C-Flow LAB 1x1 User manual

21/08/2019 1

C-Flow® LAB 1x1

Instruction Manual

21/08/2019 2

Table of Contents

1Introduction....................................................................................................................3

2Safety .............................................................................................................................4

3Unpacking.......................................................................................................................4

4Specifications ..................................................................................................................5

5Assembly Instructions .....................................................................................................6

6Parts List and Exploded View ...........................................................................................7

7Troubleshooting..............................................................................................................9

8Cleaning..........................................................................................................................9

9Templates .......................................................................................................................9

10 Other C-Flow Products ..................................................................................................10

11 Disclaimer .....................................................................................................................11

21/08/2019 3

1Introduction

C-Flow® LAB 1x1 has been designed for general purpose laboratory electrochemical work. This

includes research and development, electrochemical reaction study, and the development of

electrodes, electrolytes and membranes.

A stand is provided to make assembly quick and easy. The use of the stand is shown in the on-line

video demonstration. The unit is designed for ease of use and no tools are required for assembly.

The cell comes equipped with a set of electrodes but it is designed so that you can fit your own

electrodes very easily. Templates are provided so that you can cut your own gaskets and

membranes.

C-Flow® LAB 1x1 has been designed based on our long experience of electrochemical R&D. We are

constantly improving our products and we welcome any feedback or suggestions you have about

C-Flow® LAB 1x1.

21/08/2019 4

2Safety

C-Flow® LAB 1x1 weighs 1.25 kg when assembled and precautions should be taken to avoid injuries

to feet if the unit is accidentally dropped. Safety shoes should be worn when unpacking, assembling,

disassembling or moving the cell.

The user should carry out a risk assessment before using the C-Flow® LAB 1x1. This should include

a COSHH assessment for the substances under test. Suitable Personal Protective Equipment should

be worn and other suitable measures taken to control the risk of exposure to substances hazardous

to health.

Due to risk of chemical release at pressure, it is recommended that the user measure the pressure

at the entrance to the cell and restrict the liquid flow rate so that the pressure does not exceed 1

bar (gauge). The user should check the pressure rating of any tubing or fittings used with the cell

(not provided). It is recommended that the cell be checked for leaks with a non-hazardous substance

(e.g. water) every time it is reassembled. It is the responsibility of the user to complete a risk

assessment for all aspects of use.

3Unpacking

C-Flow® LAB 1x1 is shipped already assembled but not tightened. It is recommended that the cell

be dismantled and reassembled before use. This will familiarise the user with its construction and

to allow user to make changes to the cell set-up e.g. addition of membrane (not provided).

Take care when unpacking the cell to avoid dropping it and causing damage or injury.

21/08/2019 5

4Specifications

Height

110 mm

Width

100 mm with fittings

Depth

150 mm with fittings

Weight

1.25 kg

End plates

304 stainless steel

Electrode gap

10 mm

Electrode dimensions

20 mm x 20 mm for working electrode area of 10 mm x 10 mm

Electrode material

carbon supplied as standard

Current collectors

brass

Electrolyte ports

PEEK

Reference electrode blanks

PEEK

Cell Frames

CPVC

Gasket material

EPDM

Membrane material

not supplied

Electrode gasket material

expanded EPDM

O-rings

EPDM

Stand

polypropylene

Gasket templates

stainless steel

Maximum applied voltage

10 V

Operating temperature

up to 80°C

Throughput

depending on fluid properties

Pressure

up to 1 bar (g)

21/08/2019 6

5Assembly Instructions

Place Stand with triangular base on a work surface with wide end towards user.

Place Back Frame (plastic block, not the metal Back Plate) O-Ring groove side down

onto inner notch on Stand.

Carefully fit Electrode Gasket into recess of Back Frame and then fit Electrode,

ensuring that the Electrode Gasket stays in place. Current Collector, Insulating Disc,

Insulating Sleeve.

Place Back Plate over the Back Frame, feet towards user, threaded rods passing

through the Back Frame. Screw Electrode Pressure Knob into Back Plate, knurled ring

to rear of Back Plate, until it just touches the Electrode Assembly.

Pick up the whole sub-assembly, turn it over, place it on the Stand. Fit O-Ring (note

that the O-Ring grooves on the two Frames are of different sizes, with O-Rings to

match, so take care to match the two O-rings to the grooves.

Optional - Fit Membrane Gasket, Membrane and second Membrane Gasket. The

purpose of the Membrane Gaskets is to locate a Membrane, if used.

Fit O-Ring into face of Front Frame and fit the Front Frame over the threaded rods.

Fit the Electrode Gasket into recess and fit the Electrode ensuring that the Electrode

Gasket stays in place

Place brass Current Collector onto Electrode. Fit Insulating Disc and Insulating Sleeve

onto the Current Collector.

Place Front Plate over the threaded rods.

Fit Electrode Pressure Knob. Loose fit only –knob just touching collector

Fit Insulating Disc, then Washers, then Terminal Knob.

Fit four Thumb Nuts loosely –do not tighten fully

Take the unit off the stand and rest it on its feet to ensure that frames are aligned

Tighten the four corner Thumb Nuts, bit by bit, opposite corners together.

Finally tighten the two Electrode Pressure Knobs

Fit Electrode Ports and Reference Electrode Ports as required. Use Teflon tape for a

good seal. If reference electrodes are not used then fit Reference Electrode Port Plugs.

The cell is now complete.

