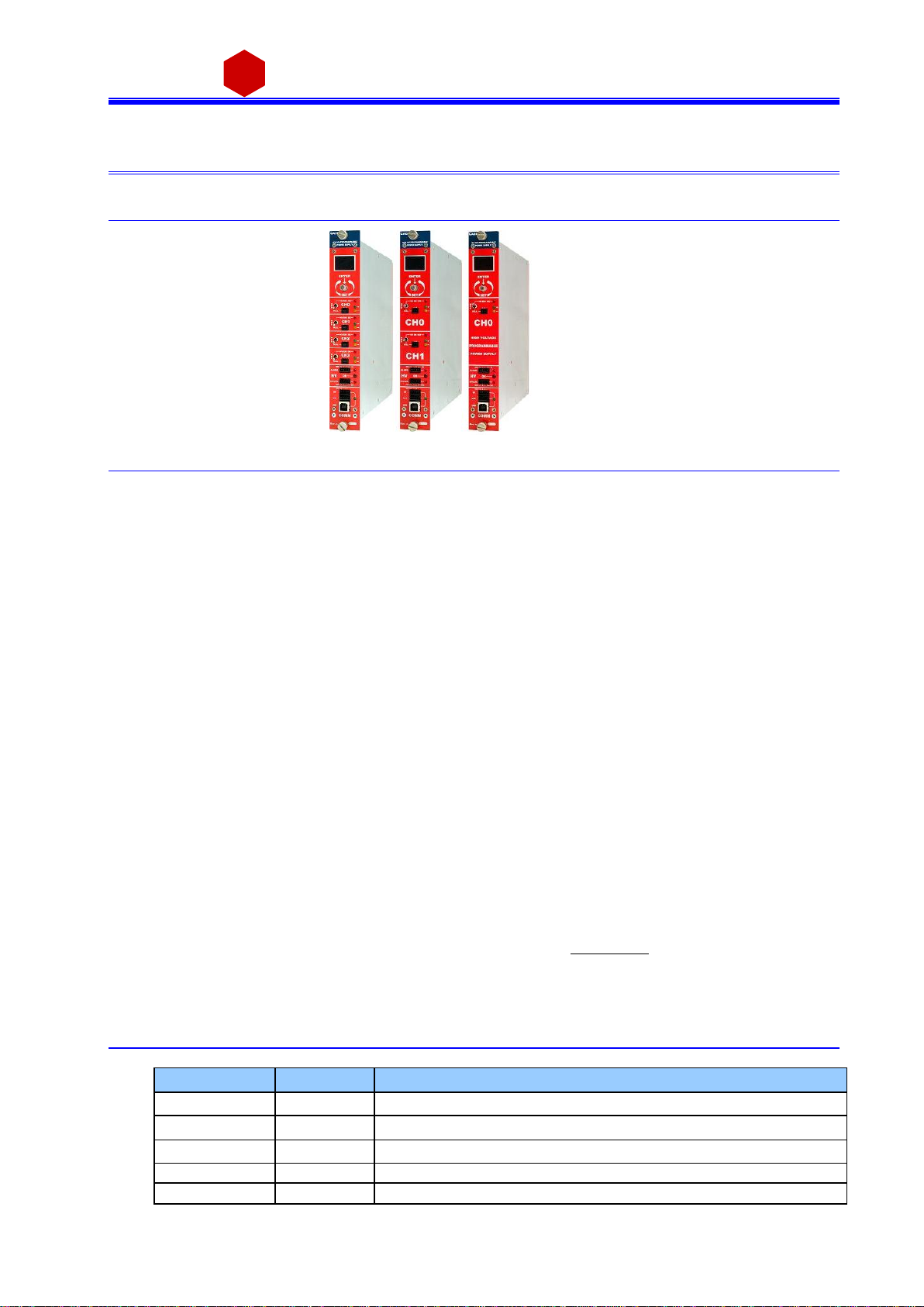

Programmable HV Power Supply

Revision19

TABLEOF CONTENTS

1General description ..............................................................................................................................................................5

