Cannondale Headshok D50 User manual

1 of 4

138681 Rev 1 (12/21)

cannondale.com

Owner’s Manual

Headshok D50 Suspension Fork

About this Manual

This owner’s manual provides important model safety, use, and

maintenance information. This is not a service manual and does

not contain any installation, removal, or disassembly information

for the product.

Proper use, and installation, and service of the fork is important

to your safety. You should consult with a qualied professional

bicycle mechanic about installing a fork and other bicycle

components for compatibility such as the stem, handlebar,

fenders or racks, braking systems, headsets, lighting, and

reectors.

You can download Adobe Acrobat PDF versions of any

Cannondale manual/supplement from our website:

http://www.cannondale.com.

Fork Specications

Intended Use

ASTM Condition 2, General

Purpose Riding. See Important

Safety Information on page 4.

Headset 1.8 “ tapered, 1.5”tapered

Compression assembly type 1-1/8” star nut only

External adjustment None

Suspension mechanism Internal spring with damping

cartridge

Travel 55mm

Axle-to-crown length 490mm

Axle-to-crown length

(compressed) 440mm

Brake mount type Post Mount

Brake Rotor Direct: 160mm

Maximum: 203mm

Hub width 110mm

Thru axle Cannondale p/n K83012 only

Wheel sizes 700C, 650B

Wheel-to-fender clearance 6 mm, minimum

Tire Size x Max. Tire Width 700C: 749 X 56.5mm

650B: 711 X 56.5

Rim bead width limit 25mm

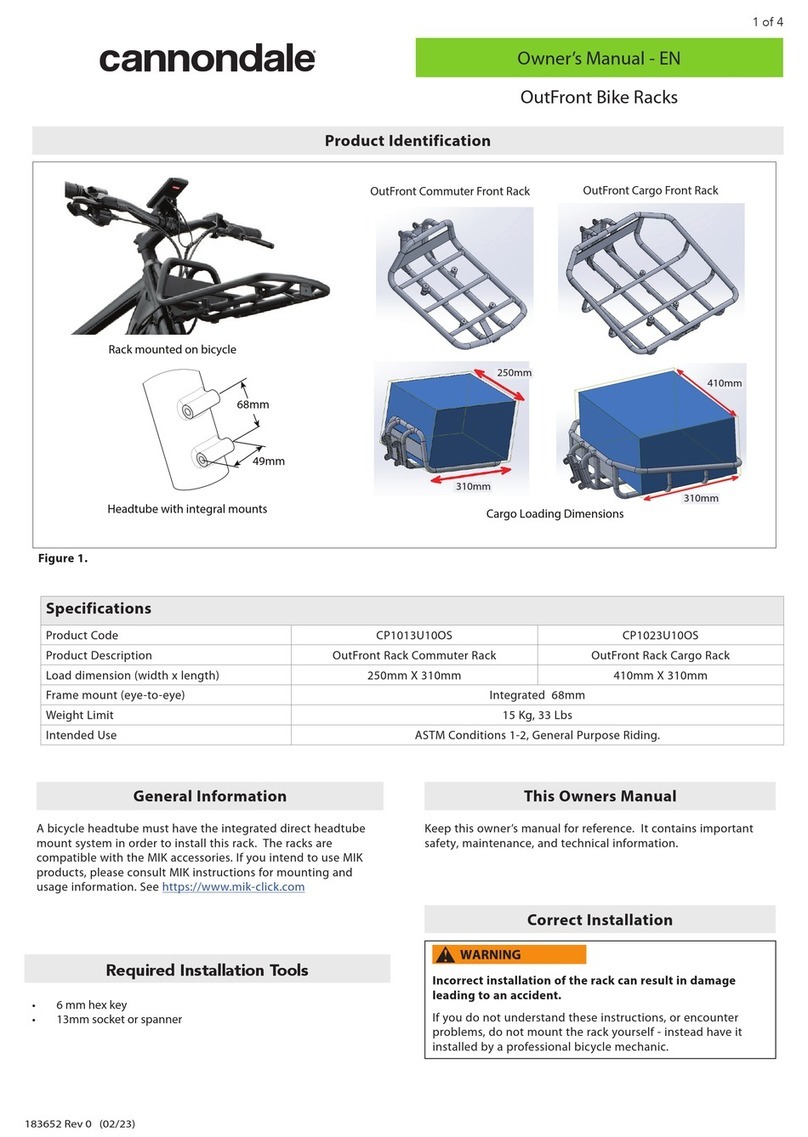

NOTICE: Observe maximum bolts lengths shown in Figure 1.

NOTICE: Upper guide item 10 intended only for unavailable product

options. Keep grommet shown in place. Do not route standard brake

line out of this outlet.

Product Identification

2

3

1

4

5

6

9

10

8

7

12

16

14

15

11

13

17

M5 THRU

M5X12

M5X18

M5X18

M6X16

Do not remove!

11 N·m

NLGI-2

Apply a light coat of

high-quality bicycle bearing grease.

Grommets/Guides

NLGI-2

Observe steerer

minimum cut length

marking.

Figure 1.

1. Frame Headtube

2. Steerer

3. Locking screws

4. Garter spring

5. Boot

6. Garter spring

7. Brake guide, crown

8. Threaded mount

9. Fork Legs

10. Routing, guide, upper

11. Threaded mount

12. Routing, guide, lower

13. Threaded mount

14. Threaded mount,

15. Brake Post Mounts

