operation.

Ⴇ7KHYDOYHW\SHPD\EHXVHGH[FOXVLYHO\LQWKHUHWXUQRID

ıULQJSODQWLQFRPELQDWLRQZLWKDYDOYHRIW\SH'1LQ

WKHIJRZ)ROORZLQVWDOODWLRQLQVWUXFWLRQVLQFKDSWHUŚŗ.

english