User manual 2 / 28

Document ID: AI0003CE 2015-02-16

Megger Sweden AB phone: +46 8 510 195 00

Rinkebyvägen 19 email: seinfo@megger.com

182 36 Danderyd website: www.megger.com

Sweden

Content

1Overview................................................................................................................................................... 3

1.1 General .............................................................................................................................................. 3

1.2 Measurement principle ...................................................................................................................... 3

2Specification.............................................................................................................................................. 3

3Safety......................................................................................................................................................... 5

3.1 General .............................................................................................................................................. 5

3.2 Instrument symbols ........................................................................................................................... 5

3.3 Warning and Caution Notices............................................................................................................ 6

3.3.1 Warning..................................................................................................................................... 6

3.3.2 Caution ...................................................................................................................................... 6

3.4 General safety information ................................................................................................................ 6

3.5 Instrument safety ............................................................................................................................... 7

4Maintenance .............................................................................................................................................. 8

5Warranty.................................................................................................................................................... 8

5.1 Receiving Instructions....................................................................................................................... 8

5.2 Warranty............................................................................................................................................ 8

5.3 Warranty repair.................................................................................................................................. 8

6Control, indicators and connectors............................................................................................................ 9

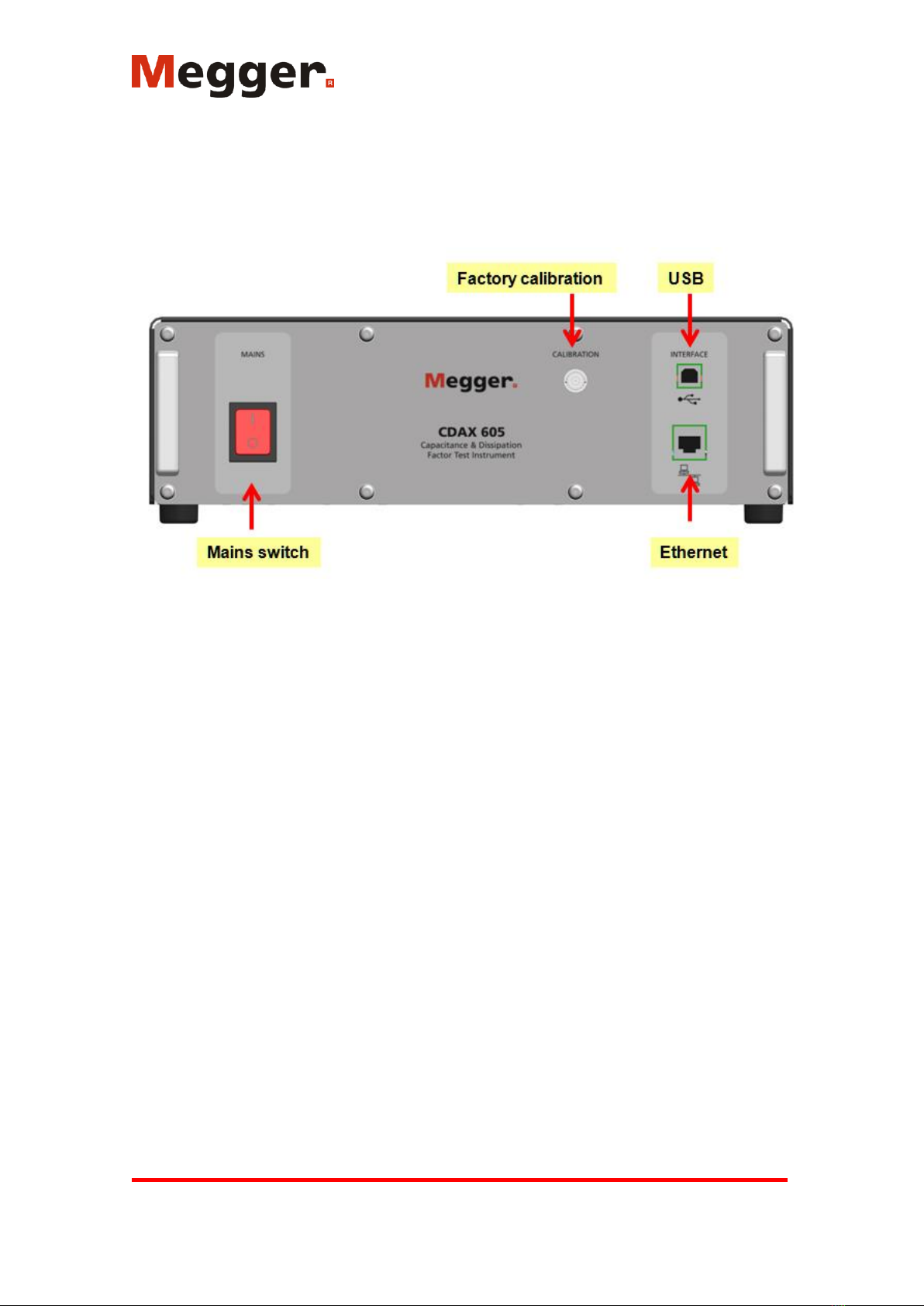

6.1 Front panel......................................................................................................................................... 9