16. Thru-Axle

17. Axle washer, serrated

2 of 4

138681 Rev 1 (12/21)

cannondale.com

Wheel Removal

1. Secure the bike upright in a bike stand with the front wheel

o the ground.

2. Insert the tool into the right side of the axle. Turn the wrench

counter-clockwise to unthread the axle and it is free to slide

out.

UNTHREAD

Figure 2. - Loosening the thru-axle.

SLIDE-OUT

Figure 3. - Sliding out the thru-axle

3. Remove the wheel from the dropouts. You may need to tap

the top of the wheel with the palm of your hand to release

the wheel from the front fork.

LOWER WHEEL

Figure 4. - Wheel removed

Wheel Installation

1. Secure the bike upright in a bike stand with the fork o the

ground.

2. Use a clean shop towel to wipe clean the thru-axle and ends

of the fork dropouts.

3. Install the wheel into the dropouts and align the hub with the

fork dropouts.

Make sure the brake disc locates between the brake pads in

the caliper as you insert the wheel between the dropouts.

4. Apply light bicycle grease to the thru-axle threads and around

the bolt head. Make sure the serrated washer is on the thru-

axle with the serration facing the fork. Then insert the

thru-axle into the right side fork dropout and through the

wheel hub.

NLGI-2

NLGI-2

serrations face fork

Serrated

washer

Thru-axle

Dropout

threads

Axle

threads

NLGI-2

NLGI-2

Figure 5. -Preparation

3 of 4

138681 Rev 1 (12/21)

cannondale.com

5. Insert the tool into the axle head and turn the axle clockwise

to thread the axle into the left side fork dropout.

Tighten to the specied torque.

TIGHTEN

11 N·m

Figure 7. - Tightening the axle

Make sure the axle bolt is torqued correctly with a torque

wrench. Do not ride the bike if the bolt is not torqued

correctly.

6. Make sure the wheel spins freely.

7. Check to make sure the brakes work correctly.

Failure to install the wheel correctly can result in a loss

of control or the wheel coming o while riding. You can

be seriously injured or killed in an accident if the wheel is

not attached correctly.

Maintenance

Maintenance of your fork is important to your safety and to the

useful life of the fork. Frequent inspection by you and regular

professional service by your Cannondale Dealer can help ensure

years of safe/trouble-free operation.

