1.4 Recommended Operation Areas

The grease gun PNEUMAxx is designed to be utilized with lubricating grease up to a viscosity

class NLGI 3 at a minimum temperature down to –10 ºC.

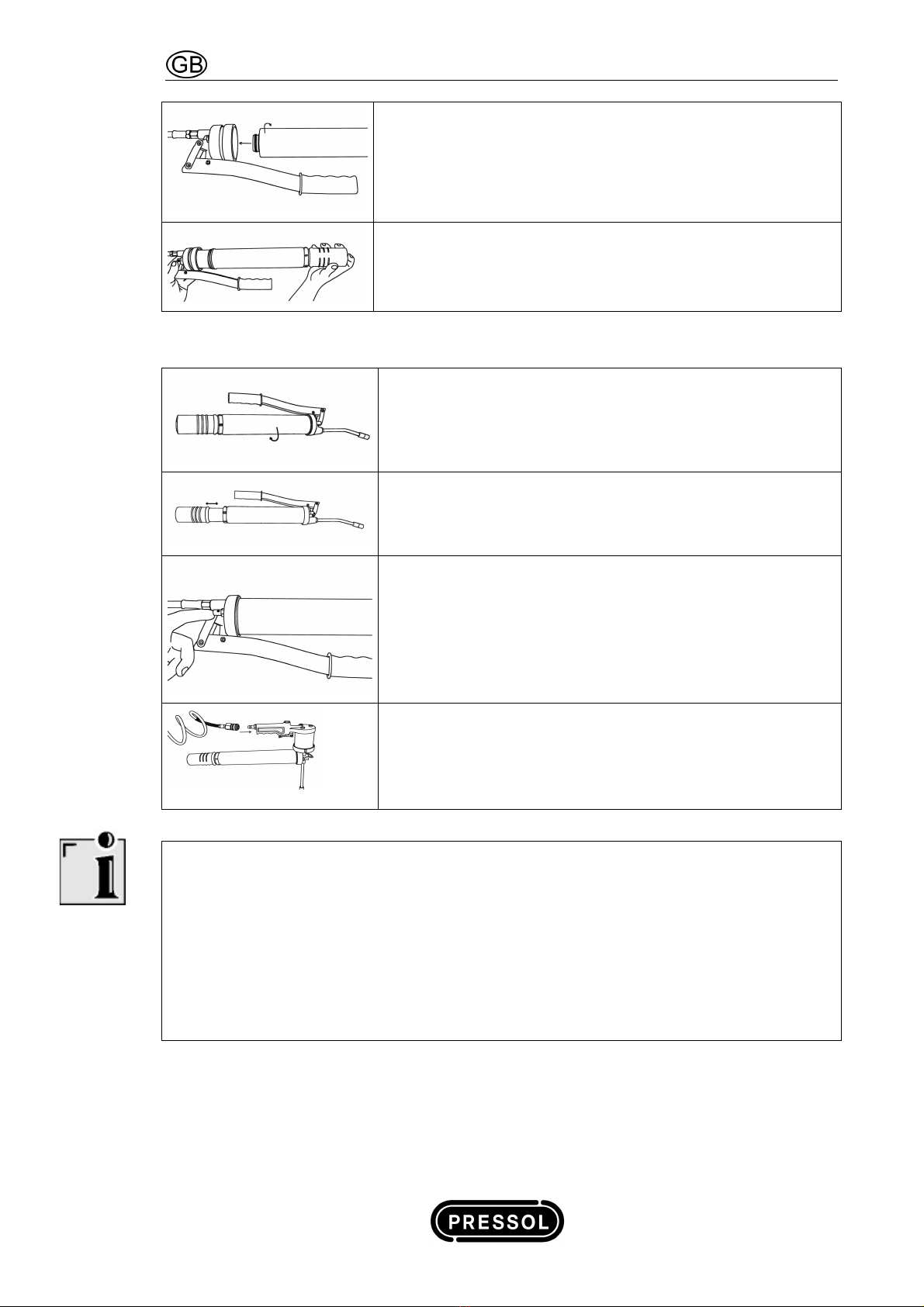

The grease gun can be filled with standard grease cartridges according to DIN 1284 or with a

grease gun filling pump (utilizing an empty cartridge placed in the grease gun tube).

Screw-in cartridges can be processed with an adapter which is available as an accessory,

PRESSOL article no. 12 091.

2. General Safety Instructions

2.1 Safety Requirements

The grease gun PNEUMAxx is designed and manufactured with regards to the general safety

and health requirements and according to the relevant European Community regulations.

