Table of Contents

Usage Classes for Vehicular Gates ........................................................................................................ Page 7

Technical Data ....................................................................................................................................... Page 8

Pre-Installation Recommendations ...................................................................................................... Page 9

Installation Procedures ....................................................................................................................... Page 10

Installation Completion / Follow-up ................................................................................................... Page 12

Pressure Adjustments ......................................................................................................................... Page 13

Purging the Operator .......................................................................................................................... Page 13

Hydraulic Fluid .................................................................................................................................... Page 13

Manual Bypass .................................................................................................................................... Page 14

Pressure & Flow Control ..................................................................................................................... Page 15

Mounting Pins & Brackets ................................................................................................................... Page 15

Optional Mounting Hardware ............................................................................................................. Page 16

Front Mounting Detail ........................................................................................................................ Page 17

Mounting Geometry ........................................................................................................................... Page 18

Mounting Bracket Dimensions ............................................................................................................ Page 19

Recommended Wire Sizes .................................................................................................................. Page 20

Wiring the Control and Accessories .................................................................................................... Page 21

Loop Detector Connections ................................................................................................................ Page 47

Recommended Placement of Safety Edges and Photobeams ............................................................ Page 48

End User Safety ................................................................................................................................... Page 49

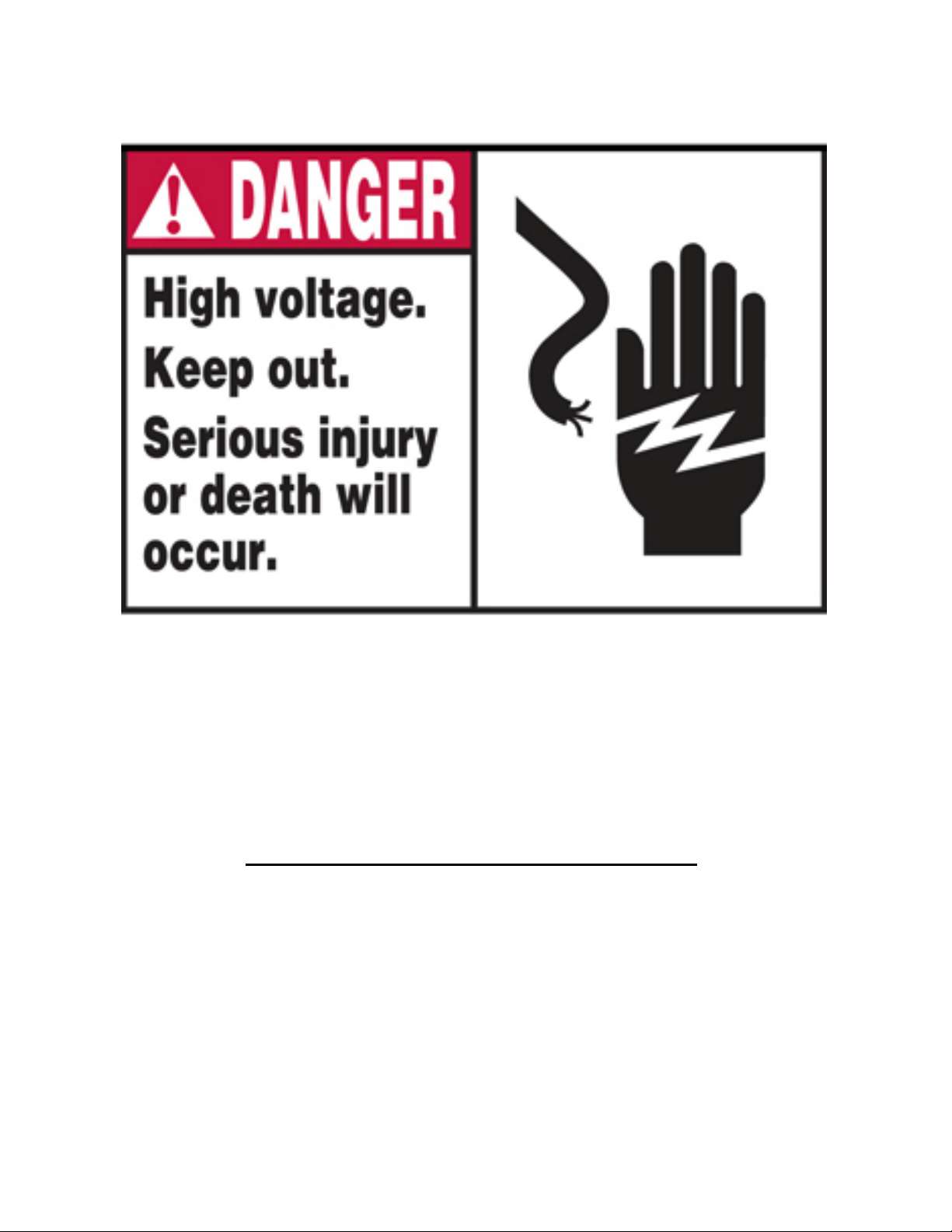

WARNING PLACARD ............................................................................................................................ Page 51

Byan Systems Warranty ...................................................................................................................... Page 52

Safety Accessories Compatible and Tested with Byan Systems Products .......................................... Page 53

Customer Acknowledgement ............................................................................................................. Page 55