Canon PIXMA MP110 User manual

Other Canon Printer manuals

Canon

Canon iR C6800 Series Service manual

Canon

Canon PIXMA MP497 User manual

Canon

Canon PIXMA MX366 User manual

Canon

Canon PIXMA G6070 Setup guide

Canon

Canon imagePROGRAF TC-20 M User manual

Canon

Canon imageRUNNER ADVANCE DX 717 Series User manual

Canon

Canon MK3000 User manual

Canon

Canon imageRUNNER 1750i User manual

Canon

Canon LBP7780CX User manual

Canon

Canon PIXUS 50i User manual

Canon

Canon imageRUNNER ADVANCE 8500 III Series Technical manual

Canon

Canon PIXMA TS8150 User manual

Canon

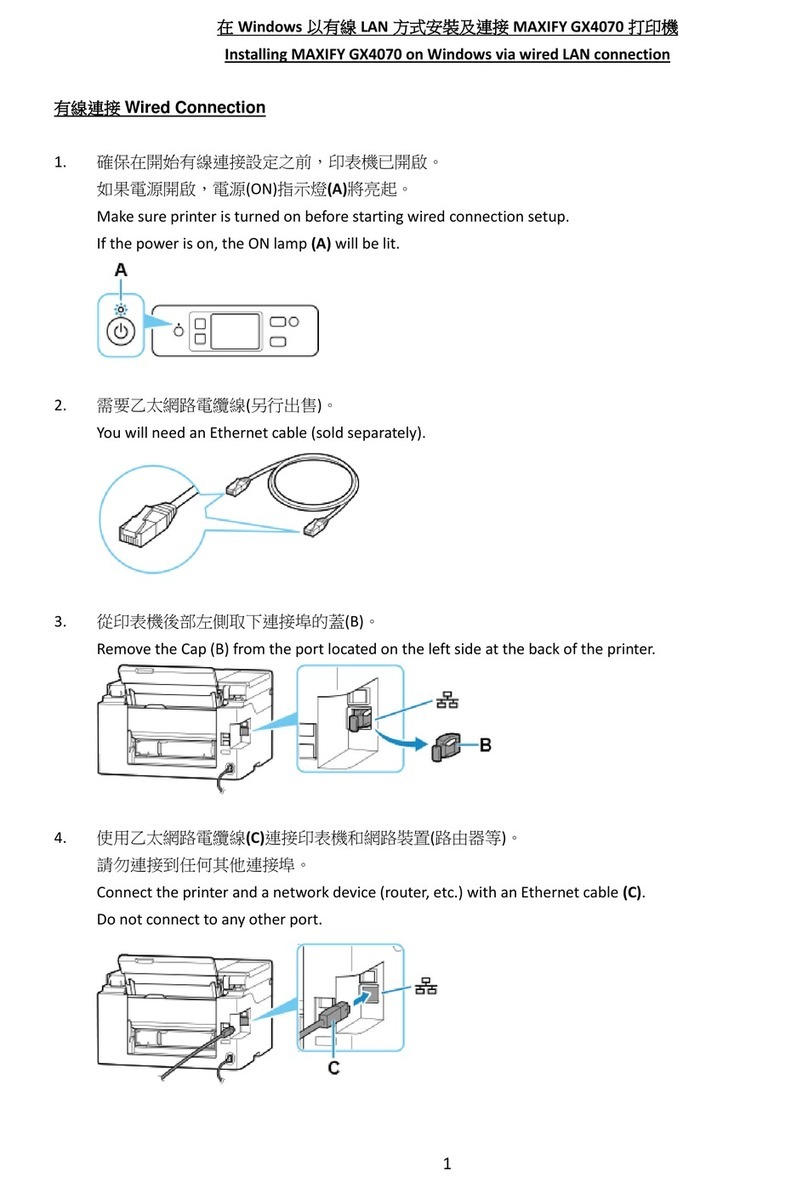

Canon MAXIFY GX4070 User manual

Canon

Canon Oce VarioPrint 110 User manual

Canon

