4

SUMMARY

SUMMARY.................................................................................................................................................. 4

1INTRODUCTION .................................................................................................................................. 6

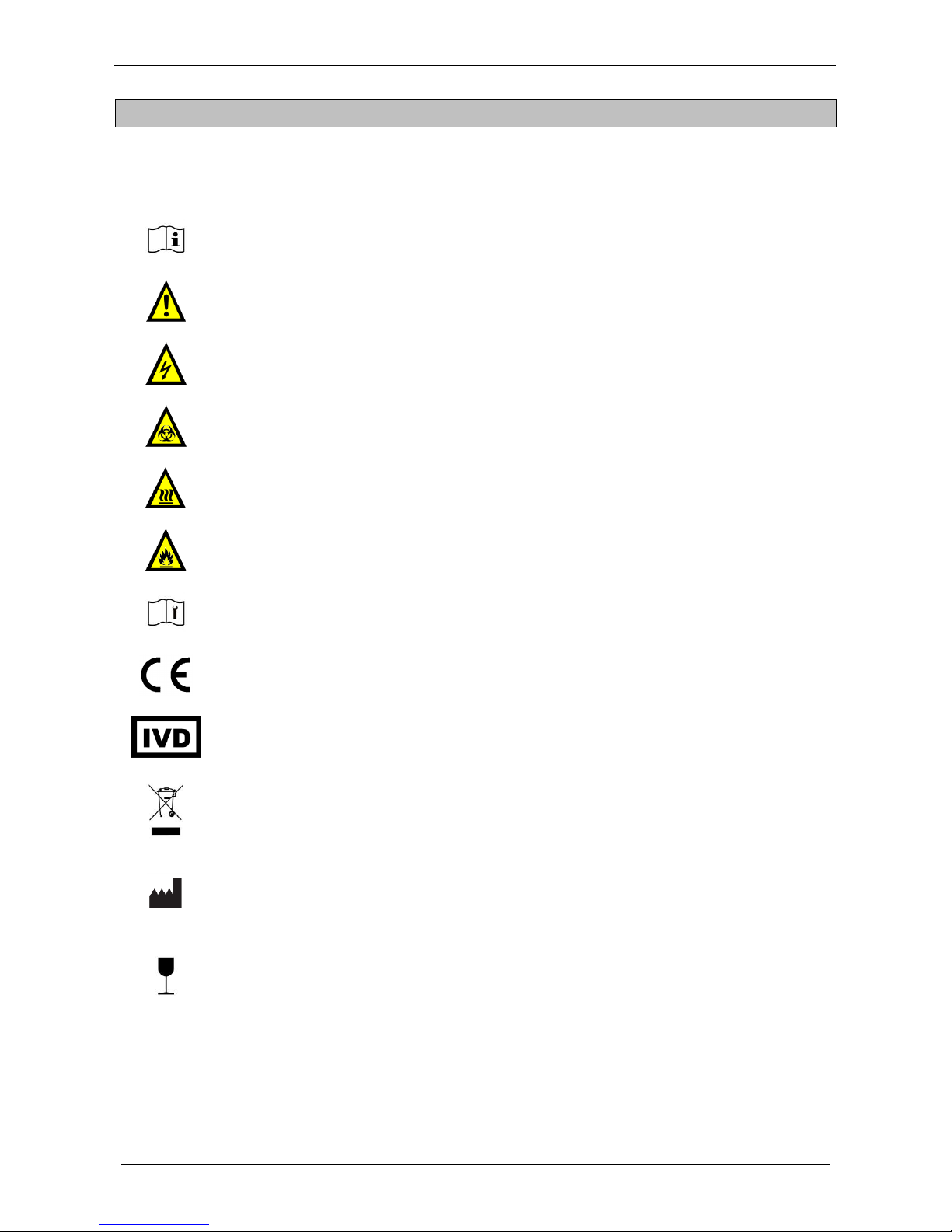

1.1 Symbol used................................................................................................................................. 6

1.2 Designated uses........................................................................................................................... 7

1.3 Technical specifications................................................................................................................ 7

