Table of Contents

51 Introduction ..........................................................................................................

61.1 About this manual ................................................................................................................................

71.2 Important user information .............................................................................................................

91.3 Associated documentation ..............................................................................................................

121.4 Abbreviations ..........................................................................................................................................

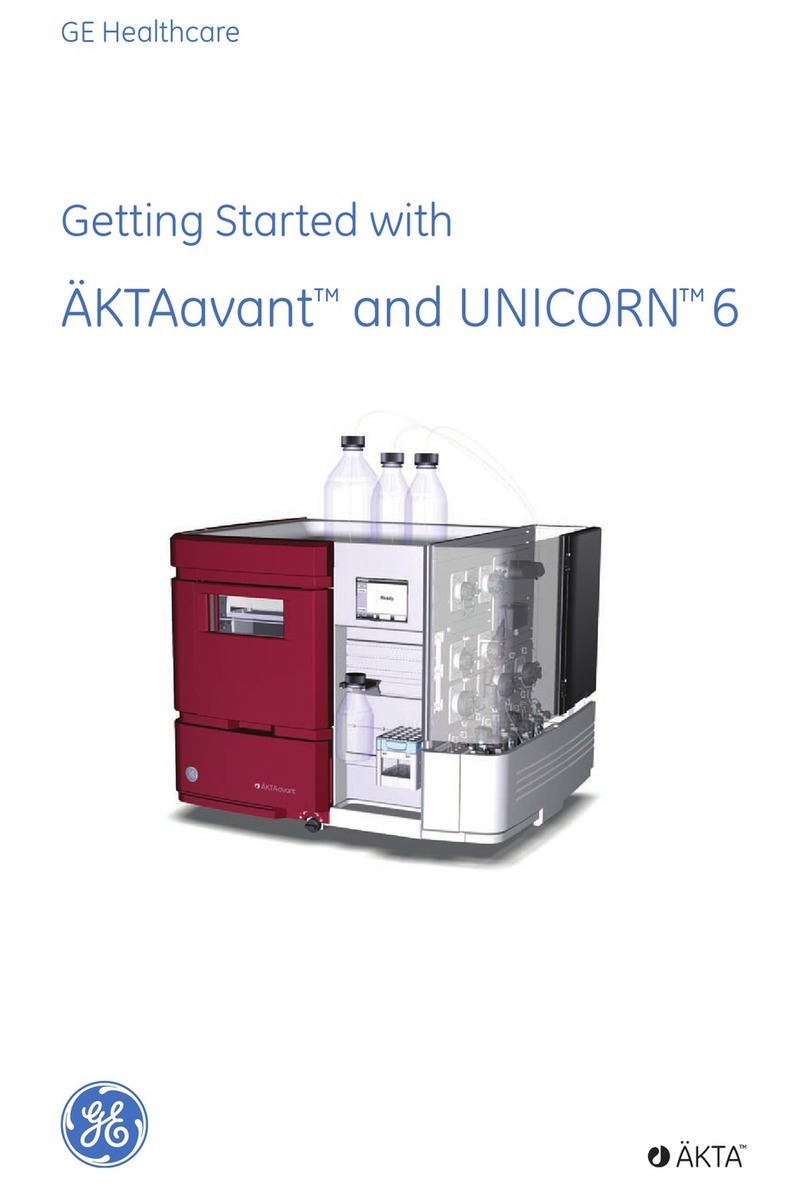

132 System description ..............................................................................................

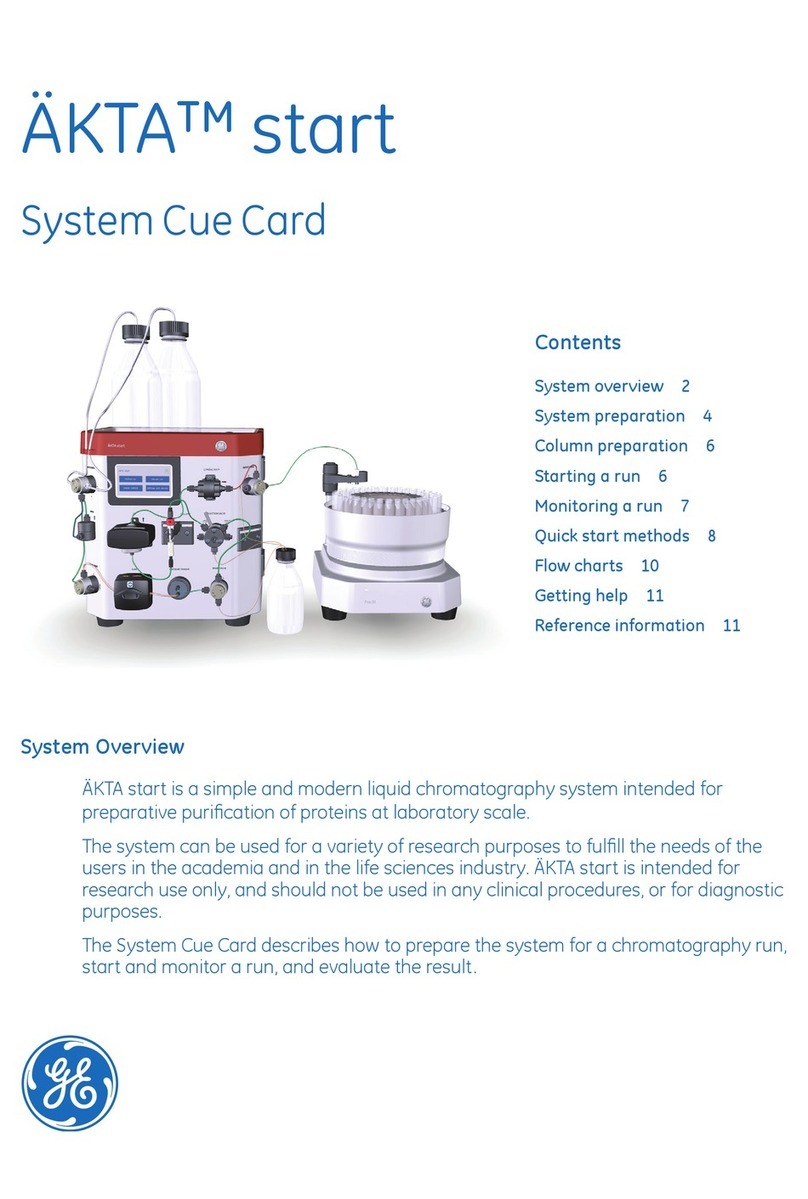

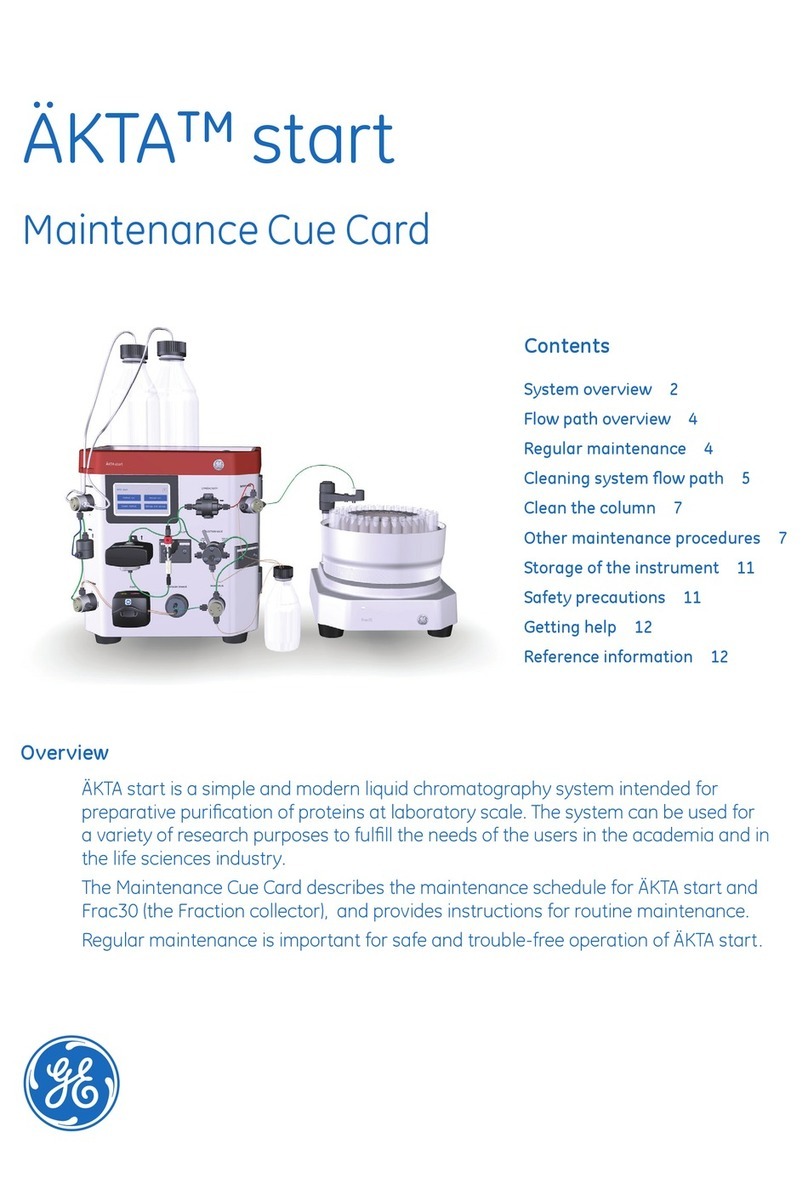

142.1 System overview ...................................................................................................................................

182.2 Instrument ...............................................................................................................................................

213 Maintenance operations ....................................................................................

233.1 Regular maintenance schedule .....................................................................................................

263.2 Clean before planned maintenance or service ......................................................................

273.3 Access the modules .............................................................................................................................

293.4 Instrument Display ...............................................................................................................................

313.4.1 Touch screen calibration .............................................................................................................

343.4.2 Color test ............................................................................................................................................