YOUR RESPONSIBILITY:

Before riding and after each ride

1.Clean and inspect entire fork for cracks or damage. Things

that can indicate a serious problem:

(1) Unusual“klunking”, knocking, or creaking noises; (2)

changes in travel: (3) Over-extended or compressed boot ;

(4) Changes in the way the fork has been working; (5) Loss of

adjustments features; and (6). Leaking uid.

2. Check the fork boot for damage, cracking, splits, or tears. Be

sure to check in the folds of the boot. Check for any cables

or lines rubbing the boot. Check the attachment of the boot

at the top and bottom. The upper and lower boot lips should

be tted over the lower collar and fork lip. Replace the garter

springs as required. Always tighten securely. Replacement

parts are available through a Cannondale Dealer.

If you nd boot damage, the area under the fork should be

inspected for damage. And the damaged boot must be

replaced with a new one. Do not try to x it.

3. Check the front wheel attachment. Follow the wheel

attachment instructions in this manual.

4. Check to make sure the brakes, steering, and all controls are

functioning normally.

5. If there are racks or fenders attached to the fork, make sure

they are secure and in good condition. If there are objects

attached to the fender or rack, make sure these items are

secure and cannot fall out or interfere with the steering or

wheel. Follow manufacturer instructions when mounting

accessories. Maintain all indicated clearances between any

accessories, brakes, fenders, fork, frame, other attachments

and wheel.

DO NOT RIDE THE BICYCLE UNTIL ALL PROBLEMS FOUND

HAVE BEEN CORRECTED.

ITEMS THAT SHOULD BE CHECKED REGULARLY BY A

PROFESSIONAL MECHANIC

RE-GREASE TELESCOPE Every 25 Hours

BOOT REPLACEMENT As Needed

(Annual

recommended)

DISASSEMBLY, INSPECTION,

REBUILD

Inspect and disassembly of

telescope and races, bearings, main

telescope parts, damper cartridge,

uids, seals, etc.

NORMAL: Every 200 Hrs

4 of 4

138681 Rev 1 (12/21)

cannondale.com

Important Safety Information

WARNING

INTENDED USE: ASTM Condition 2, General Purpose Riding.

Bikes designed for riding Condition 1, plus smooth gravel

roads and improved trails with moderate grades where the

tires do not lose ground contact. For paved roads, gravel or dirt

roads that are in good condition, and bike paths.

Please read your Cannondale Bicycle Owner’s Manual for more

information about Intended Use and Conditions 1-5.

NOT INTENDED: This fork is not for used for aggressive riding,

jumping or stunt riding. This fork must not be used on any

tandem bicycles or on electric or engine-driven motorcycles.

DO NOT MODIFY THE FORK. Do not attempt to alter or to

modify (e.g., drill, cut, weld, sand, or repaint).

HAVE ALL WORK PERFORMED BY A QUALIFIED

PROFESSIONAL BICYCLE MECHANIC. Do not attempt to

service or to repair the fork yourself. This owner’s manual does

not include information needed to install, to remove, or to

disassemble/reassemble the fork. This manual only contains

information for using the fork when mounted on the bicycle.

PERIODIC INSPECTION REQUIRED: The fork must be

periodically inspected for damage as part of your routine

bicycle maintenance. Consult with a qualied professional

bicycle mechanic to help you develop a complete maintenance

program. Frequent checks are necessary to identify the

problems that can lead to an accident.

DO NOT RIDE ON A DAMAGED FORK. Stop riding a damaged

fork immediately. Follow the fork maintenance schedule of this

supplement.

MAKE SURE ALL REQUIRED BICYCLE LIGHTING AND

REFLECTORS ARE PRESENT AND IN WORKING CONDITION.

RACKS AND OTHER MOUNTED ACCESSORIES

This fork has mounting locations to support compatible

accessories. It is your responsibility to make sure any proposed

accessory attached to the fork is safely compatible with the

fork and with the bicycle. You assume all risk for the use and

safety of any attached accessories.

USE A TORQUE WRENCH: Apply thread lock and grease

as directed. Do not exceed the torque specied for any

component including handlebar, steerer, or any adjusting

hardware.

