1

EN - 09/10

CONTENTS

SAFETY INFORMATION ........................................ 1

About this Supplement........................................... 1

Intended Fork Use................................................... 2

Fork Damage........................................................... 3

Disassembly/Modication ...................................... 3

Fork Under High-Pressure ....................................... 3

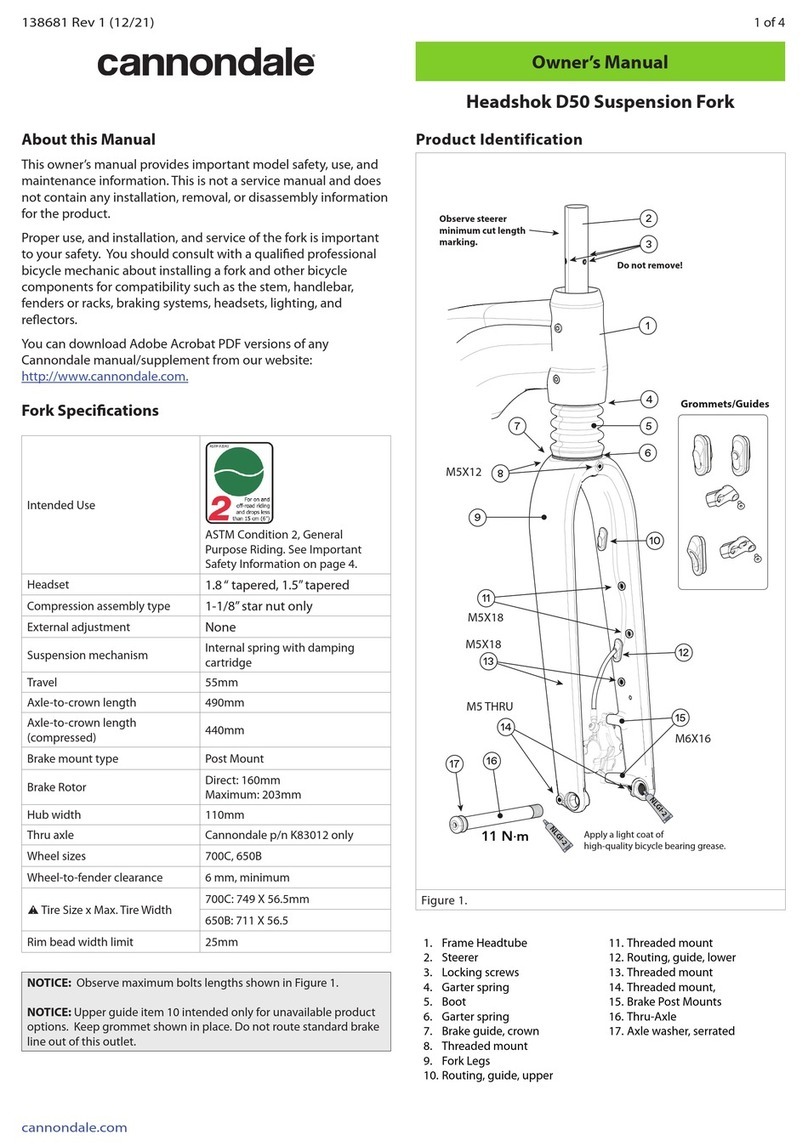

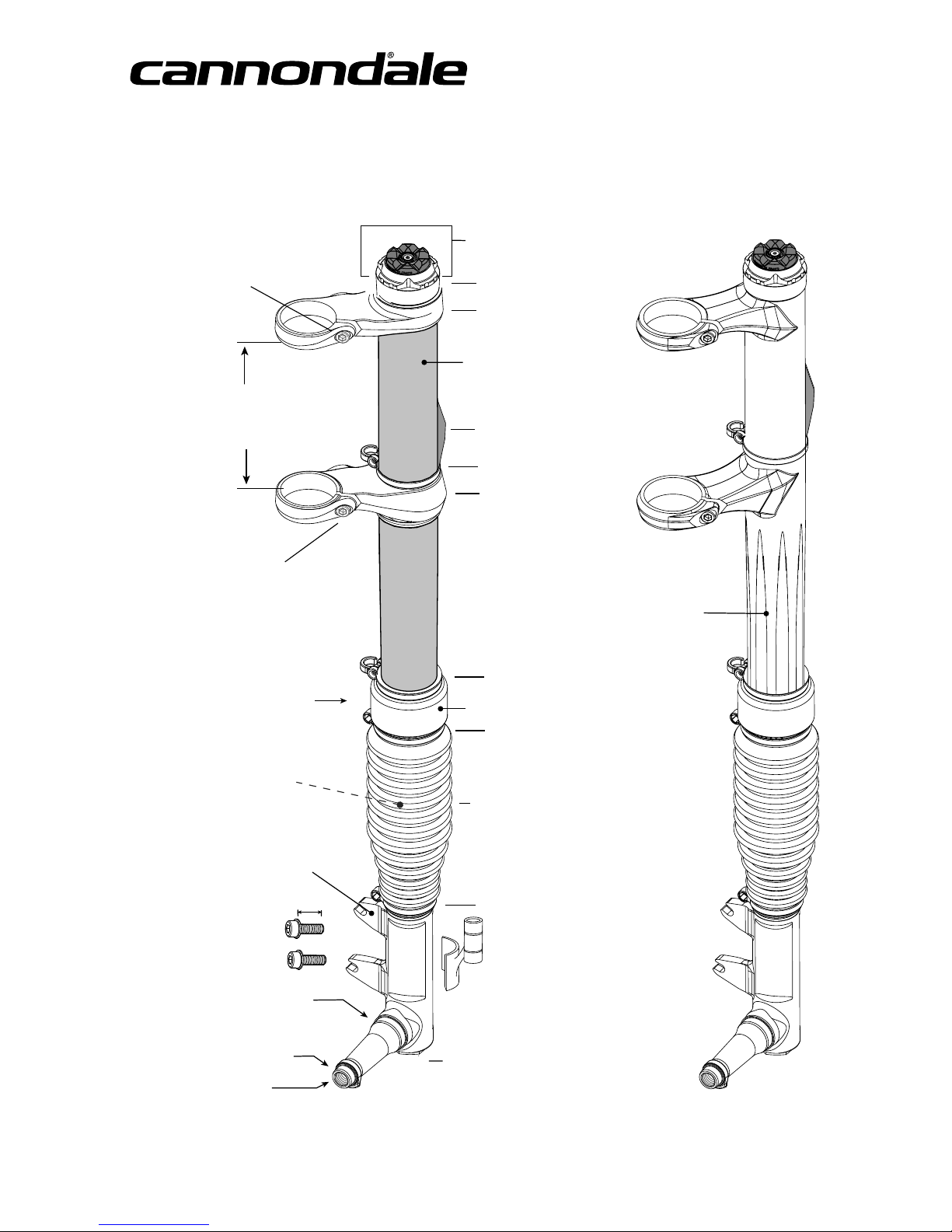

FORK IDENTIFICATION......................................... 4

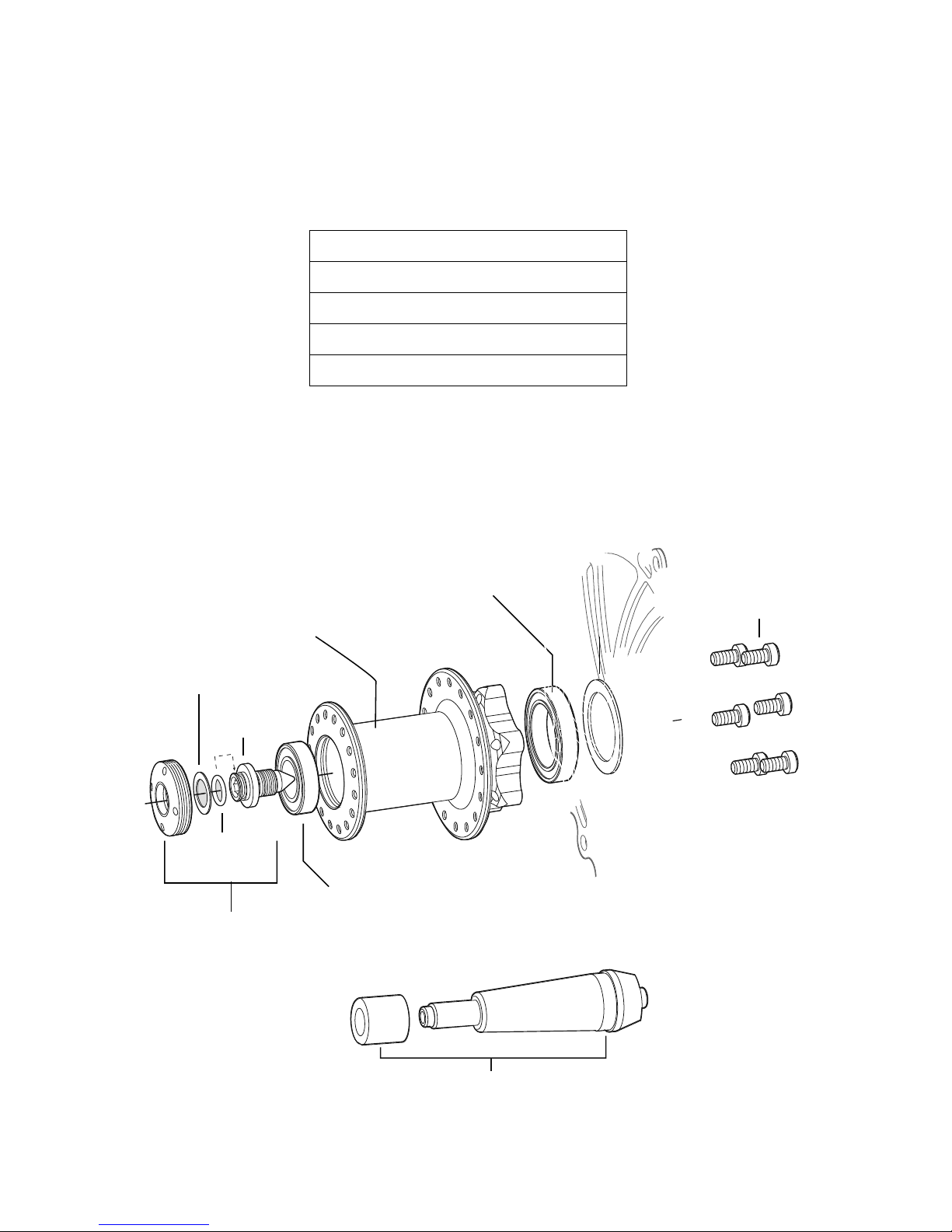