1.1 Overview.......................................................................................................................................................................5

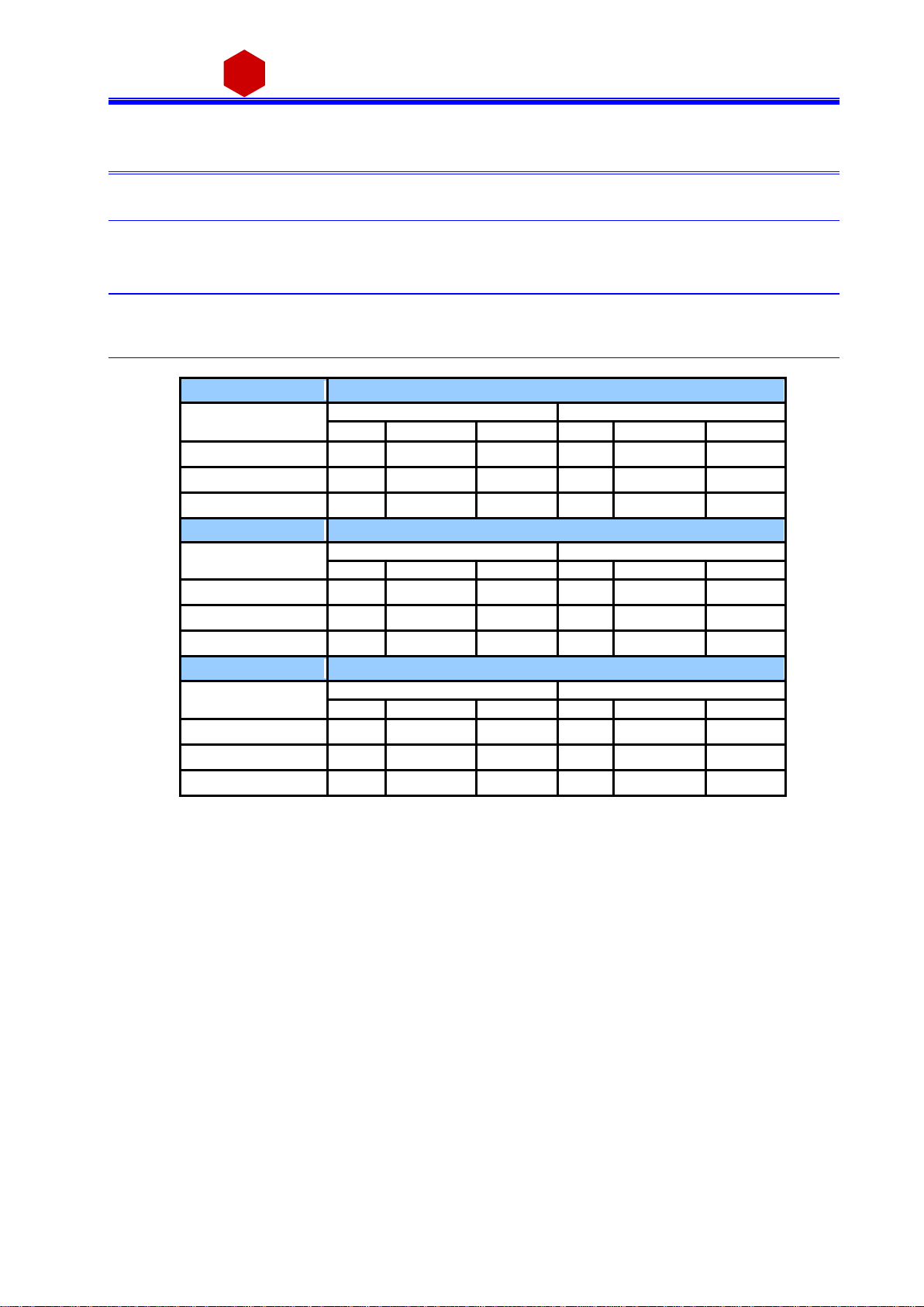

2Technical specifications......................................................................................................................................................6

