Index

1. Safety Notices ....................................................................................................................4

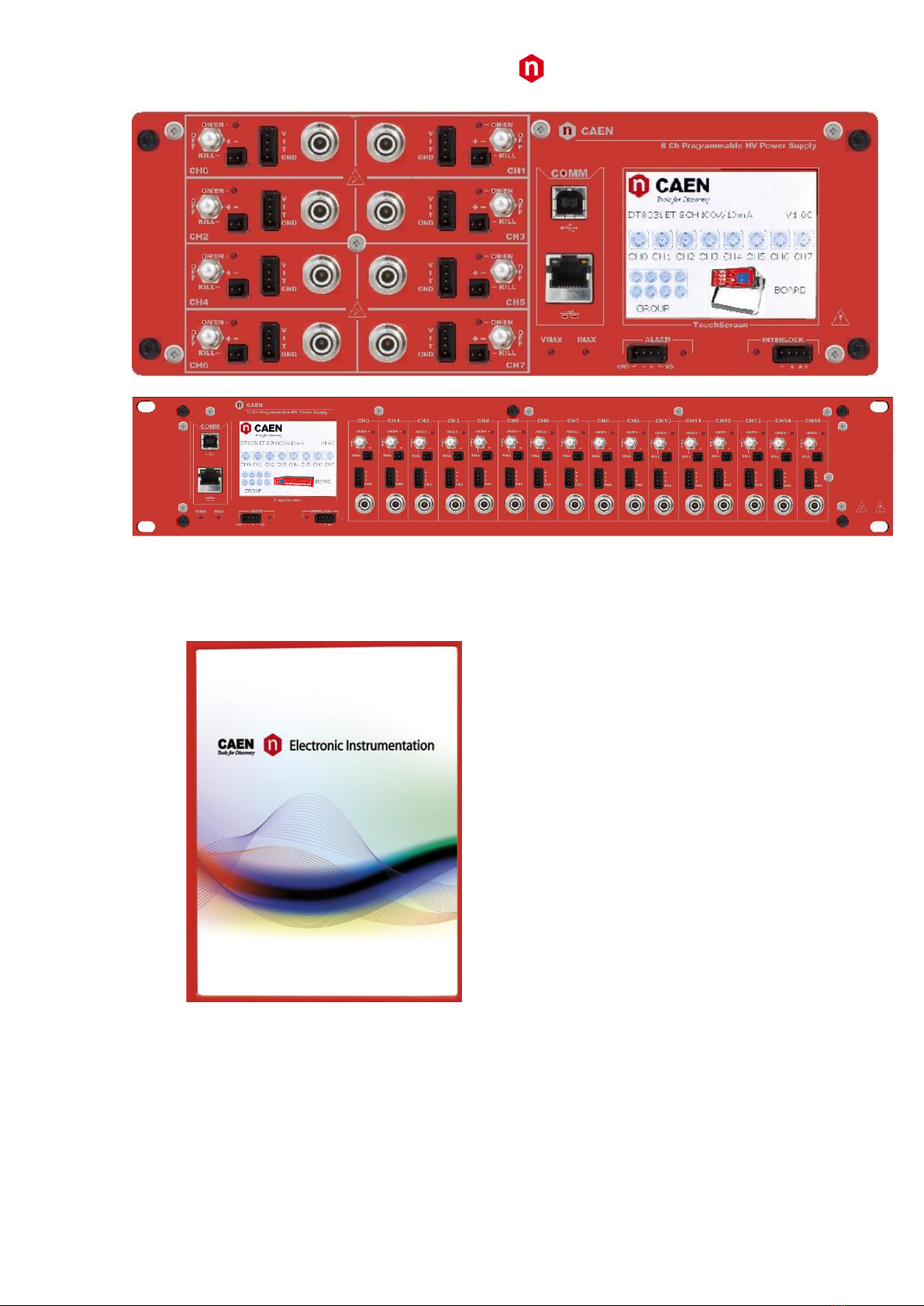

2. 803x Series Overview .........................................................................................................6

3. Technical specifications ......................................................................................................7

Packaging..................................................................................................................................................................7

Power requirements.................................................................................................................................................7

Front panel ...............................................................................................................................................................8

External connections ................................................................................................................................................9

Local control section ..............................................................................................................................................................9

Channel control section .......................................................................................................................................................10

HV Status control section.....................................................................................................................................................10

Alarm signal ...............................................................................................................................................................................10

Interlock signal...........................................................................................................................................................................10

Remote communication control section..............................................................................................................................11

HV Channel Output ..............................................................................................................................................................11

AC Input (DT803x, R803x) ....................................................................................................................................................11

Technical specifications table ................................................................................................................................. 12

4. Operating modes..............................................................................................................13

Hardware installation ............................................................................................................................................. 13

Unit Power ON........................................................................................................................................................13

Local Control........................................................................................................................................................... 14

BOARD Settings....................................................................................................................................................................14

Channel settings...................................................................................................................................................................15

Group Settings .....................................................................................................................................................................16

Status Icon............................................................................................................................................................................18

Remote Control ...................................................................................................................................................... 19

Software tools......................................................................................................................................................................19

GECO2020..................................................................................................................................................................................19

CAEN HV Wrapper .....................................................................................................................................................................19

Power Supply Modules LabVIEW Instrument Driver .................................................................................................................19

PC connection ......................................................................................................................................................................19

Module access via VT emulator ...........................................................................................................................................20

Ethernet Settings .......................................................................................................................................................................20

Format EEPROM ........................................................................................................................................................................21

Channels settings.......................................................................................................................................................................21

Voltage Temperature Compensation (VTC)............................................................................................................ 23

Communication Protocol........................................................................................................................................24

Command interface .............................................................................................................................................................24

Response to command.........................................................................................................................................................24

Command "PARLIST"............................................................................................................................................................24

Command "PARCHLIST" .......................................................................................................................................................24

Parameter descriptor...........................................................................................................................................................25

INFO Commands ..................................................................................................................................................................25

Board Parameters ................................................................................................................................................................25

Channel Parameters.............................................................................................................................................................26

EPICS Service...........................................................................................................................................................26

5. Instructions for Cleaning...................................................................................................27

Cleaning the Touchscreen ...................................................................................................................................... 27

Cleaning the air vents .............................................................................................................................................27

General cleaning safety precautions ......................................................................................................................27

6. Device decommissioning ..................................................................................................28