17

For your protection

• Read the operating instructions in full before starting up

and follow the safety instructions.

• Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations.

• Keep the operating instructions in a place where they can be

accessed by everyone.

• Ensure that only trained staff work with the appliance.

•

The device must be supervised at all times when in operation.

•

Caution! For research purposes only! Not suitable for di-

agnostic use (in accordance with the IVD Directive).

The

device

must only be operated with a tube

attached; with no tube there is a risk of injury

from the rotating locating pin.

• Hearing protection must be worn when working with BMT-20

or BMT-50 tubes.

Wear your personal protective equipment in

accordance with the hazard category of the

medium to be processed. There is a risk of:

- splashing liquids

- projectile parts

- body parts, hair, clothing and jewellery getting caught.

• Set up the

device

in a spacious area on an even, stable, clean,

non-slip, dry and fireproof surface.

• The feet of the

device

must be clean and undamaged.

• The

device

is not suitable for manual operation.

• The

device

may heat up when in use.

•

Check the device and accessories beforehand for damage each

time when you use them. Do not use damaged components.

• Ensure that the cover on the tube is screwed on tightly.

• Ensure that the tube is firmly attached to the bayonet lock con-

nector on the drive unit prior to operating the device.

• The tube must only be attached and removed while the motor

is stationary.

The IKA tubes must always be closed when the

device is in operation. Switch off the device im-

mediately if any material leaks from the tube. Clean the device.

• Always open the tube carefully after use as the media in the

tube may heat up due to transfer of energy during operation,

leading to pressurization of the container: risk of material spray-

ing, protective equipment must be worn.

• The temperature of the material must not exceed 40 °C.

• Only use tubes approved by IKA.

•

Only process media that will not react dangerously to the extra

energy produced through processing. This also applies to any extra

energy produced in other ways, e.g. through light irradiation.

• Do not use the device in explosive atmospheres, it is not EX-

protected.

•

With substances capable of forming an explosive mixture, appropriate

safety measures must be applied, e.g. working under a fume hood.

•

To avoid body injury and property damage, observe the relevant

safety and accident prevention measures when processing haz-

ardous materials.

• The device doesn’t start up again automatically following a cut

in the power supply.

• Safe operation is only guaranteed with the accessories described

in the ”Accessories” chapter.

For protection of the device

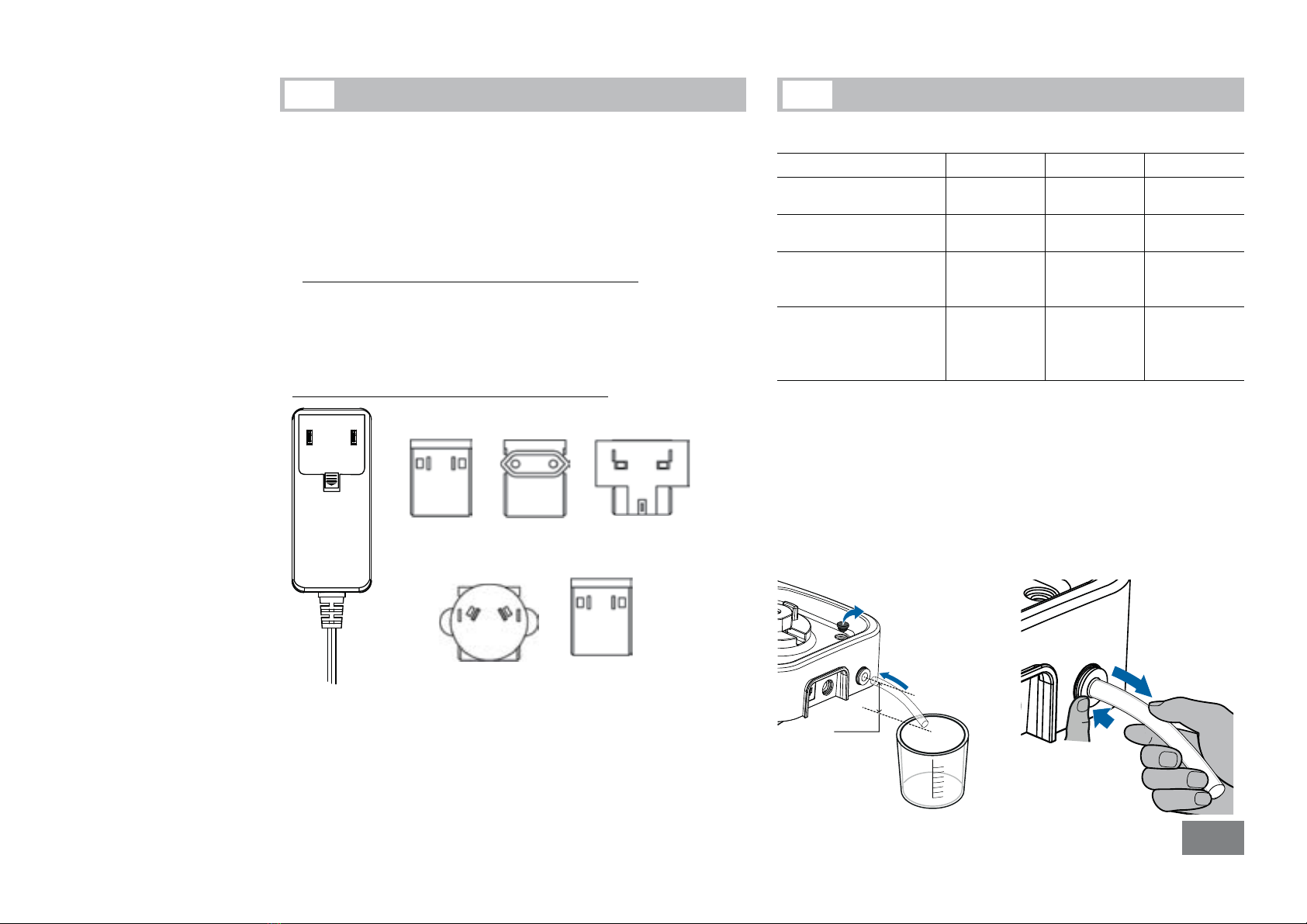

• The voltage stated on the name plate must correspond to the

mains voltage.

• The device must only be operated with the original plug-in pow-

er supply unit.

•

Protect the device and accessories from bumps and impacts.

• The device may only be opened by experts.

Safety instructions

3

DANGER

DANGER

WARNING