YOU CAN BE SEVERELY INJURED, PARALYZED OR KILLED IN

AN ACCIDENT IF YOU IGNORE THESE WARNINGS.

Cleaning

When cleaning, use clean tap water and a mild dish detergent

soap. Avoid spraying water on any attached electronic

accessories. Consider covering items with a clean plastic bag.

Use a rubber band or masking tape to hold the bag in place

temporarily.

NOTICE

Do not power wash or dry with compressed air. This will force

contaminants into the fork where they will promote corrosion,

immediately damage the fork, or result in accelerated wear.

Do not use abrasive or harsh chemical cleaners /solvents

which can damage the nish or attack and destroy both the

outside and internal fork parts.

Replacement Parts

Part Number Description

K83012 HeadShok TA Bolt 110x15 137mm

M15x1.5P

K53052 HeadShok Boot+Garter Springs 1.5

K53022 HeadShok Boot+Garter Springs 1.8

K54012 HeadShok Cable Grommets Guides

K52002 HeadShok Damper

Warranty Information

Different elements of this product are subject to the terms of

the Cannondale Limited Warranty. For more information, go

to the support area at www.cannondale.com.

NOTICE

Unauthorized service, maintenance, or repair parts can result

in serious damage and void your warranty.

Contacting Cannondale

Go to www.cannondale.com for contact information for your

region.