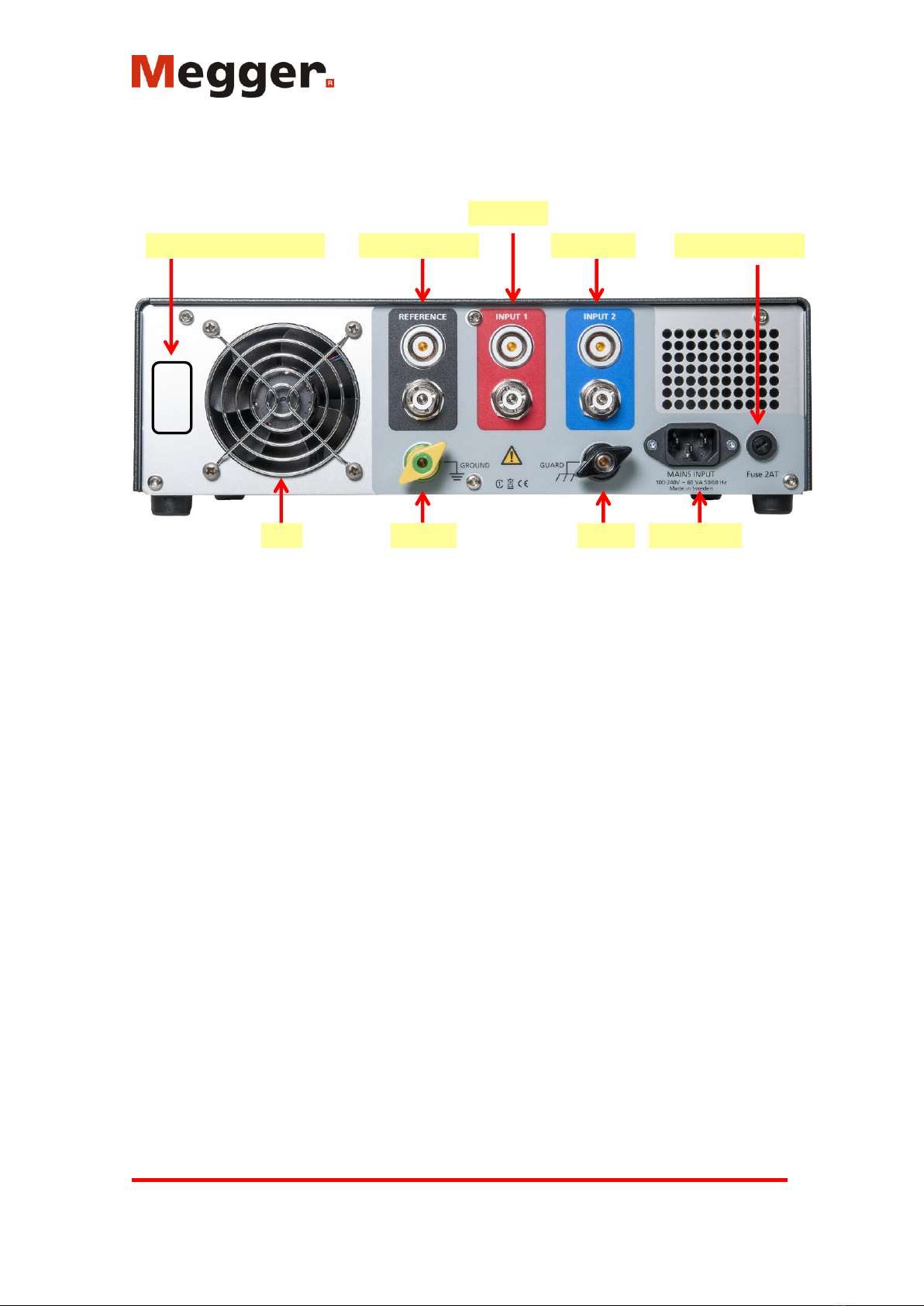

6.2 Back panel ....................................................................................................................................... 10

7Software Installation................................................................................................................................ 11

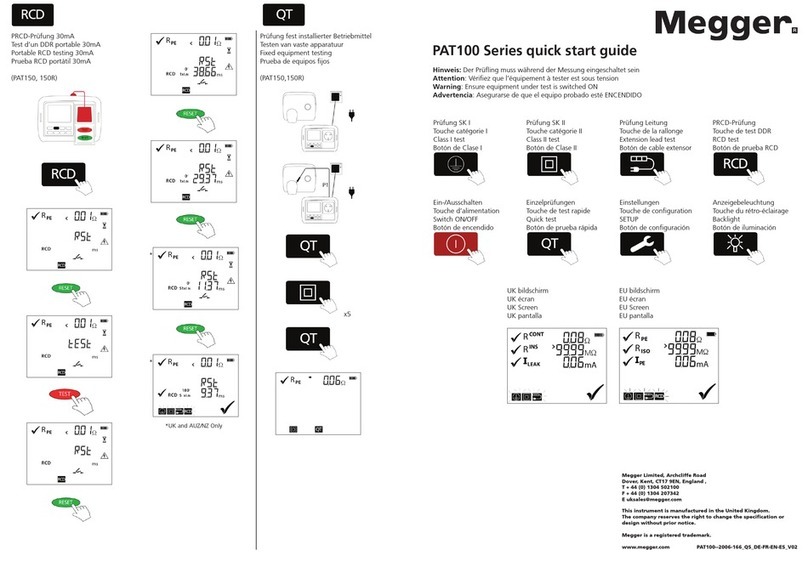

8CDAX605 Control .................................................................................................................................. 11

8.1 Connect............................................................................................................................................ 11

8.2 Control tab....................................................................................................................................... 12

8.3 Settings tab ...................................................................................................................................... 14

9Calibration............................................................................................................................................... 16

9.1 Warm-up.......................................................................................................................................... 16

9.2 Calibration procedure ...................................................................................................................... 16

9.2.1 Calibration............................................................................................................................... 17

9.2.2 Balancing................................................................................................................................. 17

10 Operating instructions ......................................................................................................................... 17

10.1 Standard test circuits........................................................................................................................ 17

10.1.1 Ungrounded Specimen Test (UST) with grounded HV Supply............................................... 17

10.1.2 Ratio transformer with grounded HV supply........................................................................... 20

10.1.3 Grounded Specimen Test (GST) with floating HV Supply ..................................................... 21

10.2 Measurements with Test Current greater than 5A (with external current transformer)................... 22

10.2.1 General information on Range Extension................................................................................ 22

10.2.2 Errors caused by an external CT.............................................................................................. 22

11 Stored data and reporting..................................................................................................................... 23

12 User fields............................................................................................................................................ 23

12.1 Editing user fields............................................................................................................................ 24

12.1.1 Description of buttons ............................................................................................................. 24

12.1.2 User field parameters............................................................................................................... 24

12.1.3 Entering a formula................................................................................................................... 26

12.1.4 Example –Creating a user field showing correction factor..................................................... 27

12.2 The Results Window ....................................................................................................................... 27