However, risks cannot be avoided if this product will not be used according to the

recommended usage or when utilizing it without the necessary diligence and care.

To prevent accidents we recommend to use our product strictly according to the local safety

regulations and as well according to our safety instructions shown in these operating

instructions.

2.2 Explanation of the General Safety Instructions

When studying these General Safety Instructions please consider the different levels of danger.

These levels of danger are marked by the following signal terms or pictograms:

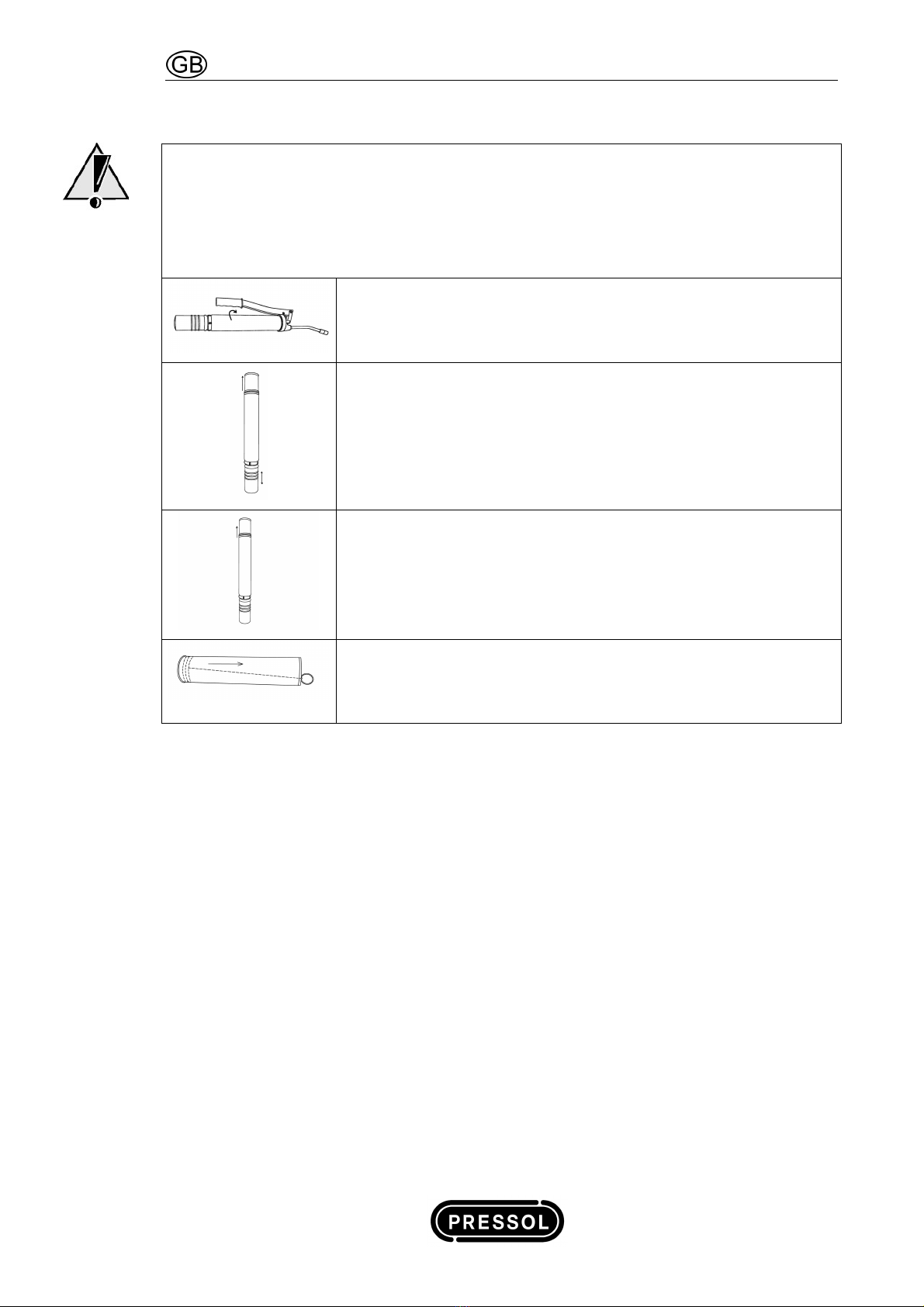

Table. 2-1: Classification of the safety instructions according to the kind of the dangers

Furthermore, an other advise for the operation of this product is also used.