122

PLUGS: These watertight plugs are always found in the front part of the JETROLL. These plugs, made of a breathable material, act as

pressure release valves, thus preventing JETROLL’s deformation due to temperature changes and pressure variations. Furthermore,

these plugs prevent any condensation inside the JETROLL.

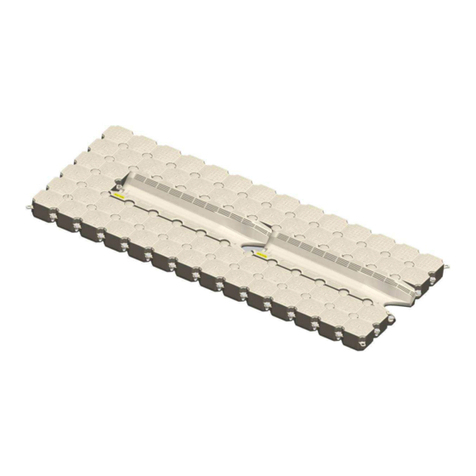

WHEELS & PLASTIC WASHERS: (12x) plastic and polyurethane wheels and (24x) nylon washers that can be positioned in numerous

configurations to ensure an optimal fit with any PWC on the market. Include (1x) small nylon washer on each side of each wheel for a

total of (24x) for each Jetroll.

SHAFTS: (12x) stainless shafts that allow for smooth rolling motion of the wheels.

BOW-STOP: Molded plastic piece positioned at the front of the JETROLL to help prevent the PWC from exceeding the front of the

system during berthing maneuvers.

HOLE CAP: A molded plastic piece that can be “snapped-on” into the circular openings on the 4 corners of the JETROLL. Depending

and the adequate anchoring layout and accessories, these are to be inserted in the remaining openings to prevent a trip hazard.

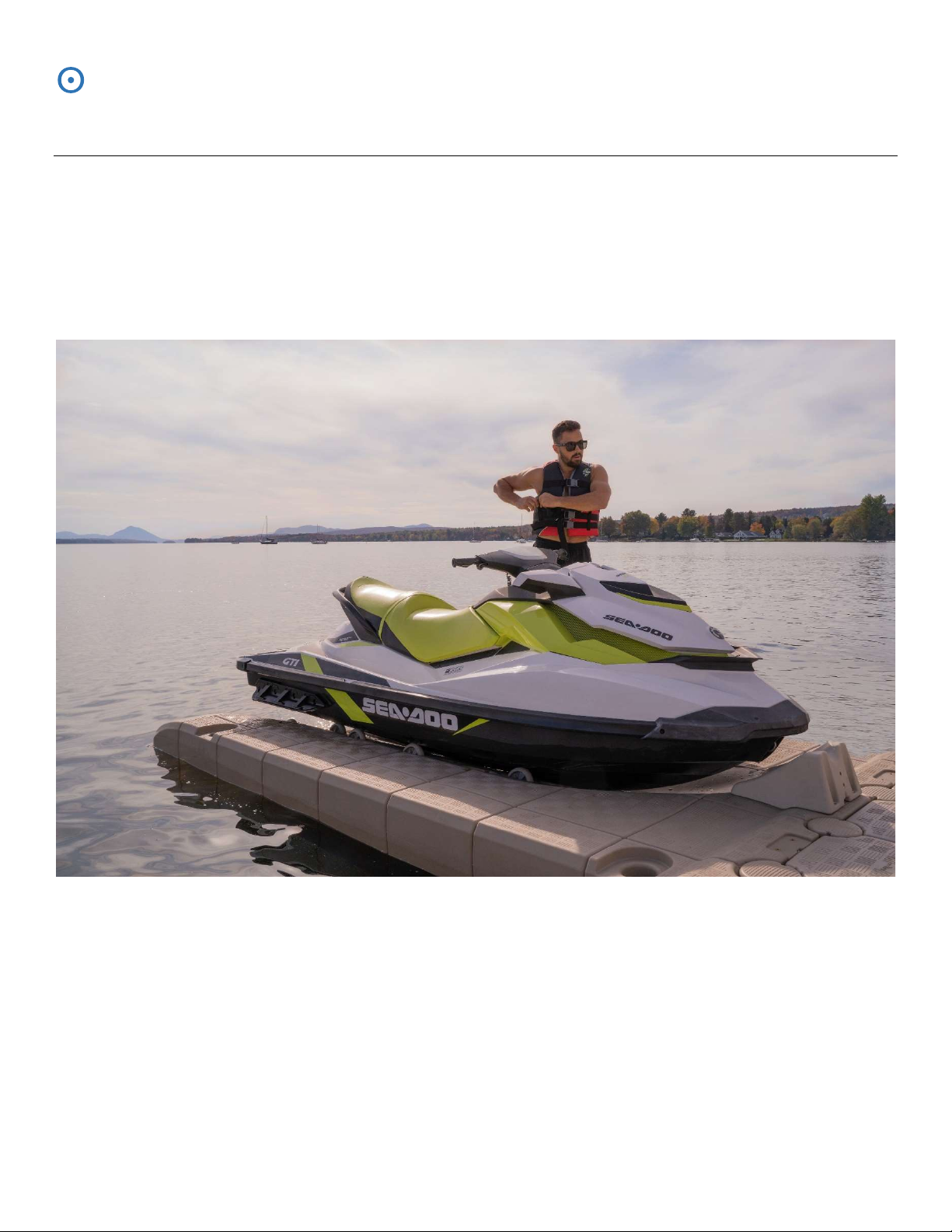

OVERVIEW

ASSEMBLY PROCEDURE

PRIOR TO INSTALLATION

1-Assemble on a flat surface rather than water.

PROCEDURE:

1-Prepare the needed parts around your JETROLL (2 HOLE CAPS, 1 BOW-STOP, and 12 WHEELS AND SHAFTS).

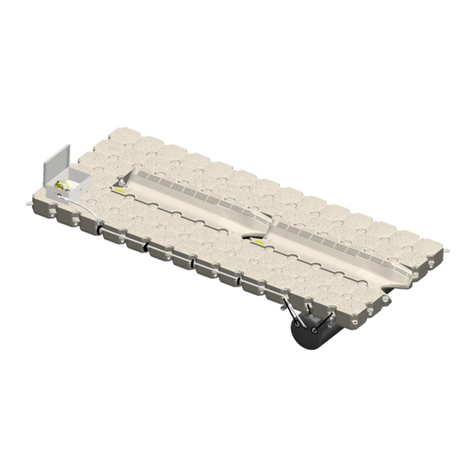

2-Determine the location of the 12 wheels. Ideally, Candock advocates using the featured pre-set (above image). The goal is to create

a lower area to create a cradle for the machine to rest in the system's middle. Especially after/during berthing maneuvers, this lower-

center geometry is highly appreciated to prevent the PWC from rolling back in the water by itself.

3-Using the rubber mallet, hammer down the wheels and shafts assembly with a single stroke motion, directly on the wheel.

4-Secure the BOW-STOP using the provided hardware. Brass inserts are already casted in the plastic of the unit.

5- If needed, using the rubber mallet, hammer down HOLE-CAPS in the proper locations.