Other Cannondale Bicycle Accessories manuals

Cannondale

Cannondale 2011 LEFTY 126564.PDF User manual

Cannondale

Cannondale 2012 IQ200 User manual

Cannondale

Cannondale LEFTY SPEED DLR2 Configuration guide

Cannondale

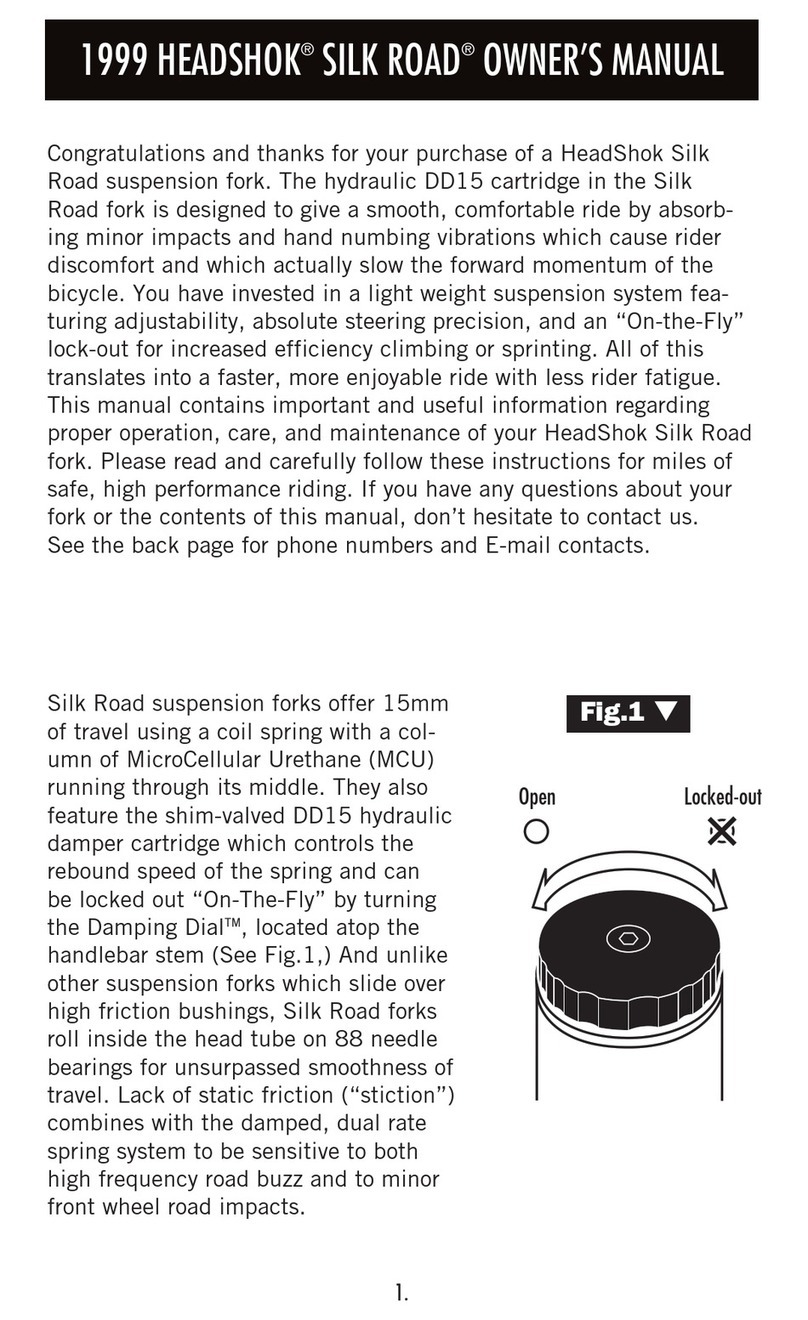

Cannondale Headshok Silk Road 1999 User manual

Cannondale

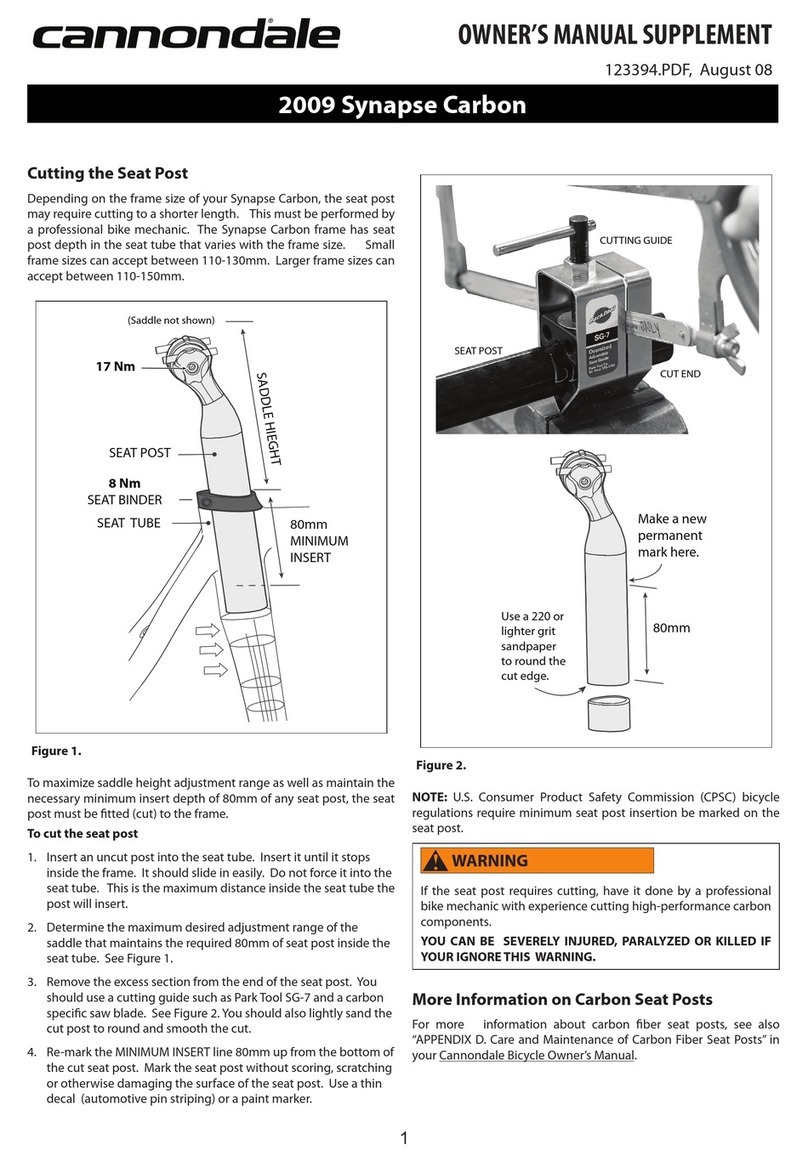