WHEELHUB......................................................... 5

FRONT WHEEL..................................................... 6

Removal ................................................................ 6

Installation ............................................................. 7

ADJUSTMENT

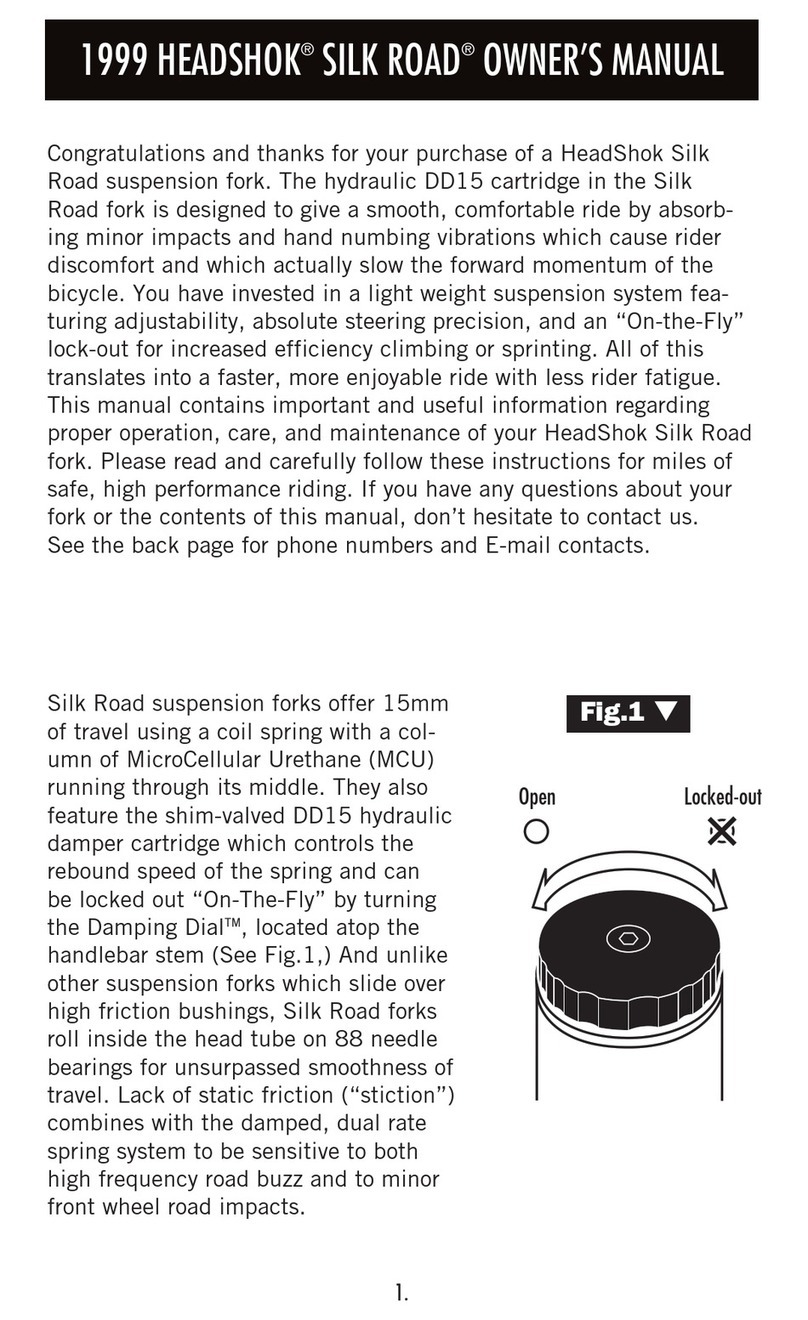

XLR Hydraulic Remote............................................. 8

PBR ................................................................ 8

XLR Rebound .......................................................... 9

PBR Rebound.......................................................... 9