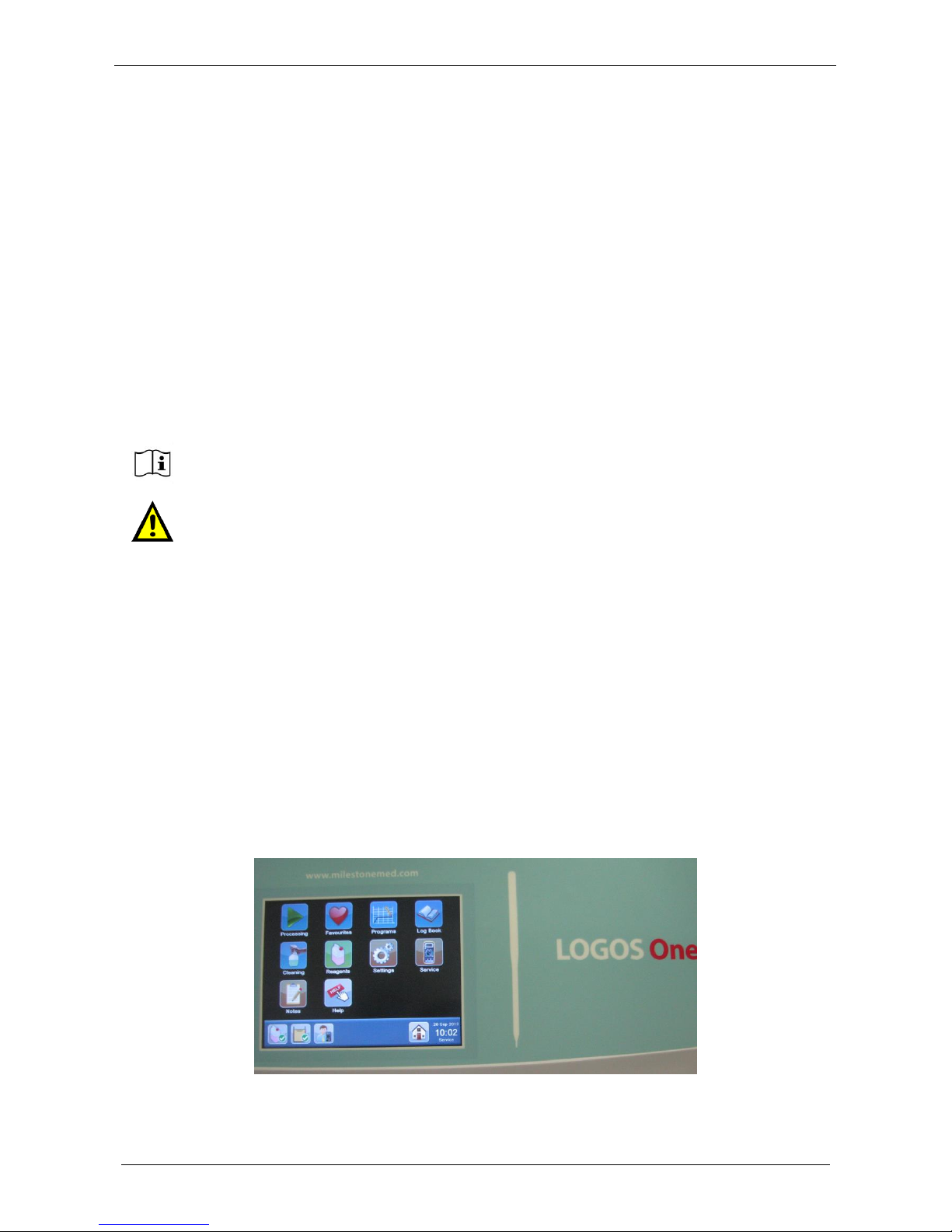

1.3.1 Touch control terminal .............................................................................................................. 7

1.4 Transportation and storage conditions .......................................................................................... 8

1.5 Warning information...................................................................................................................... 9