2.1 Packaging.....................................................................................................................................................................6

2.2 Power requirements....................................................................................................................................................6

2.3 Front and back panel..................................................................................................................................................8

2.4 Front panel connections..........................................................................................................................................10

2.4.1 Local control section...........................................................................................................................................10

2.4.2 Channel control section......................................................................................................................................10

2.4.3 HV Status control section..................................................................................................................................11

2.4.3.1 Alarmsignal..................................................................................................................................................11

2.4.3.2 Interlock signal..............................................................................................................................................11

2.4.4 Remote communication control section..........................................................................................................12

2.5 Rear panel connections...........................................................................................................................................13

2.5.1 HV Channel Output.............................................................................................................................................13

2.6 Imon Zoom................................................................................................................................................................13

2.7 Technical specifications table.................................................................................................................................14

3Operating modes ................................................................................................................................................................15

3.1 Programmable parameters.....................................................................................................................................15

3.1.1 Boards parameters.............................................................................................................................................15

3.1.2 Channel settings..................................................................................................................................................16

3.2 Local Control.............................................................................................................................................................17

3.2.1 HV connection.....................................................................................................................................................17

3.2.2 Module settings...................................................................................................................................................18

3.2.3 Channel settings..................................................................................................................................................19

3.2.3.1 Group Settings..............................................................................................................................................22

3.2.3.2 Smileys.........................................................................................................................................................24

3.3 Currentmonitor offset calibration...........................................................................................................................24

3.4 Remote Control.........................................................................................................................................................25

3.4.1 Serial Links...........................................................................................................................................................25

3.4.1.1 USB communication .....................................................................................................................................25

3.4.1.2 RS232 communication..................................................................................................................................25

3.4.1.3 RS485 communication..................................................................................................................................26

3.4.1.4 Ethernet communication...............................................................................................................................26

3.4.2 Communication Control......................................................................................................................................27

3.4.2.1 Remote Control: Main Menu.........................................................................................................................27

3.4.2.2 Remote Control: General Menu ....................................................................................................................28

3.4.2.3 Remote Control: Channels Menu..................................................................................................................28

3.4.2.4 Remote Control: firmwareupgrade...............................................................................................................29

3.4.2.5 Remote Control: format EEPROM................................................................................................................30

3.4.2.6 Remote Control: Current offset calibration....................................................................................................30

3.5 USB - RS485 Communication Protocol................................................................................................................31

3.5.1 Command Format...............................................................................................................................................31

3.5.2 Format of response string..................................................................................................................................31

3.5.3 MONITOR commands related to the Channels.............................................................................................32

3.5.3.1 Meaning of STATUS bits (value read in decimal Format) .............................................................................32

3.5.4 MONITOR commands related to themodule.................................................................................................33

3.5.4.1 Meaning of BoardAlarmbits.........................................................................................................................34

3.5.5 SET commands related to the Channels........................................................................................................34

3.5.6 SET commands related to the module............................................................................................................34

4Internal Settings..................................................................................................................................................................35

4.1 Polarityselection......................................................................................................................................................35

4.2 Internalswitches.......................................................................................................................................................37

4.2.1 Local Bus termination.........................................................................................................................................37

4.2.2 RS485 –RS232 conversion..............................................................................................................................37

4.3 Groundingspecifications.........................................................................................................................................37

4.3.1 Safety Earth connection.....................................................................................................................................38

LIST OF FIGURES

Fig.1.1: Mod. N1471 4 Channel Programmable HVPower Supply........................................................................................5