Recommended Air Pressure .................................. 10

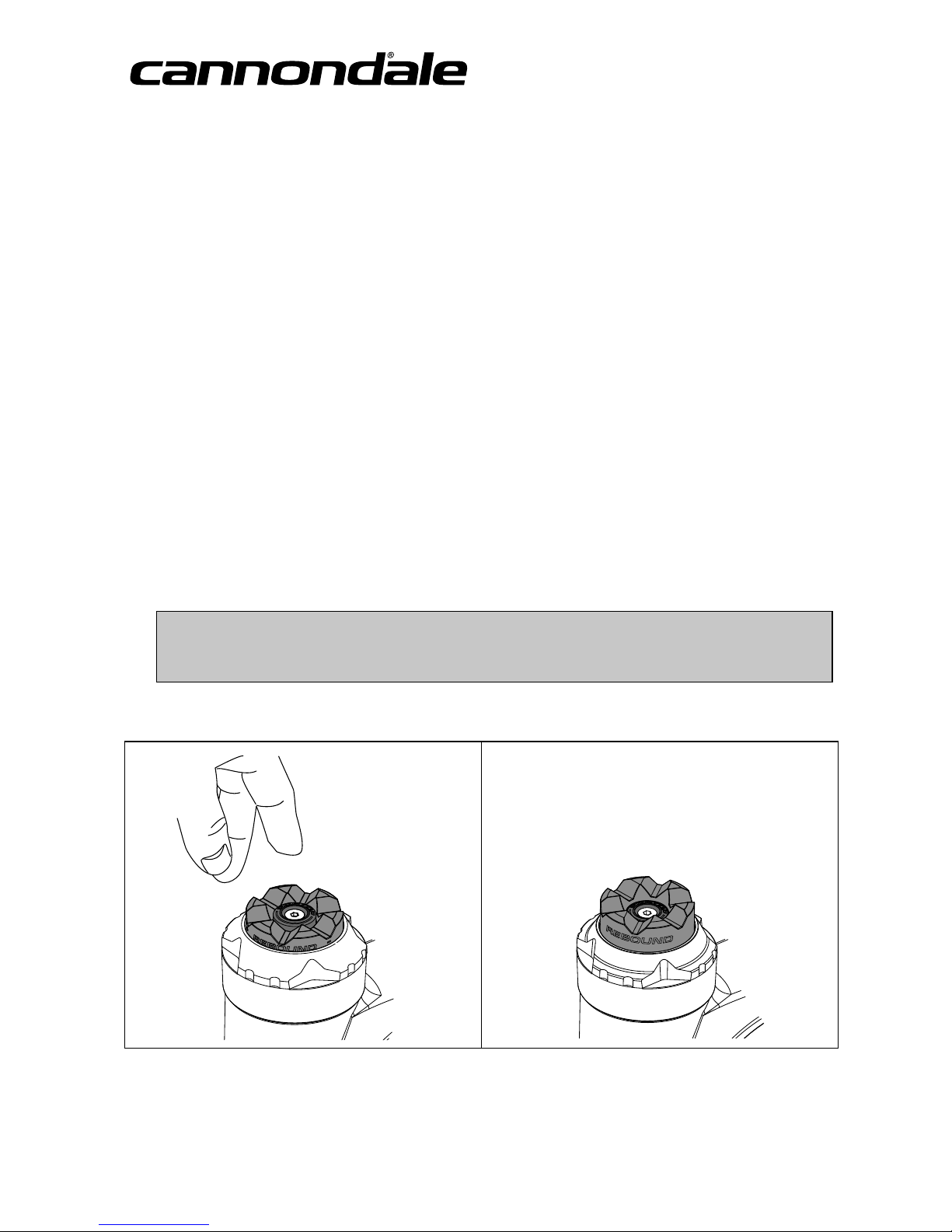

OPI STEM........................................................... 12

11/8”STEERERADAPTERKITS.......................... 14

MAINTENANCE .................................................. 16

Schedule.............................................................. 16

Cleaning .............................................................. 17

Frame Bumper Replacement ................................ 17

Boot Inspection..................................................... 18