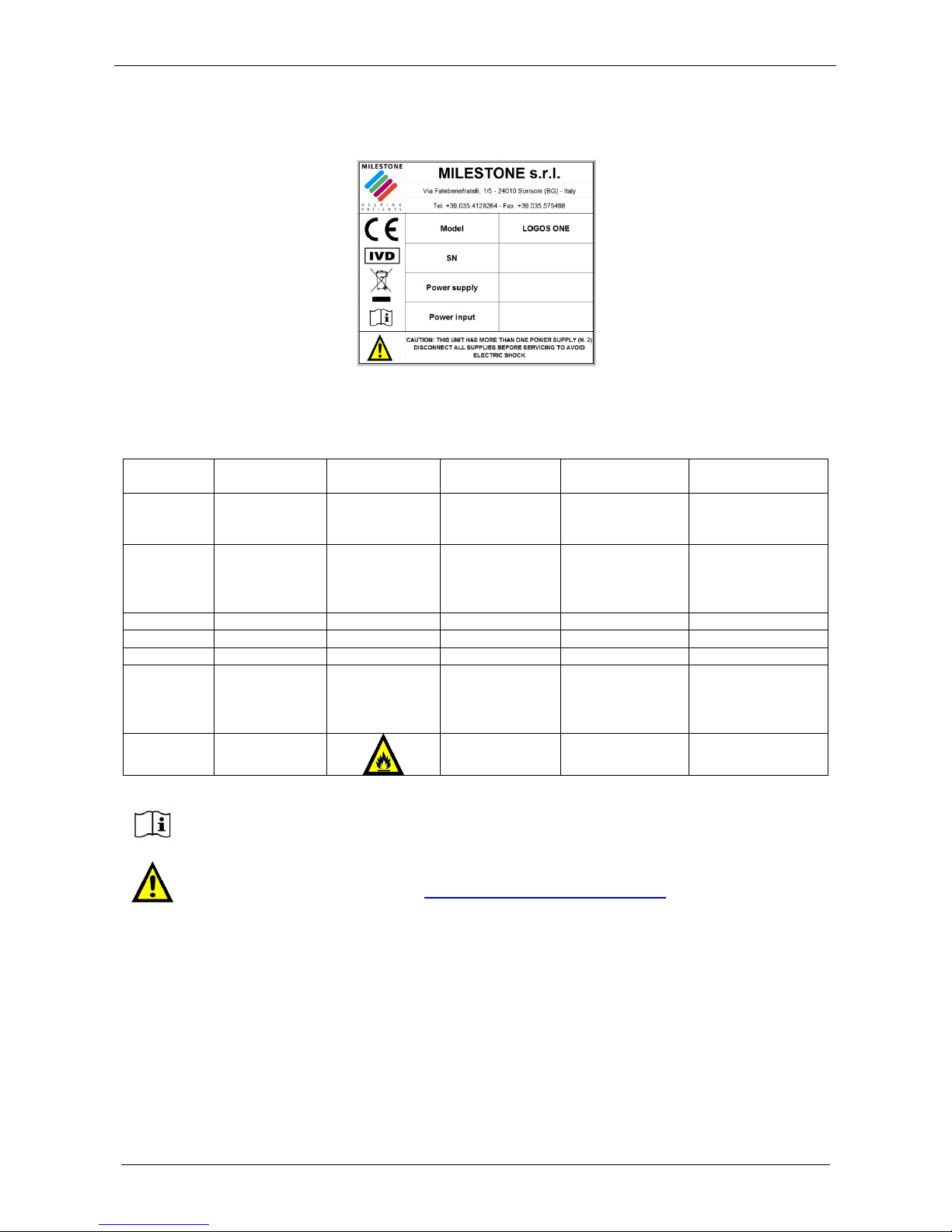

1.6 Labeling explanation....................................................................................................................10

1.7 Compatible reagents....................................................................................................................10

1.8 Waste disposal of the equipment.................................................................................................11

2INSTALLATION...................................................................................................................................12

2.1 Space requirements.....................................................................................................................12

2.2 Unpacking and checking list.........................................................................................................13

2.3 Placement...................................................................................................................................15

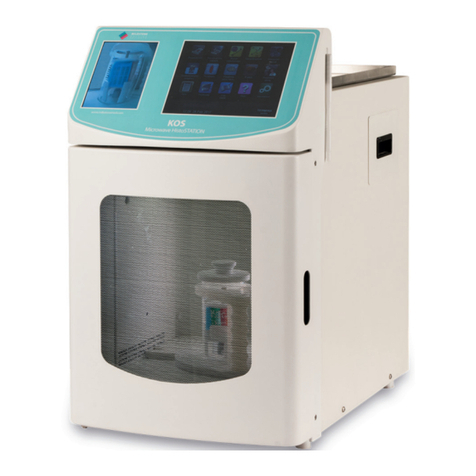

2.3.1 Unit overview...........................................................................................................................15

2.4 Fumes extraction system.............................................................................................................16

2.5 Power supply...............................................................................................................................17

2.6 Electrical installation....................................................................................................................17

2.6.1 Back side connection plate 230V Version.................................................................................18

2.6.2 Back side connection plate 115V Version.................................................................................18

2.6.3 Main power supply connection.................................................................................................19

2.6.4 Power supply connection (NO UPS mode)...............................................................................19

2.6.5 Power supply connection (Local UPS mode)............................................................................20

2.7 Remote alarm connection............................................................................................................22

2.8 Internet connection......................................................................................................................22

2.9 Reagents.....................................................................................................................................24

2.10 Log in and log out........................................................................................................................24

2.10.1 Create a new user................................................................................................................25

2.11 Set system date and time ............................................................................................................27

2.12 Set language...............................................................................................................................27

2.13 Load LOGOS ONE with wax........................................................................................................28

2.13.1 Wax heating setting .............................................................................................................30

2.14 Load LOGOS ONE with reagents ................................................................................................32

2.14.1 Set up LOGOS ONE with reagents.......................................................................................33

2.14.2 Cleaning procedure for cleaning tanks .................................................................................39

2.15 Most used programs....................................................................................................................39

2.16 Owner settings ............................................................................................................................41

3OPERATE WITH LOGOS ONE............................................................................................................44

3.1 Loading cassettes into the rack....................................................................................................44

3.1.1 Rack loading-unloading tool.....................................................................................................45

3.2 Run a program ............................................................................................................................46

3.2.1 Run of the most used program.................................................................................................46

3.2.2 Run a standard program..........................................................................................................54

3.2.3 Run two processes simultaneously ..........................................................................................57

3.2.4 Run a program using the STEP START function......................................................................59

3.2.5 Run a DELAYED PROGRAM ..................................................................................................60

3.2.6 Add WAX.................................................................................................................................63

3.2.7 Screen saver ...........................................................................................................................64

3.3 Run a cleaning cycle of the main cavity........................................................................................65

3.3.1 Tanks for process and main cavity cleaning.............................................................................66

3.4 Reagents group and programs.....................................................................................................68

3.5 Run a cleaning cycle of the WAX.................................................................................................69

3.6 Retrieving saved processes.........................................................................................................71

3.6.1 How to delete a saved process................................................................................................74

3.7 Modify a program.........................................................................................................................74

3.7.1 Modify a standard program......................................................................................................75

3.7.2 Correlation between racks and programs.................................................................................76