21/08/2019 7

6Parts List and Exploded View

Item

Description

Quantity

1

Stand

1

2

Terminal Knob

2

3

Washer

4

4

Insulating Disc

2

5

Insulating Sleeve

2

6

Electrode Pressure Knob

2

7

Back Plate

1

8

Current Collector

2

9

Electrode

2

10

Electrode Gasket

2

11

Reference Electrode Port Plug

2

12

Electrode Port 1/8”

4

13

Electrode Port 1/16”

2

14

Back Frame

1

15

O Ring ID 40.95 Dia 2.62

1

16

Membrane Gasket

2

17

Membrane (not supplied)

-

18

O Ring ID 50.47 Dia 2.62

1

19

Front Frame

1

20

Front Plate

1

21

Thumb Nut

4

22

Membrane Template

1

23

Membrane Gasket Template

1

24

Electrode Gasket Template

1

21/08/2019 8

21/08/2019 9

7Troubleshooting

Leaks

Check for leaks with water. If there are leaks then disassemble, check all components and

reassemble. Take care to ensure that Electrode Gaskets and O-Rings are in place and that the

frames are square when tightening the thumb nuts.

Check O-Rings in place

Check Membrane Gaskets in place

Check no foreign bodies or dirt on gaskets of faces of Cell Frames

Check Electrode Gaskets are in place. Replace if worn or torn

Check Electrolyte Ports are tight with Teflon Tape

Check Reference Electrode Port is tight and blanked off if not in use

Poor Flow Rate

Check piping not kinked

Poor Electrical Contact

Check Current Collector face is clean and bright. Use solvent and or gentle abrasive

Check rear-side of electrode is clean. Use solvent and gentle abrasive if not

Check Electrical Connectors are tightened

8Cleaning

After use the cell should be thoroughly flushed with water and disassembled and dried.

All components can be cleaned with detergent or ethanol or isopropyl alcohol.

Periodically check the Electrodes for degradation. Clean them and replace if necessary.

The brass current collectors should be cleaned periodically to ensure good electrical contact with

the electrodes. Keep the brass bright with fine abrasive and detergent.

9Templates

A template is provided for users to cut both Electrode Gaskets and Membranes.

21/08/2019 10

10 Other C-Flow Products

C-Flow LAB 5x5 is a hand-assembled laboratory

electrochemical cell with a 50 mm x 50 mm electrode area.

It is an ideal general purpose electrochemical cell for

research and development purposes.

C-Flow PLT is a modular pilot plant that offers very high flow

rates and flexibility of operation. It is perfect for

electrochemical process development in industry or

academia.

A wide variety of electrochemical processes can be carried

out on C-Flow PLT, including the treatment of dilute systems

(e.g. waste water), chemical synthesis, viscous liquids or

particulate containing liquids, and systems requiring high

volumetric flows.

C-Flow PRD is our production scale electrochemical system.

Its individual cells give flexibility of operation and of scale-up.

It can be customised to suit a wide range of electro-chemical

applications, from treatment of waste waters to synthesis of

electrolytes and fine chemicals.

21/08/2019 11

11 Disclaimer

Care has been taken in the preparation of this manual to give instructions of relevance to normal

use of the product. All advice, analysis, calculations, information, forecasts and recommendations

are supplied for the assistance of the user and are not to be relied on as a substitution for the

exercise of judgement by the user. C-Tech Innovation Ltd does not accept liability for any direct or

consequential loss arising from use of this manual or its contents and gives no warranty or

representation (express or implied) as to the fitness for the purpose of any process, material,

product or system referred to in the manual.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or

by any means electronic, mechanical, photocopied, recorded or otherwise, or stored in any

retrieval system of any nature without the written permission of the copyright holder.

21/08/2019 12

C-Tech Innovation Ltd

Capenhurst Technology Park

Capenhurst

Chester

UK

CH1 6EH

Tel: +44 (0) 151 347 2900

www.ctechinnovation.com

Table of contents

Popular Laboratory Equipment manuals by other brands

Shel lab

Shel lab SMI Series operating manual

Fluke

Fluke 7381 user guide

CORNING

CORNING LSE 6783 instruction manual

NanoEnTek

NanoEnTek ADAM MC2 instruction manual

PIKE Technologies

PIKE Technologies Jackfish Installation and user guide

MO BIO Laboratories

MO BIO Laboratories UltraClean GelSpin DNA instruction manual

Velp Scientifica

Velp Scientifica AREX 5 instruction manual

Siemens

Siemens PFA-100 System instruction manual

UV POD

UV POD S1 user manual

Barnstead International

Barnstead International DIamond 1265 Series Operating manual and parts list

IKA

IKA IKAMAG Maxi MR 1 operating instructions

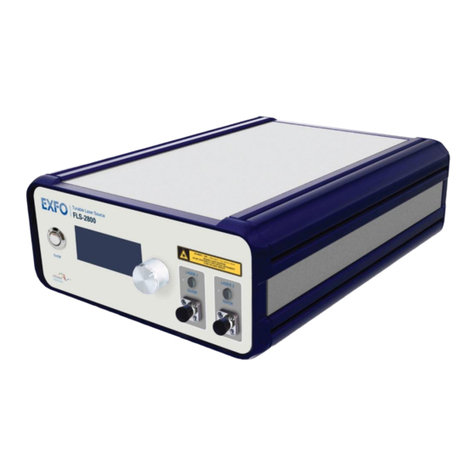

EXFO

EXFO FLS-2800 user guide