4

Maintenance

Maintenance of your fork is important to your safety and to the useful life

of the fork. Frequent inspection by you and regular professional service

by your Cannondale Dealer can help ensure years of safe/trouble-free

operation.

YOU BEFORE AND AFTER RIDING:

INSPECT - Clean and inspect entire fork for cracks or damage. Things

that can indicate a serious problem: (1) Unusual“klunking”or knocking

noises (2) changes in travel (3) Over-extended or compressed boot (4)

Changes in the way the fork has been working (5) Loss of adjustments

features. (6). Sudden air loss or leaking uid.

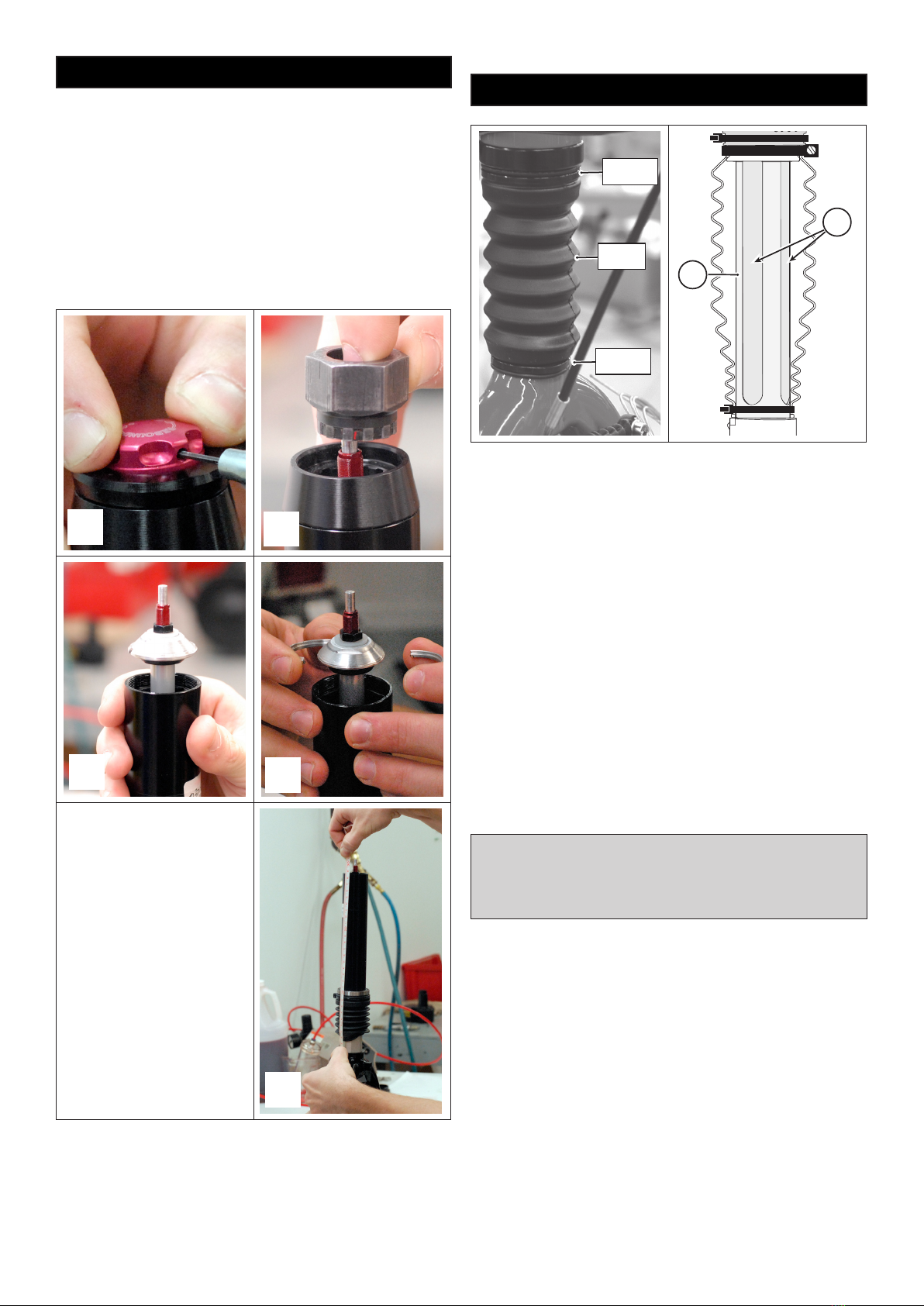

Check the fork boot for damage cracking, splits, or tears. Be sure to check

in the folds of the boot. Check for any cables or lines rubbing the boot.