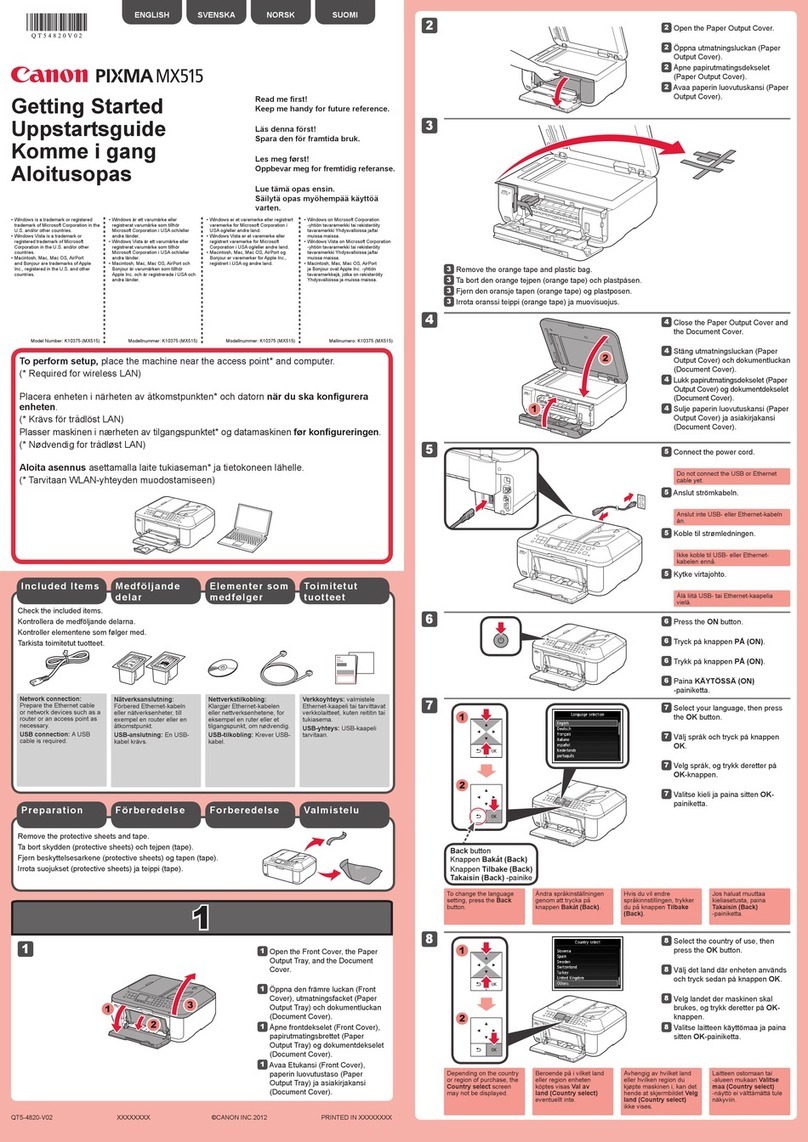

Canon Pixma MX515 User manual

Canon

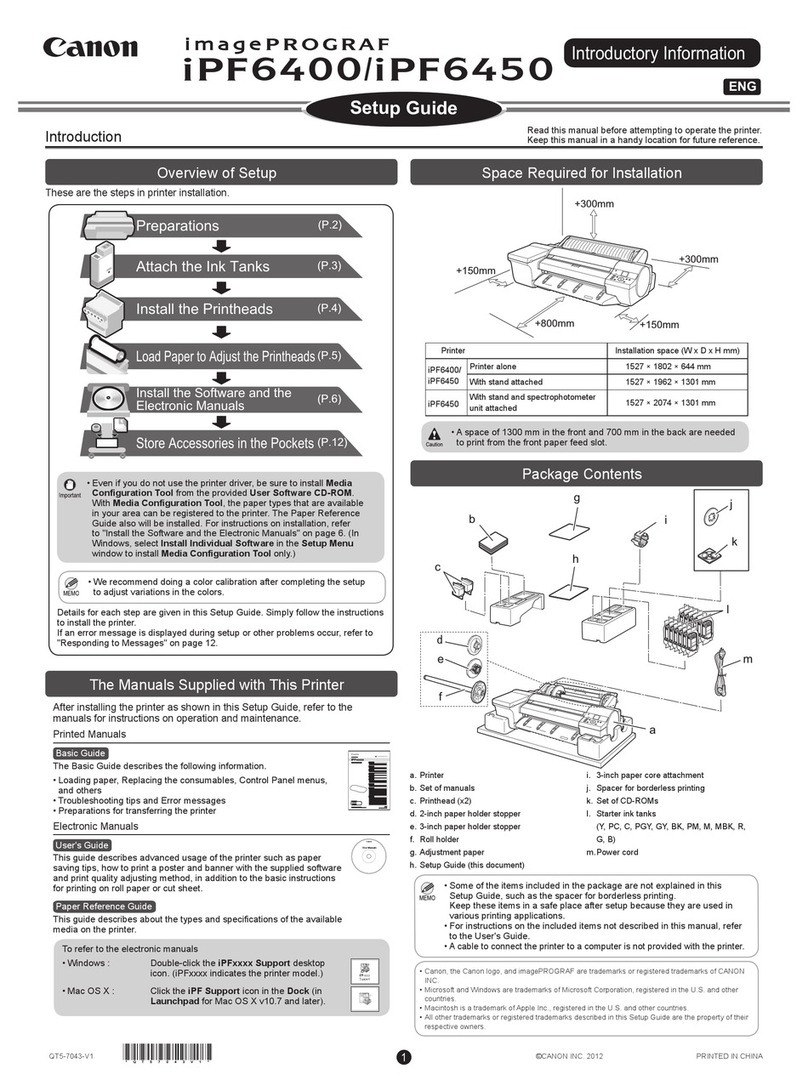

Canon imagePROGRAF iPF6400 User manual

Canon

Canon S200SP User manual

Canon

Canon Pixma G1000 series Setup guide

Canon

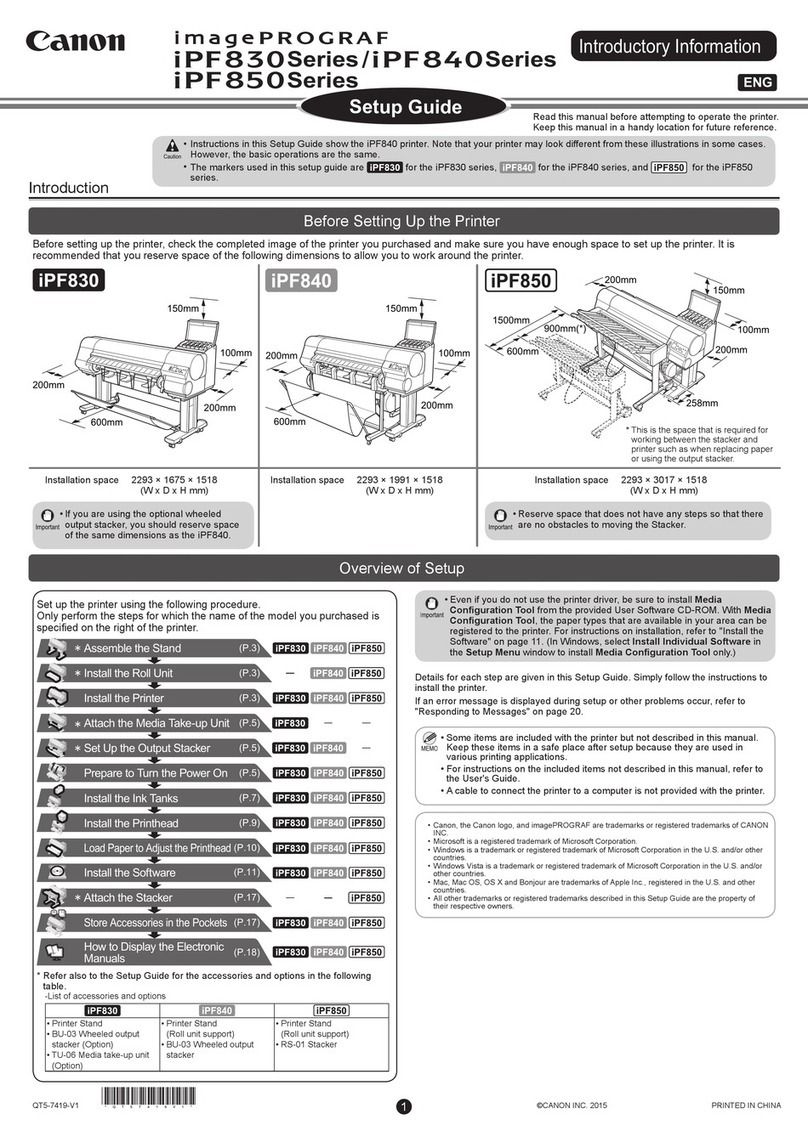

Canon imagePROGRAFi PF830 series User manual

Canon

Canon PIXMA MP150 User manual