- 4 -

951-170-218-EN

Version 06

EN Table of contents

Table of contents

EC Declaration of Incorporation ..........................................................................2

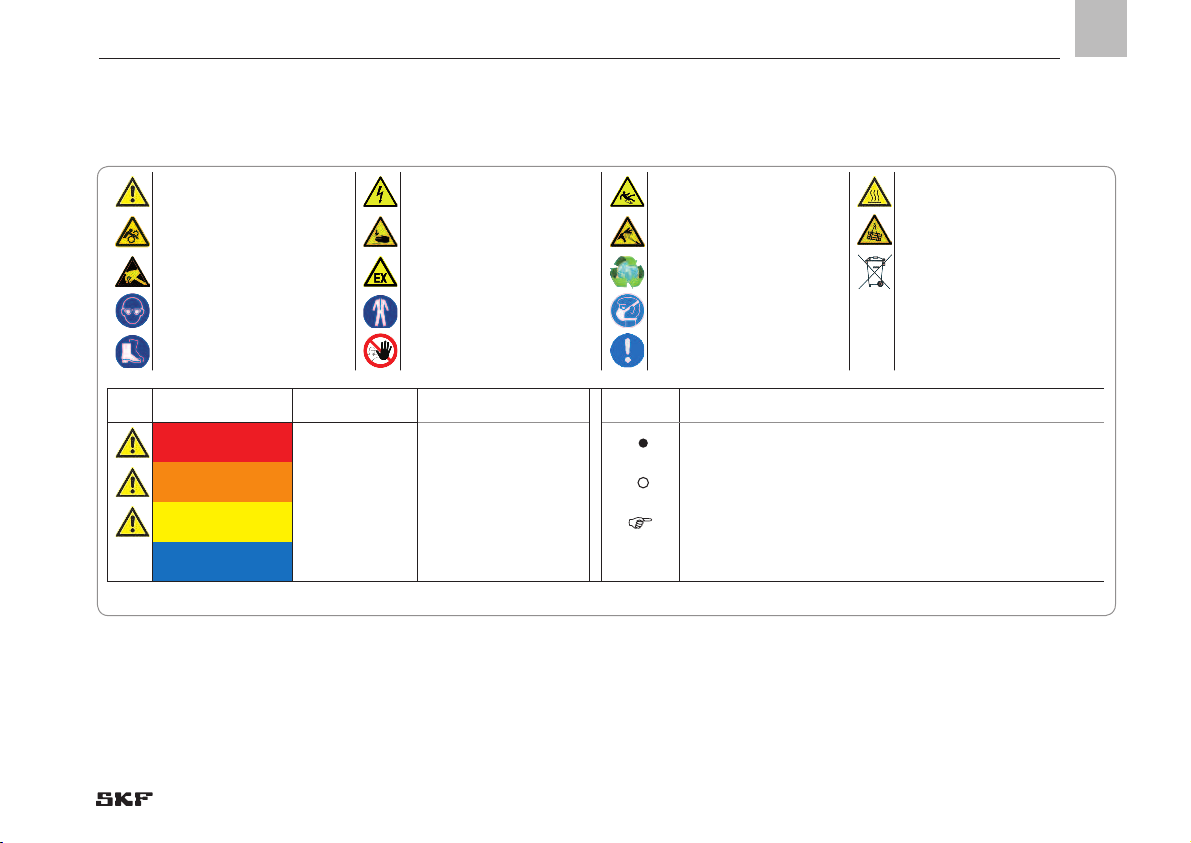

Explanation of symbols and signs ........................................................................7

1. Safety instructions ................................................................ 9

1.1 General safety instructions ....................................................................9

1.2 General behavior when handling the product .....................................9

1.3 Intended use ..........................................................................................10

1.4 Foreseeable misuse ..............................................................................10

1.5 Modifications to the product ................................................................11

1.6 Inspections prior to delivery ................................................................11

1.7 Referenced documents ........................................................................11

1.8 Notes on the rating plate .....................................................................11

1.9 Note on CE marking .............................................................................12

1.10 Persons authorized to use the product ..............................................12

1.10.1 Operator ...........................................................................................12

1.10.2 Qualified mechanic .........................................................................12

1.10.3 Qualified electrician ........................................................................12

1.11 Instruction of outside fitters ................................................................12

1.12 Provision of personal protective gear .................................................13

1.13 Operation ...............................................................................................13

1.14 Emergency shutdown ..........................................................................13

1.15 Transport, assembly, maintenance, malfunction,

repair, shutdown, disposal ...................................................................13

1.16 Initial commissioning, daily startup ....................................................15

1.17 Cleaning .................................................................................................15

1.18 Residual risks ........................................................................................16

2. Lubricants .......................................................................... 18

2.1 General information .............................................................................18

2.2 Selection of lubricants ..........................................................................18

2.3 Material compatibility ...........................................................................19

2.4 Aging of lubricants ................................................................................19

3. Overview, functional description .......................................... 20

3.1 Principle of minimal quantity lubrication ...........................................20

3.2 Principle of aerosol action ...................................................................20

3.3 General function and design ...............................................................20

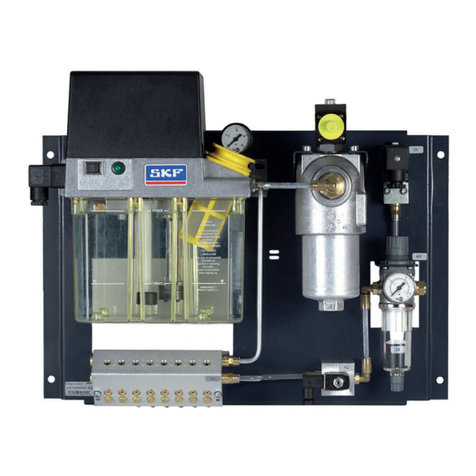

3.4 Main components of a UFD minimal quantity lubrication system..22

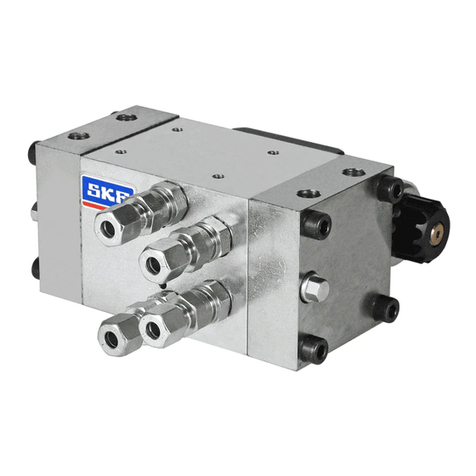

3.4.1 Aerosol generator ..........................................................................22

3.4.2 Control unit ......................................................................................23

3.4.3 Communication interface ..............................................................24

3.4.4 Flow sensor .....................................................................................24

3.4.5 Fill level indicator and monitoring ................................................24

3.4.6 Main air valve (compressed air connection) ................................24

3.4.7 Pressure gauge ...............................................................................25

3.4.8 Fine filter for compressed air ........................................................25

3.4.9 Lubricant drain valve ......................................................................25

3.4.10 Safety valve .....................................................................................25

3.5 Design-specific components ...............................................................26

3.5.1 PROFIBUS communication interface ...........................................26

3.5.2 PROFINET communication interface ...........................................29

3.5.3 Automatic filling pump ...................................................................32

3.5.4 Automatically controlled bypass valve – bypass control ............32

3.6 System designs and type codes .........................................................35

3.6.1 Minimal quantity lubrication systems with

one aerosol generator ....................................................................38

3.6.2 Minimal quantity lubrication systems with

two aerosol generators ..................................................................54