Check the attachment of the boot at the top and bottom. The upper

and lower boot lips should be tted over the lower collar and fork lip.

Replace the zip ties and cable guides (clamps) as required. Always tighten

securely. Replacement boots, zip ties, and cable clamps are available

through a Cannondale Dealer.

If you nd boot damage, the area under the fork should be inspected for

damage. And the damaged boot must be replaced with a new one. Do

not try to x it.

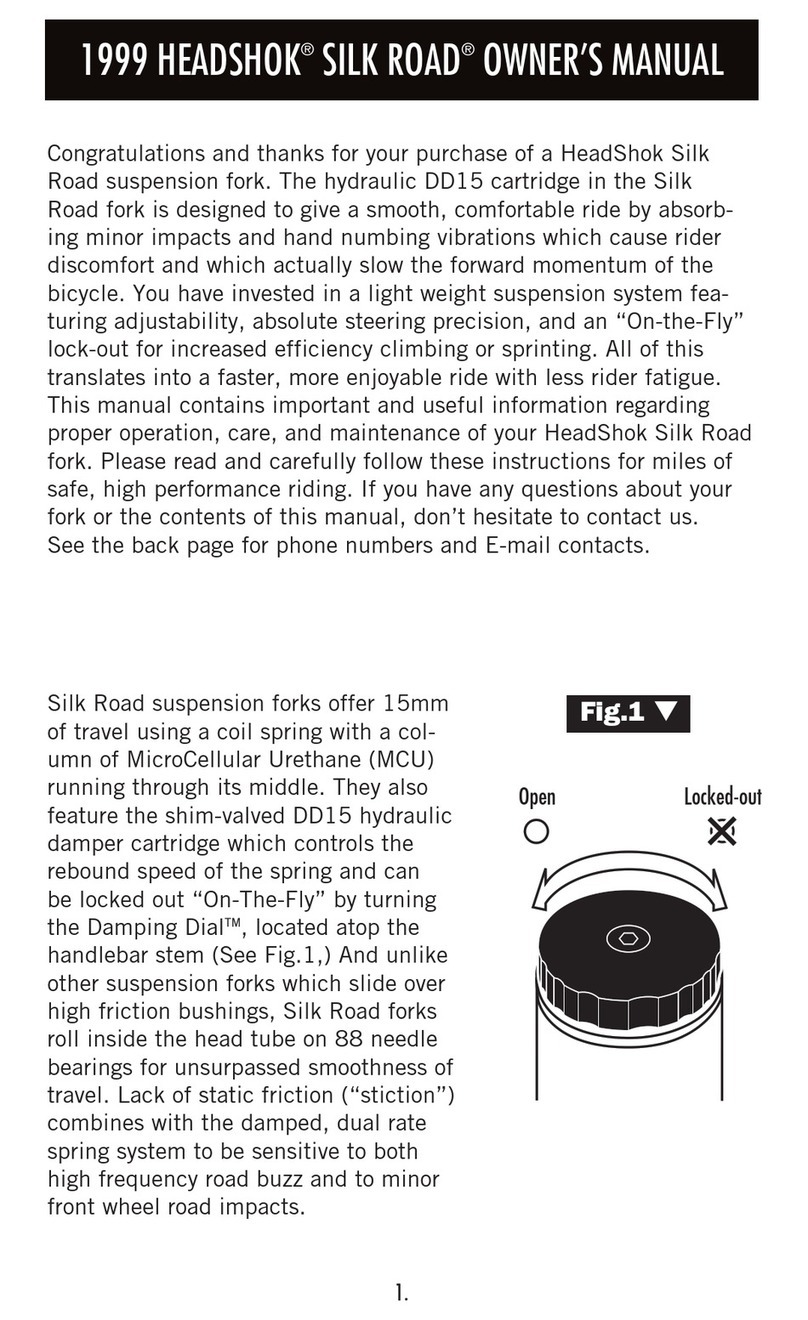

CHECK ADJUSTMENTS - Make sure the adjustment features of your fork

(air pressure, lockout, and rebound) function normally.

PERFORMED BY CANNONDALE DEALER :

RE-GREASE TELESCOPE Every 25 Hours

BEARING RESET Every 25 Hours

BOOT REPLACEMENT As Needed

(Annual recommended)

DISASSEMBLY, INSPECTION, REBUILD -

Inspect and disassembly of telescope and

races, bearings, main telescope parts,

damper cartridge, uids, seals, etc.