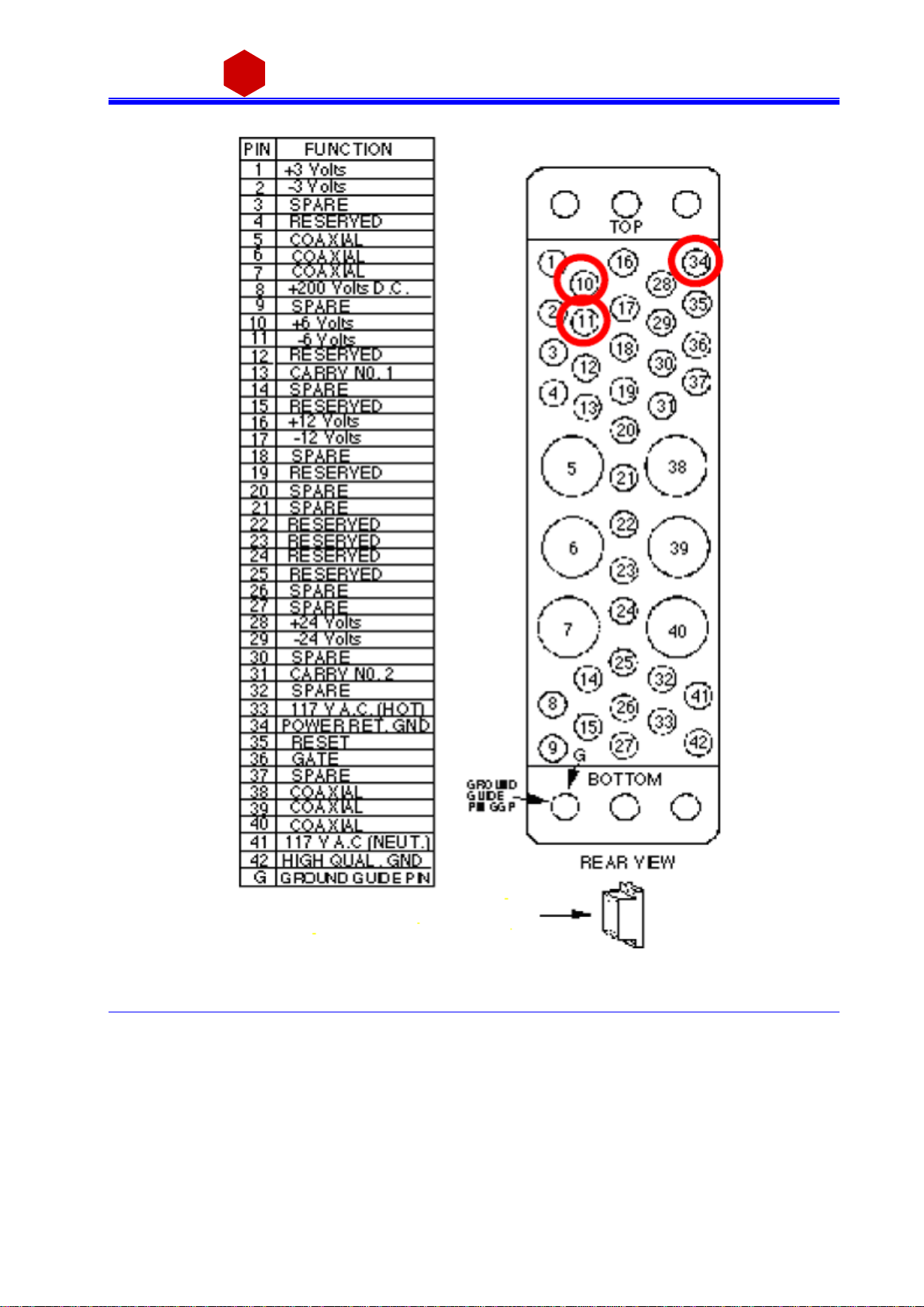

Fig. 2.1: Backplane NIMconnector................................................................................................................................................7

Fig. 2.2: Mod. N1471 series front panel (std, A, B, AL, AR) ......................................................................................................8

Fig. 2.3: Mod. N1471 series back panel (std., A, B) ...................................................................................................................9