Clean/Re-Oil Air Filter ........................................... 19

Clean/Re-grease Telescope ................................... 20

NeedleBearing Reset............................................ 23

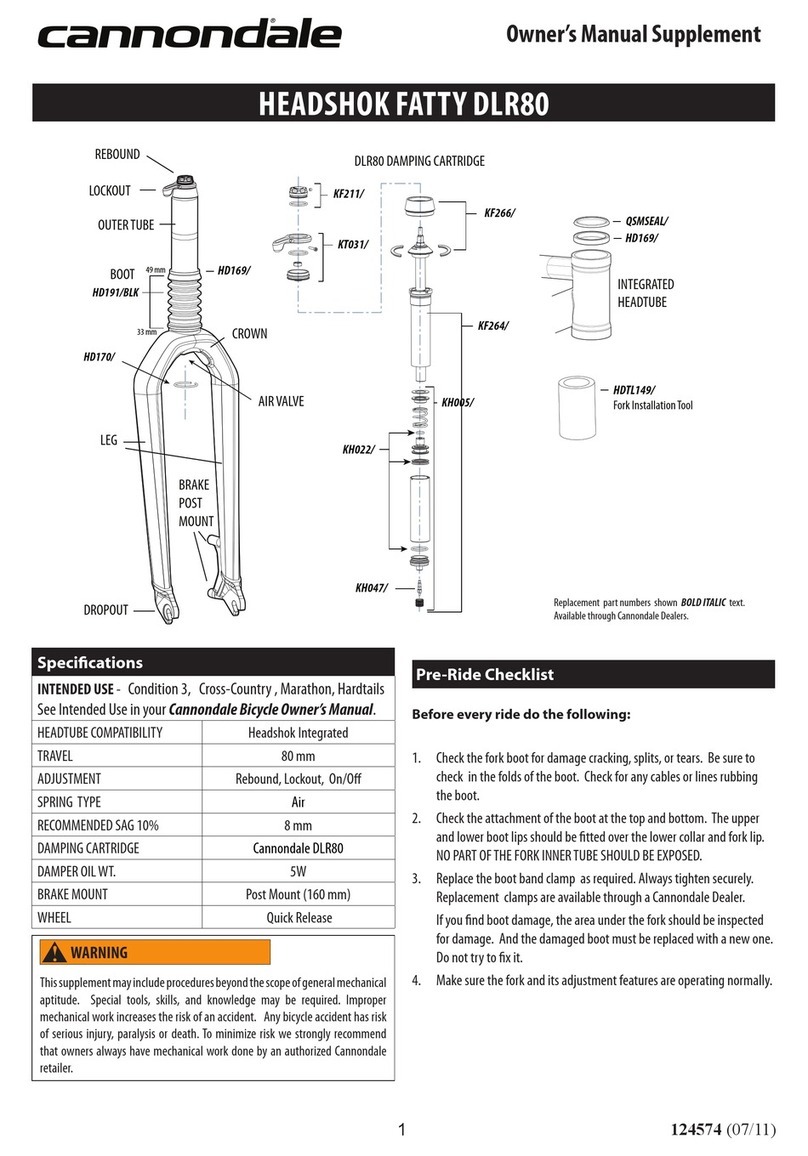

REPLACEMENT PARTS........................................ 24

Please note that the specications and information

in this manual are subject to change for product

improvement. For the latest product information, go

to http://www.cannondale.com/tech_center/

SAFETY INFORMATION

About This Supplement

CannondaleOwner’sManual Supplements provide important