NORMAL: Every 100 Hrs

Safety Information

WARNING

NOT FOR JUMPING USE. See “ SECTION B. Intended Use”in your Cannondale

Bicycle Owner’s Manual.

SERVICE BY PROFESSIONAL BIKE MECHANIC ONLY. Special tools are required.

All air pressure must be released before servicing any fork. Never attempt to

work on a pressurized fork.

DO NOT MODIFY THE FORK IN ANY WAY. Do not attempt to alter or modify the

fork in an attempt to install accessories. Please consult with your Cannondale

Dealer.

DO NOT RIDE ON A DAMAGED FORK. STOP RIDING A DAMAGED FORK

IMMEDIATELY. Follow the fork maintenance schedule of this supplement.

Additionally, please ask your Cannondale Dealer to help you develop a complete

maintenance program. Frequent checks are necessary to identify the problems

that can lead to an accident.

Our Factory Tech Room (North America) and Headshok Service Centers (Europe)

provide professional services through Cannondale Dealers for all Headshok sus-

pension forks. Please ask your dealer about the service programs available for

your model fork.

YOU CAN BE YOU SERIOUSLY INJURED, PARALYZED OR KILLED IF YOU

IGNORE THESE WARNINGS.

Cannondale Limited Warranty

Cannondale Headshok (Lefty, Fatty, Solo) suspension products are covered

under the terms and conditions of the Cannondale Limited Warranty. It is

availableonthePoliciespageofourwebsiteat: http://www.cannondale.com

Be sure to read the exclusions listed in the limited warranty. For example,

damage from accidents and improper maintenance are not covered.

Denitions related to forks:

The fork structure is covered in the FRAMES section of the Cannondale

Limited Warranty.

“Fork structure” means certain structural parts of the fork, specically the

fork legs, outer tube, the steerer tube, steerer tube clamps and the inner

tubes with attached dropouts or spindle. The boot, air lter assembly, cable

clamps, needle bearings, races, and bushings which are part of the telescopic

assembly are normal wear and tear items and ARE NOT covered by the limited

lifetime warranty.

The internal fork internal parts are covered by the 1 year (2 years in EU

countries) warranty against defects in materials or workmanship described

in the COMPONENTS section of the Cannondale Limited Warranty. “Internal

fork parts”are dened as items such as damping cartridges and their internal

parts, seals, o-rings, air cylinders, air pistons, springs, elastomers, bumpers,

bushings, needle bearings, races, and oil. Normal wear and tear on these

items is NOT covered by this 1 year (2 in EU) warranty. Like brake pads on a

car, you should expect to have these items professionally replaced or renewed

as you use the fork and they wear.

Fork Warranty Claims

For any warranty claim to be considered, the bicycle/fork must be brought

into an Authorized Cannondale Retailer on the continent on which the

bicycle/fork was purchased. The bicycle/fork must be in assembled condition

and accompanied by the original, dated sales receipt for the bicycle/fork.

Dealer Locator at: http://www.cannondale.com/Dealerlocator

Contact Cannondale

CANNONDALE USA

Cycling Sports Group, Inc.

172 Friendship Road,

Bedford, Pennsylvania, 15522 , USA

(Voice): 1-800-BIKE-USA

(Fax): 814-623-6173

custserv@cyclingsportsgroup.com

CANNONDALE EUROPE

Cycling Sports Group Europe, B.V.

mail: Postbus 5100

visits: Hanzepoort 27

7570 GC, Oldenzaal, Netherlands

(Voice): + 41 61.4879380

(Fax): 31-5415-14240

CANNONDALE AUSTRALIA

Cycling Sports Group Australia Pty Limited

Unit 8, 31-41 Bridge Road

Stanmore, NSW 2048, Australia

(Voice): 61-2-85954444

(Fax): 61-2-85954499

CANNONDALE JAPAN

Namba Sumiso Building 9F,

4-19, Minami Horie 1-chome,

Nishi-ku, Osaka 550-0015, Japan

(Voice): 06-6110-9390

(Fax): 06-6110-9361

cjcustserv@cannondale.com

CANNONDALE UK

Cycling Sports Group

Vantage Way, The Fulcrum,

Poole, Dorset, BH12 4NU

(Voice): +44 (0)1202 732288

(Fax): +44 (0)1202 723366