353.4.3 Diagnostics .......................................................................................................................................

363.4.4 Log book ............................................................................................................................................

383.5 UV Monitor ...............................................................................................................................................

393.5.1 UV LED calibration .........................................................................................................................

413.5.2 Diagnostics .......................................................................................................................................

443.5.3 Flow cell path length ....................................................................................................................

473.5.4 Reset number of run hours ........................................................................................................

483.6 Pump ..........................................................................................................................................................

503.6.1 Calibration .........................................................................................................................................

523.6.2 Diagnostics .......................................................................................................................................

543.6.3 Pump tubing log .............................................................................................................................

563.7 Buffer valve ............................................................................................................................................

593.8 Sample valve ...........................................................................................................................................

623.9 Wash valve ..............................................................................................................................................

653.10 Outlet valve ..............................................................................................................................................

683.11 Conductivity Monitor ...........................................................................................................................

693.11.1 Temperature sensor calibration ..............................................................................................

703.11.2 Sine generator calibration ..........................................................................................................

713.11.3 Conductivity flow cell calibration ............................................................................................

743.11.4 Set reference temperature .........................................................................................................

753.12 Pressure sensor ....................................................................................................................................

773.13 Frac30 ........................................................................................................................................................

783.13.1 Enable or disable Frac30 ............................................................................................................

793.13.2 Diagnostics .......................................................................................................................................

813.13.3 Run Log ..............................................................................................................................................

833.14 System .......................................................................................................................................................

853.14.1 Firmware update ............................................................................................................................

883.14.2 Export system report to USB .....................................................................................................

893.14.3 Delay volume setting ....................................................................................................................

ÄKTA start Maintenance Manual 29060308 AD 3

Table of Contents