Cannondale Synapse Carbon Configuration guide

Cannondale

Cannondale LEFTY 2.0 User manual

Cannondale

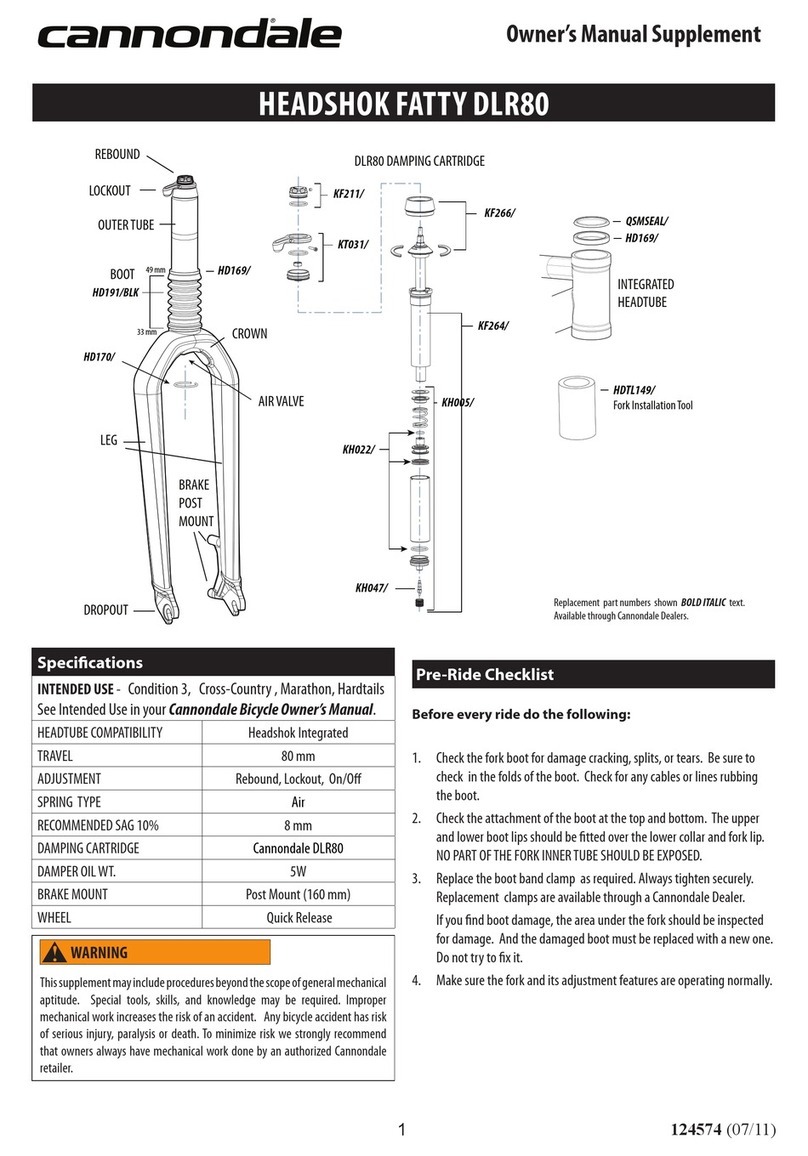

Cannondale HEADSHOK FATTY DLR80 Configuration guide

Cannondale

Cannondale Synapse Carbon Configuration guide

Cannondale

Cannondale IQ108 User manual

Cannondale

Cannondale HEADSHOK SUPER FATTY SL 1999 User manual