1

OPERATING INSTRUCTIONS

Before operating the unit, please read this manual thoroughly, and

retain it for future reference.

OWNER'S RECORD

The model and serial numbers of your set are located at the

front.Record the serial number in the space provided below. Refer

to these numbers whenever you call upon your dealer

regardingthis product.

MODEL NO._______________________

SERIAL NO._______________________

TABLE OF CONTENTS

Specifications ............................................................................................................................................................................................................. 2

Features Of Your 24"Planer .................................................................................................................................................................................. 3

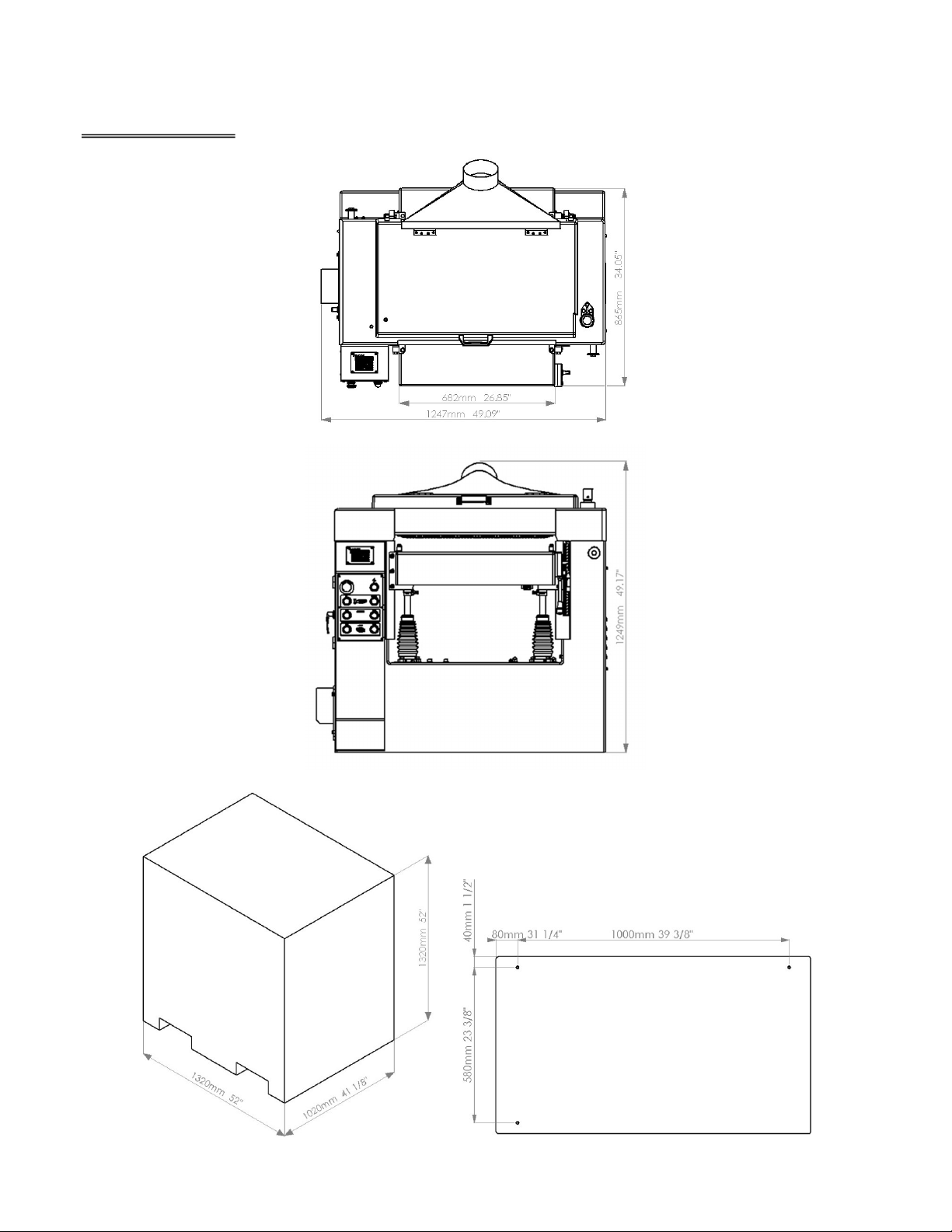

Dimensions ................................................................................................................................................................................................................. 4

General Safety Instructions .................................................................................................................................................................................. 5

Additional Safety Rules For Your Planer ......................................................................................................................................................... 6

Unpacking And Clean-UP ..................................................................................................................................................................................... 7

Installation Instructions ......................................................................................................................................................................................... 8

Installing ...................................................................................................................................................................................................................... 8

Grounding Information And Power Connections ....................................................................................................................................... 8

Adjustments And Operation ............................................................................................................................................................................... 9

Work Table .................................................................................................................................................................................................................. 9

Table Rollers ............................................................................................................................................................................................................ 10

The Depth Of Cut .................................................................................................................................................................................................. 10

Cutterhead ............................................................................................................................................................................................................... 11

Infeed Roller, Chipbreaker, Pressure Bar, Outfeed Roller and Tension Adjustment Of Infeed And Outfeed Rollers ... 12

Feed Speed Control ............................................................................................................................................................................................. 13

Feed Drive System ................................................................................................................................................................................................ 13

Maintenance .................................................................................................................................................................................................... 14-15

Trouble Shooting ........................................................................................................................................................................................... 16-17

Wiring Diagram............................................................................................................................................................................................... 18-19

Parts Lists ........................................................................................................................................................................................................... 20-52