model specic safety, maintenance, and technical information.

They are not replacements for your Cannondale Bicycle

Owner’s Manual.

This supplement may be one of several for your bike. Be sure

to obtain and read all of them.

Ifyou need amanual or supplement, or have aquestion about

your bike, please contact your CannondaleDealer immediately,

or call us at one of the telephone numbers listed on the back

cover of this manual.

You can download Adobe Acrobat PDF versions of any

CannondaleOwner’sManualsor Supplements from our

website: http://www.cannondale.com/bikes/tech.

t 5IJT NBOVBM JT OPU B DPNQSFIFOTJWF TBGFUZ PS TFSWJDF

manual for your bike.

t 5IJT NBOVBM EPFT OPU JODMVEF BTTFNCMZ JOTUSVDUJPOT GPS

your bike.

t "MM$BOOPOEBMFCJLFTNVTUCFDPNQMFUFMZBTTFNCMFEBOE

inspected for proper operation by aCannondaleDealer

before delivery to the owner.

WARNING

This supplement may include procedures beyond the scope

of general mechanical aptitude.

Special tools, skills, and knowledge may be required.

Improper mechanical work increases the risk of an

accident. Any bicycleaccident has risk of serious injury,

paralysisordeath.Tominimizeriskwe stronglyrecommend

that owners always have mechanical work done by an

authorized Cannondaleretailer.