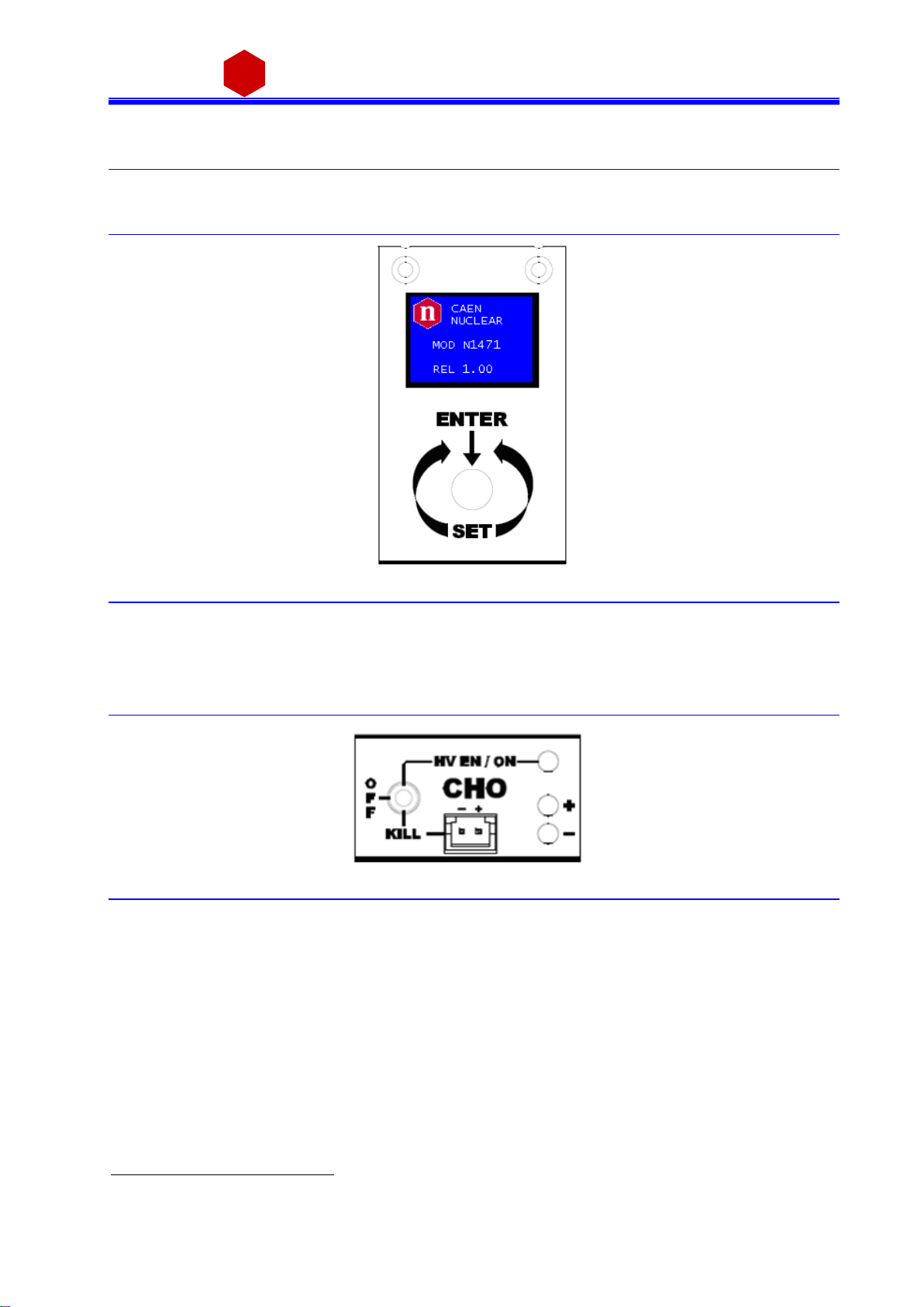

Fig.2.4: Local control panel.........................................................................................................................................................10

Fig. 2.5: Channel control panel and Kill scheme......................................................................................................................10

Fig. 2.6: N1471 HVStatus control panel...................................................................................................................................11